Summary of Contents for GEA OSD 35-0136-067

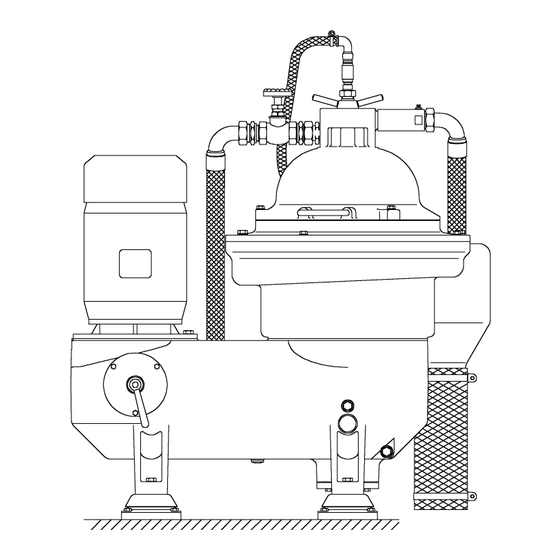

- Page 1 Westfalia Separator Mineraloil Systems GmbH Mechanical Separation Division Instruction Manual and Parts List No.: 2057-9001-020 Edition: 0905 Designation: Mineral oil centrifuge with self-cleaning bowl Model: OSD 35-0136-067 OSD 35-0196-067...

- Page 2 Mineraloil Systems GmbH Subject to modification! The authors are always grateful for comments and suggestions for improving the documentation. They can be sent to GEA Westfalia Separator Mineraloil Systems GmbH Werner-Habig-Str. 1 D-59302 Oelde © GEA Westfalia Separator 2057-9001-020 / 0905...

- Page 3 Westfalia Separator Mineraloil Systems GmbH Mineraloil Systems GmbH Westfalia Separator D-59302 Oelde (F. R. Germany) Model ø Built in in mm Max. admissible rated bowl speed in min Max. admissible density in kg/dm of product Heavy liquid Solids kg/dm kg/dm min/max throughput m min/max temp.

-

Page 4: For Your Safety

Westfalia Separator Mineraloil Systems GmbH For your safety • Strictly adhere to instructions marked with this symbol. This avoids damage to the separator and other equipment. • Take special care when carrying out operations marked with this symbol - otherwise danger to life. Note: •... - Page 5 Westfalia Separator Mineraloil Systems GmbH Safety precautions Correct usage ..................10 Safety markings ..................10 1.2.1 Safety markings and their meaning ............11 Basic operating principles..............14 Bowl speed and product ................ 14 Demands relating to service personnel and spare parts ....... 15 Operations on the separator ..............

- Page 6 Westfalia Separator Mineraloil Systems GmbH 3.5.1 Mathematical calculation ............... 56 Ejecting the bowl..................57 Shutting down the separator..............58 Trouble shooting ..................60 3.8.1 Faults on the separator................60 3.8.2 Bowl faults ..................... 62 Installation - Maintenance - Repair Installation of the separator ...............

- Page 7 Westfalia Separator Mineraloil Systems GmbH Parts list Guide to ordering spare parts ..............181 Set of plates......................183 Frame, compl....................185 Brake bolt, compl....................186 Solenoid valve block, complete ................187 Solenoid valve block, compl................188 Drive, complete – 50 Hz .................191 Drive, complete – 60 Hz .................191 Neck bearing bridge, compl................192 Spindle assembly .....................195 Bearing bush, complete..................195...

- Page 8 Westfalia Separator Mineraloil Systems GmbH • After installing certain critical spare bowl parts, the bowl must be re- balanced. Fig. 14 • The bowl parts are arranged in fixed positions relative to one another. • Locking devices alignment marks must be in perfect condition. The bowl must not be operated if these locking devices and alignment marks are not in perfect condition.

-

Page 9: Electrical Appliances

Westfalia Separator Mineraloil Systems GmbH • Carefully fasten hood 1, feed and discharge housing 2 and centripetal pump 3. Fig. 18 1.6.2 Electrical appliances • The governing accident prevention regulations apply for the electrical appliances and installations. • The frequency and voltage of the power supply must correspond to the machine specifications. - Page 10 Westfalia Separator Mineraloil Systems GmbH • The bowl must rotate in clockwise direction (see arrow on frame or sol- ids collector). Fig. 21 • The separator may only be operated with protection devices conforming to EN 294. Equip solid and liquid discharges accordingly.

- Page 11 Westfalia Separator Mineraloil Systems GmbH • Check that the product lines are set to operation. • Regularly check hoses for signs of ageing. • Check sight glasses for mechanical damage. • Replace damaged parts by recondi- tioned or new parts. Fig.

- Page 12 Westfalia Separator Mineraloil Systems GmbH • Insert the pressure piece. Fig. 202 • Position plate 2 and assembling de- vice 1. • Insert assembling device in the bowl bottom. Fig. 203 • Screw the assembling device onto closing chamber bottom as illus- trated: –...

- Page 13 Westfalia Separator Mineraloil Systems GmbH • Remove the pressure piece. Fig. 206 • Remove the mounting ring. Fig. 207 • Remove the annular piston. Fig. 208 If the dimension of the pressed-in gas- ket is more than 0.5 mm, • the polyamide gasket must be fur- ther pressed in the vice.

- Page 14 Westfalia Separator Mineraloil Systems GmbH • By carrying out several measure- ments around the entire circumfer- ence of the annular piston, check that the polyamide gasket is seated parallel in the groove. Fig. 210 FITTING – VARIANT II • Thoroughly clean and dry the groo- •...

- Page 15 Westfalia Separator Mineraloil Systems GmbH Parts list Guide to ordering spare parts ..............181 Set of plates......................183 Frame, compl....................185 Brake bolt, compl....................186 Solenoid valve block, complete ................187 Solenoid valve block, compl................188 Drive, complete – 50 Hz .................191 Drive, complete – 60 Hz .................191 Neck bearing bridge, compl................192 Spindle assembly .....................195 Bearing bush, complete..................195...

- Page 16 Guide to ordering spare parts A rapid and correct supply of spare parts can only be guaranteed if your order includes the following details: • Separator model see nameplate e.g. OSD 35-0136-067 • Serial-No. see nameplate e.g. 9000-223 • Designation see parts list e.g.

- Page 17 Westfalia Separator Mineraloil Systems GmbH Fig. 321 2057-9001-020 / 0905...

- Page 18 Westfalia Separator Mineraloil Systems GmbH Pos. Part Number Qty. Designation 0024-4310-000 Set of plates 0024-6324-000 Adhesive plate 0024-6327-000 Adhesive plate 0024-6326-000 Adhesive plate 0024-6426-000 Plate 0024-6071-000 Decal "arrow" 0024-6330-000 Adhesive plate 0024-6329-000 Adhesive plate 0024-6328-000 Adhesive plate 0024-6325-000 Adhesive plate 0024-6334-000 Maker's nameplate 0024-3413-000...

- Page 19 Westfalia Separator Mineraloil Systems GmbH Fig. 322 2057-9001-020 / 0905...

Need help?

Do you have a question about the OSD 35-0136-067 and is the answer not in the manual?

Questions and answers