SATO M-8485Se Service Manual

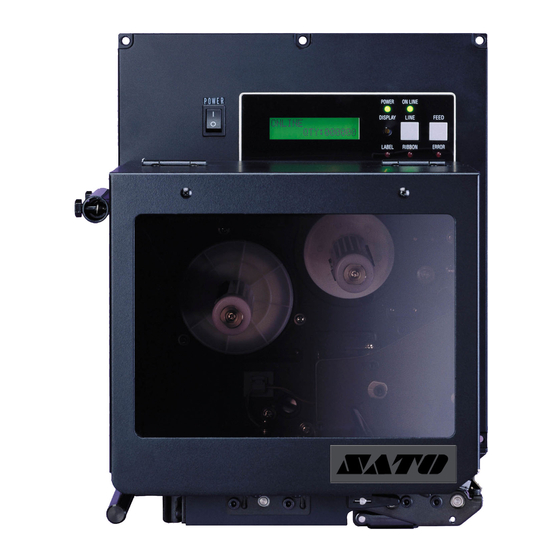

Standard oem print engine

Hide thumbs

Also See for M-8485Se:

- Operator and technical reference manual (268 pages) ,

- Programming reference manual (242 pages) ,

- Operator's manual (107 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for SATO M-8485Se

- Page 1 ® M-8485Se Standard OEM Print Engine Service Manual PN 9001080 Rev. A...

- Page 2 All rights reserved. No part of this document may be reproduced or issued to third parties in any form whatever without the express permission of SATO America, Inc. The materials in this document are provided for general information and are subject to change without notice.

- Page 3 Section 5. Mechanical Adjustments • Section 6. Replacement Procedures • Section 7. Factory Resets • Section 8. Troubleshooting • Section 9. Optional Accessories • Section 10. Parts list Page 1-1 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 4: Section 1. Overview And Specifications

Section 1. Overview and Specifications 1.2 Dimensions and Power Requirements DEEP WIDE HIGH . n i . n i . n i a t l Page 1-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... -

Page 5: Operation

PANEL RIBBON UNWIND RIBBON REWIND RIBBON LABEL EDGE GUIDE PEEL BAR PLATEN ROLLER MEDIA HOLD DOWN HEAD PRESSURE MEDIA OUT ADJUST HEAD LOCK LEVER NIP ROLLER LATCH PN 9001080 Page 1-3 SATO M-8485Se Standard Print Engine Rev. A Service Manual... - Page 6 FRONT COVER DISPLAY PANEL PC BOARD MAIN PC BOARD RIBBON MOTOR POWER SUPPLY PRINT HEAD PRINT HEAD NIP ROLLER PLATEN PEEL BAR ASSEMBLY (COVERS ROLLER THE REAR PLATEN) Page 1-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 7 Switches the printer On-Line or Off-Line. Can also be used as a Pause function key to stop label during the printing process. FEED KEY Feeds one blank label 1.5 Dip Switch Panel DIP SWITCHES POTENTIOMETERS PN 9001080 Page 1-5 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 8 For electrical checks and adjustments AC FUSE To protect the printer from abnormal power input Type 15A/250V AC POWER CONNECTOR To AC Line - Use the power cable provided Page 1-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 9: Switches And Sensors

Section 1. Overview and Specifications 1.7 Switches and Sensors (IN TOP LID) c t i c t i & E " " k PN 9001080 Page 1-7 SATO M-8485Se Standard Print Engine Rev. A Service Manual... - Page 10 Section 1. Overview and Specifications Switches and Sensors Page 1-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 11: Adjusting The Label Sensor

Section 1. Overview and Specifications 1.8 Adjusting the Label Sensor RIBBON GUIDE PLATE LABEL GAP SENSOR POSITION SENSOR SCREWS ADJUST SLOT PN 9001080 Page 1-9 SATO M-8485Se Standard Print Engine Rev. A Service Manual... - Page 12 MINIMUM WIDTH = 0.125" (3 mm) MINIMUM LENGTH = 0.5" (12 mm) " 7 n i l t n i " 0 " 5 " 7 t n i " 2 Page 1-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 13: Installation Considerations

Section 1. Overview and Specifications 1.9 Ribbon 1.10 Installation Considerations PN 9001080 Page 1-11 SATO M-8485Se Standard Print Engine Rev. A Service Manual... -

Page 14: General Printer Specifications

. n i , s l p i l . n i e l f i t c E " " k All specifications subject to change without notice. Page 1-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 15 Section 1. Overview and Specifications General Printer Specifications y t i y t i c i t All specifications subject to change without notice. PN 9001080 Page 1-13 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 16 ) f f l a i f f u (1) Plug-In Interface Modules All specifications subject to change without notice. Page 1-14 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 17: Character Fonts

All specifications subject to change without notice. PN 9001080 Page 1-15 SATO M-8485Se Standard Print Engine Rev. A Service Manual... -

Page 18: Bar Codes And Other Features

. s t e l f i t c E " " s . l e All specifications subject to change without notice. Page 1-16 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... -

Page 19: Dip Switches

• Thermal transfer or direct thermal mode • Head Check Mode • Hex Dump Mode • Label sensor enable/disable • Single Job or Multi-Job Receive Buffer • Operation Mode DIP SWITCHES DSW1 Page 2-1 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual... -

Page 20: Dip Switch Settings

Baud Rate Selection (DSW1-5, DSW1-6): DSW1 DSW1-5 DSW1-6 SETTING 9600 19200 38400 57600 Protocol Selection (DSW1-7, DSW1-8): DSW2 DSW1-7 DSW1-8 SETTING Rdy/Bsy Xon/Xoff Bi-Com 3 Bi-Com 4 Page 2-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 21 Head Check Selection (DSW2-3): DSW2 DSW2-3 SETTING Disable Enable Hex Dump Selection (DSW2-4): DSW2 DSW2-4 SETTING Disable Enable Receive Buffer Selection (DSW2-5): DSW2 DSW2-5 SETTING Single Job Multi-Job Page 2-3 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 22 SETTING Standard Non-Std. M8400S Emulation Mode (DSW2-8): DSW2 DSW2-8 SETTING Disabled Enabled Backfeed Sequence Selection (DSW3-1): DSW3 DSW3-1 SETTING Before After DSW3 Reserved for Future Use (DSW3-2): Page 2-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 23 SETTING Sensor Used Not Used Back-Feed Selection (DSW3-4): DSW3 DSW3-4 SETTING Enabled Disabled External Signal Interface EXT Print Start Signal Selection (DSW3-5): DSW3 DSW3-5 SETTING Enabled Disabled Page 2-5 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 24 External Signal Type Selection (DSW3-6, DSW3-7): DSW3 DSW3-6 DSW3-7 SETTING Type 4 Type 3 Type 2 Type 1 Repeat Print via External Signal (DSW3-8): DSW3 DSW3-8 SETTING Disabled Enabled Page 2-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 25: Default Settings

Software Default Settings LINE and .EED t n i t n i . n i t n i c i t l a t DE.AULT SETTING COMPLETED Page 2-7 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual... -

Page 26: Potentiometer Adjustments

Section 2. Configuration 2.3 Potentiometer Adjustments Pitch PITCH STEP PROCEDURE .EED LINE .EED LINE .EED .EED PITCH .EED Page 2-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 27 Backfeed Offset STEP PROCEDURE LINE .EED .EED Display Print NOTE: The PRINT potentiometer adjustment will affect the darkness in all the command code speed and darkness ranges. Page 2-9 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

-

Page 28: Lcd Panel Printer Configuration

Section 2. Configuration 2.4 LCD Panel Printer Configuration LINE .EED t n i t l u > - Page 2-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 29 Section 2. Configuration LCD Panel Printer — Normal Mode STEP PROCEDURE LINE LINE .EED Print Darkness Setting Darkness STEP PROCEDURE LINE .EED Page 2-11 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 30 Section 2. Configuration LCD Panel Printer— Normal Mode Print Speed Adjustment Speed STEP PROCEDURE LINE .EED Pitch Offset Adjustment STEP PROCEDURE LINE .EED LINE LINE Page 2-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 31 A B C D E F G line position A B C D E F G Moved with positive (+) offset to print on trailing edge of the label Page 2-13 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 32 Section 2. Configuration LCD Panel Printer — Normal Mode Cancel Print Job STEP PROCEDURE LINE Yes. .EED .EED LINE LCD Panel Printer — M8400 Compatible Mode STEP PROCEDURE Page 2-14 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 33 Section 2. Configuration LCD Panel Printer— Advanced Mode STEP PROCEDURE LINE LINE .EED Zero Slash STEP PROCEDURE LINE .EED AutoOnline STEP PROCEDURE LINE .EED Page 2-15 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 34 Print Offset STEP PROCEDURE LINE LINE .EED LINE .EED .EED Note: This setting can be overridden by the Base Reference Point Command. Set Calendar LINE LINE .EED Page 2-16 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 35 LCD Panel Printer— Advanced Mode Set Calendar (Continued) Calendar 00/00/00 00:00 STEP PROCEDURE Year LINE LINE Month .EED LINE LINE .EED LINE LINE Hour .EED LINE LINE Minute .EED LINE .EED Page 2-17 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 36 STEP PROCEDURE LINE .EED Character Pitch STEP PROCEDURE LINE .EED Note: This command can be overriden by the <ESC>PR or <ESC>PS Character Pitch Commands. Exit Advanced Mode Page 2-18 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 37 Section 2. Configuration LCD Panel Printer —Card Mode LINE .EED Mem Select (CC1) STEP PROCEDURE LINE .EED Page 2-19 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 38 Section 2. Configuration LCD Panel Printer —Card Mode Card ->MemoryCopy TrueTypeFont Y/N STEP PROCEDURE LINE Card to Memory Copy SATO .ont .EED .EED .EED Page 2-20 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 39 Section 2. Configuration LCD Panel Printer — Card Mode Card ->MemoryCopy SatoFont Y/N STEP PROCEDURE LINE .EED .EED Page 2-21 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 40 Section 2. Configuration LCD Panel Printer — Card Mode Card ->MemoryCopy All Y/N STEP PROCEDURE LINE .EED .EED Page 2-22 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 41 Section 2. Configuration LCD Panel Printer — Card Mode Memory->Card Copy All <XMB> Y/N STEP PROCEDURE LINE .EED .EED Page 2-23 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 42 Section 2. Configuration LCD Panel Printer— Card Mode Card->Memory Copy Program Y/N STEP PROCEDURE LINE .EED .EED Page 2-24 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 43 Section 2. Configuration LCD Panel Printer — Card Mode Memory->Card Copy Program Y/N STEP PROCEDURE LINE .EED .EED Page 2-25 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 44 Section 2. Configuration LCD Panel Printer— Card Mode Card Format Yes No STEP PROCEDURE LINE Memory Format Yes No STEP PROCEDURE LINE Page 2-26 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 45 Section 2. Configuration LCD Panel Printer— Service Mode To Enter Advanced Mode: STEP PROCEDURE LINE LINE LINE .EED [X.XV] Input [X.XV} Page 2-27 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 46 Section 2. Configuration LCD Panel Printer — Service Mode [X.XV] Input [X.XV} STEP PROCEDURE LINE LINE LINE .EED Page 2-28 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 47 Section 2. Configuration LCD Panel Printer — Service Mode [X.XV] Input [X.XV} STEP PROCEDURE LINE LINE LINE .EED .eed Page 2-29 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 48 LCD Panel Printer— Service Mode Auto Online Feed Yes No STEP PROCEDURE LINE Feed on Error Yes No STEP PROCEDURE LINE Reprint W/Feed Yes No .EED STEP PROCEDURE LINE .EED .EED Page 2-30 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 49 Section 2. Configuration LCD Panel Printer — Service Mode Forward/Backfeed Distance Default STEP PROCEDURE LINE LINE LINE .EED Web Acceleration Fast Normal STEP PROCEDURE LINE .EED Page 2-31 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 50 Section 2. Configuration LCD Panel Printer— Service Mode Euro Code STEP PROCEDURE LINE .EED Line .EED Select Language English STEP PROCEDURE LINE .EED Page 2-32 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 51 Section 2. Configuration LCD Panel Printer— Service Mode Priority Setting LCD Command STEP PROCEDURE LINE .EED Service Mode Page 2-33 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 52 Section 2. Configuration LCD Panel Printer — Counters Mode To Enter Advanced Mode: STEP PROCEDURE LINE LINE LINE .EED Counters DSP CUT LIFE STEP PROCEDURE LINE .EED .EED Page 2-34 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 53: Test Print Mode

Section 2. Configuration LCD Panel Printer — Counters Mode (Countinued) STEP PROCEDURE .EED .EED Test Print Mode Test Print Mode Configuration STEP PROCEDURE .EED .EED Page 2-35 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual... - Page 54 PROCEDURE LINE See last pages in this section for test label sample print-outs .EED Test Print Size 10 CM .EED STEP PROCEDURE LINE LINE LINE .EED .EED Page 2-36 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 55 Section 2. Configuration LCD Panel Printer— Default Setting Mode Default Setting Mode .EED LINE .EED LINE STEP PROCEDURE LINE .EED Page 2-37 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 56 Section 2. Configuration LCD Panel Printer— Maintenance Mode STEP PROCEDURE DSW2-4 LINE and .EED DSW-4 .EED LINE NONE .EED LINE .EED .EED Page 2-38 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 57 Section 2. Configuration LCD Panel Printer— Maintenance Mode All Clear Mode STEP PROCEDURE DSW2-4 LINE and .EED DSW-4 LINE .EED .EED LINE .EED Page 2-39 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 58 Alt. Protocol Default Complete LINE .EED STEP PROCEDURE LINE .EED Download User Defined Protocol Codes User Download Press the Line Key DSW2-7 LINE STEP PROCEDURE DSW2-7 LINE Page 2-40 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 59: Hex Dump Mode

LCD Panel Printer — Download User Defined Protocol Codes User Download Press the Line Key (Countinued) STEP PROCEDURE .EED .EED Hex Dump Mode Online DSW2-4 STEP PROCEDURE DSW2-4 Page 2-41 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual... - Page 60 Section 2. Configuration LCD Panel Printer—Download Mode STEP PROCEDURE DSW2-6 During download process, these displays may be seen .EED Page 2-42 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 61 Section 2. Configuration LCD Panel Printer—User Download Mode STEP PROCEDURE DSW2-7 LINE Page 2-43 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

- Page 62 Section 2. Configuration LCD Panel Printer—Label Out Sensor STEP PROCEDURE DSW2-4 .EED DSW2-4 LINE Page 2-44 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 63 Section 2. Configuration 2.5 Sample Test Labels CONFIGURATION BAR CODE MEMORY HEAD CHECK FACTORY ILLUSTRATIONS SHOWN ARE EXAMPLES ONLY AND MAY NOT EXACTLY MATCH YOUR OUTPUT Page 2-45 PN 9001080 SATO M-8485Se Standard Print Engine Rev. A Service Manual...

-

Page 64: Interface Specifications

Section Interface Specifications 3.1 Overview 3.2 Interface Types SATO M-8485Se Standard Print Engine Page 3-1 PN 9001080 Rev. A Service Manual... -

Page 65: Centronics Parallel Interface

This may cause damage to the interface circuitry in the printer/host and is not covered warranty. USB INTERFACE RS232C SERIAL LAN INTERFACE CENTRONICS INTERFACE PARALLEL INTERFACE Available Interfaces Page 3-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... -

Page 66: The Receive Buffer

3.3 The Receive Buffer Single Job Buffer Multi Job Buffer Ready/ Busy X-On/X-Off X-On/X-Off X-Off 2.0 MB 2.95MB *DTR High DTR Low X-On Buffer Near Full X-Off Page 3-3 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... -

Page 67: Ieee 1284 Parallel Interface

IEEE1284 Parallel, 10 ft. (3 m) or less Signal Level High = +2.4V to +5.0V Low = 0V to -0.4V Data Streams: <ESC>A .. Job#1 .. <ESC>Z<ESC>A .. Job#n .. <ESC>Z Page 3-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 68 (1) Signals required for IEEE 1284 mode. PIN ASSIGNMENTS - IEEE 1284 CABLE END Page 3-5 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 69: Rs232C Serial Interface

Cable Requirements appropriate to the RS232C protocol chosen. Signal Level High = +5V to +12V Low = -5V to -12V PIN ASSIGNMENTS - RS232C PRINTER END Page 3-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 70 * This connection at the host side of the interface would depend upon the pin that is being used as the Ready/Busy signal by the driving software. Typically on a PC, it would be either CTS (pin 5) or DSR (pin 6) on a DB-25 connector. Page 3-7 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 71 . l e Ready/Busy Flow Control Page 3-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 72: Universal Serial Bus (Usb) Interface

General Specifications: Connector: USB Type B Plug Cable: 10ft (3 m) max. Host: Windows 98 USB Port Electrical Specifications: Power Supply: Bus Power through cable Power Consumption:: +5V@80ma Page 3-9 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... -

Page 73: Local Area Network (Lan) Optional Interface

RJ-45 Receptical Electrical Specifications: Power Supply: Powered from printer 3.8 Bi-Directional Communications ENQUIRE/ACK/NAK Enquire (ENQ) STX/ETX <STX>{2 Byte ID}{1 Status Byte}{6 Byte Label Remaining}{16 Byte Job Name}<ETX> Page 3-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 74 Print Stop (DLE) Print Start (DC1) (1) To provide compatibility with older SATO printers, the RS232 interface can be configured to use an earlier Bi-Com 3 ENQ/ACK/NAK protocol selected via DSW2-8 and DSW1-7/8 (on the RS232 Interface module). The earlier protocol did not have provisions for the Job Name and did not respond to the DLE or DCI commands.

- Page 75 (1) Not supported by legacy Bi-Com protocols Page 3-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 76 Page 3-13 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 77 Page 3-14 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 78 Sensor Status (SOH + SG) STX-ETX e l f i t c Head Status (SOH + HC) STX-ETX t n i t l u t n i Page 3-15 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 79 Status Response (Cont) System Version Information STX-ETX f n I Memory Status STX-ETX l a t l a t l a t Form OverlayStatus (SOH + FO) STX-ETX Page 3-16 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 80 I c i l r t t r t t l a t d i l Page 3-17 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 81 I f f u - i t l e t I f f u Page 3-18 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 82 . e l . s t . t u t n i t n i Page 3-19 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 83 End of Print Cycle Standard Operation Print Start Input Print Repeat Input Print End Type 1 20 Milliseconds Print End Type 2 Print End Type 3 Print End Type 4 Page 3-20 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 84 Head Closed Motion Print Motion Stopped Paper End Ribbon End Machine Error Print End Type 1 Print End Type 2 Print End Type 3 Print End Type 4 Page 3-21 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 85: Electrical Checks And Adjustments

Section " Electrical Checks and Adjustments 4.1 Overview Checks and adjustments in this section require standard metric tools. Other equipment is listed where needed. PN 9001080 SATO M-8485Se Standard Print Engine Page 4-1 Rev. A Service Manual... -

Page 86: Dc Power Voltage Checks

Section 4. Electric Checks and Adjustments 4.2 DC Power Voltage Checks STEP PROCEDURE .ig. 4-1 .ig. 4-2 & .ig. 4-3 SLIDE OFF ACCESS COVER LOOSEN (2) SCREWS Fig. SERVICE BOARD Page 4-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 87 NOTE: The power supply voltages are not adjustable. All voltages must read within the nominal value for correct operation of the printer. POTENTIOMETERS VR1 - VR5 Fig. SERVICE BOARD SATO M-8485Se Standard Print Engine PN 9001080 Page 4-3 Rev. A Service Manual...

- Page 88 LOW LEVEL (BACKING PAPER) ADJUSTMENT (GAP) .ig. 4-4 HIGH LEVEL (LABEL) ADJUSTMENT ADJUST VR4 ADJUST VR2 ON ON MAIN PCB SERVICE BOARD TO MIDPOINT IF NECESSARY Fig. Page 4-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 89 LOW LEVEL (NO "Eye-Mark") ADJUSTMENT . .ig. 4-5 HIGH LEVEL ("Eye-Mark") ADJUSTMENT ADJUST VR5 ADJUST VR2 ON ON MAIN PCB SERVICE BOARD TO MIDPOINT IF NECESSARY Fig. SATO M-8485Se Standard Print Engine PN 9001080 Page 4-5 Rev. A Service Manual...

-

Page 90: Ribbon Sensor Adjustment

LOW LEVEL (No Slit) ADJUSTMENT .ig. 4-6 HIGH LEVEL (With Slit) ADJUSTMENT ADJUST VR5 ON MAIN PCB TO MIDPOINT IF NECESSARY ADJUST VR3 ON SERVICE BOARD Fig. Page 4-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 91 Caution: Excessive printing will cause degradation of the print head since all elements of the print head are heated at once. Be extra cautious if 5 inch wide labels are used. .EED PITCH POTENTIOMETER SATO M-8485Se Standard Print Engine PN 9001080 Page 4-7 Rev. A Service Manual...

-

Page 92: Test Print

Caution: Excessive printing will cause degradation of the print head since all elements of the print head are heated at once. Be extra cautious if 5 inch wide labels are used. Page 4-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 93 Section 4. Electric Checks and Adjustments Pitch Offset Sensor Adjustment (Factory Setting) STEP PROCEDURE PITCH POTENTIOMETER .EED SATO M-8485Se Standard Print Engine PN 9001080 Page 4-9 Rev. A Service Manual...

- Page 94 Section 4. Electric Checks and Adjustments 4.7 Feed/Backfeed Adjustment STEP PROCEDURE online qty 000000 LINE offline qty 000000 .EED RIBBON PEEL BAR 2mm to 3mm LABEL OFFSET POTENTIOMETER Page 4-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 95 Caution: Excessive printing will cause degradation of the print head since all elements of the print head are heated at once. Be extra cautious if 5 inch wide labels are used. .EED PRINT POTENTIOMETER SATO M-8485Se Standard Print Engine PN 9001080 Page 4-11 Rev. A Service Manual...

- Page 96 Section 4. Electric Checks and Adjustments 4.9 LCD Darkness Adjustment STEP PROCEDURE online qty 000000 DISPLAY POTENTIOMETER Page 4-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 97: Calendar Clock Setting

Section 4. Electric Checks and Adjustments 4.10 Calendar Clock Setting STEP PROCEDURE LINE LINE advanced mode initializing .EED calendar enabled LINE .EED calendar 00/00/00 00:00 .EED LINE .EED LINE .EED euro code SATO M-8485Se Standard Print Engine PN 9001080 Page 4-13 Rev. A Service Manual... -

Page 98: Mechanical Adjustments

• Print Head Balance Adjustment • Print Head Alignment • Timing Belt Tension Adjustments • Feed Roller Adjustment • Peel Bar Adjustment • Ribbon Unwind/Rewind Shaft Adjustment PN 9001080 SATO M-8485Se Standard Print Engine Page 5-1 Rev. A Service Manual... - Page 99 Section 5. Mechanical Adjustments 5.2 Ribbon Clutch Adjustments 5.2.1 Ribbon Unwind Clutch Adjustment STEP PROCEDURE .ig. 5-1, 5-2 Page 5-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 100 SET SCREW IS INSIDE ADJUST ADJUST NUT Fig. 5-1 TENSION GAUGE 500-700G (REWIND SPINDLE, STRING IS CCW) EMPTY RIBBON CORE Figs. 5-2 600-800G (UNWIND SPINDLE, STRING IS CW) SATO M-8485Se Standard Print Engine PN 9001080 Page 5-3 Rev. A Service Manual...

- Page 101 Section 5. Mechanical Adjustments 5.2.2 Ribbon Rewind Clutch Adjustment STEP PROCEDURE .ig. 5-1, 5-2 Page 5-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 102: Guide Plate

Section 5. Mechanical Adjustments 5.3 Ribbon Guide Plate Adjustments STEP PROCEDURE .ig. 5-3 and 5-4 .ig. 5-5 RIBBON WRINKLE (EXAGERATED FOR CLARITY) Fig. GUIDE PLATE SATO M-8485Se Standard Print Engine PN 9001080 Page 5-5 Rev. A Service Manual... - Page 103 BY RIBBON WRINKLE Fig. RETAINING SCREWS Fig. GUIDE PLATE RIBBON IF WRINKLES APPEAR BEHIND THE PRINT HEAD, ADJUST RIBBON SHAFT ECCENTRIC NUT WITH WRENCH AND Fig. PHILLIPS SCREWDRIVER Page 5-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 104 .ig. 5-8 LOOSEN SCREW ¼ TURN, USE 10 MM WRENCH TO ADJUST ECCENTRIC NUT CW OR CCW AND TIGHTEN SCREW LOOSEN SCREW HOLDING SIDE PLATE TO FRAME Fig. SATO M-8485Se Standard Print Engine PN 9001080 Page 5-7 Rev. A Service Manual...

- Page 105 ON THE OUTSIDE EXCESSIVE PRESSURE ON THE INSIDE PATTERN DENSITY EVEN BOTH SIDES Figs. CORRECT ADJUSTMENT ILLUSTRATIONS SHOWN ARE EXAMPLES ONLY AND MAY NOT EXACTLY MATCH YOUR OUTPUT Page 5-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 106 .ig. 5-10 .ig. 5-11 LOOSEN SCREWS ON PRINT HEAD LOOSEN (1) POST SCREW TWO PLACES Fig. 5-9B Fig. 5-9A SCREWDRIVER IN SLOTS OF HEAD ADJUSTMENT PLATE Fig. 5-10 SATO M-8485Se Standard Print Engine PN 9001080 Page 5-9 Rev. A Service Manual...

- Page 107 BOTTOM EDGE OF BAR CODE AND LABEL EDGE ARE PARALLEL SHOWN WITH PROPER ALIGNMENT Figs. 5-11 ILLUSTRATIONS SHOWN ARE EXAMPLES ONLY AND MAY NOT EXACTLY MATCH YOUR OUTPUT Page 5-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 108 .ig. 5-13 .ig. 5-14 .ig. 5-15 & 5-16 BRACKET #3 WITH BELT “C” ADJUSTMENT SCREWS BELT “B” BRACKET #2 WITH ADJUSTMENT SCREWS Fig. 5-13 BELT “B” Fig. 5-14 SATO M-8485Se Standard Print Engine PN 9001080 Page 5-11 Rev. A Service Manual...

- Page 109 Section 5. Mechanical Adjustments Timing Belt Tension Adjustment BELT “C” BRACKET #3 BRACKET #2 BELT “B” BELT “A” BRACKET #1 Fig. 5-12 Page 5-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 110 ADJUST BRACKET #1 BRACKET #1 WITH SCREWDRIVER MEDIA SIDE ACCESS HOLE TO ADJUST BRACKET #1 WITH SCREWDRIVER (OPPOSITE SIDE) BRACKET #1 Figs. 5-16 BELT SIDE BELT “A” SATO M-8485Se Standard Print Engine PN 9001080 Page 5-13 Rev. A Service Manual...

- Page 111 STEP PROCEDURE .ig. 5-18 .ig. 5-17 MEDIA LID COVER MEDIA LID COVER ECCENTRIC NUT LOCATED ON MEDIA RAMP ASSEMBLY TURN CW OR CCW Fig. 5-18 Fig. 5-17 Page 5-14 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 112 STEP PROCEDURE .igs. 5-19 ADJUST SCREW ON EITHER END PEEL BAR PEEL BAR PLATEN ROLLER PLATEN ROLLER (COVER SHOWN REMOVED) PEEL BAR 0.5 - 1mm 5-19 Figs. SATO M-8485Se Standard Print Engine PN 9001080 Page 5-15 Rev. A Service Manual...

- Page 113 The ribbon unwind/rewind shaft adjustment may affect the timing belt adjustment (Section 5-6). Readjust if required. REWIND/UNWIND SHAFTS ADJUSTMENT LOOSEN SLOTS SCREWS Fig. 5-20 Page 5-16 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 114: Replacement Procedures

LCD Display Panel Label Sensor • Label Gap Sensors • Dip Switch Panel • Label Out Sensor • Stepper Motor • Platen • Timing Belts • Print Head • Ribbon Clutch Washers PN 9001080 SATO M-8485Se Standard Print Engine Page 6-1 Rev. A Service Manual... -

Page 115: Rear Cover

6.2 Replacing Fuses 6.2.1 Removing and Replacing the Main Power Fuse STEP PROCEDURE .ig.6-1 Do not use a fuse with a higher rating. REAR COVER FUSE Fig. Page 6-2 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 116 6.2.2 Removing and Replacing the Internal Fuse(s) STEP PROCEDURE .ig.6-2 Do not use a fuse with a higher rating. FUSES MAIN PCB REMOVE LOCKING SCREW AND SWING CABINET OPEN Figs. SATO M-8485Se Standard Print Engine PN 9001080 Page 6-3 Rev. A Service Manual...

- Page 117 Section 6. Replacement Procedures 6.3 Replacing the Power Supply STEP PROCEDURE .ig.6-3 .ig. 6-4 & 6-5 .ig. 6-6 .igs. 6-7 REMOVE LOCKING SCREW AND SWING CABINET OPEN Figs. Page 6-4 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 118: Remove Power Supply

Section 6. Replacement Procedures Replacing the Power Supply (1) SCREW (FROM INSIDE OF CABINET) (2) SCREWS (BACK OF CABINET) Fig. Fig. REMOVE POWER SUPPLY Fig. SATO M-8485Se Standard Print Engine PN 9001080 Page 6-5 Rev. A Service Manual... - Page 119 Section 6. Replacement Procedures Replacing the Power Supply DETACH (3) CONNECTORS FROM POWER SUPPLY DETACH (2) SPADE Figs. CONNECTORS FROM POWER SUPPLY Page 6-6 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 120 6.4 Replacing the Main Circuit Board STEP PROCEDURE .igs. 6-8 .igs. 6-8 .ig. 6-9 .igs. 6-10. .igs. 6-10 .igs. 6-11 .igs. 6-12 .igs. 6-12 .igs. 6-11 .igs. 6-13 .igs. 6-14 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-7 Rev. A Service Manual...

- Page 121 Replacing the Main Circuit Board STEP PROCEDURE REMOVE (5) SCREWS TO DETACH BACK PANEL Figs. REMOVE LOCKING SCREW AND SWING CABINET OPEN REACH INSIDE CABINET AND DETACH CONNECTOR Fig. Page 6-8 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 122 TO BRACKET) SERVICE BOARD SCREW Figs. 6-10 = REMOVE (4) SCREWS SCREW - NOTE GROUNDING LUG VIEWS ARE INSIDE OF PRINTER AFTER BACK PANEL HAS BEEN REMOVED SATO M-8485Se Standard Print Engine PN 9001080 Page 6-9 Rev. A Service Manual...

- Page 123 Replacing the Main Circuit Board DETACH CONNECTORS DETACH CONNECTORS Figs. 6-11 FLASH CARD MEMORY MODULE REMOVE (2) SCREWS FROM EXT CONNECTOR REMOVE (2) SCREWS Figs. 6-12 REMOVE SCREW Page 6-10 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 124 TO RELEASE THE MEMORY PCB. STANDARD MEMORY PCB IN THE MAIN PCB MEMORY FRAME PRESS OUTWARD INDEXING NOTCHES PRESS OUTWARD Figs. 6-13 FLASH MEMORY MODULE NO NOTCH ON THIS SIDE SATO M-8485Se Standard Print Engine PN 9001080 Page 6-11 Rev. A Service Manual...

- Page 125 MODULE INTO THE MAIN PCB MEMORY FRAME AT APPROXIMATELY 45 . NOTE THE INDEXING NOTCH ON THE MODULE. GENTLY PUSH DOWN TO SNAP INTO POSITION Figs. 6-14 Page 6-12 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 126 6.5 Replacing the Service Board STEP PROCEDURE .ig. 6-15 .ig. 6-16 DETACH CONNECTOR REMOVE (5) SCREWS TO DETACH BACK PANEL REMOVE (4) SCREWS TO DETACH Fig. 6-15 SERVICE BOARD Figs. 6-16 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-13 Rev. A Service Manual...

- Page 127 .ig. 6-17 .ig. 6-18 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-17 REMOVE (4) MOUNTING SCREWS DETACH (2) CONNECTORS Figs. 6-18 LCD DISPLAY GROUND WIRE PANEL Page 6-14 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 128: Remove (2) Screws

.ig. 6-19 .ig. 6-20 .ig. 6-21 INSERT A NARROW PROBE INTO COVER SLOTS FOR EASE IN REMOVAL REMOVE (2) SCREWS Fig. 6-19 Fig. 6-20 DETACH CONNECTION Fig. 6-21 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-15 Rev. A Service Manual... - Page 129 Section 6. Replacement Procedures 6.8 Replacing the Stepper Motor STEP PROCEDURE .ig. 6-22 .igs. 6-23 .ig. 6-24 & 6-25 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-22 Page 6-16 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 130 Replacing the Stepper Motor REMOVE (2) MOTOR MOUNTING SCREWS Figs. 6-23 DETACH CABLE FROM CABLE HOLDER Fig. 6-24 DISCONNECT THE CABLE CONNECTOR FROM THE MAIN PCB BOARD Fig. 6-25 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-17 Rev. A Service Manual...

- Page 131 REAR PLATEN ROLLER - TWO LEVEL GEAR BELT “A” FRONT PLATEN ROLLER MOTOR IDLER PULLEY REAR PLATEN FEED ROLLER - TWO “A” ROLLER LEVEL GEAR Fig. 6-27 Page 6-18 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 132 FROM IDLER GEAR “B” BRACKET THREE LEVEL IDLER GEAR “B” RIBBON ROLLER GEAR IDLER PULLEY “C” BELT “B” MOTOR REAR PLATEN Fig. 6-29 ROLLER - TWO LEVEL GEAR SATO M-8485Se Standard Print Engine PN 9001080 Page 6-19 Rev. A Service Manual...

- Page 133 Section 6. Replacement Procedures Replacing the Timing Belts STEP PROCEDURE Refer to all .igs. in this section before replacing belts. Page 6-20 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 134 IDLER PULLEY “C”- LOOSEN (2) SCREWS TO REMOVE BELT “B” IDLER PULLEY “A” BRACKET REMOVE MOTOR REMOVE SCREW FROM REFER TO SECTION 6-8 MECHANICAL SIDE OF PRINTER Figs. 6-30 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-21 Rev. A Service Manual...

- Page 135 REMOVE CENTER SCREW REMOVE (2) SCREWS FROM IDLER GEAR BRACKET “B” RIBBON REWIND SPINDLE USE WRENCH TO PREVENT SHAFT FROM SLIPPING WHEN REMOVING BELT “C” 6-31 Figs. Page 6-22 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 136 6.10 Replacing the Ribbon Drive Clutch Washers STEP PROCEDURE .ig. 6-31 .igs. 6-32 REMOVE LOCKING SCREW AND SWING CABINET OPEN Figs. 6-31 ITEM NO. DESCRIPTION QTY EA ASSY SATO M-8485Se Standard Print Engine PN 9001080 Page 6-23 Rev. A Service Manual...

-

Page 137: Rewind Spindle

Section 6. Replacement Procedures Replacing the Ribbon Drive Clutch Washers UNWIND SPINDLE TEETH MUST REF. FACE ITEM 10 B REWIND SPINDLE A UNWIND SPINDLE COMPONENTS ARE SHOWN ASSEMBLED Figs. 6-32 Page 6-24 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual... - Page 138 PROCEDURE NOTE: Do not over-tighten the adjustment nut since this screw is used to adjust the clutch tension. Adjust the clutch tension as outlined in Section 5-2. SATO M-8485Se Standard Print Engine PN 9001080 Page 6-25 Rev. A Service Manual...

- Page 139 6.11 Replacing the Ribbon Motion Sensor STEP PROCEDURE .ig. 6-33 .ig. 6-34 .ig. 6-34 .ig. 6-35 & 6-36 .ig. 6-34 .ig. 6-37 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-33 Page 6-26 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 140 SENSOR HARNESS CONNECTOR TO PCB BOARD (2) SCREWS ATTACHING RIBBON MOTION SENSOR TO BRACKET CONNECTOR FROM RIBBON MOTION SENSOR INTO SENSOR HARNESS MARKED “SEN4” Figs. 6-36 Fig. 6-37 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-27 Rev. A Service Manual...

- Page 141 6.12 Replacing the Cover Open Switch STEP PROCEDURE .ig. 6-38 .ig. 6-39 & 6-40 .ig. 6-41 & 6-42 .ig. 6-43 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-38 Page 6-28 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 142 6-42 CONNECTOR TO PCB BOARD REMOVE (2) SCREWS TO DETACH SWITCH FROM CABINET CONNECTOR FROM COVER OPEN SWITCH INTO SENSOR HARNESS MARKED “SEN6” Figs. 6-40 Fig. 6-43 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-29 Rev. A Service Manual...

- Page 143 Section 6. Replacement Procedures 6.13 Replacing the Head Open Switch STEP PROCEDURE .ig. 6-44 .ig. 6-45 .ig. 6-46 & 6-47 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-44 Page 6-30 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 144 SENSOR HARNESS @ (CN9) CONNECTOR FOR SEN4, SEN5, SEN6 & SEN7 SENSOR HARNESS CONNECTOR TO PCB BOARD CONNECTOR FROM HEAD OPEN SWITCH INTO SENSOR HARNESS MARKED “SEN5” Figs. 6-47 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-31 Rev. A Service Manual...

- Page 145 .ig. 6-51, 6-52 & 6-53 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-48 PLACE SIDE OF CABINET Fig. 6-49 DOWN ON FLAT SURFACE TO EXPOSE BOTTOM Page 6-32 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 146 OPEN BUNDLE TIE SENSOR HARNESS MARKED “SEN1” LABEL GAP Figs. 6-52 SENSOR (BOTTOM 1/2) SEN1 CABLE Fig. 6-53 SENSOR HARNESS @ (CN8) CONNECTOR FOR SEN1, & SEN2 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-33 Rev. A Service Manual...

- Page 147 6.15 Replacing the Label Gap Sensor Board (Top 1/2) STEP PROCEDURE .ig. 6-54 .igs. 6-55 .igs. 6-56 .ig. 6-57 .ig. 6-58 .ig. 6-59 REMOVE LOCKING SCREW AND SWING CABINET OPEN Fig. 6-54 Page 6-34 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 148 DRIVER THROUGH SPACE AND REMOVE (2) SCREWS TO DETACH SENSOR ASSY Figs. 6-56 USE ALLEN WRENCH AND REMOVE TO SCREWS TO DETACH SENSOR MODULE FROM BRACKET Fig. 6-57 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-35 Rev. A Service Manual...

- Page 149 Replacing the Label Gap Sensor Board (Top 1/2) UNSNAP CABLE HOLDER AND DETACH SENSOR CABLE Fig. 6-58 Figs. 6-59 UNPLUG SENSOR CONNECTOR FROM SENSOR HARNESS MARKED “SEN2” AND PULL THROUGH ACCESS HOLE Page 6-36 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 150 STEP PROCEDURE .igs. 6-60 .ig.6-61 .ig. 6-61 .igs. 6-62 .ig. 6-63 .ig. 6-64 .ig. 6-65 .ig. 6-66 .ig. 6-67 .igs 6-67 & 6-68 .igs. 6-68 .igs. 6-69 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-37 Rev. A Service Manual...

- Page 151 THE UNDERSIDE OF THE PRINTER PEEL BAR UNLATCH HEAD PLATEN ROLLER LOCK LEVER NIP ROLLER ASSEMBLY RELEASE THE NIP ROLLER Fig. 6-61 LATCH AND SWING OPEN THE NIP ROLLER ASSEMBLY Page 6-38 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 152 Fig. 6-63 SCREWS ATTACHING BRACKET TO PLATEN FRAME PRY OFF COVER AND REMOVE ALLEN SCREW UNDER COVER Fig. 6-64 USE AN OPEN END WRENCH AND REMOVE PIN SATO M-8485Se Standard Print Engine PN 9001080 Page 6-39 Rev. A Service Manual...

- Page 153 6-66 LOOSEN (2) MOTOR PLATEN ROLLER MOUNTING SCREWS TO FREE BELTS FROM PLATEN AND FEED CAREFULLY SEPARATE ROLLERS CRADLE FRAME FROM THE CHASSIS “E” CLIPS Fig. 6-67 Page 6-40 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 154 GEARS ON PLATEN COLLAR PLATEN SCREW “E” CLIP POSITION COLLAR AGAINST BUSHING AND TIGHTEN SCREW AFTER INSTALLATION POSITION COLLAR BUSHING AGAINST BUSHING AND TIGHTEN SCREW AFTER INSTALLATION Figs. 6-69 SATO M-8485Se Standard Print Engine PN 9001080 Page 6-41 Rev. A Service Manual...

- Page 155 .igs. 6-71 .igs. 6-71 .ig. 6-72 .ig. 6-73 .ig. 6-74 .igs. 6-75 .ig. 6-76 .ig. 6-77 .ig. 6-78 REMOVE LOCKING SCREW AND SWING THE CABINET OPEN Fig. 6-70 Page 6-42 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 156 Figs. 6-73 MOVE BRACKET SLIGHTLY OUT OF POSITION AT THE SAME TIME HOLDING DOWN THE NIP ROLLER LATCH FOR ACCESS TO THE SCREW ON THE COVER PLATE SATO M-8485Se Standard Print Engine PN 9001080 Page 6-43 Rev. A Service Manual...

- Page 157 DETACH SENSOR MODULE FROM FRAME UNSNAP THE CABLE HOLDER AND DETACH THE SENSOR CABLE Fig. 6-76 UNPLUG SENSOR CABLE Fig. 6-78 FROM SENSOR HARNESS Fig. 6-77 MARKED “SEN7” Page 6-44 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

- Page 158 Caution: Do not remove or loosen the two screws on either side of the center screw. .ig. 6-81 Caution: Head is very fragile and can be easily scratched so handle carefully. SATO M-8485Se Standard Print Engine PN 9001080 Page 6-45 Rev. A...

- Page 159 REMOVE (2) SCREWS AND DETACH RIBBON ADJUST DATA CABLE PLATE POWER CABLE RECESS Fig. 6-80 ALIGNMENT PINS PRINT HEAD DO NOT REMOVE OR Fig. 6-81 LOOSEN THESE TWO SCREWS Page 6-46 SATO M-8485Se Standard Print Engine PN 9001080 Rev. A Service Manual...

-

Page 160: Factory Resets

Section Factory Resets 7.1 Overview • Factory Settings/Test Print • Clear Head Counters • Clear Dispenser Counter • Clear Cutter Counter • Clear EEPROM PN 9001080 SATO M-8485Se Standard Print Engine Page 7-1 Rev. A Service Manual... -

Page 161: Counter Clear

.EED counter clear none LINE NONE counter clear .EED print size small large Warning: test print press feed key SATO M-8485Se Standard Print Engine Page 7-2 PN 9001080 Rev. A Service Manual... - Page 162 The Head Counter will be cleared by the following steps: .EED counter clear none LINE NONE HEAD counter clear head .EED print size small large Warning: test print press feed key PN 9001080 SATO M-8485Se Standard Print Engine Page 7-3 Rev. A Service Manual...

- Page 163 .EED counter clear none LINE NONE counter clear .EED print size small large Warning: test print press feed key SATO M-8485Se Standard Print Engine Page 7-4 PN 9001080 Rev. A Service Manual...

- Page 164 .EED counter clear none LINE NONE counter clear .EED print size small large Warning: test print press feed key PN 9001080 SATO M-8485Se Standard Print Engine Page 7-5 Rev. A Service Manual...

- Page 165 LINE all clear mode .EED all clear counter eeprom .EED counter all clear LINE .EED all clear mode counter all clear completed SATO M-8485Se Standard Print Engine Page 7-6 PN 9001080 Rev. A Service Manual...

-

Page 166: Sample Test Prints

Section 7. Factory Resets 7.7 Sample Test Prints LARGE TEST PRINT SMALL TEST PRINT ILLUSTRATIONS SHOWN ARE EXAMPLES ONLY AND MAY NOT EXACTLY MATCH YOUR OUTPUT PN 9001080 SATO M-8485Se Standard Print Engine Page 7-7 Rev. A Service Manual... -

Page 167: Troubleshooting

• Initial Checklist • IEEE1284 Parallel Interface • RS232C Serial Interface • Universal Serial Bus Interface • LAN Ethernet Interface • Error Signals • Troubleshooting Tables • Head Pattern Examples Rev. A Page 8-1 SATO M-8485Se Standard Print Engine Service Manual... -

Page 168: Initial Check List

WARNING: Never connect or disconnect interface cables (or use a switch box) with power applied to either the printer or the host. This may cause damage to the interface circuitry and is not covered by warranty. Page 8-2 Rev. A SATO M-8485Se Standard Print Engine Service Manual... - Page 169 Section 8. Troubleshooting The IEEE1284 Parallel Interface (Cont) SATO M-8485Se Standard Print Engine Page 8-3 Rev. A Service Manual...

-

Page 170: The Rs232C (Serial) Interface

Warning: Never connect or disconnect interface cables (or use a switch box) with power applied to either the printer or the host. This may cause damage to the interface circuitry and is not covered by warranty. 8.5 The Universal Serial BUS (USB) Page 8-4 Rev. A SATO M-8485Se Standard Print Engine Service Manual... - Page 171 Section 8. Troubleshooting 8.6 The LAN Ethernet Interface Section 2 Configuration for information on how to run the self test SATO M-8485Se Standard Print Engine Page 8-5 Rev. A Service Manual...

- Page 172 Section 8. Troubleshooting The LAN Ethernet Interface (Cont) Note that it is always a good idea to try creating another print queue to eliminate the possibility of setup errors Page 8-6 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 173 Section 8. Troubleshooting The LAN Ethernet Interface (Cont) printer printer printer printer servicename SATO M-8485Se Standard Print Engine Page 8-7 Rev. A Service Manual...

- Page 174 Section 8. Troubleshooting The LAN Ethernet Interface (Cont) servername Page 8-8 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 175 Section 8. Troubleshooting The LAN Ethernet Interface (Cont) SATO M-8485Se Standard Print Engine Page 8-9 Rev. A Service Manual...

-

Page 176: Error Signals

Page 8-10 Rev. A SATO M-8485Se Standard Print Engine Service Manual... -

Page 177: Troubleshooting Tables

SATO M-8485Se Standard Print Engine Page 8-11 Rev. A Service Manual... - Page 178 / t s t l e t l o t i u Page 8-12 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 179 . y l y f i t n i t e l i t c i t c i t c t i s y l t t i s SATO M-8485Se Standard Print Engine Page 8-13 Rev. A Service Manual...

- Page 180 Section 8. Troubleshooting Print Quality Problems & u f l g i l g i l Page 8-14 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 181 POOR HEAD POOR HEAD ALIGNMENT, BALANCE ALIGNMENT, BALANCE OUT OF ADJUSTMENT OUT OF ADJUSTMENT IRREGULAR UNEVEN TEXT ILLUSTRATIONS SHOWN ARE EXAMPLES ONLY AND WILL NOT EXACTLY MATCH YOUR OUTPUT SATO M-8485Se Standard Print Engine Page 8-15 Rev. A Service Manual...

-

Page 182: Head Pattern Examples

POOR HEAD ALIGNMENT, POOR RIBBON TENSION, WORN PLATEN, FOREIGN MATERIAL, DAMAGED PRINT HEAD IMPROPER ALIGNMENT BOTTOM EDGE OF BAR CODE IS SHOWN NOT PARALLEL WITH EDGE OF LABEL FEED DIRECTION Page 8-16 Rev. A SATO M-8485Se Standard Print Engine Service Manual... -

Page 183: Hex Dump Diagnostic Labels

Section 8. Troubleshooting 8.10 Hex Dump Diagnostic Labels Print Buffer Hex Dump STEP PROCEDURE Receive Buffer Hex Dump STEP PROCEDURE SATO M-8485Se Standard Print Engine Page 8-17 Rev. A Service Manual... -

Page 184: Optional Accessories

Section Optional Accessories 9.1 Overview • Memory PC Board for PCMCIA Memory Cards • Flash Memory Module • Face Out Label Sensor (Factory Installed Option) Rev. A Page 9-1 SATO M-8485Se Standard Print Engine Service Manual... -

Page 185: Section 9. Options

ON MAIN PC BOARD SLOT FOR MEMORY CARD STANDOFFS SHOWN AS RECEIVED. TOP SCREWS MUST BE REMOVED FOR FASTENING TO MAIN PC BOARD OPPOSITE SIDE SHOWN MEMORY PC BOARD Page 9-2 Rev. A SATO M-8485Se Standard Print Engine Service Manual... - Page 186 9.3 Memory PC Board Installation Continue here after you have removed the Main PC Board from your printer. STEP PROCEDURE .ig. 9-1 .ig. 9-1 .ig. 9-2 .ig. 9-3 .ig. 9-3 .ig. 9-3 SATO M-8485Se Standard Print Engine Page 9-3 Rev. A Service Manual...

- Page 187 REMOVE (2) SCREWS AND WASHERS FROM THIS END OF STANDOFFS (STEP 2) CONNECTOR TO HOLES FOR MEMORY BOARD MOUNTING Fig. MAIN PC BOARD SHOWING WHERE THE MEMORY BOARD WILL BE INSTALLED Page 9-4 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 188 MEMORY PC BOARD MAIN PC INSURE STANDOFFS BOARD ARE BETWEEN MAIN PCB AND MEMORY CARD Fig. SECURE FROM UNDERSIDE OF MAIN PC BOARD WITH (2) SCREWS AND WASHERS PREVIOUSLY REMOVED. SATO M-8485Se Standard Print Engine Page 9-5 Rev. A Service Manual...

- Page 189 Section 9. Options 9.4 Flash Memory Module Installation STEP PROCEDURE .ig. 9-4 .ig. 9-5 .igs. 9-6 .igs. 9-6 & 9-7 Page 9-6 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 190 DETACH BACK PANEL Fig. REMOVE LOCKING SCREW AND SWING CABINET OPEN REACH INSIDE CABINET AND DETACH STANDARD MEMORY PCB FROM THE MAIN PCB Fig. MEMORY FRAME. SEE FIGS. 3 SATO M-8485Se Standard Print Engine Page 9-7 Rev. A Service Manual...

- Page 191 TO RELEASE THE MEMORY PCB. STANDARD MEMORY PCB IN THE MAIN PCB MEMORY FRAME PRESS OUTWARD INDEXING NOTCHES PRESS OUTWARD Figs. FLASH MEMORY MODULE NO NOTCH ON THIS SIDE Page 9-8 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

- Page 192 INDEXING NOTCH ON THE MODULE. GENTLY PUSH DOWN TO SNAP INTO POSITION Figs. 9.5 Face-Out Label Sensor Factory installed option. Top-mounted sensor for reflective "Eye-Marks" printed on the face of the label. SATO M-8485Se Standard Print Engine Page 9-9 Rev. A Service Manual...

- Page 193 LINE and .EED initializing maintenance mode rom v00.00.00.00 dipsw2-4 on->off factory mode .EED counter clear none LINE NONE counter clear .EED print size small large Warning: test print press feed key Page 9-10 Rev. A SATO M-8485Se Standard Print Engine Service Manual...

-

Page 194: Spare Parts List

• Pressure Roller Assembly • Cover Assembly • Main PCB Assembly • Check PCB Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-1 Rev. -

Page 195: Section 10. Parts List

Section 10. Parts List 10.2 Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-2 PN 9001080 Rev. A Service Manual... - Page 196 Section 10. Parts List Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-3 Rev. A Service Manual...

- Page 197 Section 10. Parts List Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-4 PN 9001080 Rev. A Service Manual...

- Page 198 Section 10. Parts List Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-5 Rev. A Service Manual...

- Page 199 Section 10. Parts List Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-6 PN 9001080 Rev. A Service Manual...

- Page 200 Section 10. Parts List Frame Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-7 Rev. A Service Manual...

-

Page 201: Print Head Assembly

Section 10. Parts List 10.3 Print Head Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-8 PN 9001080 Rev. A Service Manual... - Page 202 Section 10. Parts List Print Head Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-9 Rev. A Service Manual...

- Page 203 Section 10. Parts List Print Head Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-10 PN 9001080 Rev. A Service Manual...

- Page 204 Section 10. Parts List Print Head Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-11 Rev. A Service Manual...

-

Page 205: Ribbon Assembly

Section 10. Parts List 10.4 Ribbon Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-12 PN 9001080 Rev. A Service Manual... - Page 206 Section 10. Parts List Ribbon Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-13 Rev. A Service Manual...

- Page 207 Section 10. Parts List Ribbon Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-14 PN 9001080 Rev. A Service Manual...

-

Page 208: Feed Roller Assembly

Section 10. Parts List 10.5 Feed Roller Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-15 Rev. A Service Manual... - Page 209 Section 10. Parts List Feed Roller Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-16 PN 9001080 Rev. A Service Manual...

- Page 210 Section 10. Parts List Feed Roller Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-17 Rev. A Service Manual...

-

Page 211: Pressure Roller Assembly

Section 10. Parts List 10.6 Pressure Roller Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-18 PN 9001080 Rev. A Service Manual... -

Page 212: Cover Assembly

Section 10. Parts List 10.7 Cover Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-19 Rev. A Service Manual... - Page 213 Section 10. Parts List Cover Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-20 PN 9001080 Rev. A Service Manual...

- Page 214 Section 10. Parts List Cover Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-21 Rev. A Service Manual...

-

Page 215: Main Pcb Assembly

Section 10. Parts List 10.8 Main PCB Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. SATO M-8485Se Standard Print Engine Page 10-22 PN 9001080 Rev. A Service Manual... -

Page 216: Check Pcb Assembly

Section 10. Parts List 10.9 Check PCB Assembly WARNING! Refer to SATO AMERICA'S Web site at www.satoamerica.com for the most current data for the Spare Parts List. PN 9001080 SATO M-8485Se Standard Print Engine Page 10-23 Rev. A Service Manual...

Need help?

Do you have a question about the M-8485Se and is the answer not in the manual?

Questions and answers