Table of Contents

Advertisement

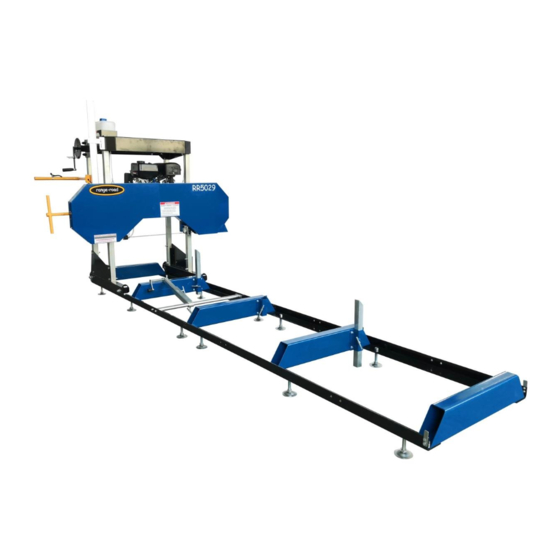

Range Road RR5022, RR5026, RR5032 and RR5036

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before

operating. Failure to follow the safety rules and other basic safety precautions may result in

serious personal injury.

Range Road Enterprises Ltd

Box 944

Eckville AB T0M 0X0

www.range-road.ca

Sawmill

Owner's Manual

Advertisement

Table of Contents

Summary of Contents for Range Road RR5036

- Page 1 Range Road RR5022, RR5026, RR5032 and RR5036 Sawmill Owner’s Manual WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury. Range Road Enterprises Ltd...

-

Page 2: Intended Use

INTENDED USE The Range Road Saw Mill is portable and versatile which makes it a great tool for any lumber project. It has the capabilities of sawing logs up to 22”, 26”, 32” and 36” in diameter, 7” thick and a cutting length of 125”. -

Page 3: Work Area

It is also a good idea to back off the blade tension when not in use, helps to preserve belt and blade life. Inspect it for good working condition prior to storage and before re-use. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca... -

Page 4: Important Safety Information

Engine exhaust contains carbon monoxide. This is a poison you cannot see or smell. NEVER use gas engines indoors EVEN IF doors and window are open. Only use OUTSIDE and far away from windows, doors and vents. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca... - Page 5 Caution is necessary when near the engine’s magneto or recoil starter. 6) Use only accessories that are recommended by Range Road for your model. Accessories that may be suitable for one piece of equipment may become hazardous when used on another piece of equipment.

-

Page 6: Service Precautions

• Maintain all labels on the saw mill. These show important information. If unreadable, missing or damaged, contact Range Road for a replacement. • Have the equipment serviced by a qualified repair person using only OEM replacement parts. This will ensure that the safety of the saw mill is maintained. - Page 7 2) The two long boxes at the bottom of the crate are the rail parts. Open these boxes and you will see a small white box, open and take out the bolts and nuts for mounting the rails. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 8 For any Sawmill to cut square and straight all pieces have to be squared to each other and level. Use the adjusting feet to level one rail and then make sure the second rail is level with the first one. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 9 4 holes on each side, this rail will eventually be the center of the rails and it has a side pocket on it. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 10 RR5022 & RR5026 845mm (33 ¼”) 1008mm (39 11/16”) RR5032 RR5036A 1099mm (43 ¼”) 7) Do cross measurements now to make sure the rails are square to each other. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 11 10) Put the levelling feet on next 2 rails and put them in position at the centre log support cross tube. 11) When you have the rails level with the log support cross tube use clamps to hold the outer rails together. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 12 15) When rails are square and level tighten 8 bolts in log support cross tube, mount the centre log support cross tube and tighten it. Re check levelness and cross measurements. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 13 17) Cut the cardboard at the base of the tube so they can go through to the floor 18) Tighten the T-handles to lock the tubes in place Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 14 19) Loosen the 4 corner bolts on the top frame 20) Place the top frame upside down and put the 2 galvanized corner posts in and tighten all 4 corner bolt Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 15 23) Put the back cover in position and put both bolts in on the side away from the water tank bracket. 24) Put the back cover on the water tank side and put the bolts in Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 16 25) Place spacers and pulleys on bottom bolts, pulley circlips face the spacers, put nuts and washers on but do not tighten up. 26) Lift complete head unit out of crate Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 17 27) Mount left and right roller assemblies onto the galvanized tubes, snug bolts up but do not tighten them. 28) Position head unit over track and line rollers up so that the track sits in the roller groove, set head unit onto tracks. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 18 29) Tighten all 8 bolts on roller frames 30) Tighten 8 bolts on top frame of head unit Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 19 32) Mount Scale bar, the metal spacer sits behind the bar at base where 2 bolts secure it. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 20 33) Tighten bolt in water tank mount bracket and put water tank in, the copper end on the water tank hose runs through the hole in the frame above the blade, loosen the 16mm bolt, put the copper tube through, aiming it towards the blade and snug the bolt up. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 21 4 supplied bolts are not used. 35) Also on the 32A/36A Sawmill, the fuel line gets connected to the white filter on the side of the engine. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 22 37) Wind the lift handle so that the pulley arms are all the way in, then find the two stubs on the inside of the top plate behind the pulley arm, place a cable loop over 1 stub and run cable around pulleys and down to head unit. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

- Page 23 The winch can be mounted at any height on the right rear post, simply drill holes where you want the unit mounted and install with the provided bolts. There are pre-drilled holes that you can use as well, if the height is suitable. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

-

Page 24: All Models

Measure distance from the blade log support on each side to double check that head unit is level. 39) Install log holder into frame rails, There are multiple frame holes for mounting, choose the one that works best for your application. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca... - Page 25 40) Install T-handles into track cross supports to hold the log supports in place, adjust bracket on head unit so that the blade is protected if the head is lower than the log support. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 26 Then tighten Nut 98C after adjustment. Continue making small adjustments until the Blade stays centered. AFTER any adjustment, tighten Bolts 96A and 96B and nuts 98A and 98B. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 27 Cable. Anchor Bolts (159) until the distance between the ends of the Blade and the top of the Middle Support (8) are the same as shown in Figure S. NOTE: Use a tape measure to verify distances. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0...

-

Page 28: Engine Operation

B) Inspect the equipment and engine. C) Fill the engine with the proper amount and type of fuel and oil. D) Read the Equipment Operation section that follows Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca... -

Page 29: Equipment Operation

NOTE: Make sure the Log Clamp Assembly (20) does NOT interfere with the Saw Blade when sawing. The Log Clamp Assembly (20) should be lower than the Saw Blade at all times. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0... - Page 30 15. Start and operate the engine according to the provided engine manual. 16. Adjust the Throttle to bring the Blade up to speed. The Locking Ring can be turned to lock the throttle in place. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 31 2. Lubricate the Tension Handle with grease monthly or as needed. Storage 1. Wait for engine to cool, then clean equipment with clean cloth. 2. Clean the engine and/or prepare it for storage according to engine manual instructions. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 32 Remove stray branches that Teeth filled with debris. prevent proper positioning. 4. Clean debris off blade. Follow all safety precautions whenever diagnosing or servicing the equipment or engine. Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 33 Parts List Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 34 Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 35 Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 36 Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

- Page 37 Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

-

Page 38: Please Read The Following Carefully

Note: Some parts are listed and shown for illustration purposed only, and are not available individually as replacement parts. WARRANTY One-year limited warranty For technical questions, please visit www.range-road.ca www.range-road.com Range Road Enterprises Ltd Box 944 Eckville AB T0M 0X0 www.range-road.ca...

Need help?

Do you have a question about the RR5036 and is the answer not in the manual?

Questions and answers