Sinoboom GTJZ0408SE Operation Manual

Hide thumbs

Also See for GTJZ0408SE:

- Parts manual (204 pages) ,

- Operation manual (108 pages) ,

- Maintenance manual (92 pages)

Summary of Contents for Sinoboom GTJZ0408SE

- Page 1 Operation Manual GTJZ0408SE&0608SE&0408ME&0608ME © Hunan Sinoboom Intelligent Equipment Co., Ltd. All Rights Reserved The fourth edition: March 2020...

-

Page 2: Table Of Contents

Only the trained and authorized personnel are allowed to operate the machine. You should regard this Manual as part of the machine and always keep it with the machine. If you have any question, please contact with Hunan SINOBOOM Intelligent Equipment Co., Ltd. Platform Controller......18 Test Emergency Stop....18... - Page 3 Address: No.128, East Jinzhou Avenue, High-tech Industrial Park, Ningxiang, Changsha City, Hunan Province Zip code: 410600 Sinoboom Intelligent Equipment © Hunan Co., Ltd. All Rights Reserved The final interpretation right of the Manual belongs to the Hunan SINOBOOM Intelligent Equipment Co., Ltd The fourth edition: March 2020...

-

Page 4: Product Performance Parameters

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Product Performance Parameters Parameter items GTJZ0408SE GTJZ0608SE Outline dimension Length 1.8 m(5 ft 11 in) 1.8 m(5 ft 11 in) Width 0.79 m(2 ft 7 in) 0.79 m(2 ft 7 in) Height (Folded railings) 1.88 m(6 ft 2 in) 1.87 m(6 ft 2 in) - Page 5 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Hydraulic system 7L/1.5 gal 7L/1.5 gal Pressure of hydraulic system 21 MPa(210bar) 21 MPa(210bar) System voltage (DC) Maximum noise for normal working 72dB 72dB Traveling speed Off-running status 0~4 km/h(0~2.5 mph) 0~4 km/h(0~2.5 mph) Lifting status 0~0.8 km/h( 0~0.5 mph) 0~0.8 km/h( 0~0.5 mph)

- Page 6 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Maximum load bearing capability of 120 kg(265 lbs) 120 kg(265 lbs) extended platform Allowable quantity of people working on 2 Person/1 Person 2 Person/1 Person the platform (Indoor/outdoor) Wheel base 1.334 m(4 ft 4 in) 1.334 m(4 ft 4 in) Wheel span 0.71 m(2 ft 4 in)

- Page 7 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Maximum allowed ambient relative humidity(20℃) Store in an environment free from rain, sun and corrosive Storage condition gases...

-

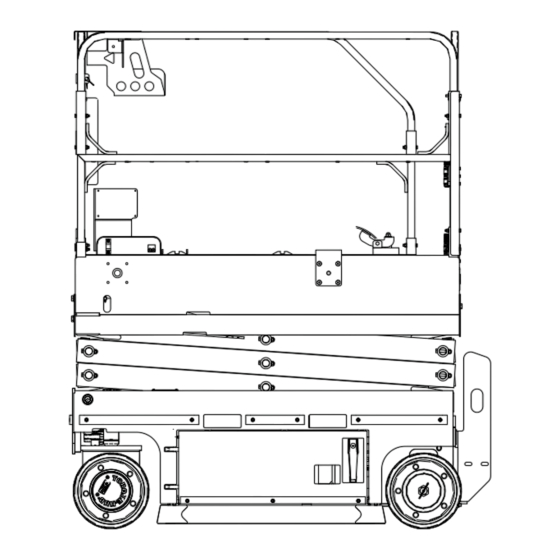

Page 8: Descriptions Of Whole Machine

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Descriptions of Whole Machine 1 Platform entry gate 2 Platform guard rails 3 Lanyard anchorage points 4 Manual storage container 5 Platform controls 6 Foot Switch (if equipped) 7 Platform extension 8 AC power support 9 Platform extension release pedal... -

Page 9: Safety Rules

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Classification of Hazards Safety Rules The symbols, colors and marks used in product labeling Hunan SINOBOOM Intelligent Equipment Co., Ltd. are meant as follows: Safety warning mark- It is used to indicate potential personal injuries. Observe all safety prompts behind this mark for the purpose of avoiding personal injuries or death. -

Page 10: Hazard Of Electric Shock

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual GTJZ0408SE Hazard of Electric Shock Maximum load bearing capability of platform The machine is not insulated and does not have electric shock protection. Retraction of platform 280 kg(617 lbs) Extension of platform - only 160 kg(353 lbs) - Page 11 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Maximum allowable side force: GTJZ0408SE&0608SE: 400N(90 lbf) (indoor) GTJZ0408ME&0608ME: 400N(90 lbf) (indoor), 200N(45 lbf) (outdoor) Do not use the tilt alarm as a horizontal indicator. The tilt alarm on the platform will ring only when Do not change and prohibit the usage of any the machine is heavily tilted.

-

Page 12: Hazard Of Falling

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Do not allow the platform to touch the adjacent Hazard of Collision object. Do not tie the platform on adjacent object. Do not put the load outside the platform. Do not operate the machine when the left or right door is open. -

Page 13: Hazard Of Crushing

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual has been locked or precautions have been taken stored in the storage box on the platform. against any potential collision. Do not have dangerous or careless driving during Hazard of Personal Injury machine operating. Do not operate the machine when there is... -

Page 14: Storage Battery Safety

Use soda water to neutralize the spilled storage machine. battery acid. For: GTJZ0408SE, GTJZ0608SE, GTJZ0408ME, Do not expose the storage battery or charger to GTJZ0608ME water or rain during charging. The weight of each storage battery must reach 28kg. -

Page 15: Pre-Operational Inspection

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Only the qualified maintenance technicians can Pre-operational Inspection repair machine according manufacturer’s regulations. After maintenance, the operator must perform another pre-operational inspection before function test. According to the requirements set forth in the manufacturer’s regulations and Duty Manual,... -

Page 16: Inspection On Machine

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual areas are damaged, and whether there are any an improper oil level, it will damage the hydraulic improperly installed, loosened or missed parts parts. Through daily inspection, the inspector can and unauthorized changes: determine the changes of hydraulic oil level,... - Page 17 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual water to neutralize the spilled storage battery acid. Notice This inspection is carried out after the storage battery is fully charged. Wear protective clothing and protective glasses. Ensure the connection of storage battery cable is not corroded.

-

Page 18: Function Test

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Test Preparation Function Test Select a test area that is solid, horizontal and free of obstacles. Ensure that storage battery connected. Ground Controller Display Enter key screen Page Do not operate, unless: Back key down key You have mastered and practiced the ... -

Page 19: Test Lifting And Lowering Function

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Platform Controller Pull out the red “emergency stop” switch to the ON position. Lowering / Lifting Turn left Test Lifting and Lowering Function Backward / forward Press and hold the ENABLE button, then Turn right press the UP button to start the lifting function. -

Page 20: Test Horn

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual slowly push forward the proportional Test Horn control handle for traveling/steering/lifting Press the horn button. and lowering functions in the direction as indicated on the control panel till the Result: The horn sounds. machine starts moving, then return the handle to the center position. -

Page 21: Test Limited Drive Speed

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual height that can be lifted (take the bigger one), Test Level Sensor the overload indicator lamp turns on with the alarm set off, and the working platform is Note: platform controller control prohibited to be moved. It can be moved again equipment on the ground and do not stand on after removing the over-load object. -

Page 22: Test Pothole Guard

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Test Pothole guard Inspection on Work Site Note: When the platform is raised, pothole guard will be automatically activated. Two normal limit switches are started to limit travelling of the machine. If pothole guard is not activated when platform is raised to the fork... -

Page 23: Operating Instructions

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Emergency Shutdown Operating Instructions Press the red "emergency stop" button on the ground controller or platform controller to the OFF position and all the functions will stop. The machine has a red "power off switch" button located on the chassis. Press the button to the OFF position, the system is powered off and all the functions will stop. -

Page 24: Steering

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Press on the function enabling button on the control handle. Selecting drive speed Move the handle according to the lift In retraction position, the drive controller can indicator on the control panel. operate in two different modes of drive speed. -

Page 25: Operate With The Controller On The Ground

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual of the platform, and fold the front failings of the extendable platform. Hands shall not 70% of the be placed where might get hurt. battery capacity Fold failings at both sides, and hands shall not be placed where might get hurt. -

Page 26: Transportation And Hoisting Instructions

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Instruction of charger LED panel: Transportation and Hoisting 1.1 When it is connected for charging, LED displays the software version of charger initially. lamp Instructions displays the current default charging curve after 3 seconds. The charger enters... - Page 27 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 1. Braking cover 2. End cap bolt 3. Separating hole Ensure that the drive chassis is fastened and there are no obstacles on the channel. Make sure the battery circuit breaker is pressed to "off" position. Remove two end cap bolts and braking cover.

-

Page 28: Maintenance

GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Lift the machine by 0.4m and then tilt the fork Maintenance backward slightly to keep the machine fixated. Keep machine horizontal when lowering the fork frame. Attention: Raise machine from side may result in damage to components. - Page 29 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Lock the tires. Description: Maintenance Schedule Use the operation manual for this machine. There are five types of repair & inspection to The preparation before delivery includes be carried out according to the schedule: Every inspection before...

- Page 30 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Items Model A-1 Inspect All Manuals A-2 Inspect All Labels Serial No. A-3 Inspect Damaged, Loose or Lost Date Parts User A-4 Inspect Hydraulic Oil Level A-5 Inspect Hydraulic Oil Leakage Signature of Inspector A-6 Functional Inspections...

- Page 31 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Record Form D Items D-1 Inspect Scissor Arm Installation Bearing D-2 Inspect Underframe Slider Replace Return Filter Element of Hydraulic Oil Tank Record Form E Items E-1 Inspect and Replace Hydraulic...

-

Page 32: Labeling Instructions

101040100009 to the horizontal surface 101055000008 Tag--Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056000008 Tag--Platform carrying 230 kg(507 lbs)(GTJZ0608ME) 101055000018 Tag--Platform carrying 280 kg(617 lbs)(GTJZ0408SE) 101058000008 Tag--Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101014100007 Electric plug for platform 101055000007 Tag--Platform carrying 280 kg(617 lbs)(GTJZ0408ME)... - Page 33 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Be careful not to touch the fork arm in the movement, please fix the 101040100010 safety rod before repair, read the repair manual 101014100008 Decal-Charger plug 101012100026 Fork lifting position 101040100012 LOGO 215050000001 Rivet 3X8 GB/T12618 101016100042...

- Page 34 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 35 101055000008 Decal--Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608ME) 101055000018 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408SE) 101058000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101014100007 Electric plug for platform 101055000007 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME)...

- Page 36 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 101038100007 Read Operation Manual 216060000003 Attention line, 100mm wide 101058103001 IPAF 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100032 Decal-Serial number 101014100021 Decal-Tiedown When the tilt alarm bell rings, lower the platform and drive the...

- Page 37 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 38 101040100009 machine to the horizontal surface 101055000008 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608ME) Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408SE) 101055000018 101058000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101014100007 Electric plug for platform 101055000009...

- Page 39 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 216060000003 Attention line, 100mm wide 101058103001 IPAF 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100021 Decal-Tiedown 101014100032 Decal-Serial number 101040103014 Decal-Detachable bracket...

- Page 40 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 41 101055000008 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608ME) 101055000018 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408SE) 101058000008 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101014100007 Electric plug for platform 101055000007 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME)...

- Page 42 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 101038100007 Read Operation Manual 216060000003 Attention line, 100mm wide 101058103001 IPAF 101014100032 Decal-Serial number 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100021 Decal-Tiedown...

- Page 43 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 44 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056000007 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608ME) 101055000017 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408SE) Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101058000007 Be careful not to touch the fork arm in the movement, please fix...

- Page 45 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 101038100007 Read Operation Manual 216060000003 Attention line, 100mm wide 101058103000 Q-LINE_LOGO(Small) 101058103001 IPAF 101014100032 Decal-Serial number 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100021 Decal-Tiedown...

- Page 46 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 47 101055103001 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME) 101056103000 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608ME) 101057103001 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408SE) 101058103002 Decal --Platform carrying 230 kg(507 lbs)(GTJZ0608SE) 101014100007 Electric plug for platform 101055000007 Decal --Platform carrying 280 kg(617 lbs)(GTJZ0408ME)...

- Page 48 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual Maintenance Manual. 101038100007 Read Operation Manual 216060000003 Attention line, 100mm wide 101014100032 Decal-Serial number 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100021 Decal-Tiedown...

- Page 49 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

- Page 50 101055103022 Decal-GTJZ0408ME Platform maximun capacity (ANSI) 101056103016 Decal-GTJZ0608ME Platform maximun capacity (ANSI) 101057103017 Decal-GTJZ0408SE Platform maximun capacity (ANSI) 101058103011 Decal-GTJZ0608SE Platform maximun capacity (American) 101014100007 Electric plug for platform 101055103023 Decal-GTJZ0408ME Platform maximun capacity (ANSI)

- Page 51 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual 101038100007 Read Operation Manual 216060000003 Attention line, 100mm wide 101058103001 IPAF 101040103008 Motor brake release 101055103018 Decal-Emergency stop handle (EN) 101055103015 Decal-Emergency stop switch (EN) 101014100032 Decal-Serial number 101014100021 Decal-Tiedown 101040103014 Decal-Detachable bracket 101040103015 Decal-Annual inspection 101012100029...

- Page 52 GTJZ0408SE&0608SE&0408ME&0608ME Operation Manual...

Need help?

Do you have a question about the GTJZ0408SE and is the answer not in the manual?

Questions and answers