Sinoboom GTJZ0408SE Operation Manual

Hide thumbs

Also See for GTJZ0408SE:

- Parts manual (204 pages) ,

- Operation manual (90 pages) ,

- Maintenance manual (92 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sinoboom GTJZ0408SE

- Page 1 Operation Part No.501055100002 Rev: B Manual Mar 2021 产品说明书 PRODU C T MAN U AL GTJZ0408SE/0408SE/1530SE GTJZ0608SE/0608SE/1930SE 0608E (2132E) G T JZ GTJZ0408ME/0408ME/1532ME 0808E (2732E) G T JZ GTJZ0608ME/0608ME/1932ME 0808E (2732E) G T JZ G T JZ 0808E (2732E)

- Page 3 Operating, servicing and maintaining this vehicle or equipment can expose you to chemicals including engine exhaust, carbon monoxide, phthalates, and lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. To minimize exposure, avoid breathing exhaust, do not idle the engine except as necessary, service your vehicle or equipment in a well-ventilated area and wear gloves or wash your...

- Page 4 : No.128, East Jinzhou Avenue, Ningxiang High-tech Industrial Park, Changsha, Hunan, China Zip Code : 410600 Copyright © Hunan Sinoboom Intelligent Equipment Co., Ltd. All Rights Reserved The final interpretation right of this manual belongs to Hunan Sinoboom Intelligent Equipment Co., Ltd.

- Page 5 See the nameplate on your machine to identify the model and serial number.(See 10 Decals/Nameplates Inspection, page 10-1 of the Operation Manual for details.) Trade identification MODELS SERIAL NO. Imperial Metric GTJZ0408SE GTJZ0408SE 1530SE From 0105700150 to Present GTJZ0608SE GTJZ0608SE 1930SE From 0105800250 to Present GTJZ0408ME...

- Page 6 This Page Intentionally Left Blank...

- Page 7 This manual covers the basic parts information of one or more products. Therefore, please use this manual according to your needs. If you find problems in the manual or have suggestions for improve- ment, feel free to share your feedback with Sinoboom, and we will address these issues as soon as possible.

- Page 8 This Page Intentionally Left Blank...

-

Page 9: Table Of Contents

Lifting the Machine with a Crane ..8-2 6 Pre-operation Function Test .. 6-1 Transporting the Machine ... . . 8-2 9 Maintenance ...... 9-1 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 10 Decals/Nameplates(ANSI) . . . 10-26 Decals/Nameplates(CSA) ..10-29 Appendix 1: Symbols and Description....... A-1 Appendix 2: Prepare the Work Record Before Delivery ..A-5 Appendix 3: Repair & Inspection Report ......A-7 © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 11: Introduction

The owner or administrator of the machine shall also provide the manufacturer’s maintenance information to the person responsible for maintaining the machine. If you have any questions, contact Hunan Sinoboom In- telligent Equipment Co., Ltd.. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 12 This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 13: Machine Specifications

MACHINE SPECIFICATIONS Table 1-1 GTJZ0408SE Specifications GTJZ0408SE (METRIC) 1530SE (IMPERIAL) MEASURE DIMENSION Max. platform height(indoor only) 4.6m 15ft 1in Max. working height(indoor only) 6.6m 21ft 8in Max. horizontal extension 0.9m Length 1.8m 5ft 11in Width 0.79m 2ft 7in Height (stowed, rails folded) 1.87m... - Page 14 MACHINE SPECIFICATIONS Table 1-1 GTJZ0408SE Specifications (continued) GTJZ0408SE (METRIC) 1530SE (IMPERIAL) MEASURE Max. allowable manual force (indoor only) 400N 90 lbf Max. noise 72dB POWER Hydraulic tank capacity 1.3 gal(imperial)/1.6 gal(US) Hydraulic system capacity (including tank) 1.5 gal(imperial)/1.8 gal(US) Hydraulic system pressure...

- Page 15 Max. noise 72dB POWER Hydraulic tank capacity 1.3 gal(imperial)/1.6 gal(US) Hydraulic system capacity (including tank) 1.5 gal(imperial)/1.8 gal(US) Hydraulic system pressure 21MPa 3046 Psi Battery specification (quantity × voltage, 4×6V,225Ah capacity) System voltage 24VDC GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 16 6ft 11.5 in Wheel base 1.334m 4ft 4in Wheel span 0.71m 2ft 4in Ground clearance (pothole guards 75mm retracted) Ground clearance (pothole guards 24mm 0.95in deployed) Tire size (diameter × width / type) Φ323×100mm/Solid Φ12.7×4 in/Solid © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 17 Pressure against ground 1230 KPa 178 Psi ENVIRONMENT Max. allowable wind speed (indoor/ 0m/s(indoor)/12.5m/s(outdoor) 0 mph(indoor)/28 mph(outdoor) outdoor) Max. allowable altitude 3000m 9843ft Allowable ambient temperature (lead-acid -10℃ to 40℃ 14℉ to 104℉ batteries) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 18 Ground clearance (pothole guards deployed) 24mm 0.95in. Tire size (diameter × width / type) Φ323×100mm/solid Φ12.7×4in/solid Platform dimension (Length × Width × height) 1.64×0.76×1.1m 5ft 4.6in×2ft 6in×3ft 7in Platform dimension (AS models) 2.34m×0.8m×0.96m 7ft 6.5in×2ft 7.5in×3ft 1.8in PERFORMANCE © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 19 Max. allowable ambient relative humidity Stored at -20℃ to 50℃(-4℉ to 122℉) in a well-ventilated environment with 90% relative humidity (20℃ [68℉]), and Storage condition away from rain, sun, corrosive gas and inflammable explosive. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 20 The ground bearing data is approximate values not considering different options and only used when it is safe enough. e) The loads of persons, accessories, tools and materials are factored into the rated platform capacity. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

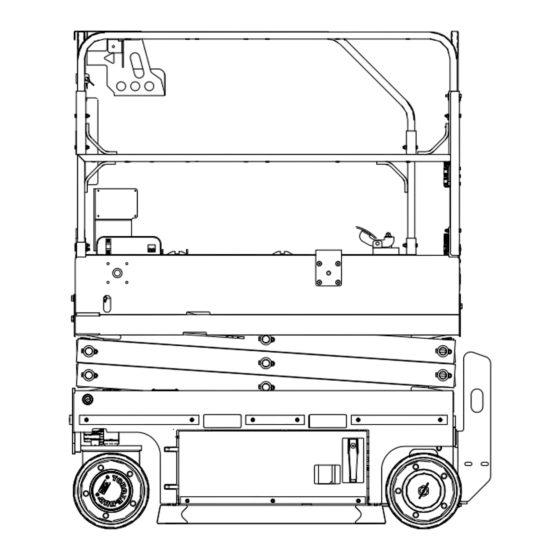

Page 21: Machine Components

MACHINE COMPONENTS Figure 2-1 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 22 23. Flash Light √ √ 24. Steer Cylinder √ 25. Steer Wheel √ 26. Drive Reducer,DC √ 27. Ground Controller √ 28. Power Unit √ 29. Hydraulic Oil Tank √ 30. Rear Wheel √ © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 23: Safety

Table 3-1 , page 3-2. Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 24: Tipping Hazards And Rated Load

500 -750 10.67 (35) 750 -1000 13.725 (45) TIPPING HAZARDS AND RATED LOAD Maximum rated load bearing capacity of the platform: Table 3-2 GTJZ0408SE&0608SE Retracting 280 kg(617 lb) Extending: Stationary only 160 kg(352 lb) © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 25 If you intend to lower the platform with a GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

-

Page 26: Work Environment Hazards

Before or during machine operation, check the possible hazards on the jobsite and beware of the restrictions within the environment, including flammable and explo- sive gas/dust. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 27: Unsafe Operation Hazards

NOTICE Maximum climbing ability is suitable for machines with platform retracted. Maximum Slope: GTJZ0408SE&0608SE: 25% (14°) GTJZ0408ME&0608ME: 25% (14°) Climbing capacity means the maximum allowable tilt angle of the machine when it is on solid ground and the platform is only capable of carrying one person. -

Page 28: Fall Hazards

• Do not place or attach any sus- pended load onto any part of the machine. • Do not use the machine as a crane. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 29: Collision Hazards

• Maintain good judgment and plan- ning when using the controller on the ground to operate the ma- chine. Maintain proper distance between operator, machine and fixed object. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 30: Crush Hazards

During operation, keep the left and right doors of the chassis closed and locked. Only trained service personnel can open the left and right doors to repair the machine. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 31: Battery Hazards

AC outlet. Be sure the charger is in proper operating condition before using. • Be sure to use the appropriate number of personnel and proper lifting methods when changing the battery. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 32: After Using The Machine

5. Block the wheels with the wheel wedges. 6. Charge the battery. NOTICE After using the machine, the power off switch must be disconnected. © Mar 2021 3-10 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 33: Jobsite Inspection

The following items present danger on the jobsite: • Steep hills or caves • Ground prominences, obstacles or debris • Ground inclines GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 34 JOBSITE INSPECTION This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 35: Pre-Operation Inspection

Level, page 5-2. the machine has obvious problems before the oper- ator performs a pre-operation function test. • Check the battery level. Charge the battery as needed. See Inspect Battery Level, page 7-10. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 36: Inspecting Parts

The condition of the battery affects the performance of the machine. Improper levels of battery electrolyte or damaged cable and wiring may harm battery parts and may pose dangerous conditions. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 37 If battery acid spills, use water mixed with bicarbonate (baking soda) to neutralize the acid. NOTE: Add wiring end protectors and antiseptic seal- ants to help eliminate corrosion of the battery terminals and cables. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 38 PRE-OPERATION INSPECTION This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 39: Pre-Operation Function Test

Mark the machine and do not use it if you discover any problems. Only qualified maintenance technicians can repair the machine according to the manufacturer’s regulations. After any maintenance, the operator must perform an- other pre-operation inspection before conducting a pre- operation function test. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 40: Testing The Platform Controller

ON position. TESTING THE PLATFORM 2. Turn the key switch to the ground control position. CONTROLLER 3. Ensure the relevant indicator turns on and does not display an error message. Emergency Stop Button © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 41 ON position. 5. Lower button Horn button 13. Drive high/low speed se- 6. Forward lect button 7. Backward Press the horn button. The horn should sound. Enable button GENCY GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 42 GENCY trol joystick, the machine should steer right. Note: The drive/steer speed vary with the joystick de- flection, the less the joystick is deflected, the slower the speed. Drive high/low speed select button © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 43: Testing The Drive Speed

4. Pull out the emergency lowering handle located at to fully stowed position. the rear of the chassis. 7. Press the drive/steer function button at the platform controls, then press the drive high/low speed select GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 44: Testing The Tilt Protection Function

8. Fully lower the platform. Switch the machine from lift function to drive function. Drive the machine off and remove the wooden blocks. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 45: Testing The Pothole Guard

1 m(3.3 ft) or 10% of the height that can be lifted (use the greater number), several things will happen. The overload indicator lamp will illuminate, an alarm will sound, and the work GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 46 15℃(59°F), an alarm failure occurs when the rated load is lower than the standard rated load (the "OL" symbol ap- pears on the platform controller screen or the ground controller screen), please re-calibrate the weighing sensor. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 47: Operating The Machine

If more than one operator uses the same ma- chine at different times of the same work shift, they must all be qualified operators and follow all the safety rules and instructions in this Operation Manual. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 48: Emergency Towing/Dragging

9. The machine allows moving by human power. 10. After the towing is completed, re-energize the ma- chine, the brake can operate properly. 11. Remove the chokes as needed. NOTICE The allowable towing speed is 3km/h(1.9mph). © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 49: Operation From Ground

To steer: Press the drive/steer function switch, hold the enable switch on the control joystick, slowly push forward the control joystick and press and hold the steer rocker switch to steer left/right. To shift speed: GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 50: Extending/Retracting The Platform

To unfold the rails: Operate in reverse order as stated above to unfold the rails. Ensure the wire rope safety pins are properly secured after unfolding the rails. Quick fold-down platform © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 51 5. The platform after folded is as shown in the figure 3. Grasp the handles located at the position ② on below. both sides of fixed platform rails and move them GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

-

Page 52: Operating With The Platform Control

2. Press down the pedal, grasp the rail of extension platform and pull to retract the platform. 3. Release the pedal, insert the extension platform end into the slot to secure the extension platform. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 53: Folding/Unfolding The Rails

Unfold the rails when using the machine. The rail folding system consists of the fold- Quick fold-down platform down rails of the extension platform and the fold-down rails of the fixed platform. To fold the the rails: GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 54 5. The platform after folded is as shown in the figure 3. Grasp the handles located at the position ② on below. both sides of fixed platform rails and move them © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 55: Driving On A Slope

1. Use a carpenter’s rule, a straight board (longer than 1. Determine the climbing ability of the machine. 1 m [3.3 ft]), and a tape measure. GTJZ0408SE&0608SE: 25% (14°) GTJZ0408ME&0608ME: 25% (14°) 2. Ensure the platform is fully folded. 3. Ensure that the slope where you plan to drive is less than the angle of the machine’s climbing ability. -

Page 56: Inspect Battery Level

The battery level is at 20%, which is low. The battery re- quires recharging. The battery level is at 10%, which is very low. The machine will become slow. The battery requires recharging. © Mar 2021 7-10 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... -

Page 57: Charging The Battery

1. Make sure the battery is connected to the machine before charging. Figure 7-7 2. Connect the battery charger to a grounded AC circuit. To switch the curve: 3. Charge the battery as needed after use. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 7-11 © Mar 2021... - Page 58 Charger in-built curve codes and respective battery models Table 7-3 Curve codes Battery models Trojan T105 Discover AGM US Battery Flooded Trojan T125 Trojan T1275 (two in series and two in tandem) Note: the default curve code is B02. © Mar 2021 7-12 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 59: Transporting And Lifting The Machine

Failure to use the forklift slot while lifting machine will NOTICE result in component damage. Do not pull/drag the machine unless an emergency, failure or loss of power occurs. Refer to Emergency Towing/Dragging, page 7-2. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 60: Lifting The Machine With A Crane

5. Lift the machine according to the following figure. NOTICE During transportation, retract the extension platform so that the extension platform is secure at the slots. Ensure that the extension platform cannot extend or shake out of the main platform during transportation. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 61 TRANSPORTING AND LIFTING THE MACHINE Figure 8-4 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 62 TRANSPORTING AND LIFTING THE MACHINE This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 63: Maintenance

1. Prepare the machine before delivery, which in- cludes performing a pre-delivery inspection, follow- – Park the machine on flat, level, firm ground. ing maintenance procedures and performing – Keep the machine in the stowed position. functional inspections. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... -

Page 64: Following Amaintenance Schedule

"NO", the machine must be stopped and re-inspected after repair is completed and marked Every year or every 1000 hours A+B+C+D in the box marked "inspection". Select the appropri- ate inspection procedure based on the inspection type. © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 65 A-13 Test the Pothole Guard A-14 Inspect Platform Weigh- ing System(optional) A-15 Inspect the Raised Limit Function A-16 Inspect Platform Lower- ing Limit A-17 Inspect the battery level A-18 Perform Maintenance After 30 Days Checklist B Procedures GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 66 D-2 Inspect Chassis Slider D-3 Replace Hydraulic Oil Tank Return Oil Filter Element D-4 Inspect and Replace Hy- draulic Oil D-5 Inspect Key Structural Parts User Inspector Signature Inspector Date Inspector Title Inspector Company © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 67: Decals/Nameplates Inspection

Do not operate the engine if there are missing or badly worn safety labels. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-1 © Mar 2021... -

Page 68: Decals/Nameplates(Gb)

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(GB) © Mar 2021 10-2 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 69 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-GTJZ0608ME use requirements 101056000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 70 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103017 Decal-Emergency stop switch 101055103016 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard Decal-Warranty period 101038100010 101014100034 Decal-Contact information © Mar 2021 10-4 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 71: Decals/Nameplates(Ce-Metric

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(CE-METRIC) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-5 © Mar 2021... - Page 72 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-GTJZ0608ME use requirements 101056000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 73 Decal-Electrocution hazard Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-7 © Mar 2021...

-

Page 74: Imperial

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(CE-IMPERIAL) © Mar 2021 10-8 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 75 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-GTJZ0608ME use requirements 101056000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 76 Decal-Electrocution hazard Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard © Mar 2021 10-10 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 77: Decals/Nameplates(As

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(AS) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-11 © Mar 2021... - Page 78 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements 101055000019 Decal-GTJZ0608SE use requirements...

- Page 79 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard 101040103014 Decal-Detachable handle mount GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-13 © Mar 2021...

-

Page 80: Gtjz0608Me

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(AS)-GTJZ0608ME © Mar 2021 10-14 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 81 101012100038 Decal-Lanyard anchorage point 101016100030 101038100007 Decal-Electrocution hazard Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101049103022 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-15 © Mar 2021...

- Page 82 DECALS/NAMEPLATES INSPECTION Description Part NO. Remarks Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard 101040103014 Decal-Detachable handle mount © Mar 2021 10-16 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 83: Decals/Nameplates(Kcs

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(KCS) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-17 © Mar 2021... - Page 84 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-GTJZ0608ME use requirements 101056000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 85 Decal-Electrocution hazard Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-19 © Mar 2021...

-

Page 86: Decals/Nameplates(Ce-Pl

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(CE-PL) © Mar 2021 10-20 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 87 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101055000018 Decal-GTJZ0608SE use requirements 101058000008 Decal-GTJZ0408ME use requirements 101055000008 Decal-GTJZ0608ME use requirements 101056000008 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 88 Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard Q-LINE(Logo) 101058103000 © Mar 2021 10-22 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 89: Decals/Nameplates(Ce-Jp

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(CE-JP) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-23 © Mar 2021... - Page 90 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101054103001 Decal-Read manuals Decal-Tipping hazard 101054103002 Decal-Tipping hazard 101049103022 Decal-GTJZ0408SE use requirements 101057103001 Decal-GTJZ0608SE use requirements 101058103002 Decal-GTJZ0408ME use requirements 101055103001 Decal-GTJZ0608ME use requirements 101056103000 Decal-GTJZ0408SE use requirements 101055000017 Decal-GTJZ0608SE use requirements 101058000007...

- Page 91 101058103017 101038100007 Decal-Electrocution hazard Decal-Tipping hazard 101041103020 101058103001 LOGO-IPAF 101040103008 Decal-Brake release Decal-Main power switch 101058103015 Decal-Emergency stop switch 101058103016 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Platform electrical plug 101014100007 Decal-Tipping hazard 101012100008 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-25 © Mar 2021...

-

Page 92: Decals/Nameplates(Ansi

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(ANSI) © Mar 2021 10-26 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual... - Page 93 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101057103017 Decal-GTJZ0608SE use requirements 101058103011 Decal-GTJZ0408ME use requirements 101055103022 Decal-GTJZ0608ME use requirements 101056103016 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 94 101040103008 Decal-Brake release Decal-Main power switch 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard Decal-Annual inspection 101040103015 101040103014 Decal-Detachable handle mount © Mar 2021 10-28 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 95: Decals/Nameplates(Csa

DECALS/NAMEPLATES INSPECTION DECALS/NAMEPLATES(CSA) GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-29 © Mar 2021... - Page 96 Yellow–black caution stripe, 50mm wide 216060000004 Decal-Lifting point 101014100020 Decal-Emergency lowering 101012100011 101040100005 Decal-Read manuals Decal-Tipping hazard 101040100009 Decal-GTJZ0408SE use requirements 101057103017 Decal-GTJZ0608SE use requirements 101058103011 Decal-GTJZ0408ME use requirements 101055103022 Decal-GTJZ0608ME use requirements 101056103016 Decal-Platform electrical plug 101014100007 Decal-GTJZ0408SE use requirements...

- Page 97 101055103018 Decal-Emergency stop switch 101055103015 101014100032 Decal-Serial number Decal-Transport tiedown 101014100021 Decal-Tipping hazard 101012100019 Decal-Tipping hazard 101012100008 101012100029 Decal-Crush hazard Decal-Annual inspection 101040103015 101040103014 Decal-Detachable handle mount 104011100021 Decal-Crush hazard Decal-Operating instructions 101048103023 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 10-31 © Mar 2021...

- Page 98 DECALS/NAMEPLATES INSPECTION This Page Intentionally Left Blank © Mar 2021 10-32 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 99: Appendix 1: Symbols And Description

Please wear work pressure fluids lease brake on ramp shoes Electrocution hazards Electrocution hazards Keep a safe distance Tip-over hazards-Avoid Tip-over hazards-Avoid on platform on the ground and from power lines uneven ground uneven ground platform GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 100 The side force Electrocution hazards Wear protective cloth- Battery explosion No smoking ing and glasses hazard No smoking Only professional Improve point Lashing points Tire to ground load maintenance person- nel can start the maintenance © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 101 DECALS/NAMEPLATES INSPECTION Forklift fork position Platform carrying Carrying capacity of Hydraulic oil filler Horn capacity fixed and extended platform Tool or weight Fast/high speed Slow/low speed GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 102 DECALS/NAMEPLATES INSPECTION This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 103: Appendix 2: Prepare The Work Record Before Delivery

2. Use the table to record the results. After each section is complete, mark the appropriate box. 3. Record the inspection results. If any inspection results are "NO", the machine must be stopped and re-in- spected after repair is completed and marked in the box marked "inspection". GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 104 DECALS/NAMEPLATES INSPECTION This Page Intentionally Left Blank © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

-

Page 105: Appendix 3: Repair & Inspection Report

A-12 Inspect the Tilt Protec- tion Function A-13 Test the Pothole Guard A-14 Inspect Platform Weigh- ing System(optional) A-15 Inspect the Raised Limit Function A-16 Inspect Platform Lower- ing Limit A-17 Inspect the battery level GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021... - Page 106 D-1 Inspect Scissor Arm In- stallation Bearing D-2 Inspect Chassis Slider D-3 Replace Hydraulic Oil Tank Return Oil Filter Element D-4 Inspect and Replace Hy- draulic Oil D-5 Inspect Key Structural Parts User Inspector Signature Inspector Date © Mar 2021 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 107 4. Record the inspection results. If any inspection results are "NO", the machine must be stopped and re-in- spected after repair is completed and marked in the box marked "inspection". Select the appropriate inspection procedure based on the inspection type. GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual © Mar 2021...

- Page 108 Solution s Alw ays For B et t er A ccess Solution s Always for Better Access Solutions AS/N ZS Hunan Sinoboom Intelligent Equipment Co., Ltd. 长沙市宁乡高新技术产业园区金洲大道东 128 号 No.128, East Jinzhou Avenue, Ningxiang High-tech Industrial Park, Changsha, Hunan, China 市宁乡高新技术产业园区金洲大道东...

Need help?

Do you have a question about the GTJZ0408SE and is the answer not in the manual?

Questions and answers