Table of Contents

Advertisement

Quick Links

Published 04/19

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

BUSH HOG

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

OPERATOR'S MANUAL

© 2019 Alamo Group Inc.

RR1114H

Rotary Rake

Part No. 50080518

$0.00

Advertisement

Table of Contents

Summary of Contents for Bush Hog RR1114H

- Page 1 RR1114H Rotary Rake Published 04/19 Part No. 50080518 OPERATOR’S MANUAL This Operator's Manual is an integral part of the safe operation of this machine and must be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment.

- Page 2 BEFORE YOU START! Read the safety messages on the implement and shown in your manual. Observe the rules of safety and common sense! For future reference, record your Bush Hog product model number and serial number. Dealer Telephone Model Number...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ......................1-1 General Safety Instructions and Practices .......................1-2 Operator Safety Instructions and Practices .....................1-3 Equipment Operation Safety Instructions and Practices..................1-4 Connection or Disconnecting Implement Safety Instructions and Practices ............1-7 Transporting Safety Instructions and Practices ....................1-8 Maintenance and Service Safety Instructions and Practices .................1-10 Storage and Parking Safety Instructions and Practices .................1-12 PARTS INFORMATION ..........................1-12... - Page 4 Hauling the Tractor and Implement........................4-25 MAINTENANCE SECTION....................5-1 LUBRICATION CHART ..........................5-3 GENERAL MAINTENANCE..........................5-4 DRIVESHAFT MAINTENANCE ........................5-4 Maintenance of Sliding Parts ...........................5-4 SCRAPPING THE RAKE ..........................5-5 STORAGE ...............................5-6 End of Season ..............................5-6 Beginning of Season ............................5-6 BOLT TORQUE VALUES ..........................5-6...

-

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 6: General Safety Instructions And Practices

Safety Messages. Always use good common sense to avoid hazards. (SG-2) Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las medidas de seguridad. (SG-3) RR1114H 04/19 Safety Section 1-2 © 2019 Alamo Group Inc. -

Page 7: Operator Safety Instructions And Practices

Never allow children to play on or around Tractor or Implement. Children can slip or fall off the Equipment and be injured or killed. Inadvertent contact with controls can cause the Implement to shift or fall crushing themselves or others. (SG-25) RR1114H 04/19 Safety Section 1-3 © 2019 Alamo Group Inc. -

Page 8: Equipment Operation Safety Instructions And Practices

(SRK-01) Equipment Operation Safety Instructions and Practices Do not back up with this implement. Backing could damage the machine or its components. (S3PT-4) RR1114H 04/19 Safety Section 1-4 © 2019 Alamo Group Inc. - Page 9 Operate the Tractor controls from the tractor seat only. (SG-9) Never allow children or other persons to ride on the Tractor or Implement. Falling off can result in serious injury or death. (SG-10) RR1114H 04/19 Safety Section 1-5 © 2019 Alamo Group Inc.

- Page 10 In case of mechanical difficulty during operation, place the transmission in the park position, set the parking brake, shut down all power, including the PTO and the engine and remove the key. Wait until all rotating motion has stopped before dismounting. (SG-39) RR1114H 04/19 Safety Section 1-6 © 2019 Alamo Group Inc.

-

Page 11: Connection Or Disconnecting Implement Safety Instructions And Practices

On a fully-assembled unit, do not remove the Wing Retaining Strap until hoses are attached to the tractor and the Wing Cylinders are filled with oil. Lower the Wings slowly and carefully. Keep bystanders away during operations. (STI-05) RR1114H 04/19 Safety Section 1-7 © 2019 Alamo Group Inc. -

Page 12: Transporting Safety Instructions And Practices

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible. When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. (SG-6) RR1114H 04/19 Safety Section 1-8 © 2019 Alamo Group Inc. - Page 13 Implement behind a truck or other type of vehicle. Never tow the Implement and another Implement connected in tandem. Never tow the Implement at speeds over 20 MPH. (STI-06) RR1114H 04/19 Safety Section 1-9 © 2019 Alamo Group Inc.

-

Page 14: Maintenance And Service Safety Instructions And Practices

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to prevent sudden or inadvertent falling which could cause serious injury or even death. (SG-14) RR1114H 04/19 Safety Section 1-10 © 2019 Alamo Group Inc. - Page 15 For more information go to www.P65Warnings.ca.gov. This website, operated by California’s Office of Environmental Health Hazard Assessment, provides information about these chemicals and how individuals may be exposed to them. (SG-48) RR1114H 04/19 Safety Section 1-11 © 2019 Alamo Group Inc.

-

Page 16: Storage And Parking Safety Instructions And Practices

These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard. Use genuine Bush Hog parts for economy and safety. -

Page 17: Decal Location

SAFETY Decal Location NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 18 D623 WARNING Pinch Point 50073511 IMPORTANT Transport Latch D628 DANGER Crushing Hazard D859 WARNING Use Genuine Bush Hog Parts 001.075 INSTRUCT Grease Label 50065309 LOGO Bush Hog 3.25” x 14.85” 50080517 LOGO Model Decal - RR1114H SER PLT Serial Plate...

-

Page 19: Decal Description

SAFETY Decal Description RR1114H 04/19 Safety Section 1-15 © 2019 Alamo Group Inc. - Page 20 SAFETY RR1114H 04/19 Safety Section 1-16 © 2019 Alamo Group Inc.

- Page 21 SAFETY RR1114H 04/19 Safety Section 1-17 © 2019 Alamo Group Inc.

- Page 22 SAFETY RR1114H 04/19 Safety Section 1-18 © 2019 Alamo Group Inc.

- Page 23 SAFETY RR1114H 04/19 Safety Section 1-19 © 2019 Alamo Group Inc.

-

Page 24: Federal Laws And Regulations

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) RR1114H 04/19 Safety Section 1-20 © 2019 Alamo Group Inc. -

Page 25: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 26 Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATH OR SERIOUS INJURY. Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR INJURY. Identifies special instructions or procedures that, if not strictly observed, co RR1114H 04/19 Introduction Section 2-2 © 2019 Alamo Group Inc.

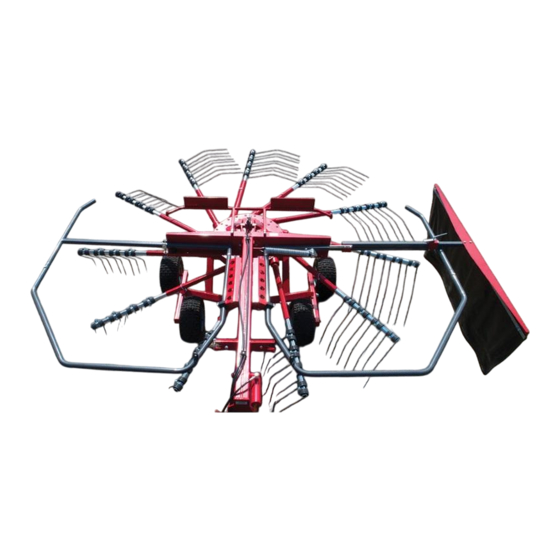

- Page 27 For the most gentle handling of your hay crops and faster drying times in wet or dry hay, choose Bush Hog’s RR Series Rotary Rake. Our RR1114H rotary rake is designed for low horsepower tractors making it ideal for small and mid-range hay operators. The versatility offered by this side delivery rotary rake is perfect for operators who want a light, fluffy windrow with low ash content and minimal crop roping.

- Page 28 3. Record the Rake Model and Serial Numbers on the Warranty page at the front of the Operator’s Manual. Keep this as part of the permanent maintenance file for the implement. RR1114H 04/19 Introduction Section 2-4 © 2019 Alamo Group Inc.

- Page 29 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgment of Bush Hog such use affects its performance, stability or reliability.

-

Page 31: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1... -

Page 32: General Instructions

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR INJURY. Identifies special instructions or procedures that, if not strictly observed, could result in damage to, or destruction of the machine, attachments or the environment. RR1114H 04/19 Assembly Section 3-2 © 2019 Alamo Group Inc. -

Page 33: Delivery And Assembly

1. Attach the arms (2) to the gear housing (1), placing them over shafts (3). Fasten the arms by inserting roll pins (4) into holes (A), and then insert the double roll pins (5). Item 4: 22 Spring Pins ø12x50 (0.47”x1.97”) Item 5: 22 Spring Pins ø7x50 (0.28”x1.97”) RR1114H 04/19 Assembly Section 3-3 © 2019 Alamo Group Inc. - Page 34 (42). Position the drawbar (1) so that pin (6) can be inserted, and fasten pin (6) with spring pin. Item 5: 2 Bushings ø30.5-40x30 (ø1.2”-1.58”x1.18”) Item 6: 1 Pin ø30x400 (ø1.18”x15.75”) Item 7: 1 Spring Pin ø8x50 (0.32”x1.97”) Item 43: 1 Spring Pin ø6x45 (0.24”x1.77”) RR1114H 04/19 Assembly Section 3-4 © 2019 Alamo Group Inc.

- Page 35 Item 7: 2 Washers ø23-50x5 (ø0.91”-1.97”x0.2”) Item 8: 2 Nuts M22 (0.87”) Item 15: 1 Pin ø15x78 (ø0.59x3.07”) Item 16: 1 Clip ø3 (ø.012”) Item 17: 2 Grease Nipples M6 (0.24”) RR1114H 04/19 Assembly Section 3-5 © 2019 Alamo Group Inc.

-

Page 36: Hydraulic System Assembly

Place washers (3) and connect the quick-release coupling (2) to the straight male ends of pipes (1). • Check to make sure that all connections are correctly fastened. • Attach the hose collar (36) to the lugs on drawbar, fastening in correct position RR1114H 04/19 Assembly Section 3-6 © 2019 Alamo Group Inc. - Page 37 (6). Insert safety pin (7) in hole (B). Item 4: 1 Spring ø1.5/ø20x85 (ø.06/ø0.79”x3.35”) Item 5: 1 Spring Pin ø4x24 (ø0.16”x0.95”) Item 6: 1 Knob Item 7: 1 Pin ø10x85 (0.39”x3.35”) RR1114H 04/19 Assembly Section 3-7 © 2019 Alamo Group Inc.

- Page 38 60 fully threaded) so that the safety hook turns partially and is positioned vertically when the protection frame is horizontal. Item 2: 1 Screw M10x60 (0.39”x2.36”) Item 3: 1 Nut M10 (0.39”) RR1114H 04/19 Assembly Section 3-8 © 2019 Alamo Group Inc.

- Page 39 (28) on the outside. Use screws (32) and nuts (33) to fasten everything into place. Use screws (23) and (26) to mount this group on plate carrier extension (19). Item 23: 2 Screws M10x55 (0.39”x2.17”) Item 26: 2 Screws M10x25 (0.39”x1”) Item 32: 12 Screws M8x20 (0.31”x0.79”) RR1114H 04/19 Assembly Section 3-9 © 2019 Alamo Group Inc.

- Page 40 Item 3: 2 Bolts M6x20 (0.24”x0.78”) Item 4: 2 Nuts M6 (0.24”) Item 5: 2 Washers ø6 (0.24”) 11. Mount the grease nipple (1) on all pins. Item: 1: 5 Grease Nipples M6 RR1114H 04/19 Assembly Section 3-10 © 2019 Alamo Group Inc.

- Page 41 (R) in holes (A) on the frame. Item 43: 11 Pins ø10x70 (ø0.39”x2.76”) Item 42: 11 Springs Pins ø2 (ø0.08”) RR1114H 04/19 Assembly Section 3-11 © 2019 Alamo Group Inc.

-

Page 43: Operation Section

OPERATION SECTION Operation Section 4-1... - Page 44 BUSH HOG RR1114H RAKE OPERATION INSTRUCTIONS Bush Hog Rakes are manufactured with quality material by skilled workers. It is the operator’s responsibility to be knowledgeable of all potential operating hazards and to take every reasonable precaution to ensure oneself, others, animals, and property are not injured or damaged by the rake, tractor or a thrown object. Do not operate the rake if passerby, pets, livestock, or property are directly in front or to the rear of the unit.

-

Page 45: Standard Equipment And Specifications

OPERATION Standard Equipment and Specifications Model RR1114H Number of Arms Number of Double Tines per Arm Working Width 13’ 9” Rotor Diameter (Raking Width) 11’ 2” Transport Width (with Arms Disassembled) 6’ 7” Transport Width (with Arms Assembled) 11’ 5”... -

Page 46: Operator Requirements

Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. (SG-27) RR1114H 04/19 Operation Section 4-4 © 2019 Alamo Group Inc. -

Page 47: Tractor Requirements

PTO master shield missing or in the raised position. OPS-U- 0004 3.3 Tractor Horsepower The power required to operate these implements is determined by the tractor PTO horsepower. The RR1114H requires a tractor with a minimum of 40 hp. Operating these implements with a tractor that does not have adequate power may damage the tractor engine. -

Page 48: Getting On And Off The Tractor

Use all handrails and steps for support and never rush or jump off the tractor. OPS-U- 0009 RR1114H 04/19 Operation Section 4-6 © 2019 Alamo Group Inc. -

Page 49: Starting The Tractor

Start tractor only when properly seated in the Tractor seat. Starting a tractor in gear can result in injury or death. Read the Tractor operators manual for proper starting instructions. (SG-13) RR1114H 04/19 Operation Section 4-7 © 2019 Alamo Group Inc. -

Page 50: Connecting The Implement To The Tractor

(7), the tilt of the machine relative to the ground is adjusted. Do Not Lock Hitch Swivel when connected to tractor drawbar. Bolt (8) should be removed allowing the hitch to pivot. Ops-2611 RR1114H 04/19 Operation Section 4-8 © 2019 Alamo Group Inc. -

Page 51: Connecting The Driveshaft

Take particular care to make sure the locking collars on driveline yokes are secured and locked. Ops-2615 A loose shaft could come apart and cause considerable mechanical damage and serious injury to operator or bystanders. RR1114H 04/19 Operation Section 4-9 © 2019 Alamo Group Inc. -

Page 52: Pre-Operation Inspection And Service

Power brake fluid level • Power steering fluid level • Fuel condition and level • Sufficient lubrication at all lube points • Air filter condition OPS-U-0030 Checking Ballast, Wheel Spacing, and Tire Inflation RR1114H 04/19 Operation Section 4-10 © 2019 Alamo Group Inc. -

Page 53: Rake Pre-Operation Inspection/Service

Ensure the manual canister is secured to the equipment with the operator’s manual inside. • Ensure all safety signs are in place and legible. Replace missing, damaged, and illegible decals. OPS-U- 0011 RR1114H 04/19 Operation Section 4-11 © 2019 Alamo Group Inc. - Page 54 The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature:___________________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT RR1114H 04/19 Operation Section 4-12 © 2019 Alamo Group Inc.

- Page 55 There is no evidence of Hydraulic leaks The tires and wheel(s) are in good condition Wheel lug nuts are tight Operator’s Signature:________________________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT RR1114H 04/19 Operation Section 4-13 © 2019 Alamo Group Inc.

-

Page 56: Driving The Tractor And Implement

When operating in traffic always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. (SG-19) RR1114H 04/19 Operation Section 4-14 © 2019 Alamo Group Inc. -

Page 57: Starting The Tractor

The tractor should never be operated at speeds that cannot be safely handled or which will prevent the operator from stopping quickly during an emergency. If the power steering or engine ceases operating, stop the tractor immediately as the tractor will be difficult to control. RR1114H 04/19 Operation Section 4-15 © 2019 Alamo Group Inc. -

Page 58: Field Adjustments

Ops-2639 After having adjusted the work height of the tine, use nuts (5) under clamp (10) to set the distance of the plate from the ground. Ops-2618 RR1114H 04/19 Operation Section 4-16 © 2019 Alamo Group Inc. - Page 59 The forage rake was designed for a maximum speed of 540 RPM. The forage rake must NEVER be used with a 1000 RPM PTO. Rotor speed should be limited so the rake works cleanly and the swath is well formed. RR1114H 04/19 Operation Section 4-17...

-

Page 60: Operating The Tractor And Implement

Stay alert and watch for trees, low hanging limbs, power lines, and other overhead obstacles and solid ground objects while you are operating. Use care to avoid hitting these items OPS-R-0028_A RR1114H 04/19 Operation Section 4-18 © 2019 Alamo Group Inc. -

Page 61: Shutting Down The Implement

Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches. (S3PT-15) RR1114H 04/19 Operation Section 4-19 © 2019 Alamo Group Inc. -

Page 62: Rake Storage

OPS-U- 0017 Never allow children or other persons to ride on the Tractor or Implement. Falling off can result in serious injury or death. (SG-10) RR1114H 04/19 Operation Section 4-20 © 2019 Alamo Group Inc. - Page 63 Use extreme caution and avoid hard applications of the tractor brakes when towing heavy loads at road speeds. Never tow the implement at speeds greater than 20 MPH (32 kph). OPS-U- 0018 RR1114H 04/19 Operation Section 4-21 © 2019 Alamo Group Inc.

- Page 64 The machine itself does not require these operations. Ops-2623 NOTE: Remember to open the valve and lower the machine after transport operations are completed. RR1114H 04/19 Operation Section 4-22 © 2019 Alamo Group Inc.

-

Page 65: Transporting On Public Roadways

Replace the SMV emblem if faded, damaged, or no longer reflective. OPS-U- 0020 RR1114H 04/19 Operation Section 4-23 © 2019 Alamo Group Inc. - Page 66 OPS- B- 0022 Reduce speed before turning or applying the brakes. Ensure that both brake pedals are locked together when operating on public roads. OPS-U- 0023 RR1114H 04/19 Operation Section 4-24 © 2019 Alamo Group Inc.

-

Page 67: Hauling The Tractor And Implement

OPS-U- 0025 RR1114H 04/19 Operation Section 4-25 © 2019 Alamo Group Inc. -

Page 69: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1 © 2019 Alamo Group Inc. - Page 70 The machine consists mainly of ferrous material which must be disposed of according to the regulations in force in the country concerned. There is also a small amount of plastic which must be disposed of according to the regulations in force in the country concerned. RR1114H 04/19 Maintenance Section 5-2 © 2019 Alamo Group Inc.

-

Page 71: Lubrication Chart

Generally checking of bolts. Security pins and split pins to be carried out initially after the first 8 hours of use. Subsequently every 50 hours and whenever the machine is laid up for extended periods. RR1114H 04/19 Maintenance Section 5-3 © 2019 Alamo Group Inc. -

Page 72: General Maintenance

1. Turn the two eccentric pins n the ferrule until the protective cone comes free. 2. Withdraw the shaft protective guard. 3. Check the condition of the ferrule and all protective parts. RR1114H 04/19 Maintenance Section 5-4 © 2019 Alamo Group Inc. -

Page 73: Scrapping The Rake

The rake consists mainly of ferrous material, a small amount of plastic and a very small amount of residual grease which must be disposed of according to the regulations in force for the area concerned. RR1114H 04/19 Maintenance Section 5-5... -

Page 74: Storage

When replacing bolts, always use the same grade of bolt as used originally. Use the chart as a guide to tightening all bolts. Torque values listed are for general use only. RR1114H 04/19 Maintenance Section 5-6 © 2019 Alamo Group Inc. - Page 75 MAINTENANCE RR1114H 04/19 Maintenance Section 5-7 © 2019 Alamo Group Inc.

- Page 77 TO THE OWNER/OPERATOR/DEALER To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety...

- Page 78 Rake RR1114H-SOM- 04/19 P/N50080518 Printed U.S.A...

Need help?

Do you have a question about the RR1114H and is the answer not in the manual?

Questions and answers