Table of Contents

Advertisement

Quick Links

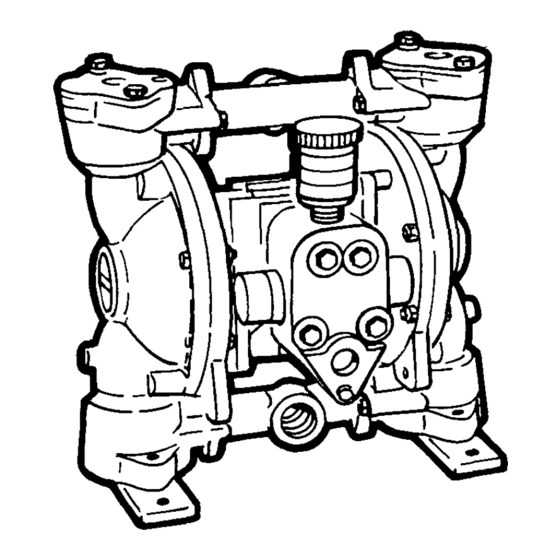

LINCOLN

Models

84852,

84853,

84855,

84856

1"AIR-POWERED

DIAPHRAGM

PUMP

Series "B"

OPERATING

AND

SERVICE

INSTRUCTIONS

HAZARD

WARNING

POSSIBLE

EXPLOSION

HAZARD

can result

if 1,1,1,

-Trichloroethane,

Methylene

Chloride

or other

Halogenated

Hydrocarbon

solvents

are used

in

pressurized

fluid

systems

having

Aluminum

or Galvanized

wetted

parts.

Death,

serious

bodily

injury

and/or

property

damage

could

result.

Consult

with

the

factory

if you

have

questions

concerning

Haloge-

nated

Hydrocarbon

solvents.

Do not use for pumping

flam-

mable

materials.

Build

up and

discharge

of

static

electricity

may

result

in a fire

and/or

ex-

plosion

causing

personal

injury

and

loss to property.

Principle

of Operation

The pump is powered

by compressed

air which

alternately

pressurizes

the

inner sides of the two diaphragm

cham-

bers while

simultaneously

exhausting

OPERATING

INSTRUCTIONS,

SERVICE

MANUAL

AND REPAIR PARTS LIST

the

opposite

inner

chambers

causing

the diaphragms,

which

are connected

by a shaft, to move endwise.

Since

air

pressure

is applied

over the entire

sur-

face of the diaphragm

which

is forcing

liquid to be discharged

by its other side,

the

diaphragm

is operating

under

a

balanced

condition

during

the

dis-

charge

stroke.

This allows

the unit to be

operated

at discharge

heads

over 200

feet (61 meters)

of water

head.

Alternate

pressurizing

and exhaust-

ing of the diaphragm

chamber

is per-

formed

by an externally

mounted,

pilot-

operated,

four way, spool type air distri-

bution

valve.

When

the spool

is at one

end of the valve body, inlet air pressure

is connected

to one diaphragm

cham-

ber and

the other diaphragm

chamber

is

connected

to the

exhaust.

When

the

spool

is moved

to the opposite

end of

the valve body, the porting

of chambers

is reversed.

The air distribution

valve

spool is moved from one end position

to

the other

in the valve body by means

of

an internal

pilot valve which

alternately

pressurizes

the ends of the air distribu-

tion

valve

spool

while

simultaneously

exhausting

the

other

ends.

The pilot

valve is positively

shifted

at each end of

the diaphragm

stroke

by the diaphragm

plate's coming

in contact

with the end of

the pilot valve spool

and pushing

it into

position

for shifting

of the air distribu-

tion

valve.

The

chambers

are

mani-

folded

together

with a suction

and dis-

charge

check valve for each chamber

to

maintain

flow

in one direction

through

the pump.

INSTALLATION

PROCEDURES

Position

the pump as close as possi-

ble to the

source

of the

liquid

to be

pumped.

Avoid

long or undersize

suc-

tion lines and use the minimum

number

of fittings.

For permanent

installation

involving

rigid

piping,

install

short

flexible

sec-

tions

of hose

between

the

pump

and

piping.

This

reduces

strains

and per-

mits

easier

removal

of the

pump

for

service

when required.

At time

of insta-

llation,

inspect

all external

gasketed

fasteners

for

looseness

caused

by

gasket

creep.

Tighten

loose

fittings

securely

to prevent

leakage.

AIR SUPPLY

Do not

connect

the

unit

to an air

supply

in excess

of 125 PSI (8 61 bars).

Install

a shutoff

valve

in the air supply

line

to permit

removal

of the

unit

for

servicing.

When

connecting

an air sup-

ply of rigid

piping,

mount

a section

of

flexible

line

to the

pump

to eliminate

piping

strain.

In permanent

installa-

tions,

an air line filter

IS recommended.

The weight

of the air supply

line

and

of the

filter

must

be supported

by

some

means

other

than

the air valve

cap.

Failure

to provide

support

may

result

in damage

to

the

pump.

A

pressure

regulating

valve

should

be

installed

to

prevent

pressure

from

exceeding

recommended

limits.

OPERATION

Your pump

has been tested

prior to

shipment

and is ready for use as received

It is completely

self-priming

and no ini-

tial filling

with fluid

is required.

If the unit is to be totally

submerged,

the

air exhaust

must

be piped

above

liquid

level

to prevent

the

liquid

and

foreign

material

from

entering

the air

distribution

valve mechanism.

Open

the inlet air valve at least one

turn to allow

sufficient

cycling

rate for

the pump to prime (30 to 60 cycles

per

minute).

After

pumping

starts,

adjust

the inlet air valve for the desired

pump

ing capacity.

When

further

opening

of

the inlet air valve

increases

cycling

rate

without

increasing

the

flow

rate,

the

pump

is being

starved

of liquid

due to

suction

limitations.

Further

opening

of

the air inlet

valve will waste compressed

air.

Set

the

inlet

air valve

for lowest

cycling

rate that does not decrease

flow

rate for most efficient

operation.

LINCOLN

Section

-

B5

Page

-

15D

FEB-95

FORM 402581

Advertisement

Table of Contents

Need help?

Do you have a question about the 84852 and is the answer not in the manual?

Questions and answers