Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ryobi RA-RW38-B

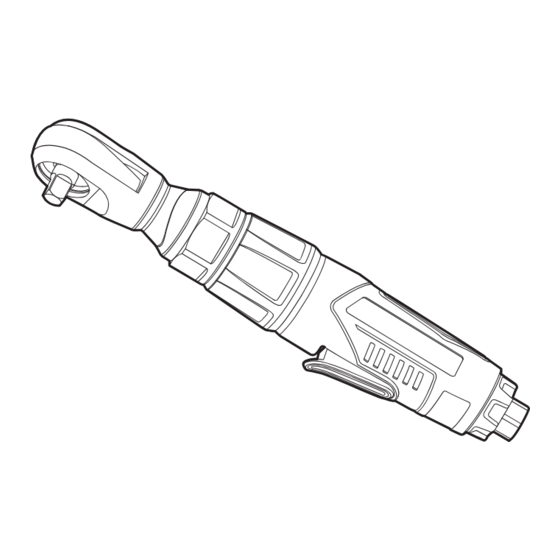

- Page 1 RA-RW38-B RATCHET WRENCH OpERATOR's MANUAL ORigiNAL iNsTRUCTiONs...

- Page 2 important! It is essential that you read the instructions in this manual before operating this machine. Subject to technical modifications.

- Page 3 DEsCRipTiON 1. Direction switch 4. Air inlet 7. Nitto style coupler 10. Reverse direction 2. Clamp nut 5. Trigger 8. Socket (not supplied) 3. Motor housing 6. Wrench anvil 9. Forward direction Fig.1 Fig.2 Fig.3 Fig.4 Quick Quick connector connector Lubricator Filter Tool...

-

Page 4: General Safety Rules

of the tool. gENERAL sAfETy RULEs ■ Hold the tool correctly; be ready to counteract normal ■ For multiple hazards, read and understand the safety or sudden movements and have both hands available. instructions before installing, operating, repairing, ■ Maintain a balanced body position and secure footing. maintaining, changing accessories on, or working near the assembly power tool for threaded fasteners. - Page 5 WORkpLACE HAzARDs a silencer, always ensure it is in place and in good working order when the assembly power tool for ■ Slips, trips and falls are major causes of workplace threaded fasteners is operating. injury. Be aware of slippery surfaces caused by the use of the tool and also of trip hazards caused by the ■...

-

Page 6: Specifications

■ Whipping hoses can cause severe injury. Always check for damaged or loose hoses and fittings. Wear ear protection. ■ Cold air shall be directed away from the hands. ■ Do not use quick-disconnect couplings at tool inlet for impact and air-hydraulic impulse wrenches. Use Lubricate with air tool oil daily. -

Page 7: Air Supply And Operation

2. Injuries and damage to property due to broken cutting lubricated by keeping the air line lubricator filled and correctly adjusted. Without proper lubrication attachments or the sudden impact of hidden objects the product will not work properly and parts will during use. -

Page 8: Troubleshooting

possible failure. REMEDiEs ■ Lubricate the product daily with a few drops of air tool ■ Check air inlet filter for blockage. oil dripped into the air inlet. ■ Pour air tool lubricating oil into air inlet as per ■ Maintenance shall be performed weekly. instructions. -

Page 9: Parts List

pARTs LisT Description Description Description Description Ratchet yoke Thread ring gear Washer Trigger Drive bushing Head socket Direction switch Roll pin Crank shaft Spring Pin 2 x 6 Housing Bearing shell Ratchet pin V-shape washer Pin 2 x 18 Needle bearing Ratchet pawl Bearing 608Z Air inlet... - Page 12 Techtronic Industries (Australia) Pty. Ltd. 31 Gilby Road Mt Waverley, VIC 3149, Australia Techtronic Industries New Zealand Ltd. 2 Landing Drive, Mangere Auckland, New Zealand 2022...

Need help?

Do you have a question about the RA-RW38-B and is the answer not in the manual?

Questions and answers