Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kistler 4502A Series

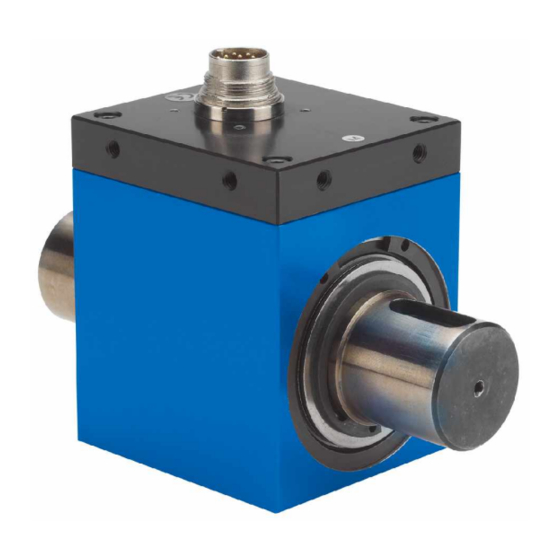

- Page 1 Instruction Manual Mini-Smart Torque Sensor Type 4502A... Version Q (with standard square connections) Version H (with standard hexagon connections) Version QA/HA (with rotating angle measuring system) Version RA (with round shaft and rotation angle measure- ment) 4502A_002-407e-02.22...

- Page 2 The specifications in this manual can change at any time without prior notification. Kistler reserves the right to im- prove and to change the product for the purpose of tech- nical progress without the obligation to inform persons and organizations as the result of such changes.

-

Page 3: Table Of Contents

Mini-Smart Torque Sensor, Type 4502A... Content Introduction ........................... 3 Important information ........................4 Disposal instructions for electrical and electronic equipment ..........4 Application and key features ......................5 Description of the measuring system ..................... 6 Mechanical design ........................ 6 Electrical block diagram ......................7 4.2.1 Examples of application ................... -

Page 4: Introduction

Please take the time to thoroughly read this instruction manual. It will help you with the installation, maintenance, and use of this product. Kistler offers a wide range of products for use in measuring technology: Piezoelectric sensors for measuring force, torque, strain,... -

Page 5: Important Information

Do not discard old electronic instruments in municipal trash. For disposal at end of life, please return this product to an authorized local electronic waste disposal service or contact the nearest Kistler Instrument sales office for return instructions. Seite 4... -

Page 6: Application And Key Features

Application and key features Application and key features Torque sensor with strain gages measuring system Wear-resistant transmission of the measuring signal, integrated amplifier Measurement of constant and variable torques Torque measurement on the rotating shaft Integrated system for rotation angle measurement (only version QA/HA) ... -

Page 7: Description Of The Measuring System

Mini-Smart Torque Sensor, Type 4502A... Description of the measuring system 4.1 Mechanical design Torque sensors model Mini Smart consist of a base body which contains the measuring shaft. The shaft ends are performed as standard square connections or standard hexagon ends. On the measuring shaft there is a torsion distance with strain gages and electronics with signal amplifier and A/D transformer. -

Page 8: Electrical Block Diagram

Description of the measuring system 4.2 Electrical block diagram Feed and inspection input of electronic measuring equipment, electrically isolated Feed Internal power supply 11 ... 26 VDC Fiber optic Control Rotor Logic and Opto- rotary 5 ... 30 VDC electronics modulator coupler joint... -

Page 9: Examples Of Application

Mini-Smart Torque Sensor, Type 4502A... 4.2.1 Examples of application Exactly use of electrical isolation for feed and measuring signal. Feed Feed device Control Feed Evaluation output electronic Shield Type 4502A… Fig. 4: Separate speed and measuring supply Shared access measuring supply for feed and measuring supply. -

Page 10: Rotation Angle Measuring System (Version Qa, Ha And Ra Only)

Description of the measuring system 4.3 Rotation angle measuring system (Version QA, HA and RA only) +5 V Fig. 6: Diagram showing the design of the rotation angle measuring system 1. Rotating shaft 2. Pulse disk 3. Forked light barrier with LED and photo diode 4. -

Page 11: Adjustment For Angle-Pulse Output (Version Qa, Ha, Ra Only)

Mini-Smart Torque Sensor, Type 4502A... 4.4 Adjustment for angle-pulse output (Version QA, HA, RA only) Output Pin B Output Pin G With drive on square socket or hexagon end sense of rota- tion cw. View A 1: Sense of rotation Drive side (Version QA) View A 2:... -

Page 12: Electrical Connections

Electrical connections Electrical connections Shielded lead Lead connector To power supply unit and display Torque sensor (all versions) Fig. 8: Electrical connections Shielded lead of 0,14 mm² nominal cross section 4502A_002-407e-02.22 Seite 11... -

Page 13: Plug Connection (Tuchel, 12 Pin)

Mini-Smart Torque Sensor, Type 4502A... 5.1 Plug connection (Tuchel, 12 pin) Description Function Supply 11 ... 26 VDC, <1 W power consumption Ground relating to U and angle of rotation pulses Shield In sensor connected to housing Torque output ±5 VDC bei M at >2 kΩ... -

Page 14: Instruction For Electrical Installation

Electrical connections 5.2 Instruction for electrical installation Plug Connector housing Load machine with in- ventor or alike device Type 4502A… anodic coating contingent to delete Stator min. 16 Stator support unit 11 … 26 VDC ripple max. 100 mV Type 4502A… Length max. -

Page 15: Connection Cable

Mini-Smart Torque Sensor, Type 4502A... 5.3 Connection cable Material No. 18008943 / 18008944 (free end) Cable definition violet yellow pink grey blue green black white grey/pink brown ---- Type 5867… Seite 14 4502A_002-407e-02.22... - Page 16 Electrical connections Type 5877… 4502A_002-407e-02.22 Seite 15...

-

Page 17: Mechanical Application

Mini-Smart Torque Sensor, Type 4502A... Mechanical application 6.1 Versions Q, QA, H and HA Torque sensors of version Q and QA have square con- nections for plug-in tools acc. to DIN 3121. Torque sensors of version H and HA have hexagon con- nections acc. -

Page 18: Torque Measuring Shaft Version Ra

Mechanical application Torque measuring shaft version RA For the electric connection of measuring shaft and supply- and evaluation unit we recommend to use the shielded signal lead, Type KSM072030-5, Mat.-No.: 18008935 with low capacity. As supply and evaluation unit we suggest the Control Monitor CoMo Torque Type 4700B... -

Page 19: Supply Circuit And Evaluation

Mini-Smart Torque Sensor, Type 4502A... The connection of shaft and coupling hub is effected by a span device. The measuring shaft is fastened with balan- cing class 6,5. The torque measuring shaft is only a part of the shaft strang. Radial and torsional vibrations may have a very bad impact on the performance of the torque shaft and the measuring signal. -

Page 20: Static Calibration

Static calibration Static calibration This procedure requires the use of a calibration device with a lever arm and weights for producing specific values of torque. The calibration procedure is as follows Apply the rated value of torque to the torque sensor and then remove it again ... -

Page 21: Calculation Example For Lever Arm Length

Mini-Smart Torque Sensor, Type 4502A... 7.2 Calculation example for lever arm length , whereby ⋅ Torque Length of lever arm required Mass required 9.80665 m/s² (= standard gravity – varies with location) Fig. 14: Calculation of lever arm length Example: m = 1 kg 10 N·m 10 N·m s... -

Page 22: Maintenance

Maintenance Maintenance Sensors of Type 4502A… are almost maintenance-free Durability of bearings in rated temperature range is approx. 20 000 hours Durability of bearings in working temperature range is approx. 10 000 hours Renewal of bearings can only be effected at works ... -

Page 23: Repairs

Mini-Smart Torque Sensor, Type 4502A... Repairs Fault Cause Remedy Shaft stiff to turn Bearing defect due to: Return to factory a) Torsional or flexural vibration b) High axial or radial loads c) Worn bearings d) Bent shaft Zero shift less than 2 % Torsional vibration The zero reading can be Torsional shock... -

Page 24: Ordering Key

Ordering key Ordering key Type 4502A Measuring Ranges in N·m/ Possible Versions H HA H HA R RA RAU H HA R RA RAU R RA RAU H HA R RA RAU Q QA H HA Q QA H HA R RA RAU Q QA R RA RAU... -

Page 25: Index

Mini-Smart Torque Sensor, Type 4502A... 11. Index Mechanical application ........16 Mechanical design..........6 Adjustment for angle-pulse output ....10 Application ............5 Ordering key ..........23 Calculation example lever arm length .... 20 Connection cable ........... 14 Plug connection ..........12 Construction calibration device ......

Need help?

Do you have a question about the 4502A Series and is the answer not in the manual?

Questions and answers