Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Enerpac B13211710

- Page 1 Operation and Maintenance Manual Enerpac B13211710 Electric Pump Document Number: L4758 Document Revision: A Document Revision Date: 17-JUL-2023 Document Language: ENGLISH EN To reduce the risk of injury, user must read and understand this document before use.

- Page 3 Enerpac for quality tools, services and solutions. For additional information, visit www.enerpac.com. WARRANTY Refer to the Enerpac Global Warranty document for terms and conditions of the product warranty. Such warranty information can be found at www.enerpac.com. L4739_a...

-

Page 4: Table Of Contents

7.2 CHANGE OIL AND CLEAN RESERVOIR ..................... 9 7.3 CHANGING THE FILTER ELEMENT ..................... 9 8. PARTS LIST ..............................10 8.1 B13211710 PARTS VIEW ........................10 8.2 RETURN FILTER ASSEMBLY ......................11 8.3 DISTRIBUTION VALVE ASSEMBLY ....................12 8.4 HOSES ASSEMBLY ..........................13 9. -

Page 5: Safety

In the event that any questions or including those that are contained within the concerns arise, contact Enerpac or a local Enerpac procedures of this manual. distributor for clarification. • Operating procedures will vary, depending on Save these instructions for future use. -

Page 6: Compliance

(as required by applicable to fit properly and to withstand high loads. Non- laws and regulations) if the load is not visible to the Enerpac parts may break or cause the product to operator. malfunction. • Operate pump and valve as required to ensure that •... -

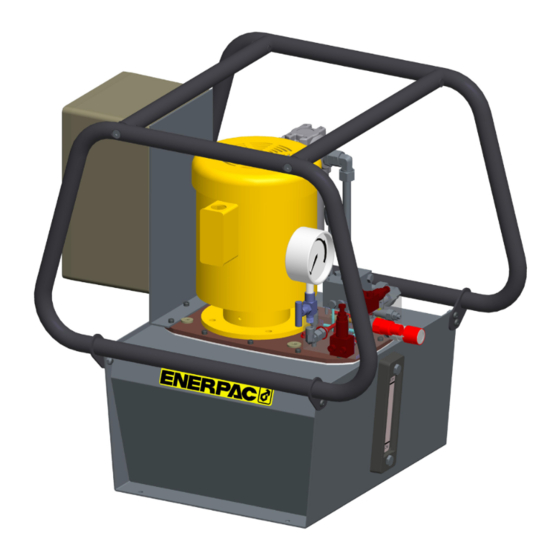

Page 7: Features & Components

3. Features & Components 3.1 Feature Diagram ZE5040 Pump Return Filter Manifold Safety Valve Safety Valve Male Coupler Gauge Female Coupler Manual Valve HIGH Figure 1: Major features and components of B13211710 L4739_a... -

Page 8: Technical Product Data

This valve is operated as follows: Measures Hydraulic Scheme 4.3 Product Description Enerpac B13211710 electric pump is an ideal solution for industrial and lifting applications. Schematic Flow Path This pump is equipped with a VHP1-L1 manual distribution valve that allows the user to control the oil... -

Page 9: Pump Specifications

230 bar. 5.2 Hydraulic Oil Requirements 4.5.7 Hoses with Flow Control Valves Use of Enerpac HF Series ISO 32 hydraulic oil is The pump includes 15-meter two hoses with flow recommended. Enerpac HF oil is available at your local control valve to connect the pump to the cylinder. -

Page 10: Electric Connections

If questions or concerns, contact CAUTION your local Enerpac Distributor or Authorized Service Center. Add oil only when all system components are fully retracted, otherwise the system will contain more oil than the reservoir can hold. -

Page 11: Disconnecting Pressurized Cylinder

7.2 Change Oil and Clean Reservoir Enerpac HF oil is a crisp blue color. Frequently check that the oil remains in good condition. As a general rule, completely drain and clean the reservoir every 250 hours, or more frequently if used in dirty environments. -

Page 12: Parts List

8. Parts List 8.1 B13211710 Parts View HIGH Figure 8: B13211710 Parts 8.1.1 B13211710 Parts List Item N.º Description Qty. Part Number Reservoir < Manifold B13211710840-1 Pressure Relief Valve MVP4A Quick Coupling Male DB2241034 Needle Valve NV251 Gauge H4049L Electric Motor... -

Page 13: Return Filter Assembly

8.2 Return Filter Assembly Exploded View Figure 9: Return filter assembly parts 8.2.1 Return Filter Assembly Parts List Item N.º Description Qty. Part Number Elbow DB2240095 Fitting 3/8” DB2158092 Fitting 3/4” DB2159092 Return Filter DB4267118 L4739_a... -

Page 14: Distribution Valve Assembly

8.3 Distribution Valve Assembly Exploded View Figure 10: Distribution valve assembly parts 8.3.1 Distribution Valve Assembly Parts List Item N.º Description Qty. Part Number Gauge H4049L Needle Valve NV251 Elbow DB2271095 Pressure Relief Valve MVP4A Quick Coupling Male DB2241034 Quick Coupling Female DB2242034 Flow Control Valve DB1044662... -

Page 15: Hoses Assembly

8.4 Hoses Assembly Figure 11: Hoses assembly parts Item N.º Description Part Number Hose with male couplings Hose with female couplings (B13211710900-1) (B13211710900-2) Quick Coupling DB2241034 DB2242034 Bonded Seal JMB-G38-I Fitting male-male DB2013091 Fitting DB2149095 Hose B13211710686 Flow Control Valve DB1118662 L4739_a... -

Page 16: Troubleshooting Guide

To determine the cause of the problem, the complete system must be included in any diagnostic procedure. The following information is intended to be used only as an aid in determining if a problem exists. For repair service, contact your local Authorized Enerpac Service Center. Troubleshooting Guide Problem... - Page 17 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 18 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 19 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 20 © 2023 Enerpac Tool Group, All Rights Reserved.

Need help?

Do you have a question about the B13211710 and is the answer not in the manual?

Questions and answers