Summary of Contents for Arkel ARL-700

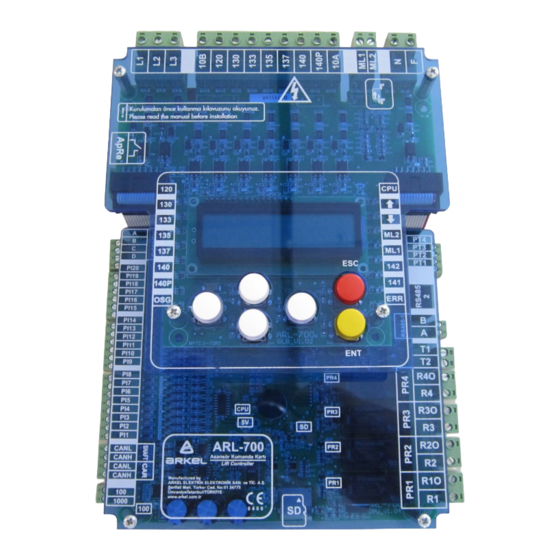

- Page 1 ARL-700 Quick Installation Guide V1.22 ARL-700 ELEVATOR CONTROLLER FOR TRACTION & HYDRAULIC LIFTS (COMPATIBLE FOR EN81-20) QUICK INSTALLATION GUIDE...

- Page 2 This document has been created to be a guide for Arkel customers. Reproduction, transfer, distribution or storage of part or all of the contents in this document in any form without the prior written permission of Arkel is prohibited. Arkel reserves the right to make changes and improvements to any of the products described in this document without prior notice.

-

Page 3: Table Of Contents

12.5. MSP-32 Settings ................................19 12.6. FX-CAN Settings ................................20 13. Clearing Permanent Errors .............................. 20 13.1. Clearıig Permanent Errors with ARL-700 Keypad ......................20 13.2. Clearing Permanent Errors with AREM ........................... 20 14. New Functions Which Are Coming With EN81-20 ......................20 By-Pass key .................................... -

Page 4: Mechanical Installation Of Control Cabinet

ARL-700 Quick Installation Guide V1.22 Mechanical Installation Of Control Cabinet Mount ARL-700 control cabinet, brake resistor, battery pack and UPS (if required) to their places. 12cm 16cm 38cm Figure-1: Dimensions of battery pack (it is required only when the inverter is supplied with battery during emergency... -

Page 5: Motor Connections

ARL-700 Quick Installation Guide V1.22 Motor Connections Make the connections of motor phases & motor PTC, brakes & brake release contacts, motor fan, encoder, brake resistor and battery pack with UPS (if required). ARL-700 Control Brake Resistor Panel Synchronous motor Batteries &UPS... -

Page 6: Preparations For Auto-Tune

ARL-700 Quick Installation Guide V1.22 Figure-5: UPS connections ***If there is SERVOSAN brand UPS inside the control panel these connections are not used. ***If you do not have UPS you must bridge connectors U-LI with U-LO and U-NI with U-NO using with suitable cables. - Page 7 CANBus input/output, and car connections. If you prefer pre-wired connections, all connector connections are sign with labels on flex cables. Figure- 8b: AREM hand terminal ARL-700 can be programmed with two ways. It can be • programmed either internal keypad onto ARL-700 or AREM hand terminal.

- Page 8 Down-Red (ESC) button together. Select “Advanced” from the appearing screen by pressing ENT button. The advanced menu is activated. Press “ENT” button onto the ARL-700 keypad to enter • the ARL-700 menu. Password screen will be displayed. If no password is •...

-

Page 9: Adrive Settings And Auto-Tuning Process

ARL-700 Quick Installation Guide V1.22 ADrive settings and Auto-tuning process The machine plate information should be entered to ADrive parameters before starting auto-tuing process. The machine • plate informations are entered by following below steps. 4.1. The Parameters For Asynchronous (Geared) Machines Go to 2-MOTOR SETUP parameter. -

Page 10: The Parameters For Synchronous (Gearless) Machines

ARL-700 Quick Installation Guide V1.22 6- CONTROL TYPE should be arranged to open loop with the parameter 6.1- CONTROL TYPE CT: OPEN LOOP. If • there is an encoder in the system, it should be arranged to CT: CLOSED LOOP after autotune process is complated with motor first running. -

Page 11: The Autotune Process For Synchronous (Gearless) Machines

ARL-700 Quick Installation Guide V1.22 The number of poles of the motor. Enter the data on • • Nominal current of the motor is arranged. This the motor name plate. value is specified on the motor plate by the motor... - Page 12 ARL-700 Quick Installation Guide V1.22 Move the car to the bottom floor. Car must be exactly at • Black Side of the magnets the floor level. Install the round magnet with red color side above the • SKSR1 magnetic switch as deceleration distance.

-

Page 13: Shaft Learning (With Motor Encoder Systems) & Test Driving

“deceleration distance” In shaft copy systems, ARL-700 should do shaft learning procedure once to sense the car and floor positions before normal operation. Therefore, check the magnetic switch, magnets layout and encoder connections according to the encoder counting system as described earlier. -

Page 14: Landing And Car Calls Settings

MSP-16 or MSP-32 board has to be used. (see “Software Update” and “Settings” for more information) If CANBus is wanted to use for landing calls, position of landing calls’ buttons would be defined to ARL-700. This •... -

Page 15: Lop Learning With Arem Hand Terminal

ARL-700 Quick Installation Guide V1.22 “LOP-A learn:Actv” is displayed on the screen. When the display is in this state, the process of teaching LOPs of A- • door is started. Please go to the top floor without pressing any key. You will see the car door is open. And you will see “??”... -

Page 16: Other Settings

When AREM is first connected to the CANBus line, if • AREM’s SD card doesn’t have the software found in ARL-700, AREM will inform that an update is needed. Start the update pressing the button F1. The system will be restarted when the update is complete. All ARL-700 peripherals are updatable. -

Page 17: Software Update By Arl-700 Keypad

• In order to update the software with the ARL-700 keypad, a microSD card must be exist in the SD card slot on the ARL- 700. ARCODE and ARL-700 use the same software folders. For this reason, the relevant software folders should already be copied into the SD card. -

Page 18: Dip Switch Settings Of Cpc Board

Dip Switch Settings Of CPC Board ARL-700, that can work with two-door support up to a total of 64 stops, collects car calls with the help of a CPC card. Each CPC card can serve up to 24 stops. If there are more than 24 floors or on condition that it has two doors, two CPC cards must be used. -

Page 19: Msp-16 Settings

ARL-700 Quick Installation Guide V1.22 000000 “IO-0210-1 board PI1 and IO-0210-1 board PI2” 000001 “IO-0210-2 board PI1 and IO-0210-2 board PI2” 000010 “IO-0210-3 board PI1 and IO-0210-3 board PI2” 000011 “IO-0210-4 board PI1 and IO-0210-4 board PI2” 000100 “IO-0210-5 board PI1 and IO-0210-5 board PI2” and so on... This can be chosen from 0 up to 63. (64 pcs.) Programmable inputs should be assigned from the related parameter depending on the dip-switch settings. -

Page 20: Fx-Can Settings

FX-CAN Settings The FX-CAN board is an ARL-700 peripheral that is used to collect up to 16 car calls and fulfill some of the features of the IBC- S board. FX-CAN board can not be used with IBC-S, CPC or CPC-T. If the double doors on the same floor are opened independently, this card can not be used (It sends the calls that received as AB door to the ARL-700.). -

Page 21: Inspection Hand Terminals

Check the PTCs of motor, control panel and brake resistor. • Check T1 and T2 terminals on ARL-700. T1 and T2 should be short circuit for normal operation. When the temperature • increases, the short circuit is cut, and turns to open circuit. - Page 22 V1.22 22- 3-Phase sequence is wrong: Phase L3 or L1 must be replaced with Phase L2 23- 24V supply voltage too low: Measure ARL-700 24v inputs. This error is taken if the value measured is below 20 VDC. • Control 24V power distribution unit (transformer) output. It must be 19 VAC in transformer output. If SMPS is used instead of transformer the output voltage of SMPS must be 24VDC.

- Page 23 ARL-700 Quick Installation Guide V1.22 32- Door(s) could not open: this error is received when the command “open the door” comes and the safety circuit (120-130- 140) doesn’t cut in door’s opening time. Door opening time may not be enough. Raise this time. Check the connections of door open relay in the revision box.

- Page 24 ADrive must be checked. Cable must be plug into the sockets properly. If the problem isn’t solved the cable should be replaced. If the error is getting HSR and ARL-700 combination the CAT cable must be checked between ARL-700 and HSR. The CPU led of HSR board must be flash every second.

- Page 25 V1.22 elevators working of the UCM valves must be tested by ARL-700. If any problem is detected during test that error is getting. Wittur HDU: parameter “HSV valve delay” must be set minimum 1 second. If it is selected 0 second error is gotten.

- Page 26 “P1006” parameter, firstly “P1005” maintenance time control parameter should be set as “On”. 94- Car light fuse is blown: If 3-phases are OK in ARL-700, but there is no voltage value(220V) on IBC-S, it gives this error. 95- Manual rescue (SEV key): If “ Acceptance test tools” parameter is OFF and “MEM” signal is ON, this warning shown on the screen.

Need help?

Do you have a question about the ARL-700 and is the answer not in the manual?

Questions and answers