Case WX145 Operator's Manual

Hide thumbs

Also See for WX145:

- Operator's manual (375 pages) ,

- Manual (20 pages) ,

- Operator's manual (324 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Case WX145

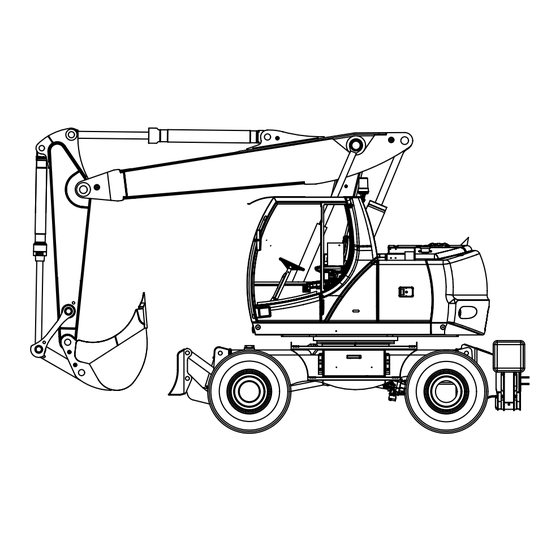

- Page 1 WX145, WX165, WX185 Operator’s Manual 87590052 EN *Tier III*...

- Page 2 CASE WX 145 WX 165 WX 185 OPERATOR’S MANUAL 87590052 EN * Tier III * Find manuals at https://best-manuals.com...

-

Page 3: Introduction, Safety, Plates And Decals

SUMMARY OF SECTIONS 1 - INTRODUCTION, SAFETY, PLATES AND DECALS 2 - CONTROLS AND INSTRUMENTS 3 - OPERATING THE MACHINE 4 - SUPPLIES AND SERVICE CHART 5 - TROUBLESHOOTING 6 - STORAGE 7 - ACCESSORIES 8 - DATA AND TECHNICAL SPECIFICATIONS 9 - ALPHABETICAL INDEX Find manuals at https://best-manuals.com... - Page 4 CAUTION damages to the machine that can involve the It warns the operator of a possible hazard of operator’s safety. machine damage in case he does not follow a determined procedure. DANGER With specific warnings about potential dangers for the operator’s or other persons integrity directly or indirectly involved.

- Page 5 Find manuals at https://best-manuals.com...

-

Page 6: Table Of Contents

INDEX SECTION 1 INTRODUCTION, SAFETY, PLATES AND DECALS ................. 1-1 FOREWORD.............................. 1-1 SAFETY INSTRUCTIONS ......................... 1-2 GENERAL SAFETY INSTRUCTIONS....................1-2 DESIGNATED USE ..........................1-3 NOISE LEVELS ............................1-4 LEVEL OF VIBRATIONS TRANSMITTED TO THE OPERATOR ............1-5 BEFORE OPERATING THE MACHINE ....................1-6 OPERATING THE MACHINE ......................... - Page 7 INDEX DISPLAY SETTING, MAIN MENU ....................... 2-20 CONTRAST ............................2-21 BRIGHTNESS ............................2-22 TIME ..............................2-23 UNITS ..............................2-26 SYMBOLS ............................2-28 STARTER SWITCH ..........................2-29 RADIO ..............................2-31 CAB ................................. 2-32 ENTRY AND EXIT ..........................2-32 DOOR OPENING ..........................2-32 DOOR CLOSING ..........................

- Page 8 INDEX BASIC SETTING ..........................3-16 TRAVEL ..............................3-18 GEARBOX - GEAR CHANGE ......................3-21 TRAVEL WITH LOAD APPLIED TO CRANING HOOK................ 3-23 FLOATING AXLE BLOCKING AND UNBLOCKING................3-24 WORKING OPERATION ......................... 3-25 SAFETY INSTRUCTIONS ........................3-25 BEFORE BEGINNING THE WORK...................... 3-26 HOLDING AND RELEASING THE UPPER STRUCTURE SLEW ............

- Page 9 INDEX TYRES - PRESSURE CHECK ......................4-22 TYRES - NUTS TIGHTENING......................4-24 WEEKLY SERVICE (50 HOURS)......................4-25 CAB AIR FILTER - CLEANING ......................4-25 AIR FILTER - CLEANING ........................4-26 AIR INTAKE LINE - CHECK ......................... 4-28 MULTI-COOLER - CLEANING ......................4-28 FUEL SYSTEM - AIR BLEEDING AND WATER DRAINING ...............

- Page 10 INDEX SLEWING GEARBOX - OIL CHANGE ....................4-70 SERVICE WHEN NECESSARY ......................4-71 MACHINE - CLEANING........................4-71 WINDSCREEN WIPER - CHECK AND CLEANING................4-73 DRIVE BELT - CHANGE ........................4-73 INJECTORS - REPLACEMENT ......................4-74 HYDRAULIC SYSTEM AND TANK - PRESSURE RELEASE.............. 4-74 TYRES - CHANGE ..........................

- Page 11 INDEX SECTION 7 ATTACHMENTS............................7-1 HYDRAULIC HAMMER ..........................7-1 HYDRAULIC HAMMER SELECTION..................... 7-1 SAFETY INSTRUCTIONS........................7-1 USE OF HYDRAULIC HAMMER......................7-3 HYDRAULIC SHEARS ..........................7-8 SELECTING THE HYDRAULIC SHEARS....................7-8 SAFETY INSTRUCTIONS........................7-8 USE OF HYDRAULIC SHEARS ......................7-10 HYDRAULIC QUICK COUPLER ......................7-15 SAFETY INSTRUCTIONS........................

- Page 12 INDEX WX 165 MODELS ........................... 8-4 WX 185 MODELS ........................... 8-7 DIGGING PERFORMANCE ........................8-9 WX 145 MODELS ........................... 8-9 WX 165 MODELS ..........................8-14 WX 185 MODELS ..........................8-19 LIFTING CAPACITIES..........................8-23 HYDRAULIC SYSTEM ..........................8-24 PUMPS ..............................8-24 CYLINDERS (ø...

- Page 13 INDEX...

-

Page 14: Foreword

SECTION 1 INTRODUCTION, SAFETY, PLATES AND DECALS FOREWORD The current Operator’s Manual is the user’s guide SPARE PARTS for correct run-in, use and maintenance of the The “non-genuine” spare parts have not been con- machine. trolled and authorized by the Manufacturer. The Carefully read this Operator’s Manual and store it in assembly and/or use of such products may have the cab for quick location and reference. -

Page 15: Safety Instructions

CAUTION It warns the operator of a possible hazard of machine damage in case he does not follow a determined procedure. Your safety and that of people around you depends on you. It is essential that you understand this man- ual for the correct operation, inspection, lubrication and maintenance of this machine. -

Page 16: Designated Use

INTRODUCTION, SAFETY, PLATES AND DECALS DESIGNATED USE The machine has been built in accordance with state-of-the-art standards and the recognized safety rules. Nevertheless, its use may constitute a risk to life and limb for the user or third parties or cause damage to the machine and to other material prop- erty. -

Page 17: Noise Levels

SECTION 1 NOISE LEVELS Sound power level (acoustic external) LWA: WX 145 models: 101 dB (A) WX 165 models: 102 dB (A) WX 185 models: 103 dB (A) Sound power level guaranteed (1), determined in compliance with European standard 2000/14/EC. Sound pressure level in the operator’s seat (acoustic internal) LpA:... -

Page 18: Level Of Vibrations Transmitted To The Operator

INTRODUCTION, SAFETY, PLATES AND DECALS LEVEL OF VIBRATIONS TRANSMITTED TO THE OPERATOR The vibration level to the operator depends mainly on the conditions of the ground where the machine is being operated and on the use conditions of the machine and its equipment. The exposition to vibrations can be remarkably reduced if the recommendations here below are fol- lowed:... -

Page 19: Before Operating The Machine

- respirator or filter mask. Wear close fitting clothing and safety equipment appropriate for the job. Do not leave anything to the case. Avoid wearing loose clothing, jewellery, or other items that can catch on control levers or other parts of the machine. - Page 20 INTRODUCTION, SAFETY, PLATES AND DECALS PREPARE FOR EMERGENCIES Be prepared if a fire starts or an accident occurs. Keep the first-aid kit and fire extinguisher on hand. Thoroughly read and understand the label attached to the fire extinguisher to use it properly. Establish emergency priority procedures to cope with fires and accidents.

- Page 21 SECTION 1 OPERATING THE MACHINE USE HANDHOLDS AND STEPS Falling is one of the major causes of personal injury. When you get on and off the machine, always main- tain a three-point contact with the steps and hand- rails and face the machine. Do not use any controls as hand-holds.

- Page 22 INTRODUCTION, SAFETY, PLATES AND DECALS AVOID INJURY FROM REVERSE TRAVEL AND SWING ACCIDENTS If someone stands near the machine when this is swinging or in reverse travel, the same can hit or run over this person causing heavy injuries or even death.

-

Page 23: Travel

SECTION 1 TRAVEL BEFORE SETTING OFF Remove any soil, mud, snow, ice, grease and oil from your working footwear before operating the machine. You might otherwise slip from steps and pedals and thus initiate inadvertent movements. Adjust the driver’s seat and the mirror before setting off. - Page 24 INTRODUCTION, SAFETY, PLATES AND DECALS TRAVELLING OVER LONG DISTANCES Before travelling over long distances: - return the machine to basic position; - activate the upper structure holding brake in auto- matic mode. The machine is then in basic position. Before driving on public highway, familiarize yourself with local laws and the regulations in force.

-

Page 25: Travelling On Public Roads

SECTION 1 TRAVELLING ON PUBLIC ROADS WARNING Road circulation (on public roads) is ruled by special pro- visions varying from country to country. Check before- hand with local authorities for circulation provisions. Transfer on public roads (each time you leave a yard) is allowed only with an approved configuration, com- plying with dimensions (A), (B) as shown on the tables. - Page 26 INTRODUCTION, SAFETY, PLATES AND DECALS WX 185 MONOBOOM 2800 2400 2000 Dipper (in) (110.24) (94.98) (78.73) 3850 3800 3800 A Maximum height (in) (151.57) (149.60) (149.60) 4750 4750 4850 B Frontal off-set (in) (187.00) (187.00) (190.94) PLACING BOOM 2400 2000 Dipper (in) (94.98)

-

Page 27: Machine

SECTION 1 MACHINE LAY-OUT The clamshell switching over valve has to be set to “clamshell” position. In this way, the bucket cylinder is hydraulically locked. Assemble the overall lights on the dipper. Connect the overall lights to outer socket, installed on the frame. - Page 28 1st gear. With remarkable gradients, engage the creep speed. Travel only in basic position and ahead, in this case the flywheel is positioned on the steering axle. Do not travel across slopes or reverse the machine across slopes as it could overturn.

- Page 29 SECTION 1 JOB SITE OPERATION INVESTIGATE JOB SITE BEFOREHAND Clear all persons from area of operation and machine movement. Make sure worksite footing has sufficient strength to firmly support the machine. When digging deeply, avoid hitting bottom of boom or bucket cylinder hoses against the ground. Use the bucket only for digging.

-

Page 30: Engine

INTRODUCTION, SAFETY, PLATES AND DECALS AVOID ELECTRIC LINES Serious injury or death can result if the machine or front attachments are not kept a safe distance from electric lines. When operating near an electric line, never move any part of the machine or load closer than 3 m (9.84 ft) plus twice the line insulator length (L). - Page 31 This as a preview PDF file from best-manuals.com Download full PDF manual at best-manuals.com...

Need help?

Do you have a question about the WX145 and is the answer not in the manual?

Questions and answers