Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KNF N838 DC Series

- Page 1 KNF 347395-347606 09/23 N838_DC TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTION ENGLISH DIAPHRAGM PUMP Notice! Before operating the pump and accessories, read and observe the operat- ing and installation instructions as well as the safety information!

-

Page 2: Table Of Contents

Contents 1 About this document ................ 3 1.1 Using the operating and installation instructions...... 3 1.2 Exclusion of liability............... 3 1.3 Symbols and markings.............. 4 2 Safety .................... 6 2.1 Personnel and target group ............ 6 2.2 Responsibility of the operator ............ 7 2.3 Working in a safety conscious manner ......... -

Page 3: About This Document

The manufacturer assumes no liability for damages and mal- functions resulting from impermissible spare parts and acces- sories. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 4: Symbols And Markings

An activity to be carried out is specified here (a step). 1. The first step of an activity to be carried out is specified here. Other sequentially numbered steps follow. This symbol indicates important information. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 5 Warning of hot surface Warning of electrical voltage Warning of poisonous substances Warning of hand injuries through crushing Observe the operating instructions General mandatory sign Use hand protection Tab.2: Explanation of pictograms Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 6: Safety

Tab.3: Target group Who-does-what Lifecycle phase User Specialized per- matrix sonnel Transport Mounting Connection Commissioning Operation Servicing Troubleshooting Disposal Tab.4: Who-does-what matrix Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 7: Responsibility Of The Operator

Make sure that an EMC-compliant installation of the pump is ensured at all times to prevent the occurrence of dangerous situations. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 8: Operating Conditions

Make sure that a dangerous situation cannot arise as a result. When pumping hazardous media, observe the safety regula- tions for the handling of said media. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 9: Use

2.6.2 Foreseeable misuse The pumps must not be operated in explosive atmospheres. The pumps are not suitable for transferring the following: § Dusts § Liquids § Aerosols § Biological and microbiological substances Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 10: Directives And Standards

1.5.9. / 1.7.4. / 1.7.4.1. / 1.7.4.3. Standards The following standards apply: § EN IEC 61000-6-1 § EN 60034-1 § EN IEC 55014-1/2 § EN IEC 63000 The protective goals of the following directive(s) are achieved: Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 11: Customer Service And Repair

Alternatively, KNF products (old devices) may also be returned to KNF for a fee (see chapter 11 Re- turns [} 47]). Translation of Original Operating and Installation Instruction, KNF 347395-347606... -

Page 12: Technical Data

[bar gauge] rated speed rated speed [l/ min]* N838KNDC N838ANDC Tab.6: Pneumatic values Pneumatic connections Pump type Value N838AN_ Thread size G 1/8 N838KN_ Thread size G 1/8 Tab.7: Pneumatic connections Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 13 Highest permissible relative 80% for temperatures up to air humidity of the environ- 31°C, decreasing linearly to ment 50% at 40°C. Maximum installation altitude 2000 [m above sea level] Tab.10: Other parameters Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 14: Product Description

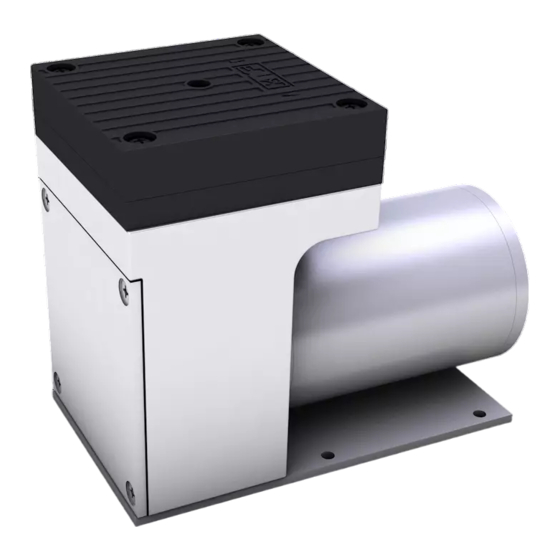

Product description Diaphragm pump N838_DC 4 Product description Design 1 Outlet (pres- sure side) 2 Inlet (suction side) 3 Motor Fig.1: Design N838_NDC Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 15 (2). In the upwards stroke, the diaphragm presses the medium out of the pump head via the outlet valve (1). The transfer chamber (3) is separated from the pump drive by the di- aphragm. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 16: Transport

There is a risk of injury from cutting on the sharp edges when grabbing cor- CAUTION ners or when opening the packaging. à Where appropriate, wear suitable personal protective equipment (e.g., safety shoes, safety gloves). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 17 Permissible humidity (non- 30 to 85 condensing) [%] Tab.11: Transport parameters and storage parameters Prior to commissioning, make sure that the pump has reached the ambient temperature (3 Technical data [} 12]). NOTICE Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 18: Installation And Connection

Store the pump at the installation site to allow it to adapt to the ambient temperature before installation (condensa- tion must not be allowed to form). à Mounting dimen- For mounting dimensions, see the following illustrations: sions Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 19 (head, motor). à Installation loca- Make sure that the installation location is dry and that the tion pump is protected from rain, spray water, splash water, dripping water and other contaminants. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 20 Make sure that pump vibrations cannot lead to dangers in combi- nation with adjacent components. à Protection Protect the pump against contact and the ingress of for- against foreign eign bodies. objects Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 21: Electrical Connection

à Install a device for separating the pump motor from the electrical grid in the electrical installation (e.g. in accor- dance with EN 60335-1). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 22 à Magnetic field with energy frequency à Electromagnetic RF field, amplitude modulated à Electromagnetic RF field, pulse modulated à Static electricity discharge à High frequency, asymmetric à Fast transients Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 23: Pneumatic Connection

à Connected com- Only connect components to the pump that are designed ponents for the pneumatic data and thermal requirements of the pump. (see Chapter 3 Technical data [} 12]). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 24 3. Connect the suction line and the pressure line (for mount- ing dimensions, see Chapter 3 Technical data [} 12]). 4. Lay the suction line and pressure line with a descent so that no condensate can run into the pump. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 25: Operation

The pumps are built-in devices. Before they are commis- sioned, it must be ensured that the machines or systems into which the pumps are installed comply with the rele- vant provisions. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 26 NOTICE of the pump. Further information is available from KNF Customer Service (contact data: see www.knf.com). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 27 à KNF recommends: When pumping corrosive media, flush the pump before switching off (see Chapter 8.2.1 Flushing the pump [} 30]) to extend the service life of the di- aphragm. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 28: Information On Switching The Pump On And Off

Before recommissioning, observe the applicable stan- dards, guidelines, regulations and technical standards at the electrical connection. à Inspecting the Inspect the pump periodically for external damage or leak- pump age. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 29: Servicing

Perform periodic inspec- tions for external damage or leakage. à Diaphragm and valve plates At the latest, replace when the pump flow rate decreases. à Silencer (accessories) Replace if soiled. Tab.12: Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 30: Cleaning

8.2.1 Flushing the pump When transferring dangerous and environmentally hazardous media, KNF recommends flushing the pump with air at atmo- spheric pressure for a few minutes prior to switch-off (if nec- essary for safety reasons: with an inert gas) to extend the ser- vice life of the diaphragm. -

Page 31: Replacing The Diaphragm And Valve Plates

If the diaphragm is not replaced at the same time as the valve plates/seals, the specified output of the pump can no longer be ensured after the maintenance is performed. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 32 à CAUTION Allow the pump to cool after oper- ation. 8.3.1 Changing diaphragms and valve plates (for pump heads made of plastic) Fig.4: One-headed pump N838KN_DC Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 33 Fig.5: Pump head N 838 KN_ versions (plastic pump head) The diaphragm and valve plates/seals are to be replaced in the following order: Initial steps 1. Disconnect the pump from the power supply and ensure that it is voltage-free. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 34 8. Perform steps 1 to 7 for the second pump head. Replacing the valve plates/seals 1. Loosen the screw (9) with a small screw driver. 2. Separate the head plate (3) from the intermediate plate (2). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 35 11. Perform steps 1 to 9 for the second pump head. Fig.6: Alignment of the disk springs For two-headed pumps: (11) Fig.7: Removal of connection tubes and O-rings (two-headed pumps) Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 36 1. Mount the cover (1). 2. Connect the pump to the power supply. If you have questions with regard to maintenance, please contact our KNF technical adviser (contact data: www.knf.de). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 37 Servicing Diaphragm pump N838_DC 8.3.2 Changing diaphragms and valve plates (for pump heads made of aluminum) Fig.8: One-headed pump N838ANDC Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 38 3 Head plate 4 Head plate screw 5 Cover 6 Valve plate/ seal 7 Diaphragm 8 Shim 9 Connecting 10 Counter- weight M Marking Fig.9: Sectional drawing of head N828AN Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 39 Replacing the valve plates/seals 1. Separate the head plate (3) from the intermediate plate (2). 2. Remove the valve plates/seals (6) from the intermediate plate (2). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 40 3.5 Nm). Final steps 1. Connect the pump to the power supply. If you have questions with regard to maintenance, please con- tact our KNF technical adviser (contact data: www.knf.com). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

-

Page 41: Spare Parts And Accessories

Spare parts and accessories Diaphragm pump N838_DC 9 Spare parts and accessories To order spare parts and accessories, please contact your KNF sales partner or KNF Customer Service (con- tact data: see www.knf.com). 9.1 Spare parts Spare part set A spare part set consists of: For one-headed pumps: à... -

Page 42: Accessories

007006 Hose connector (straight) 000360 Except N838.1.2KN_: PA, G 1/8, ID6 Hose connector 004975 N838.1.2 KN_: PA, G 1/8, ID8 Angled hose connector 001858 Except N838.1.2KN_: PA, G1/8, ID6 Tab.15: Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... -

Page 43: Troubleshooting

à Check and ensure that no voltage is present. à Allow the pump to cool before troubleshooting. à Check the pump (see following tables). Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23... - Page 44 Install the pump at the highest location in the sys- tem. à Diaphragm and valves Replace diaphragm and valves (see Chapter 8 Ser- are worn or defective. vicing [} 29]). Tab.16: Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 45 Replace diaphragm and valves (see Chapter 8 Ser- are worn or defective. vicing [} 29]). à Replaced diaphragms Ensure that shim rings were fitted on the diaphragm and valve plates. thread. Translation of Original Operating and Installation Instruction, KNF 347395-347606 09/23...

- Page 46 Tab.18: Fault cannot be rectified If you are unable to identify any of the specified causes, send the pump to KNF Customer Service (contact data: see www.knf.com). 1. Flush the pump with air for a few minutes (if necessary for...

-

Page 47: Returns

If necessary, request original packaging for a fee. Returns KNF shall undertake to repair the pump only under the condi- tion that the customer presents a certificate regarding the medium that is pumped and the cleaning of the pump. In this case too, old devices can be returned. - Page 48 KNF Neuberger GmbH Alter Weg 3 79112 Freiburg Germany Tel. +49 (0)7664/5909-0 E-mail: info.de@knf.com www.knf.com KNF worldwide You can find our local KNF partners at: www.knf.com...

Need help?

Do you have a question about the N838 DC Series and is the answer not in the manual?

Questions and answers