Subscribe to Our Youtube Channel

Summary of Contents for TLV A-COSR-10

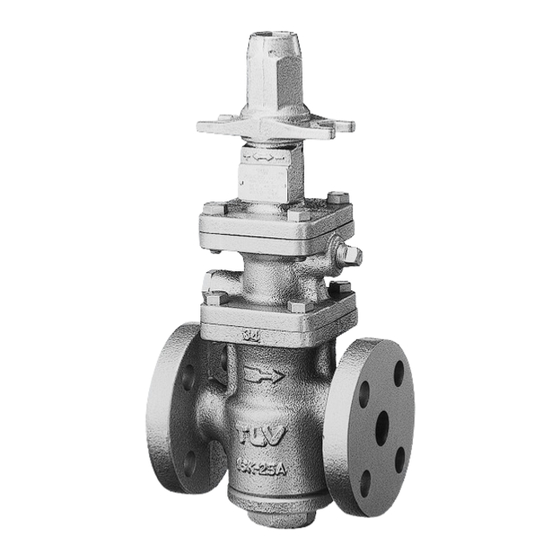

- Page 1 172-65255M-05 (A-COSR-10) 6 October 2021 Pressure Reducing Valve for Air A-COSR-10 Copyright © 2021 by TLV CO., LTD. All rights reserved...

-

Page 2: Table Of Contents

TLV EXPRESS LIMITED WARRANTY ......21 Service ................23 Introduction Thank you for purchasing the TLV A-COSR pressure reducing valve for air. This product has been thoroughly inspected before being shipped from the factory. When the product is delivered, before doing anything else, check the specifications and external appearance to make sure nothing is out of the ordinary. -

Page 3: Safety Considerations

The three types of cautionary items above are very important for safety: be sure to observe all of them as they relate to installation, use, maintenance, and repair. Furthermore, TLV accepts no responsibility for any accidents or damage occurring as a result of failure to observe these precautions. - Page 4 Use only under conditions in which no water hammer will occur. The impact of water hammer may damage the product, leading to fluid discharge, which may cause burns or other injury. 172-65255M-05 (A-COSR-10) 6 Oct 2021...

-

Page 5: Specifications

Maximum Primary Minimum Pressure Pressure Differencial Operating Model Adjustable Flow Range Adjustable Range Pressure Temperature Rate (MPaG) (MPaG) (MPa) (°C) For Air A-COSR-10 10% of rated 0.1 - 0.9 0.05 - 0.7 0.05 flow rate 172-65255M-05 (A-COSR-10) 6 Oct 2021... -

Page 6: Correct Usage Of The A-Cosr Pressure Reducing Valve

If the safety valve is installed on the outlet side of the A-COSR between the A-COSR and a control valve, an eventual pressure rise could activate the safety valve. 172-65255M-05 (A-COSR-10) 6 Oct 2021... - Page 7 30 d or more when a A-COSR A-COSR Automated control valve or an Valve automated valve (on-off valve) is installed. Less than (Example: if nominal size is 25 30 d 30 d or more mm, have 750 mm or more) 172-65255M-05 (A-COSR-10) 6 Oct 2021...

-

Page 8: Configuration

13 Diaphragm Support 5 Piston 14 Coil Spring 6 Cylinder 15 Spring Housing 7 Pilot Valve Body 16 Adjustment Screw 8 Pilot Valve 17 Spanner Cap 18 Plug – Sensing Line Port 9 Pilot Valve Seat 172-65255M-05 (A-COSR-10) 6 Oct 2021... -

Page 9: Installation

Spacer Installation Correct Incorrect If spacing adjustment is Spacer Spacer スペーサ necessary to accommodate Location Location installation, install a spacer on the outlet flange. The spacer should consist of a spacer, gaskets, bolts and nuts. 172-65255M-05 (A-COSR-10) 6 Oct 2021... - Page 10 Strainer should be angled in the 3 o 9 o’clock positions for horizontal installations to prevent condensate accumulation. ディフューザ Diffuser 減圧弁 A-COSR 0.2m以上 0.2 m or more Straight-run Piping Lengths: Upstream = 10 d or more; Downstream = 15 d or more (d = pipe diameter) 172-65255M-05 (A-COSR-10) 6 Oct 2021...

- Page 11 減 圧 弁 A-COSR 172-65255M-05 (A-COSR-10) 6 Oct 2021...

- Page 12 The bypass pipe should be at least one half of the size of the inlet (primary side) pipe. Globe Valve Safety Valve ボールバルブ (Relief Valve) Pressure Gauge Pressure Gauge Ball Valve 減圧弁 ボールバルブ ボールバルブ Ball Valve A-COSR 減圧弁 A-COSR 172-65255M-05 (A-COSR-10) 6 Oct 2021...

-

Page 13: Adjustment

7. Slowly, fully open the shut-off valve at the outlet of the A-COSR. 8. After setup, retighten the locknut and replace the cap. 9. When shutting down the system, always close the outlet shut-off valve first and then the inlet valve. 172-65255M-05 (A-COSR-10) 6 Oct 2021... -

Page 14: Maintenance

Replace after approximately 30,000 hours. If hunting or chattering takes place, premature wear may result. Diaphragm Replace after approximately 30,000 hours. If hunting or chattering takes place, cracks or fatigue may develop in a short period of time. 172-65255M-05 (A-COSR-10) 6 Oct 2021... -

Page 15: Disassembly

Check for seizure or any damaged screw threads. Adjustment Screw Locknut Spring Housing Ball Spanner Cap Spring Guide Bolt Coil Spring Nameplate Diaphragm Support 172-65255M-05 (A-COSR-10) 6 Oct 2021... - Page 16 (open downward), with the printed “UP” mark on the top. Diaphragm Pilot Valve Seat Upper Pilot Valve Body Gasket & Gasket Pilot Valve Body Bolt Pilot Valve Notch Pilot Valve Spring Pilot Screen Pilot Screen Holder & Gasket 172-65255M-05 (A-COSR-10) 6 Oct 2021...

- Page 17 At start-up following shut-down for a long period, always blow down the piston section of the body through the plug (option). Main Body Cover Cover Gasket Main Valve Seat (with Gasket) Cover Bolt Main Valve Main Valve Spring 172-65255M-05 (A-COSR-10) 6 Oct 2021...

- Page 18 It is permissible to clean using water, however cleaning with a mild detergent is recommended for more effective cleaning. (Coat threaded position with anti-seize after cleaning.) Exploded View Adjustment Section Pilot Section Piston Section Main Valve Section 172-65255M-05 (A-COSR-10) 6 Oct 2021...

-

Page 19: Reassembly

Main Valve Seat 15, 20 32, 40 Cover Bolt 15 - 40 1 Nm 10 kgcm Caution: If a torque greater than that recommended is applied, the A- or components may be damaged. COSR 172-65255M-05 (A-COSR-10) 6 Oct 2021... -

Page 20: Troubleshooting

Flow rate exceeds Check the flow rate, rated flow rate replace with a larger size The adjustment screw Replace with a new has seized adjustment screw Continued on the next page 172-65255M-05 (A-COSR-10) 6 Oct 2021... - Page 21 Chattering never Condensate is Check the trap stops contained, or the trap is Check the piping blocked The selected model is Check the model inappropriate for the selection, replace the service conditions if necessary COSR (specifications) 172-65255M-05 (A-COSR-10) 6 Oct 2021...

-

Page 22: Tlv Express Limited Warranty

Subject to the limitations set forth below, TLV CO., LTD., a Japanese corporation (“TLV”), warrants that products which are sold by it, TLV International Inc. (“TII”) or one of its group companies excluding TLV Corporation (a corporation of the United States of America), (hereinafter the “Products”) are designed and manufactured by... - Page 23 WARRANTY NOT NEGATED HEREBY, AND ANY IMPLIED WARRANTY NOT NEGATED HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR ITS TLV GROUP COMPANIES WILL IN ANY EVENT BE LIABLE FOR, INCIDENTAL OR...

-

Page 24: Service

Service For Service or Technical Assistance: Contact your TLV representative or your regional TLV office. In Europe: Tel: [49]-(0)7263-9150-0 Daimler-Benz-Straße 16-18, 74915 Waibstadt, Germany Fax: [49]-(0)7263-9150-50 Tel: [44]-(0)1242-227223 Units 7 & 8, Furlong Business Park, Bishops Cleeve, Gloucestershire GL52 8TW, U.K.

Need help?

Do you have a question about the A-COSR-10 and is the answer not in the manual?

Questions and answers