Table of Contents

Advertisement

Quick Links

Operator's Manual

FlexCool 35

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10423

| Issue D ate Apr-18

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

12748

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric FlexCool 35

- Page 1 Operator’s Manual FlexCool 35 For use with machines having Code Numbers: 12748 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10423 | Issue D ate Apr-18...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS INSTALLATION............................. SECTION A TECHNICAL SPECIFICATIONS - K4816-1 - FLEXCOOL™ 35..................A-1 GENERAL DESCRIPTION.............................A-2 RECOMMENDED PROCESSES AND EQUIPMENT......................A-2 DESIGN FEATURES..............................A-2 UNPACKING THE FLEXCOOL™ 35..........................A-3 ™ MOUNTING THE FLEXCOOL™ 35 UNDERNEATH THE FLEXCUT 200...............A-3 FILLING THE COOLANT RESERVOIR..........................A-3 COOLANT "IN"... - Page 7 FLEXCOOL INSTALLATION PHYSICAL DIMENSIONS Technical SpecificaTionS - K4816-1 - flexcool™ 35 WEIGHT W/ SHIPPING LENGTH WIDTH HEIGHT RESERVOIR INPUT POWER RATINGS WEIGHT FULL CURRENT CURRENT FREQUENCY PHASE VOLTAGE DRAW DRAW 30.70 IN 15.99 IN 14.93 IN 92 LB 114 LB @ 60 HZ @ 50 HZ (78.0 CM)

-

Page 8: Installation

• Reliable 115 VAC tubeaxial fans. The FlexCool™ 35 is a cooler designed for PAC (Plasma Arc • Manufactured by the Lincoln Electric Company in Cleveland, Cutting) and specifically designed to integrate with the FlexCut™ 200 system (FlexCut™ 200, FlexStart™ console, •... -

Page 9: Unpacking The Flexcool™ 35

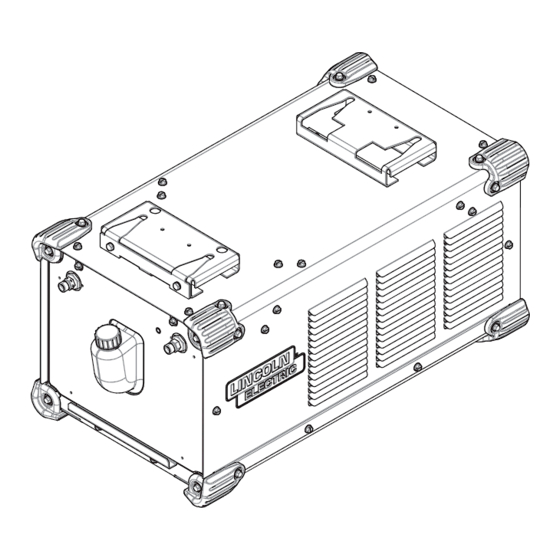

FLEXCOOL INSTALLATION FIGURE A.1 UnpacKinG The flexcool™ 35 The packaging of the cooler is designed to withstand shipping abuse. If any shipping damage has occurred, contact your certified Lincoln distributor or service center. When unpacking the unit, avoid thrusting sharp objects through the carton, which may damage the machine. -

Page 10: Coolant "In" And "Out" Connections

FLEXCOOL INSTALLATION FIGURE A.3 Filling: Pour 2.375 gallons (9.0 liters) of coolant into the coolant reservoir fill hole through a funnel. Use the coolant purge command in the machine UI menus to help prime the system. While priming, add additional coolant to keep the reservoir full. The cooler is "FULL"... -

Page 11: Operation

FLEXCOOL OPERATION OPERATION • Hot coolant can burn skin. Always be sure coolant is NOT HOT before servicing the cooler. SAFETY PRECAUTIONS Read this entire section of operating instructions • Do not pour used ethylene glycol coolant down the before operating the machine. drain. -

Page 12: Options / Accessories

FLEXCOOL ACCESSORIES OPTIONS / ACCESSORIES Field Installed Options/Accessories K1543-8, -25, -50, -100 Arclink Cable - An Arclink cable is used to communicate between the FlexCool™ 35 and the FlexCut™ 200. Coolant Hoses Available lengths include 8’, 25’, 50’, and 100’. Only the specified coolant hoses should be used between the FlexCool™... -

Page 13: Maintenance

FLEXCOOL MAINTENANCE MAINTENANCE peRioDic MainTenance The torch coolant and particulate filter should be replaced every 6 WARNING Safety Precautions months. The pump strainer should also be cleaned before refilling the coolant. Replacing coolant and filter cartridge: ELECTRIC SHOCK can kill. 1. -

Page 14: Drawer Removal Procedure

FLEXCOOL MAINTENANCE WARNING DRaWeR ReMoVal pRoceDURe filTeR eleMenT ReplaceMenT pRoceDURe 1. Remove the cooler drawer as described earlier. 2. Loosen the two 5/16” nuts securing filter bracket to the FIGURE D.2 ELECTRIC SHOCK can kill. drawer back. See figure D.2 •... -

Page 15: Pump Strainer Cleansing Procedure

FLEXCOOL MAINTENANCE pUMp STRaineR cleanSinG pRoceDURe 1. Remove the cooler drawer as described earlier. 2. While holding the pump head securely, remove the 15/16” acorn nut from the pump body. be prepared for some coolant to escape from the pump when removing the nut. 3. -

Page 16: Troubleshooting

USinG The STaTUS leD To TRoUbleShooT SYSTeM pRobleMS The FlexCool 35 is equipped with an externally mounted status light. If a problem occurs it is important to note the condition of the status light. Therefore, prior to cycling power to the system, check the power source status light for error sequences as noted below. - Page 17 FLEXCOOL TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION BASIC MACHINE PROBLEMS Error 446 – Cooler Not Found 1. Arclink cable disconnected 2. 40V circuit breaker on machine is tripped Error 817 – Coolant Temp Too High 1.

-

Page 18: Diagrams

FLEXCOOL DIAGRAMS... - Page 19 FLEXCOOL DIAGRAMS...

- Page 20 FLEXCOOL DIAGRAMS...

- Page 21 FLEXCOOL DIAGRAMS...

- Page 22 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 23 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 24 We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the FlexCool 35 and is the answer not in the manual?

Questions and answers