Summary of Contents for KLINGER KHD-311FF

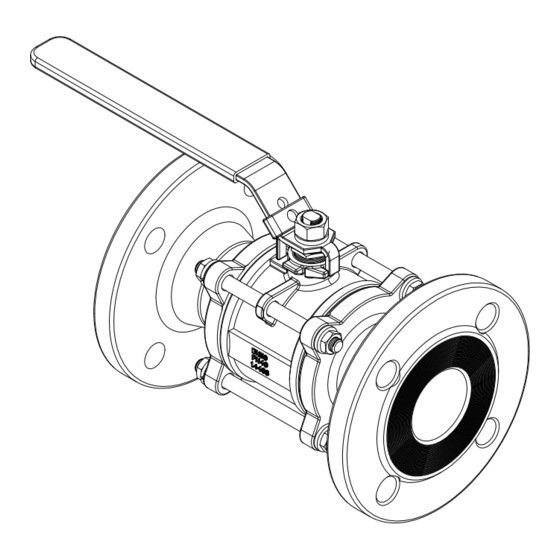

- Page 1 3-Piece Flanged Ball Valve KHD-311FF Installation, Operation, & Maintenance Manual KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

-

Page 2: Table Of Contents

3.2 Cleaning 3.3 Manual Operation 3.4 Remote Operation Chapter IV Maintenance 4.1 General Notes 4.2 Maintenance Frequency 4.3 Disassembly 4.4 Reassembly 4.5 Troubleshooting 4.6 Technical Data and Product Information KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 3: Chapter I Introduction

However, the processes used are completely 4) Ensure that running water is readily accessible. non-toxic. 5) Fire extinguisher must be obtainable if media is flammable. KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 4: Storage

3) Fittings Select the correct size of fittings according to the pipeline specification. Tighten the valve to the pipe- KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 5: Installation Of Ends

Fail-to-close actu- ated valves should be brought to the half-OPEN position. NOTE: Do not fasten supports to the flange bolting or the actuator. KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 6: Operation

Operation will be in accordance with KLINGER Die Erste Installation, Operation and Main- tenance Instructions for the relevant actuator. Figure 3.1 Rotation Direction for CLOSED and OPEN position KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. - Page 7 Also, the segment position may change when the valve is moved. The failure may result in damage or personal injury. KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

-

Page 8: Maintenance

3. Insert the Thrust Washer (7) thru the Stem (6). valve. 4. Install the Stem (6) from inside the Body (1). KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 9: Troubleshooting

Damaged seats Replace seats Confirm the pres- Valve too hard to High pressure sure rating operate Foreign particles in Clean the internals valve KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD. -

Page 10: Technical Data And Product Information

PTFE / MG1241 SS304 Body Bolt SS304 Stem SS316 Body Bolt Washer Thrust Washer PTFE / MG1241 SS304 Body Bolt Nut Stem Packing PTFE Gland SS304 Handle Washer SS304 KIOM-KHD-311FF-112_V2.1_EN Copyright © 2023 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

Need help?

Do you have a question about the KHD-311FF and is the answer not in the manual?

Questions and answers