Fronius Primo GEN24 10.0 Plus Operating Instructions Manual

Hide thumbs

Also See for Primo GEN24 10.0 Plus:

- Operating instructions manual (196 pages) ,

- Quick start manual (12 pages)

Summary of Contents for Fronius Primo GEN24 10.0 Plus

- Page 1 Operating Instructions Fronius Primo GEN24 8.0 Plus / 10.0 Plus Operating Instructions 42,0426,0419,EN 019-06112023...

-

Page 3: Table Of Contents

Environmental conditions Qualified personnel Noise emission values EMC measures Backup power Data protection Copyright Protective earthing (PE) General information Fronius Primo GEN24 Device concept Function overview Fronius UP Scope of supply Intended use Thermal concept Fronius Solar.web Local communication The various operating modes Operating modes –... - Page 4 Connection area Connection area divider Ground electrode terminal DC disconnector Data communication area Button functions and LED status indicator Internal schematic connection diagram of the IOs Backup power variant - PV Point (OP) General PV Point (OP) Explanation - PV Point (OP) Backup power variant - Full Backup General Prerequisites for backup power mode...

- Page 5 Maximum alternating current fuse protection Connecting the inverter to the public grid (AC side) Safety Connecting the inverter to the public grid (AC side) Connecting solar module strings to the inverter General comments regarding PV modules Safety Module array - general information Module array configuration 8 ‑...

- Page 6 Components for automatic Full Backup backup power changeover Components for manual Full Backup backup power changeover Status codes and remedy Display Status Codes Technical data Fronius Primo GEN24 8.0 / 8.0 Plus Fronius Primo GEN24 10.0 / 10.0 Plus WLAN...

- Page 7 Circuit diagrams Fronius Primo GEN24 and BYD Battery-Box Premium HV Circuit Diagram Fronius Primo GEN24 with two BYD Battery-Box Premium HV connected in parallel Circuit Diagram Fronius Primo GEN24 with three BYD Battery-Box Premium HV connected in parallel Circuit Diagram...

-

Page 8: Safety Rules

Safety rules Explanation of WARNING! safety notices Indicates a potentially hazardous situation. ▶ Death or serious injury may result if appropriate precautions are not taken. CAUTION! Indicates a situation where damage could occur. ▶ If not avoided, minor injury and/or damage to property may result. NOTE! Indicates a risk of flawed results and possible damage to the equipment. -

Page 9: Environmental Conditions

All safety and danger notices on the device: Must be kept in a legible state Must not be damaged Must not be removed Must not be covered, pasted or painted over Only operate the device when all protection devices are fully functional. If the protection devices are not fully functional, there is a risk of: Serious or fatal injury to the operator or third parties Damage to the device and other material assets belonging to the operating... -

Page 10: Emc Measures

Where an automatic backup power supply is installed, a notice (https://www.fronius.com/en/search-page, item number: 42,0409,0275) must be fitted on the electrical distributor. Maintenance and installation work in the home network requires both disconnec- tion on the utility side and deactivation of the replacement power mode by open- ing the integrated DC disconnector on the inverter. -

Page 11: Data Protection

voltage. The simultaneous operation of electronic devices in the same backup power supply system should be avoided. IMPORTANT! The inverter may only be operated within the limits of its technical capabilities. Operation outside of its technical capabilities can cause the inverter to shut down. -

Page 13: General Information

General information... -

Page 15: Fronius Primo Gen24

Backup power variant - PV Point (OP) Available as an op- Battery connection* tion** Available as an op- Backup power variant - Full Backup tion** For suitable batteries, see chapter Suitable batteries. The functions are optionally available via Fronius UP (see chapter Fronius UP). -

Page 16: Fronius Up

Fronius UP With Fronius UP*, the inverter can be expanded by the authorised specialist to Function overview). include optionally available functions (see chapter The availability of Fronius UP varies from country to country. For more in- formation on Fronius UP and availability, see Installation guide: Fronius GEN24 &... -

Page 17: Thermal Concept

The Fronius GEN24 inverter is a grid-connected inverter with a backup power function – it is not a stand-alone inverter. The following restrictions must there- fore be observed in backup power mode: Backup power mode may be in operation for at max. 2000 hours... -

Page 18: Local Communication

Fronius recommends testing the Internet connection on site according to the minimum requirements. Local commu- The inverter can be found via the Multicast DNS protocol (mDNS). It is recom- nication mended to search for the inverter by the assigned host name. -

Page 19: The Various Operating Modes

Fronius GEN24 inverter converts direct current into alternating current and charges the bat- tery (battery charging is only possible with Fronius GEN24 Plus invert- ers). The integrated system monitoring enables the inverter to be in- tegrated into a network by means of WLAN. -

Page 20: Operating Mode - Inverter With Battery

Operating mode In order to be able to obtain the highest rate of self-consumption with your PV – Inverter with system, a battery can be used to store excess energy. The battery is coupled to battery the inverter on the direct current side. Multiple current conversion is therefore not required, and the efficiency is increased. -

Page 21: Operating Mode - Inverter With Battery And Backup Power Function

0 0 1 Operating mode IMPORTANT! – Inverter with In the fully equipped hybrid PV system with a Fronius Ohmpilot, the Ohmpilot battery, Ohmpi- cannot be operated in the event of a power failure for regulatory reasons. It is lot and backup therefore sensible to install the Ohmpilot outside of the backup power branch. -

Page 22: Energy Flow Direction Of The Inverter

0 0 1 Energy flow dir- In the case of hybrid inverters, there are four different energy flow directions: ection of the in- verter PV module – inverter – load/grid PV module – inverter – battery* Battery – inverter – load/grid* Grid –... - Page 23 Operating state Description Min. state of charge (SOC) Battery has reached the minimum SOC set or achieved specified by the manufacturer. The battery cannot be discharged any further. Energy saving mode The system has been put into energy saving mode. (standby) Energy saving mode is automatically ended as soon as sufficient excess energy is available again.

-

Page 24: Energy Saving Mode

Both the inverter and the battery automatically switch to energy sav- ing mode under certain conditions. The inverter switches to energy saving mode if the battery is flat and no PV power is available. Only the inverter's communication with the Fronius Smart Meter and Fronius Solar.web is maintained. Switch-off con-... -

Page 25: Indication Of Energy Saving Mode

Indication of en- During energy saving mode: ergy saving Operating LED for the inverter lights up orange (see Button functions and mode LED status indicator on page 35). The user interface of the inverter can be reached. All the available data is saved and transmitted to Solar.web. The real-time data can be seen on Solar.web. -

Page 26: Suitable Batteries

Fronius explicitly points out that the third-party batteries are not Fronius products. Fronius is not the manufacturer, distributor or retailer of these batter- ies. Fronius accepts no liability and offers no service or guarantees for these bat- teries. Obsolete firmware/software states may lead to incompatibilities between the in- verter and the battery. -

Page 27: Lg Resu Flex

BYD Battery-Box Premium HVM 11.0 13.8 16.6 19.3 22.1 Fronius Primo GEN24 8.0 - 10.0 Plus Number of battery modules Battery parallel operation** Battery support optionally available. Max. 3 batteries with the same capacity can be combined. IMPORTANT! According to the manufacturer's specifications, the max. DC cable length is 20 m. - Page 28 LG RESU FLEX 12.9 17.2 Fronius Primo GEN24 8.0 - 10.0 Plus Number of battery modules Battery support optionally available. IMPORTANT! According to the manufacturer's specifications, the max. DC cable length is 30 m. More detailed information can be found in the manufacturer's documents.

-

Page 29: Manual System Start

Manual system start Requirements There is no energy available from the PV modules or from the public grid. If backup power operation or battery operation are not possible (e.g. deep dis- charge protection of the battery), the inverter and battery switch off. Notification of Status codes about the inactive state of the battery are displayed on the user in- system shut-... -

Page 30: Protection Of People And Equipment

▶ Check plug connections are in good condition. ▶ Repair incorrect insulation as appropriate. ▶ Complete connections as per the specifications. IMPORTANT! Fronius will not accept any costs associated with production downtimes, installer... -

Page 31: Safe State

Fronius accepts no liability for damage that can occur despite the presence of the integrated Arc Fault Circuit Interrupter/extinguishing system ( e.g. caused by a parallel arc). -

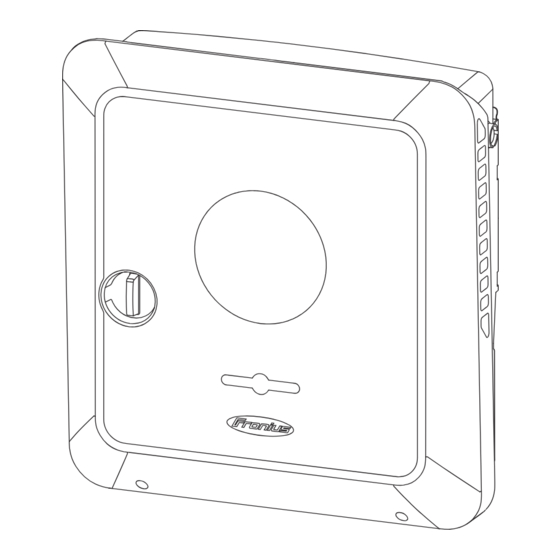

Page 32: Control Elements And Connections

Control elements and connections Connection area 2 x 5-pin DC push-in terminal Push-in WSD (wired shutdown) terminal Push-in terminals in the data communication area (Modbus, digital inputs and outputs) 3-pin push-in terminal for PV Point (OP) 3-pin AC push-in terminal Cable gland/strain-relief device AC 6-pin ground electrode terminal Cable gland/strain-relief device in the data communication area... -

Page 33: Connection Area Divider

Connection area divider (10) 10 x DC cable glands (11) Optional cable gland (M16) (12) Optional cable gland (M16 - M20) (13) Optional cable gland (M16 - M32) (14) Optional cable gland (M16 - M25) Connection area The connection area divider separates the high-voltage conductors (DC and AC) divider from the signal lines. -

Page 34: Dc Disconnector

DC disconnector The DC disconnector has 3 switch set- tings: Locked/off (turned to the left) IMPORTANT! In switch settings (1) and (3), a conven- tional padlock can be used to secure the inverter against being switched on/ off. The national guidelines must be complied with in this respect. -

Page 35: Button Functions And Led Status Indicator

LED status shown via the operating status indicator LED. In the event of faults, carry out the individual steps in the Fronius Solar.start app. The optical sensor is actuated WLAN access point by touching with a finger. 3-6 sec. - Page 36 Sensor functions = WLAN Access Point (AP) is opened. Flashing blue = WLAN Protected Setup (WPS) is activated. Flashing green 3 seconds (max. 6 seconds) = the service message is terminated. Lights up yellow LED status indicator The inverter is operating correctly. Lights up green The inverter starts.

-

Page 37: Internal Schematic Connection Diagram Of The Ios

LED status indicator The inverter is operating correctly, a network fault is in- dicated. Lights up red The network connection is active. Lights up blue The inverter is performing an update. Flashing blue Internal schem- On the V+/GND pin, it is possible to feed in a voltage of around 12.5–24 V (+ max. atic connection 20%) with an external power supply. -

Page 39: Backup Power Variant - Pv Point (Op)

Backup power variant - PV Point (OP) -

Page 41: General

General PV Point (OP) IMPORTANT! If several backup power variants are available, please note that only one backup power variant may be installed and configured. With the PV Point, in the event of a failure of the public grid, electrical devices can be connected to the Op- portunity Power (OP) terminal and supplied with a maximum power of... -

Page 43: Backup Power Variant - Full Backup

Backup power variant - Full Backup... -

Page 45: General

The inverter is operating in backup power mode. from backup The public grid is functioning correctly again. power mode to The Fronius Smart Meter monitors the grid parameters on the public grid feeding energy and passes this information to the inverter. into the grid The stability of the returned public grid is determined by checking the meas- ured values of the Fronius Smart Meter. -

Page 46: Backup Power And Energy Saving Mode

Backup power Under the following conditions, the battery and the inverter are switched to en- and energy sav- ergy saving mode after a waiting time of 8 - 12 minutes and backup power mode ing mode is ended: The battery is discharged to the minimum state of charge and no energy is coming from the PV modules. -

Page 47: Automatic Switch To Backup Power Including Backup Power Circuits And 1-Pin Separation, E.g

Public grid available again. feeding energy The Fronius Smart Meter monitors the grid parameters on the public grid into the grid and passes this information to the inverter. The stability of the returned public grid is determined by checking the meas- ured values of the Fronius Smart Meter. -

Page 48: Automatic Switch To Backup Power All-Pin Separation, E.g. Germany, France, Uk, Spain

Transitioning The public grid is monitored by the inverter's internal grid and system pro- from feeding en- tection unit and by the Fronius Smart Meter connected to it. ergy into the grid Failure of the public grid. to backup power... -

Page 49: Transitioning From Backup Power Mode To Feeding Energy Into The Grid

Public grid available again. feeding energy The Fronius Smart Meter monitors the grid parameters on the public grid into the grid and passes this information to the inverter. The stability of the returned public grid is determined by checking the meas- ured values of the Fronius Smart Meter. -

Page 50: Automatic Switch To Backup Power All-Pin Separation, Italy

Italy Functions Measuring and transferring the required parameters for energy management and Solar.web by the Fronius Smart Meter. Monitoring of the voltage and frequency grid parameters by the inverter. Disconnecting from the public grid to enable operation in backup power mode if the grid parameters are outside the country-specific standards. -

Page 51: Transitioning From Backup Power Mode To Feeding Energy Into The Grid

Public grid available again. feeding energy The Fronius Smart Meter monitors the grid parameters on the public grid into the grid and passes this information to the inverter. The stability of the returned public grid is determined by checking the meas- ured values of the Fronius Smart Meter. -

Page 52: Functions

0. This causes the inverter to shut down immedi- ately. This behaviour is ensured via 2 contacts. Communication between the inverter and Fronius Smart Meter is optionally interrupted via a contact. The suspended communication prevents automatic termination of backup power mode when the public grid returns, so that the inverter remains in backup power mode until it is manually switched back. -

Page 53: Transitioning From Backup Power Mode To Feeding Energy Into The Grid

The inverter is again connected to the entire home network and to the public grid. Communication between the inverter and Fronius Smart Meter is re-estab- lished. The inverter can start feeding energy into the grid again after performing the... -

Page 55: Installation

Installation... -

Page 57: General

General Quick-lock sys- A quick-lock system (3) is used to mount the connection area cover and front cover. The system is opened and closed with a half-rotation (180°) of the captive screw (1) into the quick- lock spring (2). The system is independent of torque. NOTE! Danger when using a drill driver. - Page 58 A 4-digit number (coded production date) is printed on the rating plate at the very bottom, from which the production date can be calculated. If you subtract the value 11 from the first two digits, you get the production year. The last two digits stand for the calendar week in which the device was produced.

-

Page 59: System Component Compatibility

WARNING! An electric shock can be fatal. Before opening the device, it must be disconnec- ted and de-energized at the input and output. System compon- All installed components in the photovoltaic system must be compatible and ent compatibility have the necessary configuration options. The installed components must not re- strict or negatively influence the functioning of the photovoltaic system. -

Page 60: Installation Location And Position

Installation location and position Choosing the Please note the following criteria when choosing a location for the inverter: location of the inverter Only install on a solid, non-flam- mable surface. ≥ 200 mm ≥ 275 mm ≥ 150 mm (≥ 7.87 inch) (≥... -

Page 61: Choosing The Location Of Third-Party Batteries

The inverter should be installed in a protected location, for ex- ample, below the PV modules or under an overhanging roof. The inverter must not be installed or used at altitudes above 4000 m. 4001 m Do not install the inverter in: Areas where it may be exposed to ammonia, corrosive gases, acids or salts (e.g. -

Page 62: Installation Position Of Inverter

Installation posi- The inverter is suitable for vertical installation on a vertical wall tion of inverter or column. The inverter is suitable for installation on a sloping surface (min. slope to underside 10°). Do not install the inverter on a sloping surface with its connec- tion sockets at the top. - Page 63 Do not install the inverter on the ceiling.

-

Page 64: Install The Mounting Bracket And Hang Up The Inverter

Install the mounting bracket and hang up the in- verter Selecting the fix- Use the corresponding fixing materials depending on the subsurface and observe ing material the screw dimension recommendations for the mounting bracket. The installer is responsible for selecting the correct type of fixing. Properties of the The mounting bracket (illustration) can mounting brack-... -

Page 65: Installing The Mounting Bracket On A Mast Or Beam

Installing the When installing the inverter on a mast mounting brack- or beam, Fronius recommends using et on a mast or the "Pole clamp" (order no. SZ beam 2584.000) mounting kit from Rittal GmbH. The "Pole clamp" kit covers the follow-... -

Page 66: Attaching The Mounting Bracket To Mounting Rails

Attaching the IMPORTANT! mounting brack- The mounting bracket must be affixed et to mounting at a minimum of four points. rails Attaching the in- There are integrated grips on the side verter to the of the inverter which facilitate lifting/ mounting brack- attaching. -

Page 67: Prerequisites For Connecting The Inverter

Prerequisites for connecting the inverter Different cable Fine-stran- Fine-stran- types ded with fer- ded with fer- Fine-stran- Multi-stran- rule and col- rule without Solid collar Permissible Round copper conductors can be connected to the terminals of the inverter as cables for the described below. -

Page 68: Permissible Cables For The Data Communication Connection

0.39 inch AWG 26 - 16 AWG 26 - 16 AWG 26 - 18 AWG 26 - 16 sible LAN connections Fronius recommends at least CAT 5 STP (shielded twisted pair) cables and a maximum distance of 100 m (109 yd). -

Page 69: Cross Section Of The Ac Cable

For this reason, in accordance with national legislation, Fronius re- commends that a residual-current cir- cuit breaker with a tripping current of at least 100 mA suitable for frequency converters be used. - Page 70 Recom- Phase AC out- Maximum mended Inverter fuse rating fuse rating Fronius Primo GEN24 8.0 8000 W C 63 A C 50 A Fronius Primo GEN24 10,000 W C 63 A C 63 A 10.0 kW...

-

Page 71: Connecting The Inverter To The Public Grid (Ac Side)

Connecting the inverter to the public grid (AC side) Safety WARNING! Danger due to incorrect operation and incorrectly performed work. This can result in serious injury and damage to property. ▶ Read the Installation and Operating Instructions before installing and com- missioning the equipment. - Page 72 Turn off the automatic circuit breaker. Make sure that the DC disconnector is in the "Off" switch setting. Loosen the five screws of the connec- tion area cover by rotating them 180° to the left using a screwdriver (TX20). Remove the connection area cover from the device.

- Page 73 Phase conductor Neutral conductor Ground conductor Insert the AC terminal into the AC slot until it engages. Fasten the cap nut of the strain-relief device with a torque of 6 ‑ 7 Nm.

-

Page 74: Connecting Solar Module Strings To The Inverter

Commissioning as well as maintenance and service work in the power module of the inverter must only be carried out by service personnel trained by Fronius and only within the scope of the respective technical regulations. ▶ Read the Installation and Operating Instructions before installing and com- missioning the equipment. -

Page 75: Module Array - General Information

WARNING! Danger due to damaged and/or contaminated terminals. This can result in serious injury and damage to property. ▶ Before making any connections, check the terminals for damage and con- tamination. ▶ Remove contamination in the de-energized state. ▶ Have defective terminals repaired by an authorised specialist. Module array - 2 independent PV inputs (PV 1 and PV 2) are available. -

Page 76: Connecting The Solar Module Strings To The Inverter

Module array settings: PV 1: ON PV 2: ON PV 1 less than or equal to 41.25 A (I SC PV1 ) PV 2 less than or equal to 36 A (I SC PV2 ) Connecting the solar module strings to the in- verter Push the DC cables through the DC bushings by hand. - Page 78 Select the cable cross section in ac- cordance with the instructions in Per- missible cables for the electrical con- nection from page 67. Strip the insulation of the single con- ductors by 12 mm. Lift to open the ter- minal's operating lever and insert the stripped single conductor into the slot provided, in each case as far as it will go.

- Page 79 Use a suitable measuring instrument to check the voltage and polarity of the DC cabling. Remove both DC ter- minals from the slots. CAUTION! Danger due to polarity reversal at the terminals. This may result in severe damage to the inverter. ▶...

-

Page 80: Connecting The Battery To The Inverter

Connecting the battery to the inverter Safety WARNING! Danger due to incorrect operation and incorrectly performed work. This can result in serious injury and damage to property. ▶ Commissioning as well as maintenance and service work on the inverter and battery must only be carried out by service personnel trained by the respect- ive inverter or battery manufacturer and only within the scope of the re- spective technical regulations. - Page 81 Manually push the battery cables through the DC bushings. * The battery ground conductor must be connected externally (e.g. switch BAT+ cabinet). When connecting an LG BAT- RESU FLEX battery, the battery BAT PE ground conductor can be connected in the inverter (see chapter Connecting the LG RESU FLEX ground conductor...

- Page 82 Select the cable cross section in ac- cordance with the instructions in Per- missible cables for the electrical con- nection from page 67. Strip the insulation of the single con- ductors by 12 mm. Lift to open the ter- minal's operating lever and insert the stripped single conductor into the slot provided, in each case as far as it will go.

- Page 83 CAUTION! Risk due to overvoltage when using other slots on the terminal. This may result in damage to the bat- tery and/or the PV modules due to dis- charge. ▶ Only use the slots marked BAT for battery connection. BAT+ BAT- CAUTION! Danger due to polarity reversal at the...

-

Page 84: Connecting The Lg Resu Flex Ground Conductor

Fasten the screws of the cable guide to the housing using a screwdriver (TX20) and a torque of 1.3-1.5 Nm. NOTE! Risk due to overtorque on the strain relief. This may result in damage to the strain-relief device. ▶ Do not use a drill driver. TX 20 1,3 - 1,5 Nm BAT+... -

Page 85: Connecting Backup Power - Pv Point (Op)

In order to ensure the residual-current circuit breaker operates properly, a con- nection must be established between the neutral conductor N´ (OP) and earth. Circuit Diagram - PV For the Circuit Diagram recommended by Fronius, see Point (OP) on page 187. - Page 86 Switch off the automatic circuit break- er and DC disconnector. Make sure that the DC disconnector is in the "Off" switch setting. Loosen the five screws of the connec- tion area cover by rotating them 180° to the left using a screwdriver (TX20). Remove the connection area cover from the device.

- Page 87 Drill out the optional cable guide with a step drill. Insert the strain-relief device into the hole and secure to the torque specified by the manufacturer. Guide the mains cable through the strain-relief device from below. Remove the OP terminal.

- Page 88 Strip the insulation of the single con- ductors by 12 mm. The cable cross section must be between 1.5 mm and 10 mm . Lift to open the terminal's operating lever and insert the stripped single conductor in- to the slot provided, all the way up to the stop.

- Page 89 Insert the OP terminal into the OP slot until it engages. Tighten the cap nut of the strain-relief device to the torque specified by the manufacturer.

-

Page 90: Connecting Backup Power - Full Backup

Connecting backup power - Full Backup Safety WARNING! Danger from incorrect installation, commissioning, operation or incorrect use. This can result in severe personal injury/damage to property. ▶ Only trained and qualified personnel are authorised to install and commis- sion the system, and only within the scope of the technical regulations. ▶... -

Page 91: Automatic Switch To Backup Power 2-Pin Separation, E.g. Germany, France, Uk, Spain

The supply voltage for contactor K1 is provided by the public grid and must be connected to phase 1 (L1) after the Fronius Smart Meter and fused ac- cordingly. An NC contact for relay K3 interrupts the supply voltage to contactor K1. - Page 92 The supply voltage for contactors K1 and K2 is provided by the public grid and must be connected to phase 1 (L1) downstream of the Fronius Smart Meter and fused accordingly.

- Page 93 The protective measure must be tested regularly; if this is not regulated by law, it must be performed annually. Data transfer between the Fronius Smart Meter and the inverter may be in- terrupted in backup power mode (switch position 2). This is optionally en- sured via a contact of the changeover switch.

-

Page 94: Testing Backup Power Mode

For test mode, a battery charge of min. 30 % is recommended. backup power check- A description on how to run test mode can be found in the list (https://www.fronius.com/en/search-page, item number: 42,0426,0365). -

Page 95: Connecting The Data Communication Cable

"Com- munication” → "Modbus" menu, no Modbus participants are possible. It is not possible to send and receive data at the same time. Example 1: Quantity Quantity Fronius Input Battery Primary Secondary Ohmpilot meter meter Example 2: Quantity... -

Page 96: Routing Data Communication Cables

Routing data IMPORTANT! communication If data communication cables are wired into the inverter, observe the following cables points: Depending on the number and cross section of the wired data communica- tion cables, remove the corresponding blanking plugs from the sealing insert and insert the data communication cables. - Page 97 Guide the data cables first through the strain-relief device cap nut and then through the housing opening. Insert the sealing ring between the cap nut and the housing opening. Press the data cables into the seal's cable guide. Then press in the seal until it reaches the underside of the strain-relief device.

-

Page 98: Connecting The Battery Communication Cable

"SHIELD" slot. IMPORTANT! Improperly fitted shielding can cause data communication problems. For the wiring proposal recommended by Fronius, see page 183. Terminating res- It may be possible for the system to function without terminating resistors. istors However, owing to interference, the use of terminating resistors according to the following overview is recommended for trouble-free functioning. - Page 99 OPTION 1 Modbus 1 Modbus 0 Manufacturer manual Manufacturer manual 0 0 1 Modbus 0 / 1 Modbus 0 / 1 (min. CAT 5) (min. CAT 5) OPTION 2 M0 / M1 Manufacturer manual Manufacturer manual 0 0 1 Modbus 0 / 1 Modbus 0 / 1 (min.

-

Page 100: Installing The Wsd (Wired Shutdown)

Installing the IMPORTANT! WSD (wired The push-in WSD terminal in the in- shutdown) verter's connection area is delivered with a bypass ex works as standard. The bypass must be removed when in- stalling a trigger device or a WSD chain. The WSD switch of the first inverter with connected trigger device in the WSD chain must be in position 1 (primary device). -

Page 101: Closing And Commissioning The Inverter

Closing and commissioning the inverter Closing the in- NOTE! verter's connec- The housing cover is fitted with a lock for safety reasons, which allows the hous- tion area/hous- ing cover on the inverter to be pivoted only when the DC disconnector is ing cover, and commissioning switched off. -

Page 102: Installation With The App

/ Technical Support team. Installation with The "Fronius Solar.start" app is needed for this installation method. Depending the app on the end device with which the installation will be carried out, download the app for the respective platform. - Page 103 In the browser address bar, enter and confirm the IP address 192.168.250.181. The installation wizard is opened. Follow the installation wizard in the individual sections and complete the in- stallation. Add system components in Solar.web and start up the PV system. The network wizard and the product setup can be carried out independently of each other.

-

Page 104: Switching Off Current Supply And Restarting The Inverter

Switching off current supply and restarting the inverter De-energising Turn off the automatic circuit the inverter and breaker. switching it on Turn the DC disconnector to the again "Off" switch position. To start up the inverter again, follow the steps listed above in reverse order. -

Page 105: Settings - User Interface Of The Inverter

Settings - user interface of the in- verter... -

Page 107: User Settings

User settings User login Open the user interface of the inverter in your browser. In the "Login" menu, log in using your user name and password, or go to the "User" menu and click on the "User login" button and then log in with your user name and password. -

Page 108: Device Configuration

Primary meter To ensure smooth operation in conjunction with other energy producers and in Full Backup backup power mode, it is important to install the Fronius Smart Meter at the feed-in point. The inverter and other producers must be connected to the public grid via the Fronius Smart Meter. -

Page 109: Functions Andi/Os

Functions and Backup power I/Os "Off", "PV Point" or "Full Backup" can be selected for backup power mode. ”Full Backup” backup power mode can only be activated once the required I/O assignments have been configured for backup power. In addition, a meter must “Full Backup”... -

Page 110: Demand Response Modes (Drm)

Mode Description Information DRM pin DRM5 Export P ≤ 0% currently not supported DRM 1/5 without disconnec- tion from the grid DRM6 Export P ≤ 50% currently not supported DRM 2/6 DRM7 Export P ≤ 75% & currently not supported DRM 3/7 * ≥... - Page 111 Nevertheless, false alarms can be triggered for the type A residual-current cir- cuit breaker in individual cases and depending on local conditions. For this reas- on, in accordance with national legislation, Fronius recommends that a residual- current circuit breaker with a tripping current of at least 100 mA suitable for fre- quency converters be used.

- Page 112 Parameter Value range Description "Iso Alternative Accurate Isolation monitoring is performed with the Mode" highest accuracy and the measured insula- tion resistance is displayed on the user in- terface of the inverter. Fast Isolation monitoring is performed with lower accuracy, which shortens the dura- tion of the isolation measurement, and the isolation value is not displayed on the user interface of the inverter.

-

Page 113: Energy Management

.This means that energy can be drawn from the home network and fed into the battery via the Fronius GEN24 Plus inverter. You can restrict how much power is consumed by the Fronius GEN24 Plus inverter by specifying the maximum AC power (AC max.). -

Page 114: Examples - Time-Dependent Battery Control

The following values can be selected for the rules of the time-dependent battery control: "Max. charging power" The battery is charged to the maximum level with the value set in the "Power" input field. If no feed-in to the public grid and/or direct consumption in the house is possible, the set "Max. - Page 115 Example: Battery system without photovoltaics, including second producer in the house Power into the battery 1500 W Power consumption (AC) of the inverter 1500 W Second producer in home network 2000 W Target value set at feed-in point Infeed into the public grid Consumption in home 500 W 2000 W...

-

Page 116: Allowed Battery Control Rules

Example: Battery system including second producer in the house (with AC max. limitation) PV system available power 1000 W Power into the battery 2000 W Power consumption AC max. limited to 1000 W Power consumption (AC) of the inverter 1000 W Second producer in home network 2000 W Target value set at feed-in point... - Page 117 Specifying the charging range It is possible to define a charging range with a min. and max. charging limit. In this case, it is not possible for the battery to discharge. Limit Min. charging Max. charging Limit discharge power power 500 W power 3800 W charging power Min.

-

Page 118: Pv Power Reduction

IMPORTANT! If there is a Fronius Wattpilot in the photovoltaic system, it is seen as a load. The priority for the load management of the Wattpilot must be configured in the Fronius Solar.Wattpilot app. - Page 119 I/Os controlled by the produced power are always prioritised over a battery and Fronius Ohmpilot. That is to say that an I/O can switch on and result in the bat- tery no longer being charged or the Fronius Ohmpilot no longer being activated.

-

Page 120: System

Update All available updates are made available on the product page and in the "Down- load search" area under www.fronius.com Firmware update Drag the firmware file into the "Drag&Drop file here" field or select it using "Select file". The update will start. -

Page 121: License Manager

Save as PDF Click on the "Save as PDF" button. Individually select information with the "tick" next to the information or tick to "Select all". Enter the file name in the input field and click on the "Save" button. The PDF is created and displayed. License Manager The licence file contains the performance data and the scope of functions of the inverter. -

Page 122: Support

Click the "Enable Support User" button. The support user is enabled. IMPORTANT! The support user only allows Fronius Technical Support to implement settings on "Terminate Support User Ses- the inverter via a secure connection. The button sion" deactivates the access. -

Page 123: Communication

If a firewall is used for outgoing connections, the following protocols, server ad- dresses and ports must be allowed for successful data transfer: Tcp fronius-se-iot.azure-devices.net:8883 Tcp fronius-se-iot-telemetry.azure-devices.net:8883 Tcp fronius-se-iot-telemetry.azure-devices.net:443 Udp sera-gen24.fronius.com:1194 (213.33.117.120:1194) Tcp cure-se.fronius.com:443 Tcp firmware-download.fronius.com:443 Tcp froniusseiot.blob.core.windows.net:443 Tcp provisioning.solarweb.com:443 Upd/Tcp 0.time.fronius.com:123... -

Page 124: Modbus

For connection type "automatic" - enter WLAN password and host name. For connection type "static" - enter IP address, subnet mask, DNS and gate- way. "Connect" Click on the button. The connection is established. After connecting, the status of the connection Services"... -

Page 125: Remote Control

"SunSpec Model Type" Depending on the SunSpec model, there are two different settings. float: SunSpec Inverter Model 111, 112, 113 or 211, 212, 213. int + SF: SunSpec Inverter Model 101, 102, 103 or 201, 202, 203. "Meter address" The value entered is the identification number (Unit ID) assigned to the meter.Can be found on the user interface of the inverter in the “Communication”... -

Page 126: Fronius Solar Api

For monitoring, Fronius recommends using Fronius Solar.web instead, which provides secure access to inverter status and production information. When performing a firmware update to version 1.14.x, the setting of the Fronius Solar API is adopted. The Solar API is activated for systems with a version below 1.14.x. -

Page 127: Safety And Grid Requirements

M0/M1- / M0/M1+ connections for Mod- bus data. With the inverter, any PV power that is not allowed to be fed into the public grid is used to charge the battery instead and/or used by the Fronius Ohmpilot so... - Page 128 If there is no meter in the system or if a meter has failed, the inverter limits the feed-in power to the set value. Example: Feed-in limitation (without consideration of the efficiency) PV system on Fronius inverter: 5 000 W Consumption in home: 1 000 W...

-

Page 129: Dynamic Power Regulation With Several Inverters

IMPORTANT! With two primary meters at the feed-in point without a secondary meter, Fronius SnapINverter and Fronius Primo GEN24 inverters cannot be displayed as a com- bined PV system in Solar.web. Two individual PV systems must be created in Sol-... - Page 130 In order to be able to record all PV system data in Solar.web in full, only the Fronius Primo GEN24 inverter may be created in this PV system. The Fronius SnapINverter data is transmitted from the secondary meter to the Fronius Primo GEN24 inverter and thus displayed in Solar.web.

- Page 131 0 0 1 0 0 1 0 0 1 = 10 kW AC nom Settings on the user interface of the Fronius Primo GEN24 inverter: Configure the primary meter at the feed-in point in the "Device configura- tion" "Components" →...

-

Page 132: Connection Diagram - 4 Relay

Control priorities For setting the control priorities for the ripple control signal receiver, the feed-in limitation and control via Modbus. 1 = highest priority, 3 = lowest priority Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 4 relay connected to one another in accordance with the connection diagram. -

Page 133: I/O Power Management

I/O power man- I/O Power Management agement set- V+/GND tings - 4 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 IO control IO control Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 134: Connection Diagram - 3 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 3 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 135: I/O Power Management Settings - 3 Relays

I/O power man- I/O Power Management agement set- V+/GND tings - 3 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 IO control None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 136: Connection Diagram - 2 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 2 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 137: I/O Power Management Settings - 2 Relays

I/O power man- I/O Power Management agement set- V+/GND tings - 2 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 None None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 138: Connection Diagram - 1 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 1 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 139: I/O Power Management Settings - 1 Relay

I/O power man- I/O Power Management agement set- V+/GND tings - 1 relay None None None None None DNO Feedback None not used None None DNO Rules IO control None Rule 1 None None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... - Page 140 "Grid Code" menu. The access code for the "Grid Code" menu corresponds to the installer code (PROFI menu) and is only made available after a written request to Fronius. A corresponding application form is available from the national technical support.

-

Page 141: Options

Options... -

Page 143: Surge Protective Device (Spd)

"Notific- ations" as well as in Fronius Solar.web. In this case, the inverter must be repaired by an authorised specialist. IMPORTANT! The inverter also switches off if the 2-pin signal cable of the surge protective device is interrupted or damaged. -

Page 144: Energising The Inverter

PC board 4 TX20 screws Ground conductor 2-pin signal cable PV cable PV+ cable User Information De-energising Turn off the automatic circuit breaker. the inverter Set the DC disconnector to the "Off" switch position. Disconnect connections from the solar module strings (+/-). Switch off the battery connected to the inverter. -

Page 145: Installation

Installation CAUTION! Danger due to insufficiently dimensioned ground conductor. Damage to the inverter due to thermal overload can result. ▶ The national standards and guidelines must be observed for dimensioning the ground conductor. Loosen the two screws on the under- side of the housing cover by rotating them 180°... - Page 146 Remove the DC push-in terminals from the slots and disconnect them from the cables (only necessary if the in- stallation already exists). DC Voltage PUSH PV+ / PV- Connect the supplied PV+/PV- cables to the respective connections. IMPORTANT! Note the labelling of the cables when connecting.

- Page 147 Insert the PC board into the inverter and secure with the four screws (TX20) supplied at a torque of 1.0 ‑ 1.2 Nm. IMPORTANT! max. Depending on national standards and Ø10mm guidelines, a larger cross section of the ground conductor may be required. 1,5 Nm TX 20 Dimension the cable cross section of...

- Page 148 Strip the insulation on the single con- ductors by 12 mm and secure to the corresponding slot of the terminal on the PC board with a torque of 1.2 - 1.5 IMPORTANT! The cable cross-section must be selec- ted according to the specifications for the respective inverter power category Permissible cables for (see chapter...

- Page 149 Remove the factory installed bypass on the push-in WSD terminal. Connect the signal cable to the push- in WSD terminal on the IN- and IN+ slots, observing the labelling. IN- & IN+ Check whether the WSD switch is in position 1, adjust if necessary (factory setting: position 1).

-

Page 150: Commissioning The Inverter

Place the cover on the connection area. Tighten the five screws by rotat- ing them 180° to the right in the indic- ated order using a screwdriver (TX20). Clip the housing cover onto the invert- er from above. Press on the lower part of the housing cover and tighten the two screws by rotating them 180°... - Page 151 Set the DC disconnector to the "On" switch position. Switch on the auto- matic circuit breaker.

-

Page 152: Dc Connector Kit Gen24

Commissioning as well as maintenance and service work in the power module of the inverter must only be carried out by service personnel trained by Fronius and only within the scope of the respective technical regulations. ▶ Read the Installation and Operating Instructions before installing and com-... -

Page 153: Scope Of Supply

WARNING! Danger due to grid voltage and DC voltage from solar modules that are exposed to light. This can result in serious injury and damage to property. ▶ Ensure that the AC and DC side of the inverter are de-energised before car- rying out any connection, maintenance or service tasks. -

Page 154: Installation

Disconnect connections from the solar module strings (+/-). Switch off the battery connected to the inverter. Wait for the capacitors of the inverter to discharge (2 minutes). Installation CAUTION! Danger due to insufficiently dimensioned DC cables. Damage to the inverter due to thermal overload can result. ▶... - Page 155 Insert the DC Connector GEN24 into the inverter and secure with the two screws (TX20) supplied at a torque of 1.0 ‑ 1.2 Nm. Manually push the DC cables through the DC bushings. Press the lock on the back of the ter- minal and remove the DC terminals.

- Page 156 Use a slotted screwdriver to push in the lock on the terminal. Insert the stripped single conductor into the slot provided, in each case as far as it will go. Then withdraw the slotted screw- driver from the lock. Connect the solar module strings (+/-). Use a suitable measuring instrument to check the voltage and polarity of the DC cabling.

- Page 157 Insert the DC terminals into the re- spective slot until they engage. Fasten the screws of the cable guide to the housing using a screwdriver (TX20) and a torque of 1.3-1.5 Nm. NOTE! Do not use a drill driver as this could result in overtorque.

-

Page 158: Commissioning The Inverter

Commissioning Connect the solar module strings (+/-). the inverter Switch on the battery connected to the inverter. Set the DC disconnector to the "On" switch position. Switch on the auto- matic circuit breaker. -

Page 159: Appendix

Appendix... -

Page 161: Care, Maintenance And Disposal

▶ The connection area must only be opened by an authorised electrician. ▶ The separate power stage set area must only be opened by Fronius-trained service technicians. ▶ Prior to any connection work, disconnect the inverter on the AC side and the DC side. -

Page 162: Disposal

Switch off power to the inverter and wait for the specified time until the ca- pacitors have discharged and the fan has shut down. Turn the DC disconnector to the "Off" switch position. Loosen the screws on the underside of the housing cover by rotating them 180°... - Page 163 Packaging materials Collected separately. Check your municipality’s regulations. Reduce the volume of the box.

-

Page 164: Guarantee Provisions

Guarantee provisions Fronius manu- Detailed, country-specific warranty terms are available on the internet: facturer's war- www.fronius.com/solar/warranty ranty To obtain the full warranty period for your newly installed Fronius inverter or storage system, please register at: www.solarweb.com. -

Page 165: Components For Switching To Backup Power

Fronius Smart Meter TS 100A-1 43,0001,0045 Fronius Smart Meter TS 5kA-3 43,0001,0046 Fronius Smart Meter 240 V-3 UL 43,0001,3529 Grid and system protection unit (fuse protection: 1-pin, 6 A)Other manufactur- ers and types are permissible if they are technically and functionally identical to the examples below: VMD460-NA-D-2 (Bender GmbH &... -

Page 166: Components For Manual Full Backup Backup Power Changeover

Min. short circuit cur- 3 kA (make contacts) rent Test standard IEC 60947-4-1 Examples of contact- ISKRA IKA225-02 ors and relays Components for Current trans- manual Full Device name former Item number Backup backup power Fronius Smart Meter 63A-1 43,0001,1477 changeover... - Page 167 Current trans- Device name former Item number Fronius Smart Meter TS 100A-1 43,0001,0045 Q1 manual changeover switch Number of pins 3-pin or 4-pin(depending on the cabling variant) Rated current depends on house connection Coil voltage 230/400 V Rated frequency 50/60 Hz...

-

Page 168: Status Codes And Remedy

This can result in serious injury and damage to property. ▶ Installing and connecting a surge protective device (SPD) must only be car- ried out by service personnel trained by Fronius and only within the scope of the respective technical regulations. ▶... - Page 169 1191 - AfciDataTransfer (operation LED: flashes yellow) Cause: An arc on the PV system was detected. Remedy: No action required.

-

Page 170: Technical Data

Technical data Fronius Primo DC input data GEN24 8.0 / 8.0 MPP voltage range 260 - 480 V Plus (at rated power) Max. input voltage 600 V at 1000 W/m²/-10° C in an open cir- cuit Min. input voltage 65 V... - Page 171 DC input data battery Max. voltage 455 V Min. voltage 150 V Max. current 22 A Max. output 8000 W DC inputs AC input/output data Nominal output power (P 8000 W Max. output power 8000 W Rated apparent power 8000 W Nominal grid voltage 1 ~ NPE 220V / 230V / 240 V Min.

- Page 172 AC output data Full Backup Nominal grid voltage 1 ~ NPE 220 V 1 ~ NPE 230 V 1 ~ NPE 240 V Nominal frequency for Full Backup 53 / 63 Hz Switching time < 90 s 0 - 1 Power factor cos phi General data Maximum efficiency...

-

Page 173: Fronius Primo Gen24 10.0 / 10.0 Plus

Power per digital output 1 A at >12.5 V-24 V (external supply) (max. 3 A in total) Datalogger/web server Integrated Fronius Primo DC input data GEN24 10.0 / MPP voltage range 260 - 480 V 10.0 Plus (at rated power) Max. - Page 174 DC input data Max. inverter backfeed current to the array 41.25 A PV 1 PV 2 36 A Number of inputs - PV 1 Number of inputs - PV 2 Max. capacity of the PV generator 2000 nF against earth Insulation resistance test limit value 100 kΩ...

- Page 175 AC input/output data Nominal frequency for Full Backup 53 / 63 Hz Initial short circuit alternating cur- 45.5 A rent / phase I Total harmonic distortion < 3% 0.8 - 1 (adjustable) Power factor cos phi Max. permitted mains impedance Z None at PCC Maximum output fault current / dura-...

- Page 176 General data Inverter topology Non-insulated transformerless Permitted ambient temperature -40 °C - +60° C Permissible humidity 0 - 100% (incl. condensation) EMC emission class DC/AC overvoltage category 2 / 3 (in accordance with IEC 62109-1) Pollution degree Sound pressure 47 dB(A) (ref. 20µPa) Safety class (according to IEC62103) Protection devices Warning / shutdown at R...

- Page 177 Data communication Total power for digital output 6 W at 12 V (USB not connected) (internal supply) Power per digital output 1 A at >12.5 V-24 V (external supply) (max. 3 A in total) Datalogger/web server Integrated WLAN WLAN Frequency range 2412–2462 MHz Channels / power used Channel: 1–11 b,g,n HT20...

-

Page 178: Explanation Of Footnotes

The sum of the rated power per phase must not exceed the rated power of the inverter. Valid for Fronius Primo GEN24 with battery connection and Fronius Primo GEN24 Plus. Specified values are standard values; depending on the requirement and PV power, these values must be adjusted accordingly. - Page 179 Rated operating current and rated breaking capacity Number of pins...

-

Page 181: Circuit Diagrams

Circuit diagrams... -

Page 183: Fronius Primo Gen24 And Byd Battery-Box Premium Hv

Fronius Primo GEN24 and BYD Battery-Box Premium HV Circuit Diagram... -

Page 184: Fronius Primo Gen24 With Two Byd Battery-Box Premium Hv Connected In Parallel

Fronius Primo GEN24 with two BYD Battery-Box Premium HV connected in parallel Circuit Diagram... -

Page 185: Fronius Primo Gen24 With Three Byd Battery-Box Premium Hv Connected In Parallel

Fronius Primo GEN24 with three BYD Battery- Box Premium HV connected in parallel Circuit Diagram... -

Page 186: Fronius Primo Gen24 And Lg Resu Flex

Fronius Primo GEN24 and LG RESU FLEX Circuit Diagram... -

Page 187: Circuit Diagram - Pv Point (Op)

Circuit Diagram - PV Point (OP) Circuit Diagram... -

Page 188: Circuit Diagram - Pv Point (Op) Australia

Circuit Diagram - PV Point (OP) Australia Circuit Diagram... -

Page 189: Backup Power Terminal - Pv Point (Op) With Battery Only For France

Backup power terminal - PV Point (OP) with bat- tery only for France Circuit Diagram... -

Page 190: Backup Power Terminal - Pv Point (Op) Manual Changeover

Backup power terminal - PV Point (OP) manual changeover Circuit Diagram... -

Page 191: Automatic Switch To Backup Power 1-Pin Single Separation - E.g. Austria

Automatic switch to backup power 1-pin single separation - e.g. Austria Circuit Diagram... -

Page 192: Automatic Switch To Backup Power 1-Pin Single Separation - E.g. Australia

Automatic switch to backup power 1-pin single separation - e.g. Australia Circuit Diagram... -

Page 193: Automatic Switch To Backup Power 2-Pin Single Separation - E.g. Germany

Automatic switch to backup power 2-pin single separation - e.g. Germany Circuit Diagram... -

Page 194: Automatic Switch To Backup Power 2-Pin Single Separation - E.g. France

Automatic switch to backup power 2-pin single separation - e.g. France Circuit Diagram... -

Page 195: Automatic Switch To Backup Power 2-Pin Single Separation - E.g. Uk

Automatic switch to backup power 2-pin single separation - e.g. UK Circuit Diagram... -

Page 196: Automatic Switch To Backup Power 2-Pin Single Separation - E.g. Spain

Automatic switch to backup power 2-pin single separation - e.g. Spain Circuit Diagram... -

Page 197: Circuit Diagram

Automatic switch to backup power 2-pin double separation with ext. grid and system protection - e.g. Italy Circuit Diagram... -

Page 198: Fronius Primo Gen24 With Enwitec Box

Fronius Primo GEN24 with Enwitec Box Circuit Diagram... -

Page 199: Manual Switch To Backup Power 1-Pin Separation, E.g. Australia

Manual switch to backup power 1-pin separation, e.g. Australia Circuit Diagram... -

Page 200: Manual Switch To Backup Power 2-Pin Separation, E.g. Germany

Manual switch to backup power 2-pin separation, e.g. Germany Circuit Diagram... -

Page 201: Wiring Diagram - Surge Protective Device Spd

Wiring diagram - surge protective device SPD Circuit Diagram... -

Page 203: Dimensions Of The Inverter

Dimensions of the inverter... -

Page 205: Fronius Primo Gen24 8 - 10 Kw

Fronius Primo GEN24 8 - 10 kW Fronius Primo GEN24 8 - 10 kW...

Need help?

Do you have a question about the Primo GEN24 10.0 Plus and is the answer not in the manual?

Questions and answers