Table of Contents

Advertisement

Quick Links

Instructions - Parts List

Power-Star

Used to pump high volumes of petroleum and synthetic based oils. For professional use only.

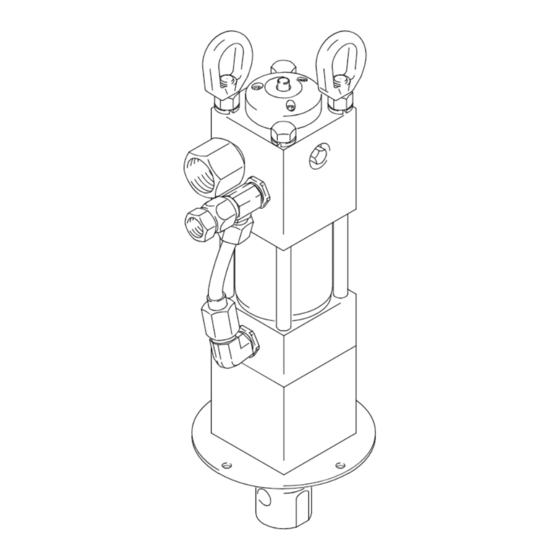

Model No. 236754, Series B

1:1 Ratio Universal Pump and Reciprocator

Model No. 236752, Series B (Square Housings), Series C (Cylindrical Housings)

Reciprocator Only

1500 psi (10 MPa, 103 bar) Maximum Hydraulic Input Pressure

1500 psi (10 MPa, 103 bar) Maximum Fluid Outlet Pressure

Important Safety Instructions

Read all warnings and instructions in

this manual before using the equipment.

Save these instructions.

Model 236752,

Series B

™

This pump is designed to be used only in pumping

non-corrosive and non-abrasive oils and lubricants. Any

other use of the pump can cause unsafe operating

conditions and result in component rupture, fire, or

explosion, which can cause serious injury, including fluid

injection.

Model 236752,

Series C

WARNING

Model 236754,

Series B

308391P

EN

Advertisement

Table of Contents

Summary of Contents for Graco Power-Star B Series

- Page 1 Instructions - Parts List ™ Power-Star 308391P Used to pump high volumes of petroleum and synthetic based oils. For professional use only. Model No. 236754, Series B 1:1 Ratio Universal Pump and Reciprocator Model No. 236752, Series B (Square Housings), Series C (Cylindrical Housings) Reciprocator Only 1500 psi (10 MPa, 103 bar) Maximum Hydraulic Input Pressure 1500 psi (10 MPa, 103 bar) Maximum Fluid Outlet Pressure...

-

Page 2: Table Of Contents

California Proposition 65 ....21 Graco Standard Warranty....22 IMPORTANT The design of the Viscount II hydraulic pump upper and lower motor housings has been updated. -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable. - Page 4 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

-

Page 5: Installation

Installation Installation Grounding Maximum Working Pressure of Accessories To reduce the risk of serious injury including fluid The equipment must be grounded to reduce the risk injection and splashing in the eyes or on the skin, of static sparking. Static sparking can cause fumes which may be caused by component ruptures, all to ignite or explode. -

Page 6: Hydraulic Power Supply

Pressure Reducing Valve supply, blow out all hydraulic lines with air, flush Flow Control Valve Hydraulic Supply Line (Use only Graco Hydraulic power thoroughly with solvent, and then blow out with air supply) again before connecting the lines to the motor. -

Page 7: Hydraulic Components

Installation Hydraulic Components Hydraulic Fluid Control: The hydraulic fluid control provides pressure regulator, and pump isolation. (F Pressure Regulation: The hydraulic fluid control reduces the hydraulic oil pressure to the operating pressure Always turn off the hydraulic supply side valve (K) required for the application. -

Page 8: Operation

Recommended Hydraulic Oil supply container and prime the pump to eliminate air. Use a Graco-approved Hydraulic Oil or a premium, ISO grade 46 petroleum-based hydraulic oil containing rust To prevent the pump from running dry, use a low-level and oxidation inhibitors and anti-wear agents. -

Page 9: Shutdown And Care

Operation Shutdown and Care Emergency Stop Procedure Close the supply line shutoff valve marked STOP. At the end of the work shift or when the pump is unattended, always relieve the pressure, see Pressure Relief Procedure on page 8. 308391P... -

Page 10: Troubleshooting

Troubleshooting Troubleshooting 1. Follow Pressure Relief Procedure, page 8, before checking or repairing gun. 2. Check all possible problems and causes before disassembling gun. Problem Cause Solution Closed dispense valve Pump only runs with valve open. Increase supply pressure using the Pressure too low pressure adjusting valve. -

Page 11: Repair

Repair Repair Refer to Parts Drawing on page 15 unless otherwise 3. Place the hydraulic motor horizontally in a bench specified. vise at the pump adapter (42) and bottom cylinder cap (43). 4. Remove the displacement pump with a strap wrench. -

Page 12: Reassembly

24. Remove the trip rod nut (10) and piston stop (37). If the piston is replaced, remove the compression springs (18), and compression rings (15) to use the Graco recommends replacing piston (44a), retainer new piston. (44b), and retaining ring (44c) together in kit 26C143. -

Page 13: Intake Valve

Repair 7. Install the upper housing (36). Install a 3/4 inch flat 24. Remove the hydraulic motor from the bench vise. stock shim between the upper housing and the 25. Unplug all hydraulic connections and lines and cylinder. Install the trip rod guide (41), the spring connect the hydraulic hoses. -

Page 14: Displacement Pump

Repair Displacement Pump Refer to F . 5 for the following instructions. Clean and inspect all parts for wear of damage as you disassemble them. Replace parts as needed. For the best results, always replace all the o-rings and packings when you disassemble the pump. 1. -

Page 15: Parts

Rings must be positioned with joints opposed 180 Torque to 70–80 ft–lb (95–108 N.m) Torque to 120–130 ft–lb (163–176 N.m) Lips face up Lips face down ti20637b Graco recommends replacing 44a,44b, and 44c all together in Kit 26C143 308391P... - Page 16 † Parts included in Pump Repair Kit 236862 (purchase 29† GASKET, plug separately). 167210 GUIDE, ball 167431 PLUG, spring retaining Graco recommends replacing 44a, 44b, and 44c all 171407 ROD, trip ◆ together in Kit 26C143. 171411 SPRING, compression 171412 CYLINDER Items marked --- are not available separately.

-

Page 17: Model 236752, Series C - Cylindrical Housings

Parts Model 236752, Series C - Cylindrical Housings 308391P... - Page 18 † Parts included in Pump Repair Kit 236862 (purchase 29† GASKET, plug separately). 167210 GUIDE, ball 167431 PLUG, spring retaining Graco recommends replacing 44a, 44b, and 44c all 171407 ROD, trip ◆ together in Kit 26C143. 171411 SPRING, compression 171412 CYLINDER Items marked --- are not available separately.

-

Page 19: Model 236754, Series B - Cylindrical Housings

Parts Model 236754, Series B - Cylindrical Housings Ref. Part Description Qty. 236752 RECIPROCATOR, hydra, Power-Star 101178 BALL, metallic 108001 BALL, metallic, sst 105† PACKING, o-ring 107† SEAL, block vee 108† PACKING, o-ring 189707 PISTON, fluid 189708 CYLINDER, pump 189709 VALVE, housing 189710 RETAINER, ball 189711 WASHER, piston †... -

Page 20: Technical Data

Technical Data Technical Data ™ Power-Star Metric Fluid Ratio Maximum Cycle Rate 60 cpm Maximum Output Flow 12.0 gpm 45.4 lpm Maximum Output Pressure 1500 psi 10.3 MPa, 103 bar Maximum Input Flow 12.0 gpm 45.4 lpm Maximum Hydraulic Fluid Input Pressure 1500 psi 10.3 MPa, 103 bar Maximum Input Fluid Temperature... -

Page 21: Performance Chart

Performance Chart Performance Chart California Proposition 65 WARNING: This product can expose you to chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, go to www.P65warnings.ca.gov. 308391P... -

Page 22: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Power-Star B Series and is the answer not in the manual?

Questions and answers