Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks VM100-A Series

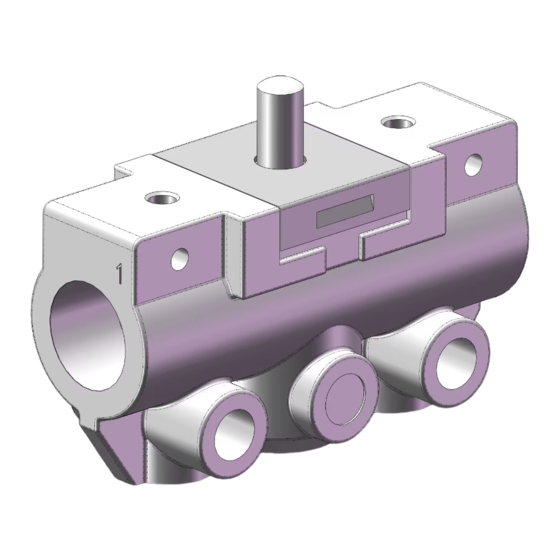

- Page 1 Document No. VM-OMR0011-A Pr oduct Name Mechanical Valve Model/ Series VM100-A Series...

-

Page 2: Table Of Contents

Contents 1. Safety Instructions 2. Application 3. Specifications 4. Models and Strokes 5. Installation and Mounting Orientation 6. Operating Force 7. Mechanical Operating Conditions 8. Replacement of the Actuator 9. Product Number of the Actuator... -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution We develop, design, and manufacture our products to be used for automatic control equipment, and provide them for peaceful use in manufacturing business. Use in non-manufacturing business is not covered. Products we manufacture and sell cannot be used for the purpose of transactions or certification specified in the Measurement Act.

- Page 5 Design precautions Warning ! (1) Actuator drive When an actuator, such as a cylinder, is to be driven take appropriate measures to prevent potential danger caused by actuator operation. (2) Maintenance space When installing the products, allow access for maintenance. (3) Ventilation When using the valve in a closed control panel, etc., install ventilating openings to prevent an increase of pressure inside the control panel, and to prevent heat generated by other equipment...

- Page 6 There is a risk of injury. (2) Do not disassemble or modify the product. This may cause human injury and/or an accident. Contact SMC for repairs and maintenance of the product. (3) Do not wipe the product using chemicals. Piping Caution !...

- Page 7 Besides, if the lubrication is suspended halfway, the original lubricant will be lost and may result in a malfunction. Be sure to keep lubricating continuously. Refer to the lubricant manufacturer's website for brand name of the lubricants compliant with Class 1 turbine oil (with no additives), ISO VG32.

- Page 8 Maintenance Warning ! 1. Removal of equipment, and supply/exhaust of compressed air When equipment is serviced, first confirm that measures are in place to prevent dropping of driven objects and/-or equipment running out of control, etc. Then cut the supply pressure and power, and exhaust all compressed air from the system using its residual pressure release function.

- Page 9 Specific Product Precautions for Mechanical Valve Design precautions Warning ! 1. Cannot be used for sealing pressure. Since VM100 is a poppet type valve, fluid flows backwards when the pressure on port 2 rises. Since the valve is subject to a little amount of air leakage, it cannot be used for applications such as holding pressure (including vacuum).

- Page 10 2. Select the angle and the maximum speed of the operating cam and the dog of the mechanism so that they do not exceed the maximum values. This could damage the mechanical valve itself and lead to equipment malfunction. Refer to Chapter 7, "Mechanical Operating Conditions"...

-

Page 11: Application

2. Application This product is a valve for signal transmission used for a pneumatic control circuit of machining equipment or general industrial machinery, etc. 3. Specifications Piping Side ported type Bottom ported type Fluid Compressed air Operating pressure -100 kPa to 1 MPa Operating temperature -5 to 60 C (No freezing) - Page 12 F.O.F. P.T. O.T. T.T. Model Type at 0.5 MPa (Note 1) (Note 1) (Note 1) 2 port 3 port (Note 1) VM120-01-00A VM130-01-00A VM121-01-00A VM131-01-00A Basic type 1.5mm 1.5mm VM122-M5-00A VM132-M5-00A VM123-M5-00A VM133-M5-00A VM121-01-01A VM131-01-01A VM121-01-01SA VM131-01-01SA Roller lever 3.2mm 2.3mm 5.5mm VM123-M5-01A...

-

Page 13: Installation And Mounting Orientation

5. Installation and Mounting Orientation 5-1. Product number with each actuator Model Type Mounting dimensions 2 port 3 port VM121-01-01A VM131-01-01A VM121-01-01SA VM131-01-01SA Mounting Roller lever plate VM123-M5-01A VM133-M5-01A M4 screw VM123-M5-01SA VM133-M5-01SA VM121-01-02A VM131-01-02A VM121-01-02SA VM131-01-02SA VM123-M5-02A VM133-M5-02A VM123-M5-02SA VM133-M5-02SA One way roller lever 25.4 Fix at two points using M4 screws. - Page 14 Model Type Mounting dimensions 2 port 3 port VM120-01-30RA VM130-01-30RA VM120-01-30BA VM130-01-30BA VM120-01-30GA VM130-01-30GA VM120-01-30YA VM130-01-30YA Mushroom push button VM122-M5-30RA VM132-M5-30RA Fastening VM122-M5-30BA VM132-M5-30BA ring VM122-M5-30GA VM132-M5-30GA VM122-M5-30YA VM132-M5-30YA VM120-01-32RA VM130-01-32RA VM120-01-32BA VM130-01-32BA VM120-01-32GA VM130-01-32GA Mounting plate VM120-01-32YA VM130-01-32YA Extended push button VM122-M5-32RA VM132-M5-32RA Spacer VM122-M5-32BA VM132-M5-32BA...

- Page 15 5-2. Bottom mounting type Selector type (for 3 position) has the thread depth of 3.2 and four mounting screw positions. Mounting plate Use two M4 screws (four for 3 position selector) mounting. 2×M4 25.4 4×M4 25.4 5-3. With bracket 2 x ø4.4 Use two M4 screws for mounting.

-

Page 16: Operating Force

6. Operating Force Full operating force increases according to the increase of the supply pressure. Full operating force for each product type can be found by the formula below. F ≒ × F2 F1: Full operating force at 0.5MPa of the product type (F.O.F on page 11) F2: Full operating force at supply pressure found from Fig.1 -0.1 supply pressure(MPa)... -

Page 17: Mechanical Operating Conditions

7. Mechanical Operating Conditions 7-1. Stroke range Use a mechanical operating product within the stroke range calculated by the formula below. Stroke range = (P.T. + 0.5 x O.T.) to (P.T. + O.T. -0.1) Actuator Stroke range (mm) Basic 2.2 to 2.9 Roller lever 4.3 to 5.4 One way lever... - Page 18 7-4. Operation mechanism and configuration 1. Avoid acute angles on limit switch actuator. (Bad) (Good) Section 7-2 Section 7-2 Wider than Not larger than the maximum angle maximum angle Abrupt angle 2. Do not allow stroke beyond the maximum travel position. (Bad) (Good) (Good)

-

Page 19: Replacement Of The Actuator

8. Replacement of the Actuator 8-1. Plunger and flip toggle types Mount an actuator to the mechanical valve with two screws (M3x8 with spring washer) as shown in the Fig. below. Phillips head screw driver is needed. Cross recessed round head screw M3x8 with spring washer Actuator Mechanical valve... - Page 20 8-3. Replacement of the button Follow the procedure below to change the button. (1) Flat button Installation - Choose the button from 4 colors (red, green, black and yellow). Push the protruding part of the button into the body. Removal - Remove fastening ring. Insert a small screwdriver into the groove of the button to take the button out.

-

Page 21: Product Number Of The Actuator

9. Product Number of the Actuator [Actuator number] Actuator Actuator Remarks number Basic ― ― Roller lever Not replaceable ― One way roller lever Not replaceable ― Straight plunger VM-05B ― VM-06B POM roller Roller plunger VM-06BS Hard steel roller VM-07B POM roller Cross roller plunger... - Page 22 Revision history D : Safety Instructions changed. 2023.12 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 URL https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the VM100-A Series and is the answer not in the manual?

Questions and answers