Table of Contents

Advertisement

Quick Links

1.2 System Features

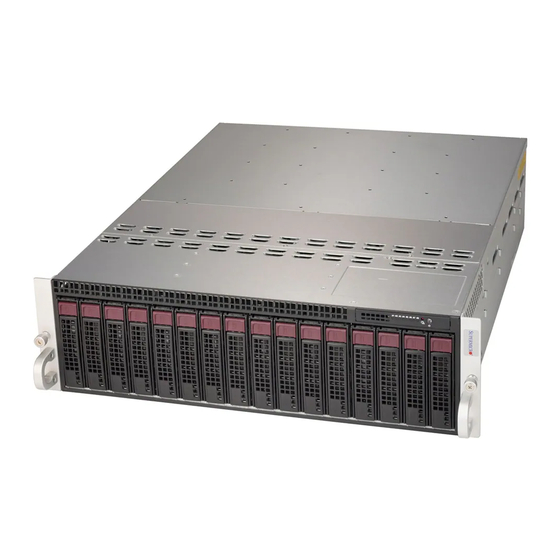

The CSE-938NH-R2K20BP2 is a 3U chassis that supports 16 front hot-swape drives and

eight rear hot-plug nodes.

Front View

1A

1B

2A

Feature

Description

Control Panels

Power buttons and status indicators; details on the next page

Storage Drives

Sixteen 3.5" drive bays, two for each computing node; drive carriers display status lights

Color

LED

Blue

Activity LED

Blue

Red

Red

Red

Status LED

Red

Red

Green

Amber

2B

3A

3B

4A

4B

Figure 1-1. System: Front View

System Features: Front

Drive Carrier LED Indicator

Blinking Pattern

Solid On

Blinking

Solid On

Blinking at 1 Hz

Blinking with two blinks and one

stop at 1 Hz

On for five seconds, then off

Blinking at 4 Hz

Solid On

Blinking at 1 Hz

10

Chapter 1: Introduction

Control Panel

5A

5B

6A

6B

7A

Behavior for Device

SAS/NVMe drive installed

I/O activity

Failure of drive with RSTe support

Rebuild drive with RSTe support

Hot spare for drive with RSTe support

(not supported in VMD mode)

Power on for drive with RSTe support

Identify drive with RSTe support

Safe to remove NVMe device (not

supported in VMD mode)

Attention state---do not remove NVMe

device (not supported in VMD mode)

7B

8A

8B

Advertisement

Table of Contents

Need help?

Do you have a question about the CSE-938NH-R2K20BP2 and is the answer not in the manual?

Questions and answers