Advertisement

Quick Links

Doc No 700105 (06-15), Page

All manuals and user guides at all-guides.com

INSTALLATION / OPERATION / MAINTENANCE

Applies to:

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance instructions

thoroughly

before

Part # 700105

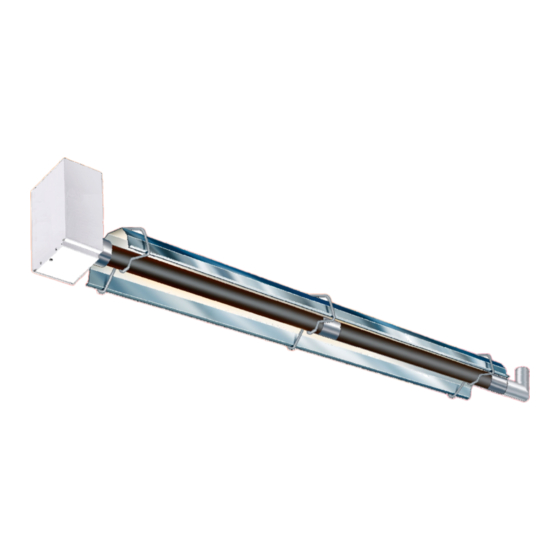

Model VPLUS HL120V 60Hz

Gas-Fired, Tubular, Radiant,

Low-Intensity Infrared Heater

Vision Range

VPLUS HL OWNERS MANUAL

installing

or

servicing

this

Advertisement

Summary of Contents for Ambirad Vision VPLUS HL120V

- Page 1 All manuals and user guides at all-guides.com INSTALLATION / OPERATION / MAINTENANCE Model VPLUS HL120V 60Hz Applies to: Gas-Fired, Tubular, Radiant, Low-Intensity Infrared Heater Vision Range VPLUS HL OWNERS MANUAL WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death.

- Page 2 All manuals and user guides at all-guides.com Introduction. Welcome to the new range of powered HiLo and servicing is undertaken on radiant tube infra-red heaters. Local regulations may vary heaters specified in these instructions, due care and it is the installer’s responsibility to ensure and attention is required to ensure that working that such regulations are satisfied.

- Page 3 All manuals and user guides at all-guides.com accordance with Standard attachments to overhead steelwork etc. must Parking Structures, ANSI/NFPA 88A, or be purpose made to sound engineering practice the Standard for Repair Garages, ANSI/ or supplied by others. They must be adequately NFPA 88B, or the Canadian Natural Gas fixed and designed to carry the whole weight of the heater.

- Page 4 All manuals and user guides at all-guides.com ON VENTED HEATERS, THE HEATER SHOULD SLOPE DOWNWARDS AWAY FROM THE BURNER AND ON UNVENTED HEATERS SHOULD SLOPE DOWNWARDS TOWARDS BURNER BY APPROX. ½” FOR HORIZONTAL INSTALLATIONS AS SHOWN BELOW (DIAGRAMS EXAGGERATED FOR CLARITY) 1/2”...

- Page 5 All manuals and user guides at all-guides.com Figure 2 Clearance to Combustibles (Standard indoor reflectors).. The minimum clearances to combustible materials are given in Table 1 These minimum distances MUST be adhered to at all times. Adequate clearance MUST be provided around air openings into the combustion chamber and there MUST be suitable clearance for accessibility and for combustion / ventilating air supplies.

- Page 6 All manuals and user guides at all-guides.com Gas Connection and Supply Figure 3. Correct orientation of Ball Valve WARNING: Before installation, check that the local distribution conditions, nature of gas and pressure, and adjustment of the appliance are compatible. Gas Flow The gas connection on the heater is ½”...

- Page 7 All manuals and user guides at all-guides.com CONNECTOR MUST BE INSTALLED IN A “U” CONFIGURATION. FOR HEATERS UP TO 150,000 BTU/H, A 24” LONG CONNECTOR OF AT LEAST ½” ID MUST BE USED. FOR HEATERS ABOVE 150,000 BTU/H, A 36” LONG CONNECTOR OF AT LEAST ¾” NOMINAL ID MUST BE USED.

- Page 8 All manuals and user guides at all-guides.com Figure 6a. Internal Burner Wiring Diagram. 24V Two stage Thermostat 24V AC Stat 120V AC Fan 120V AC KEY: Terminals Terminals Supply BL - BLUE BK - BLACK BR - BROWN GR - GREY G - GREEN K - PINK R - RED...

- Page 9 All manuals and user guides at all-guides.com The external two stage thermostat is connected 1.5.1 Multiple burner configurations (Master to the Master burner and powered via the inbuilt & Slave) via Optional Relay. transformer. The total burner load for the Master Refer to figure 6b and 6d.

- Page 10 All manuals and user guides at all-guides.com Figure 6d. Internal Slave Burner Wiring/External Schematic Diagram with Optional Relay. OPTIONAL RELAY WIRING COIL 24V AC RELAY 24V Two stage Thermostat Relay mini harness leads 24V AC Stat 120V AC Fan 120V AC KEY: Terminals Terminals...

- Page 11 All manuals and user guides at all-guides.com This protects building material from 1.6 Vent Requirements and Details degradation by the vent gasses. 1.6.1 Unvented units Vent joints should be sealed and secured according vent manufacturers Heaters may be installed unvented providing instructions.

- Page 12 All manuals and user guides at all-guides.com Figure 7.a Vertical Venting. Approved Vent Cap Figure 7.b Horizontal Venting (plan view shown). Approved Vent Cap Note The vent terminal should be installed so as to be in the same atmospheric pressure zone as the combustion air inlet of the appliance.

- Page 13 All manuals and user guides at all-guides.com Technical Details - Table 5 No of Injectors ½” N.P.T Gas Connection 120 volt 1 phase 60Hz Electrical Supply 4” or 6” (101mm or 152mm) Vent size (in) 120 volt 1 phase 60Hz Unitary Fan Motor Details 1.8A MAX (models 40 - 150);...

- Page 14 All manuals and user guides at all-guides.com Technical Details continued USA & CANADA Natural Gas 0- 2000 ft (0-610m) Size 201063-24 201063-57 201063-77 201063-67 201063-23 201063-26 201063-78 Burner Orifice Plate Part No. Flame Plate Part No. 201957 202132 Fan Part No. 202483 201654 L200301...

- Page 15 All manuals and user guides at all-guides.com 2. Assembly Instructions. PLEASE READ this section prior to Please ensure that all packaging is assembly to familiarize yourself with the disposed of in a safe environmentally components and tools you require at the friendly way.

- Page 16 All manuals and user guides at all-guides.com 2.2.2.2 Where a heater configuration requires more than three turbulator strips and has the exhaust heat exchanger tube adjacent to an “L” or “U” heat exchanger tube, refer to the diagram below for positions. Slide the connected sections into the tube(s).

- Page 17 All manuals and user guides at all-guides.com Moving between the two screws, tighten each 2.2.3.2 Reflector Support Brackets one in turn ensuring that equal pressure is applied to both. Complete assembly by drilling Reflectors are positioned above the emitter and screwing self tapping retention zip screws. tube with a reflector support bracket part #L201008-SUB RADIANT...

- Page 18 All manuals and user guides at all-guides.com These overlapped reflectors are allowed to 2.2.5 Reflectors. ‘float’ within the support bracket by leaving a reflectors must positioned/ minimum of 1/8” gap of the fixing screws before attached to the brackets exactly as tightening the locknuts.

- Page 19 All manuals and user guides at all-guides.com Note: high wind applications additional drill screws to secure end cap to the reflector 2.2.7 Bend(s) (where fitted) The heater can be installed with 1 or 2 90° bends or a 180° U bend. Slide the bend into the open end of the Connect Electrical...

- Page 20 All manuals and user guides at all-guides.com 2.2.8.1 Model 200 S50 fan orifice plate 2.2.10 Detailed Assembly Drawings This model has a different fan orifice plate (Part following pages show technical No.202254) to all other models in the range. It dimensional details of the range of heaters.

- Page 21 All manuals and user guides at all-guides.com Figure 8. Possible Heater Orientations Doc No 700105 (06-15), Page 21...

- Page 22 All manuals and user guides at all-guides.com Figure 9. Heater Assembly: Model Linear 40-S10. Doc No 700105 (06-15), Page 22...

- Page 23 All manuals and user guides at all-guides.com Figure 10. Heater Assembly: Model Linear 40-S20 and 60-S20. Doc No 700105 (06-15), Page 23...

- Page 24 All manuals and user guides at all-guides.com Figure 11. Heater Assembly: Model Linear 60-S30, 80-S30, 100-S30 and 125-S30. Doc No 700105 (06-15), Page 24...

- Page 25 All manuals and user guides at all-guides.com Figure 12. Heater Assembly: Model Linear 60-S40, 80-S40, 100-S40, 125-S40 and 150-S40. Doc No 700105 (06-15), Page 25...

- Page 26 All manuals and user guides at all-guides.com Figure 13. Heater Assembly: Model Linear 125-S50, 150-S50, 170-S50 and 200-S50 Doc No 700105 (06-15), Page 26...

- Page 27 All manuals and user guides at all-guides.com Figure 14. Heater Assembly: Model Linear 150-S60, 170-S60 and 200-S60. Doc No 700105 (06-15), Page 27...

- Page 28 All manuals and user guides at all-guides.com Figure 15. Heater Assembly: Model Linear 170-S70 and 200-S70. Doc No 700105 (06-15), Page 28...

- Page 29 All manuals and user guides at all-guides.com Figure 16. Heater Assembly: Model U tube 40-U20 and 60-U20 3' 3" Doc No 700105 (06-15), Page 29...

- Page 30 All manuals and user guides at all-guides.com Figure 17. Heater Assembly: Model U tube 60-U40, 80-U40, 100-U40, 125-U40 and 150-U40. 3' 3" Doc No 700105 (06-15), Page 30...

- Page 31 All manuals and user guides at all-guides.com Figure 18. Heater Assembly: Model U tube 150-U60, 170-U60 and 200-U60. 3' 3" Doc No 700105 (06-15), Page 31...

- Page 32 All manuals and user guides at all-guides.com 3. Start Up Instructions. These appliances should be commissioned by a qualified mechanical contractor. Tools Required. The following tools and equipment are advisable Suitable alternative tools may be used. to complete the tasks laid out in this manual. Large Adjustable Small Flat Leather...

- Page 33 All manuals and user guides at all-guides.com The high fire gas pressure should be set first followed by the low fire gas pressure. Re-check the high fire and re-adjust if necessary. To enable post purge ensure that the setting of any time switch and thermostat are such that the heating system will be required to turn off.

- Page 34 All manuals and user guides at all-guides.com Commissioning chart Check installation has Ensure gas and electricity Disconnect gas hose from been carried out to these supplies are isolated. burner instructions. Remove burner from tube and inspect burner head. (See servicing instructions) Reconnect gas hose.

- Page 35 All manuals and user guides at all-guides.com 4. Servicing Instructions. These appliances should be serviced annually by a competent person to ensure safe and efficient operation. In mildly dusty or polluted conditions more frequent servicing may be required. Servicing work should be carried out by a qualified mechanical contractor. to complete the tasks laid out in this manual.

- Page 36 All manuals and user guides at all-guides.com 4.3 Burner Removal Step 1: Isolate power and gas supplies. Step 2: Disconnect the external power/control connections. Step 6: Remove the burner and position the burner in a safe area to prevent the burner or components attached to the burner from falling to the ground.

- Page 37 All manuals and user guides at all-guides.com Step 3: The gas injector can be inspected and replaced if contaminated or blocked. When replacing the gas injector ensure approved thread sealant is used. Step 4: Reconnect ignition leads and silicone tube to test nipple. Refit gasket and support casting.

- Page 38 All manuals and user guides at all-guides.com continued reliability. Detach the electrode 4.7 Radiant Tube Servicing assembly from the burner head by removing the two screws as shown and separating the Step 1: Brush any dust from the exterior of the igniter assembly lead connectors.

- Page 39 All manuals and user guides at all-guides.com 5. Troubleshooting Guide. START Ensure gas & electricity supplies are enabled. Turn any external timer to call for heat (if fitted). CHECK: - Does the Power On Is there power to the 1. Transformer light illuminate? burner? 2.

- Page 40 All manuals and user guides at all-guides.com To aid in the troubleshooting process the UT controller has an LED flash code diagnostic sequence: Steady Off No control Power Steady On Power Applied, Control OK Combustion Pressure Switch Open With Blower On 1 Flash Combustion Pressure Switch Closed With Blower Off 2 Flashes...

- Page 41 All manuals and user guides at all-guides.com 6. Replacing Parts. Turn off gas and any electrical supplies to 6.2 Air Pressure Switch Replacement the heater before starting repair work. Step 1: Disconnect the two silicone tubes from the pressure switch. 6.1 Burner Controller Replacement Step 1: Remove the four screws securing the bottom access door.

- Page 42 All manuals and user guides at all-guides.com Step 5: Fit the new air pressure switch ensuring the tubes are connected as shown below. Step 5: Remove the four screws (circled) securing the gas valve inlet plate to the burner housing and remove plate. Step 6: Re-connect wiring.

- Page 43 All manuals and user guides at all-guides.com Notes: Doc No 700105 (06-15), Page 43...

- Page 44 Website www.ambirad.com/us For the Distributor Nearest please call AmbiRad is a registered trademark of Nortek Global HVAC. Because of continuous product 1-888-330-4878 innovation, AmbiRad reserves the right to change product specification without due notice. Doc No 700105 (06-15), Page 44...

Need help?

Do you have a question about the Vision VPLUS HL120V and is the answer not in the manual?

Questions and answers