Subscribe to Our Youtube Channel

Summary of Contents for Toro GrandStand 72520

- Page 1 Form No. 3455-800 Rev A GrandStand ® Mower With 60in TURBO FORCE ® Cutting Unit Model No. 72520—Serial No. 400000000 and Up *3455-800* Register at www.Toro.com. Original Instructions (EN)

- Page 2 It is a violation of California Public Resource Code Dealer or Toro Customer Service and have the model Section 4442 or 4443 to use or operate the engine on and serial numbers of your product ready. Figure 1 any forest-covered, brush-covered, or grass-covered...

-

Page 3: Table Of Contents

Contents Removing the Fuel Tank ........35 Replacing the Fuel Filter ........35 Electrical System Maintenance ......36 Safety ............... 4 Electrical System Safety ........36 General Safety ........... 4 Servicing the Battery......... 36 Safety and Instructional Decals ......4 Servicing the Fuses .......... -

Page 4: Safety

Safety • Keep bystanders and children out of the operating area. Do not allow children to operate the machine. Allow only people who are responsible, trained, General Safety familiar with the instructions, and physically capable to operate the machine. This product is capable of amputating hands and •... - Page 5 decal116-8283 116-8283 1. Warning—read the Operator's Manual for instructions on decal131-3507 torquing the blade bolt/nut to 75 to 81 N∙m (55 to 60 ft-lb). 131-3507 1. Read the Operator's 2. Belt tensioner Manual. decal116-8775 116-8775 1. Read the Operator’s Warning—fill to the bottom Manual.

- Page 6 7.5A decal131-3528 131-3528 1. Key switch—15 A 3. Power takeoff (PTO)—10 decal133-4604 133-4604 2. Accessory port—15 A 4. Infocenter—7.5 A 1. Thrown object 3. Severing hazard of hand hazard—keep bystanders or foot—keep away from away from the machine. moving parts. 2.

- Page 7 decal131-3526 131-3526 1. Power takeoff (PTO)—disengaged 5. Reverse 2. Fast 6. Traction drive 3. Slow 7. Engage the handles. 4. Neutral decal139-2878 139-2878 6. Thrown object hazard—keep bystanders away. 1. Warning—read the Operator’s Manual. 2. Warning—all operators should be trained before operating 7.

-

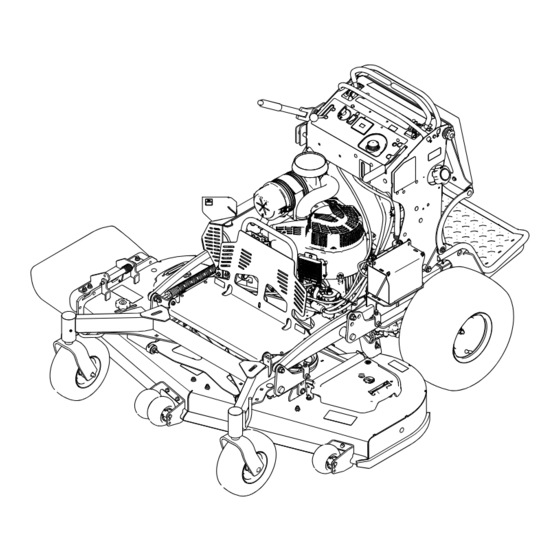

Page 8: Product Overview

Controls Product Overview Become familiar with all the controls before you start the engine and operate the machine (Figure Control Panel g403061 Figure 3 1. Anti-scalp roller 7. Hydraulic tank 2. Front caster wheel 8. Fuel tank g301785 3. Side-discharge chute 9. - Page 9 Power-Takeoff Switch (PTO) Battery-Indicator Light If you turn the key to the O position for a few Use the power-takeoff switch (PTO) to engage and disengage mower blades or start and stop powered seconds, the battery voltage displays in the area attachments (Figure 4);...

-

Page 10: Specifications

• Inspect the area where you will use the machine To ensure optimum performance and continued safety and remove all objects that the machine could certification of the machine, use only genuine Toro throw. replacement parts and accessories. Replacement •... -

Page 11: Adding Fuel

• – If you spill fuel, do not attempt to start the Do not use gasoline containing methanol. engine. Avoid creating a source of ignition until • Do not store fuel either in the fuel tank or fuel the fuel vapors have dissipated. containers over the winter unless you use a fuel –... -

Page 12: Performing Daily Maintenance

Performing Daily Maintenance Before starting the machine each day, perform the Each Use/Daily procedures listed in Maintenance (page 25). Breaking in a New Machine New engines take time to develop full power. Mower g031282 decks and drive systems have higher friction when Figure 7 new, placing additional load on the engine. -

Page 13: During Operation

Avoid mowing in • Use only accessories and attachments approved wet conditions. by The Toro® Company. • Before you start the engine, ensure that all drives are in neutral, the parking brake is engaged, and Slope Safety you are in the operating position. -

Page 14: Operating The Parking Brake

Operating the Parking operation. Use common sense and good judgment when performing this evaluation. Brake Changes in the terrain, such as moisture, can quickly affect the operation of the machine on Always engage the parking brake when you shut off a slope. -

Page 15: Operating The Mower-Blade-Control Switch (Pto)

Operating the Disengaging the Mower Blades (PTO) Mower-Blade-Control Disengage the mower blades using 1 of the 2 ways Switch (PTO) shown. Use the blade-control switch (PTO) in conjunction with the motion-control levers to engage and disengage the mower blades. DANGER The rotating blades under the mower deck are dangerous. -

Page 16: Operating The Throttle

Operating the Throttle Starting the Engine You can move the throttle control between F Important: Do not engage the starter for more positions (Figure 12). than 5 seconds at a time. If the engine fails to start, wait 15 seconds between attempts. Failure Always use the F position when engaging the PTO. -

Page 17: Shutting Off The Engine

Shutting Off the Engine Using the Platform You can use the machine with the platform in the CAUTION up or down position. It is your preference on which position to use. Children or bystanders may be injured if they move or attempt to operate the machine while WARNING it is unattended. -

Page 18: Driving Forward Or Backward

Driving Forward Disengage the parking brake; refer to Operating the Parking Brake (page 14). Move the motion-control levers to the center, unlocked position. g031026 Figure 17 1. Platform up 3. Pull the knob out to release the platform. 2. Platform down g030983 Figure 18 1. -

Page 19: Side Discharging Or Mulching The Grass

Side Discharging or Mulching the Grass This machine has a hinged grass deflector that disperses clippings to the side and down toward the turf. DANGER Without the grass deflector, discharge cover, or complete grass catcher assembly mounted in place, you and others are exposed to blade contact and thrown debris. -

Page 20: Adjusting The Height-Of-Cut

Adjusting the Height-of-Cut Adjusting the Anti-Scalp Rollers The height-of-cut can be adjusted from 38 to 127 mm (1-1/2 to 5 inches) in 6 mm (1/4 inch) increments. Whenever you change the height-of-cut, adjust the Note: Using a height-of-cut under 51 mm (2 inches) height of the anti-scalp rollers. -

Page 21: Positioning The Flow Baffle

Position B Use this position when bagging (Figure 25). g301806 Figure 23 1. Slot 2. Knob g012678 Figure 25 Positioning the Flow Baffle The following figures are for recommended use only. Adjustments vary by grass type, moisture content, Position C and the height of the grass. -

Page 22: Using Weights

Using Weights Using the Fuel-Shutoff Valve • Install weights to improve balance. You can add or remove weights to create optimized performance under different operating conditions and for your Close the fuel-shutoff valve for transport, maintenance, preference. and storage (Figure 27). -

Page 23: Pushing The Machine By Hand

Pushing the Machine by Transporting the Machine Hand Use a heavy-duty trailer or truck to transport the machine. Use a full-width ramp. Ensure that the trailer The bypass valves allow you to push the machine by or truck has all the necessary brakes, lighting, and hand without the engine running. - Page 24 g031405 Figure 30 1. Back the machine up the 2. Walk the machine down ramp. the ramp. Shut off the engine, remove the key, and engage the parking brake. Tie down the machine near the front caster wheels and the rear bumper with straps, chains, cable, or ropes (Figure 31).

-

Page 25: Maintenance

To ensure optimum performance and continued the engine running. safety certification of the machine, use only • Carefully release pressure from components with genuine Toro replacement parts and accessories. stored energy. Replacement parts and accessories made by • Check the parking brake operation frequently. -

Page 26: Pre-Maintenance Procedures

Maintenance Service Maintenance Procedure Interval • Change the engine oil and filter. Every 100 hours or yearly, • Replace the spark plug. whichever comes first • Check and adjust the valve clearance. Contact an Authorized Service Dealer. Every 250 hours •... -

Page 27: Opening The Engine Guard

Opening the Engine Guard Lubrication Rotate the engine guard forward as shown in Figure Greasing the Machine Grease with No. 2 lithium or molybdenum grease. Disengage the PTO and set the parking brake. Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 28: Greasing The Front Caster Pivots

Greasing the Front Caster Note: Thread-locking adhesive has been applied to lock the spacer nuts to the axle. Pivots Remove the axle (with the other spacer nut still assembled to it) from the wheel assembly. Service Interval: Yearly Pry out the seals, inspect bearings for wear or Grease type: Lithium or molybdenum grease damage, and replace them if necessary. -

Page 29: Greasing The Motion Controls

Greasing the Motion Engine Maintenance Controls Engine Safety Service Interval: Yearly • Shut off the engine before checking the oil or Grease the operator-presence-control balljoint and adding oil to the crankcase. the motion-control bushing for both levers. • Keep your hands, feet, face, clothing, and other body parts away from the muffler and other hot Note: Use an oil drip between the lever brackets to... -

Page 30: Servicing The Engine Oil

Servicing the Engine Oil Remove the inner filter only to replace it. Inspecting the Filters Engine-Oil Specifications Inspect the safety filter. If it is dirty, replace both Oil Type: Detergent oil (API service SJ or higher) the safety and primary filters. Oil Capacity: 2.0 L (68 fl oz) with the filter;... - Page 31 Disengage the PTO, move the motion-control levers to the N position, and EUTRAL LOCK engage the parking brake. Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. Change the engine oil as shown. g403449 g403449 g373146...

- Page 32 g403450 g373565 Figure 42 Start the engine and drive to a flat area. Check the oil level again. g027477 Figure 41 Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the additional oil to bring it to the Full mark.

-

Page 33: Servicing The Spark Plug

Servicing the Spark Plug Checking the Spark Plug Important: Do not clean the spark plug(s). Service Interval: Every 100 hours or yearly, Always replace the spark plug(s) when it has a whichever comes first black coating, worn electrodes, an oily film, or Ensure that the air gap between the center and side cracks. -

Page 34: Checking The Spark Arrester

Checking the Spark Fuel System Arrester Maintenance For Machines with a Spark Draining the Fuel Tank Arrester You can drain the fuel tank by removing it and pouring Service Interval: Every 50 hours the fuel out of the fill neck; refer to Removing the Fuel Tank (page 35). -

Page 35: Removing The Fuel Tank

Removing the Fuel Tank Replacing the Fuel Filter Lower the platform. Service Interval: Every 400 hours or yearly, whichever comes first Release the cushion; refer to Releasing the Cushion for Rear Access (page 26). DANGER Remove the cross bracket. In certain conditions, fuel is extremely flammable and highly explosive. -

Page 36: Electrical System Maintenance

Electrical System Maintenance Electrical System Safety • Disconnect the battery or remove the spark-plug wire before making any repairs. Disconnect the negative terminal first and the positive terminal last. Connect the positive terminal first and negative last. • Charge the battery in an open, well-ventilated area, away from sparks and flames. - Page 37 Charging the Battery Installing the Battery Install the battery as shown in Figure WARNING Charging the battery produces gasses that can explode. Never smoke near the battery and keep sparks and flames away from battery. Important: Always keep the battery fully charged (1.265 specific gravity) to prevent battery damage when the temperature is below 0°C (32°F).

-

Page 38: Servicing The Fuses

Servicing the Fuses Drive System Maintenance The electrical system is protected by fuses. It requires no maintenance. If a fuse blows, check the component or circuit for a malfunction or short. Adjusting the Tracking Park the machine on a level surface, disengage the PTO, and engage the parking brake. -

Page 39: Checking The Tire Pressure

Adjusting the Caster-Pivot Check for proper tracking, and adjust the rod as necessary. Bearing Note: If you are unable to achieve proper tracking by adjusting the left control rod, contact Service Interval: Every 500 hours/Yearly (whichever your Authorized Service Dealer. comes first) Check that the machine does not creep from Disengage the blade-control switch (PTO), move... -

Page 40: Servicing The Caster Wheels And Bearings

Servicing the Caster Tighten the locknut until the spanner bushing bottoms against the inside of the caster forks Wheels and Bearings (Figure 56). Grease the fitting on the caster wheel. The caster wheels rotate on a roller bearing supported by a spanner bushing. If the bearing is kept well lubricated, wear will be minimal. - Page 41 Check the condition of the wire-harness leads, Using a 0.010 inch thick-feeler gauge, verify connectors, and terminals. Clean or repair them that a gap is present between the rotor and as necessary. armature face on both sides of the brake pole as shown in Figure 61 Figure...

-

Page 42: Checking The Wheel-Lug Nuts

Cooling System Perform the following safety check: Start the engine from the operator’s Maintenance position. Make sure that the blades do not engage when the PTO switch is in Cleaning the Air-Intake the O position and the clutch is Screen disengaged. -

Page 43: Brake Maintenance

Brake Maintenance Testing the Parking Brake Service Interval: Before each use or daily Before each use, test the parking brake on both a level surface and slope. Always engage the parking brake when you stop the machine or leave it unattended. If the parking brake does not hold securely, adjust it. -

Page 44: Belt Maintenance

Belt Maintenance Checking the Belts Service Interval: Every 100 hours—Check the mower-deck belt(s). Check belts for cracks, frayed edges, burn marks, wear, signs of overheating, or any other damage. The signs of a worn mower belt are squealing while the belt is rotating, blades slipping while you are cutting grass, frayed belt edges, burn marks, and cracks. -

Page 45: Replacing The Transmission Belt

Replacing the Transmission CAUTION Belt The spring is under tension when installed and can cause personal injury. Service Interval: Every 1,000 hours—Replace the Wear safety glasses and be careful when transmission belt. removing the spring. Remove the fuel tank; refer to Removing the Fuel Tank (page 35). -

Page 46: Controls System Maintenance

Controls System Maintenance Adjusting the Motion-Control Levers If the motion-control levers do not align horizontally, adjust the motion-control levers. Park the machine on a level surface, disengage g031538 the PTO, and engage the parking brake. Figure 69 Shut off the engine, remove the key, and wait 1. -

Page 47: Hydraulic System Maintenance

Hydraulic System Add fluid to the reservoir until it reaches the reaches the minimum cold fill level. Specifications Install the cap on the filler neck. Hydraulic Fluid Type: Toro ® HYPR-OIL ™ hydraulic fluid Replacing the Hydraulic Hydraulic System Fluid Capacity: 4.7 L (159 fl oz) -

Page 48: Bleeding The Hydraulic System

Important: Remove the hydraulic-reservoir cap. Use the fluid specified in Hydraulic System Specifications (page 47) Locate the drain plug in the bottom of each equivalent. Other fluids could cause system transmission and place a drain pan under the damage. plugs (Figure 71). -

Page 49: Mower Deck Maintenance

Mower Deck Maintenance Blade Safety A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, resulting in serious personal injury or death. g006530 Figure 73 • Inspect the blades periodically for wear or damage. 1. - Page 50 Sharpening the Blades WARNING Use a file to sharpen the cutting edge at both A blade that is bent or damaged could ends of the blade (Figure 76). break apart and could critically injure you or bystanders. Note: Maintain the original angle. Note: •...

-

Page 51: Leveling The Mower Deck

Checking the Mower Deck Side-to-Side Height Adjust the rear-tire pressure. Ensure that the blades are not bent; refer to Checking for Bent Blades (page 49). Position the blades side to side. Measure at the B and C locations from a level surface to the cutting edge of blade tips (Figure 80). - Page 52 Leveling the Mower Deck from Side to Side Loosen the side nut and jam nut in the yokes you want to adjust (Figure 81). g001041 Figure 82 1. Measure the blade at 2. Measure from a level points A and B surface g031415 Figure 81...

-

Page 53: Adjusting The Deck-Lift Spring

Adjusting the Deck-Lift Note: Rotate the bolt clockwise to raise the deck; rotate the bolt counterclockwise to lower it. Spring Tighten the jam nuts and side bolts. Note: Adjusting the compression spring alters how Check the front-to-rear pitch; refer to Checking much the deck floats and the amount of effort needed the Mower Deck Front-to-Rear Pitch (page... -

Page 54: Replacing The Grass Deflector

Replacing the Grass Cleaning Deflector Cleaning under the Mower WARNING Deck An uncovered discharge opening could allow the machine to throw objects toward you or Service Interval: Before each use or daily bystanders, resulting in serious injury. Also, Remove the grass buildup under the mower daily. contact with the blade could occur. -

Page 55: Storage

Storage Shut off the engine, allow it to cool, and drain the fuel tank; refer to Draining the Fuel Tank (page 34), or operate the engine Storage Safety until it shuts off. Start the engine and allow it to run until it •... -

Page 56: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine does not start, starts hard, or 1. The fuel tank is empty or the shutoff 1. Fill the fuel tank with fuel and open the fails to keep running. valve is closed. valve 2. - Page 57 Problem Possible Cause Corrective Action The cutting height is uneven. 1. Blade(s) are not sharp. 1. Sharpen the blade(s). 2. Cutting blade(s) is/are bent. 2. Install new cutting blade(s). 3. The mower deck is not level. 3. Level the mower deck side-to-side position.

-

Page 58: Schematics

Schematics g403684 Electrical Schematic—145-3556 (Rev. A) - Page 59 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

Need help?

Do you have a question about the GrandStand 72520 and is the answer not in the manual?

Questions and answers