Fisher & Paykel DishDrawer DD60 Service Manual

Hide thumbs

Also See for DishDrawer DD60:

- Service manual (78 pages) ,

- User manual (60 pages) ,

- Diagnostic service manual (21 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Fisher & Paykel DishDrawer DD60

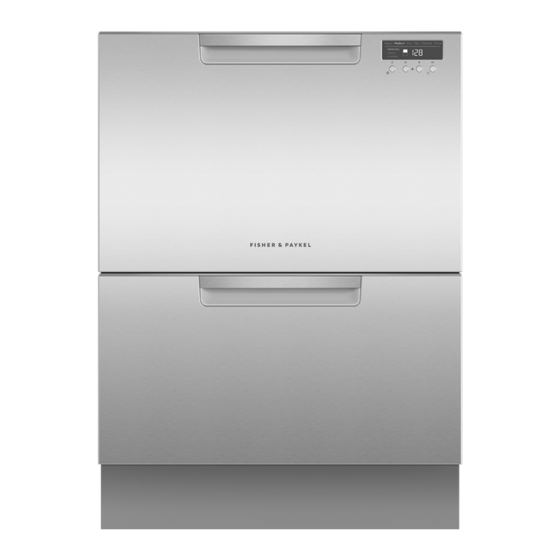

- Page 1 SERVICE MANUAL DishDrawer DD60, DD24 Phase 9 AA GB EU DK PF SG US CA TW...

- Page 2 FEATURED PRODUCT & CONTACT ADDRESSES BRAND MODEL DESCRIPTION MARKET (NEW (NEW LOGO) STEEL COLOUR) Fisher & Paykel DD60DAW9 Double white model 81075 81584 Fisher & Paykel DD60DAX9 Double stainless steel model 81585-B 81076 81585 Fisher & Paykel DD60DCW9 Double classic white model 81077 81586 Fisher &...

- Page 3 FEATURED PRODUCT & CONTACT ADDRESSES BRAND MODEL DESCRIPTION MARKET (NEW (NEW STEEL LOGO) COLOUR) Fisher & Paykel DD24SCTX9 Single classic tall tub stainless steel model 81606-B 81097 81606 Fisher & Paykel DD24SCHTX9 Single classic water softener tall tub stainless steel model 81098 81607 81607-B...

-

Page 4: Table Of Contents

CONTENTS HEALTH & SAFETY SPECIFICATIONS Product Dimensions 2.1.1 AA, GB, EU, IE, DK Double Models 2.1.2 AA, GB, EU, IE, DK Single Models 2.1.3 US Double Models 2.1.4 US Single Models Clearances & Dimensions 2.2.1 AA, GB, EU, IE, DK Double Models 2.2.2 AA, GB, EU, IE, DK Single Models 2.2.3... - Page 5 CONTENTS 8.11 Removing the motor rotor 8.12 Removing the pump cap cover 8.13 Removing the tub 8.14 Removing the kickstrip 8.15 Removing the lower cowling 8.16 Removing the wiring cover 8.17 Removing the heater 8.18 Replacing the motor 8.19 Replacing a fill hose, drain hose or wiring harness 8.20 Replacing the motor controller 8.21...

-

Page 6: Health & Safety

1 HEALTH & SAFETY IMPORTANT ! PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE. When servicing the Dishwasher, health and safety issues must be considered at all times. 1.1 Health & Safety Note: Specific safety issues are listed below with their appropriate icon. These are illustrated throughout the service information. - Page 7 1 HEALTH & SAFETY 1.1.9 Diagnostics While in diagnostics some safety devices are bypassed. Ensure you do not run components unattended. They may overheat, flood or burn out or cause water damage. 1.2 Specialised Tools For servicing this product, some specialist tools are required. 1.2.1 Static Strap An anti static strap is required to prevent ESD (electrocstatic discharge) when handling electronic components.

-

Page 8: Specifications

2 SPECIFICATIONS PRODUCT DIMENSIONS 2.1 Product Dimensions 2.1.1 AA, GB, EU, DK, PF, SG Double Models DD60DA MODELS DD60DC MODELS FRONT PROFILE PROFILE PRODUCT DIMENSIONS DD60DA PRODUCT DIMENSIONS Overall height of product 820-880 DD60DA MODELS DD60DC MODELS Overall width of product Overall depth of product Depth of chassis (to back of front drawer panel) -

Page 9: Aa, Gb, Eu, Ie, Dk Single Models

2 SPECIFICATIONS 2.1.2 AA, GB, EU, DK, PF, SG Single Models PRODUCT DIMENSIONS FRONT PROFILE PRODUCT DIMENSIONS PRODUCT DIMENSIONS Overall height of product Overall width of product Overall depth of product Depth of chassis (to back of front drawer panel) Depth of drawer front panel PROFILE Height of drawer front panel... -

Page 10: Double Models

2 SPECIFICATIONS PRODUCT DIMENSIONS PRODUCT DIMENSIONS 2.1.3 US, TW Double Models FRONT PROFILE PRODUCT DIMENSIONS FRONT PROFILE PRODUCT DIMENSIONS Overall height of product 32 5/1 Overall width of product PRODUCT DIMENSIONS Overall depth of product Overall height of product 32 5/16 - Depth of chassis (to back of front drawer panel) Overall width of product Depth of drawer front panel... -

Page 11: Single Models

2 SPECIFICATIONS PRODUCT DIMENSIONS 2.1.4 US, TW Single Models FRONT PROFILE PRODUCT DIMENSIONS DD24SA PRODUCT DIMENSIONS Overall height of product 16 1/8” (410 Overall width of product 23 9/16” (599 Overall depth of product 22 9/16” (573 Depth of chassis (to back of front drawer panel) 21 3/4”... -

Page 12: Clearances & Dimensions

2 SPECIFICATIONS Bracket slots PLAN PROFILE 2.2 Clearances & Dimensions DD60DA DD60DC 2.2.1 AA, GB, EU, DK, PF, SG Double Models min. 820 min. 820 Minimum clearances from adjacent cabinetry min. 560 min. 560 cent cabinet space 100-160 100-160 min. 13 mm min. -

Page 13: Aa, Gb, Eu, Ie, Dk Single Models

2 SPECIFICATIONS Bracket slots 2.2.2 AA, GB, EU, DK, PF, SG Single Models PLAN PROFILE DD60SA DD60SCT vity min. 412 min. 456 vity Minimum clearances from adjacent cabinetry vity min. 560 min. 560 llow you to match dishwasher with your cabinetry or companion products DD60SCT ht models) (Tall height models) -

Page 14: Double Models

2 SPECIFICATIONS CABINETRY DIMENSIONS 2.2.3 US, TW Double Models CABINETRY DIMENSIONS CABINETRY DIMENSIONS PLAN PROFILE PLAN PROFILE DD24DA DD24DCT CABINETRY DIMENSIONS DD24DA DD24DCT Inside height of cavity* min. 32 5/16” (820) min. 34” (864) NSIONS Inside width of cavity 23 5/8” (600) 23 5/8”... -

Page 15: Single Models

2 SPECIFICATIONS CABINETRY DIMENSIONS CABINETRY DIMENSIONS 2.2.4 US, TW Single Models PLAN CABINETRY DIMENSIONS PLAN PROFILE PROFILE DD24SA DD24SCT DD24DA DD24DCT RY DIMENSIONS min. 16 1/4” (412) min. 18” (456) e height of cavity* min. 32 5/16” (820) min. 34” (864) 23 5/8”... -

Page 16: Plumbing Requirements

2 SPECIFICATIONS 2.3 Plumbing Requirements 2.3.1 AA, GB, EU, DK, PF, SG Double Models... -

Page 17: Aa, Gb, Ie, Eu, Dk Single Models

2 SPECIFICATIONS 2.3.2 AA, GB, EU, DK,PF, SG Single Models... -

Page 18: Double Models

2 SPECIFICATIONS THERE ARE THREE DIFFERENT PLUMBING AND DRAINAGE OPTIONS. CHOOSE WHICH IS MORE SUITABLE. 2.3.3 US, TW Double Models DRAINAGE OPTION 1 Dishwasher and Ø 1 1/2” (38 mm) Standpipe Screw Drain hose support to back wall at correct height If space is limited for fixing, push hose through drain... -

Page 19: Single Models

2 SPECIFICATIONS DRAINAGE OPTION 3 Dishwasher using drain hose joiner onto sink trap/waste tee Screw Drain hose support to back wall Supplied drain at correct height hose joiner to suit Ø 3/4” (19 mm) If space is limited waste tee for fixing, push hose through drain hose support... - Page 20 2 SPECIFICATIONS DRAINAGE OPTION 2 Dishwasher using Air Break with Drain Hose Joiner Secure drain hose to drain hose joiner and secure to Air Break 37 3/8” (950mm) Max. height to top of Air Break step 14 (countertop or wall mounted) min.

-

Page 21: Electrical Specifications

2 SPECIFICATIONS 2.4 Electrical Specifications MARKET VOLTAGE (V) FREQUENCY (HZ) CURRENT ( A) AA GB EU DK PF SG 220/240 US TW 2.5 Component Specifications COMPONENT SPECIFICATION Controller AA/GB/EU/DK/PF/SG 240V US/TW 120V Water inlet valve 24v DC 65 +- 10 Ohms per coil 4L per minute 2.5L per minute Dispenser coil... -

Page 22: Wash Profiles

2 SPECIFICATIONS 2.6 Wash Profiles AA market... - Page 23 2 SPECIFICATIONS GB IE EU DK market...

- Page 24 2 SPECIFICATIONS US market...

-

Page 25: Model Number Location & Identification

3 MODEL NUMBER LOCATION & IDENTIFICATION 3.1 Model Number & Product Code The model number and product code is shown on the product data plate, which is located on the front of the chassis trim. The product code is a specific code relating to that product, which if ordering spare parts, you need to use the product code to ensure you get the correct parts manual, as some parts for the Phase 9 DD are specific for this model. -

Page 26: Technical Overview

4 TECHNICAL OVERVIEW 4.1 Chassis The DishDrawer chassis is one complete assembly composed of 5 steel metal components locked together by a proprietary riveting process. The chassis exterior is made of a lacquered electro- galvanised material. 4.2 Drawer Fronts Prefinished drawer fronts are formed from steel blanks. The drawer fronts are attached to the tub by means of formed hooks and two square pins that are inserted through either side of the tub. - Page 27 4 TECHNICAL OVERVIEW 4.3.1 Wash Controller Wash controller, one situated in each tub. Outputs: Drying fan Rinse Dispenser coil Motor controller 4.3.2 Motor Controller Motor controller situated in the base panel area. There are 2 types of motor controller: NZ, AU, GB, EU, DK, SG 230V US, CA, TW 110V...

- Page 28 4 TECHNICAL OVERVIEW 4.5 Tub Home Sensor The tub home sensor determines when the tub is closed. The tub home sensor consists of an infrared transmitter and receiver mounted on the right side of wash controller. When the tub is fully closed, infrared light is transmitted from the sender through a light pipe on the side of the tub, through a prism mounted in the chassis trim, then back through the other light pipe to the receiver.

- Page 29 4 TECHNICAL OVERVIEW 4.10 Drain Filter The drain filter is a combination of a large catchment area for solid food pieces and a fine mesh for straining wash water, it is designed to minimise soils re-depositing on the wash load. The Drain filter assembly can be separated into 2 pieces for fine cleaning, but we recommend rinsing out as one piece.

- Page 30 4 TECHNICAL OVERVIEW 4.12 Filling with Water The wash tubs of the DishDrawer fill by a single water inlet hose. Hot water connection is recommended for the USA market only, while cold water connection recommended for the AU & NZ markets.

- Page 31 4 TECHNICAL OVERVIEW 4.12.2 Amount of Water The tub fills with approximately 2.8 litres (3/4 gallon) of water. The phase 9 model uses a new HYBRID filling system. This new filling system works slightly differently to the older dynamic filling system by looking for a good consistent prime over a LONGER time period (about 15 secs) and looks for this over a 40 sec period.

- Page 32 4 TECHNICAL OVERVIEW 4.13.2 Heating the Water The heater plate is situated below the water duct cover. The water is passed over the heating element during the wash cycle via the duct. The heated water is then picked up by the motor rotor and distributed to the wash load via the spray arm.

- Page 33 4 TECHNICAL OVERVIEW 4.15 Water Softener ( some markets only) The Water Softener uses a softening material (resin) to prevent most of the elements that cause hard water from being present in the wash water. The resin can only treat a limited amount of water before it needs to be regenerated.

-

Page 34: Operation

5 OPERATION 5.1 LED Display CONTROLS AND DISPLAY Single models Keylock Start / Delay Start Keylock disables all the buttons – Press to start the wash. helpful when cleaning the To pause: dishwasher. Press again. The wash stage To activate: press and hold indicator (Double together until you hear one tone. - Page 35 5 OPERATION OPERATING INSTRUCTIONS 5.2 Using the Wash Modifiers (some models only) SETTING WASH MODIFIERS (DD***C MODELS ONLY) Along with setting the wash programme, you may select one of the following the additional options: Extra dry: Increases the wash temperature and the length of the drying phase for improved drying performance.

- Page 36 5 OPERATION SETTING WASH MODIFIERS (DD***C MODELS ONLY) Using sanitize The sanitize wash modifier adjusts the wash program to meet the conditions required by Section 6, NSF 184 for sanitization to occur. While sanitize is running, the wash program is monitored to ensure that these conditions are met.

- Page 37 5 OPERATION PREFERENCE OPTIONS 5.3 User Preference Settings You can change the setting of these options to suit your preferences or circumstances. We recommend selecting the most suitable settings before you start using your dishwasher. WATER SOFTENER OPEN DRAWER CLOSED DRAWER OPTION RINSE AID TURN TONES OFF...

- Page 38 Cleaning the drain filter and filter plate IMPORTANT! 5 OPERATION If a dishwasher cleaner / descaler is used, you must run a wash programme with detergent immediately afterward to prevent any damage to your dishwasher. The dishwasher must be used with the filter plate, drain filter and spray arm correctly in place.

- Page 39 5 OPERATION USER MAINTENANCE INSTRUCTIONS Removing the drain filter and filter plate to clean 3 Twist the circular drain filter anti/counter- clockwise and lift to remove. It is normal to find some water under it. 4 Remove the drain filter mesh by pinching one side only and pulling it off, as shown.

- Page 40 5 OPERATION USER MAINTENANCE INSTRUCTIONS 5.5 Cleaning the Spray Arm Cleaning the spray arm 1 Unplug the dishwasher or turn it off at the power supply. 2 Unclip the glass supports (if fitted) from the rack wires and fold up all the foldaway cup racks, so that they are all upright and close to the top.

- Page 41 5 OPERATION 5.6 Fold Down Tines RACKING FEATURES - FOLDING TINE RACK Folding tines For optimum stability, place larger plates between the longer tines in the front. Fold the tines down if you need the space for pots or other large items. Release by pushing the small clips at the rear and fold the tine sections down towards each other.

-

Page 42: Diagnostics

6 DIAGNOSTICS 6.1 Entering Diagnostics To enter diagnostic mode, ensure there is nothing showing on the LED display, (power off at the display), then press and hold the START/PAUSE and POWER buttons simultaneously for 5 seconds, making sure that the START/PAUSE button is pressed slightly ahead of the POWER button. - Page 43 6 DIAGNOSTICS Hardware Output (‘HO ’) 1The WASH SELECTOR button scrolls through various outputs. Output Display Code Element relay (ensure there is water in the tub before running the element) Lid down or up Detergent diverter Fill valve Wash motor direction Drain motor direction Rinse aid pump Drying fan...

-

Page 44: Fault Diagnostics

7 FAULT DIAGNOSTICS 7.1 Troubleshooting PROBLEM POSSIBLE CAUSE WHAT TO DO Unclean dishes Wash program unsuitable for Heavily soiled items may need soaked the load before washing, and use the ehavy cycle. Spray arm unable to rotate Ensure no items are obstructing the spray arm path. - Page 45 7 FAULT DIAGNOSTICS PROBLEM POSSIBLE CAUSE WHAT TO DO Foaming Wrong type of detergent Ensure the customer is only using used detergents designed for automatic dishwashers. Incorrect amount of Ensure the customer is following the detergent. directions in the user guide for detergent quantities.

- Page 46 7 FAULT DIAGNOSTICS PROBLEM POSSIBLE CAUSE WHAT TO DO Fan noise starts This is normal, the drying No action required, normal operation. when drawer is fan will run whenever the closed drawer is closed for a set period of time after the program has finished.

-

Page 47: Fault Codes

7 FAULT DIAGNOSTICS 7.2 Fault Codes If there is a fault, the LED display will be displaying either a fault code or a user warning. Fault codes begin with the letter “F”, user warnings begin with the letter “A”, the fault code is shown with a number which corresponds to that particular fault. e.g. - Page 48 7 FAULT DIAGNOSTICS F1: Flood Detected Remove the bottom tub, this will require some force to pull it open, is there water in >>2 >>9 the base of the chassis? Was there anything in the tubs which obstructed the lid from closing? like large >>3 >>9 utensils?

- Page 49 7 FAULT DIAGNOSTICS F3X: Over-Temperature Faults F30 fault: Invalid Temperature Is the thermistor damaged or disconnected? >>A >>2 Measure the resistance of the thermistor ( between pins 1 & 2 of the TEMP connector >>5 >>3 on the wash controller). It should be approx 10k Ω at F), is it within spec? Replace the thermistor.

- Page 50 7 FAULT DIAGNOSTICS F8X: Motor Controller Faults F82 fault: Motor Controller ADC Check Failure >>1 F84 fault: Fill Valve Drive Failure >>1 F85 fault: Bridge Temperature Sensor >>1 F86 fault: Motor Bridge Failure >>1 F87 fault: Motor Controller Current Sense Error >>1 Replace the motor controller >>A...

-

Page 51: Component Testing

7 FAULT DIAGNOSTICS 7.3 Component Testing Note: motor controller is situated on the inside rear chassis panel behind bottom tub Motor Controller (Back View) Wash Controller (Front View) P404 P406 P407 P402 P410 P403 P405 P401 P408 Connector Device Pins Description Motor Controller (pin numbers on the connectors go from Top to Bottom) -

Page 52: Servicing The Components

8 SERVICING PROCEDURES Caution! When servicing the DishDrawer, ensure the electrical supply is turned off before attempting to service or adjust any part of this appliance. Ensure all earth wires that are removed while servicing are reattached correctly. 8.1 Removing the Drawer Front 1 Open the drawer, using long nose pliers, remove the two square door pins, one on either side of the tub. -

Page 53: Removal Of The Ui Display

8 SERVICING PROCEDURES 8.3 Removal of the UI Display 1 Remove the insulation foam from the inner door. (Fig 1) 2 Remove the aluminium brace by sliding one side down to remove it. (Fig 2) 3 To remove the user interface display module, remove the wedge by pulling downwards to release the locks. -

Page 54: Removal Of The Top Cap

8 SERVICING PROCEDURES 8.4 Removal of the Top Cap 1 Remove the drawer front, refer section 8.1. 2 To remove the stainless steel top cap, remove the 4 clips from the studs along the top of the door. (Fig 1 & 2) 3 The top cap is also held in place with tape, so may require a sharp knife to cut the tape as you life the cap off the door. -

Page 55: Removing The Wash Controller

8 SERVICING PROCEDURES 8.5 Removing the Wash Controller 1 Remove the drawer front from the tub, refer 8.1. 2 Remove the torx head screw on the left hand side of the wash controller. 3 Pull the module forward on the left hand side, and the wash controller will release from the locating pin on torx head the tub. -

Page 56: Removing The Water Softener

8 SERVICING PROCEDURES 8.8 Removing the Water Softener (some models only) 1 Remove the drawer front (refer section 8.1). Water Softener Detergent 2 Disconnect the wiring loom connections to the water dispenser softener diverter valve, brine pump and salt level detector, and remove the dispenser wiring loom connection to electronic controller. -

Page 57: Removing The Filter Plate

8 SERVICING PROCEDURES 8.10 Removing the Filter Plate 1 Open the drawer and remove the cutlery basket, then open the trap door. 2 Lift the front of the fixed tine plate rack to unclip it from the base rack 3 Slide the fixed tine plate rack forward clear of the rear anchoring loop and lift out. -

Page 58: Removing The Tub

8 SERVICING PROCEDURES 8.13 Removing the Tub Before removing a tub from the chassis, remove the lower basket and spray arm. Push clip in A good suggestion is to also remove the door panel and slide rail and handle assembly to stop any damage. backwards to Push the side clip inwards and push the rail back to disengage... -

Page 59: Removing The Wiring Cover

8 SERVICING PROCEDURES 7 Refit the torx screws and reassemble the drawer front. locating pin locating hook 8.16 Removing the wiring cover Front Clip 1 On the top tub, this can be done with the tub in place, or with the tub removed. 2 The bottom tub will require to be removed from the chassis to gain access to the securing screws and clips. -

Page 60: Removing The Heater

8 SERVICING PROCEDURES 8.17 Removing the Heater 1 Remove the tub as per section 8.13. 2 Remove the wiring cover as per section 8.16. 3 Remove the element cover by removing the three T10 torx screws and unclip the wiring harness from the element cover. -

Page 61: Replacing The Motor

8 SERVICING PROCEDURES 8.18 Replacing the Motor 1 Remove the tub as per section 8.13 phase to star 2 Remove the wiring cover as per 8.16 3 Remove the wiring harness to the stator, you will 8 ohms need to depress the clips to remove the small spade terminal. -

Page 62: Replacing A Fill Hose,Drain Hose Or Wiring Harness

8 SERVICING PROCEDURES 8.19 Replacing a fill Hose,Drain Hose or Wiring Harness 1 Remove the tub and turn it over by rotating it tub rib clip anticlockwise (refer section 8.13). 2 Remove the wiring cover, refer section 8.16. 3 Disconnect the component you need to replace (e.g. - Page 63 8 SERVICING PROCEDURES Fig 6 Fig 5 slide clips Fig 8 Fig 7 lower chassis mount clip Fig 9 Fig 10 Fig 11 Fig 12...

- Page 64 8 SERVICING PROCEDURES Fig 13 Fig 14 160mm Fig 15 Fig 16 250mm Fig 17 Fig 18 Fig 19...

-

Page 65: Replacing The Motor Controller

8 SERVICING PROCEDURES 8.20 Replacing the Motor Controller 1 Remove the bottom tub, refer section 8.13. 2 Unclip the link support rod, as this allows the tub to be moved slightly further to the left to gain access to the controller housing. 3 Remove the chassis module cover to gain access to the screw retaining the motor controller housing. -

Page 66: Replacing The Flood Sensor Harness

8 SERVICING PROCEDURES 8.21 Flood Sensor Harness 1 Remove the bottom tub, refer section 8.13. 2 Remove the chassis module cover by releasing the 2 clips, and slide forward to release. 3 Use a small flat blade to release the harness. 4 You can check continuity of the sensor wire from controller connector P201. -

Page 67: Replacing The Lid Actuator

8 SERVICING PROCEDURES 8.23 Replacing the Lid Actuator 1 Remove the tub, refer section 8.13. 2 Remove the lid actuator harness plug by releasing clip the clip on the lid actuator. 3 Release the lid actuator from the bottom of the yoke by pressing with your thumb against one of the locking tabs. -

Page 68: Replacing The Yoke Assembly

8 SERVICING PROCEDURES incorrectly located correctly located 8.25 Replacing the Yoke 1 Remove the lid, refer section 8.24 2 Release the lid actuator from the bottom of the yoke by pushing with your thumb against one of the locking tabs. 3 Slide the front of the yoke downwards at an angle until it moves out of the track in the rear of the trim, and is clear of the chassis flange as shown. -

Page 69: Replacing The Side Rail

8 SERVICING PROCEDURES 8.26 Replacing the Side Rail 1 Remove the tub, refer section 8.13 2 Remove the required lid actuator from the slide rail being replaced, refer section 8.23. 3 Remove the appropriate chassis trim (refer section 8.27) to gain access to the screws of the rail being replaced. -

Page 70: Wiring Diagram

9 WIRING DIAGRAM DD608 Wiring Diagram... -

Page 71: Notes

10 NOTES... - Page 72 www.fisherpaykel.com Copyright © Fisher & Paykel 2019. All rights reserved. The product specifications in this manual apply to the specific model described at the date of issue. Under our policy of continuous product improvement, these specifications may change at any time. AA GB EU DK US CA TW PF SG 591255 09.19...

Need help?

Do you have a question about the DishDrawer DD60 and is the answer not in the manual?

Questions and answers

the bottom draw of my dd60k6 will not open the lock is disengaged i have given the front a couple of bangs the top draw opens no problem when i press the on button i can hear the mechanics locks making a noise but not releasing