Table of Contents

Advertisement

Quick Links

Installation Instructions

and User Guide

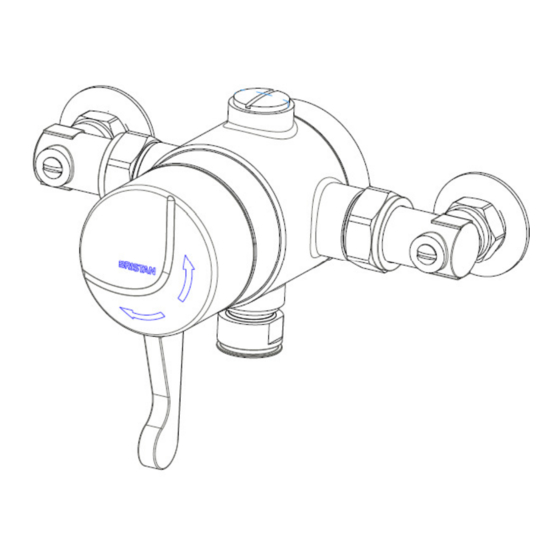

Opac Lever Thermostatic

Shower Valve

Models covered: OP TS1503 EL C,

Models covered:

Models covered:

Models covered:

OP TS1503 CL C, OP TS1503 ISOL C,

OP TS1503 SCL C

Please keep this booklet for future

Reference.

Installer, when you have read these

instructions please ensure you leave them

with the user.

Advertisement

Table of Contents

Summary of Contents for Bristan OP TS1503 CL C

- Page 1 Shower Valve Models covered: Models covered: OP TS1503 EL C, Models covered: Models covered: OP TS1503 CL C, OP TS1503 ISOL C, OP TS1503 SCL C Please keep this booklet for future Reference. Installer, when you have read these instructions please ensure you leave them...

-

Page 2: Table Of Contents

Contents Thank you for choosing Bristan, the UK’s leading taps and showers expert. We have designed this product with your enjoyment in mind. To ensure that it works to its full potential, it needs to be fitted correctly. These fitting instructions have been created to give you all of the information you need and, if you need any further help, please do not hesitate to give us a call on 0844 701 6273. -

Page 3: Important Safety Information

Important Safety Information • Please read these instructions thoroughly and retain for future use. • All products manufactured and supplied by Bristan are safe provided they are installed, used correctly and receive regular maintenance in accordance with these instructions. This fitting needs to be installed in accordance with, and meet the requirements of the •... -

Page 4: General Information

General Information This product has been tested to the TMV3 scheme which complies with the BS EN 1287:1999 (LP) and BS EN 1111:1999 (HP) thermostatic mixing valve standards and satisfies the requirements of the Water Supply (Water Fittings) Regulations 1999 and current bylaws. -

Page 5: Product Features

Concealing Shroud Concealing Shroud Conceals exposed pipework which is shown when the valve is installed in a wall cavity. Supplied with OP TS1503 CL C model. 5. 5. 5. 5. Protective Shroud Protective Shroud Protective Shroud Protective Shroud Designed for use in healthcare. -

Page 6: Specifications

Inlet Connections: 15mm compression connections. Inlet Connections: Inlet Connections: OP TS1503 EL C – 148-158mm adjustable centres. OP TS1503 CL C – 175mm fixed centres. OP TS1503 ISOL C – 175mm fixed centres. OP TS1503 SCL C – 125-132mm adjustable centres. Outlet Connections: Outlet Connections: Top or bottom G ½"... -

Page 7: Dimensions

Dimensions (mm’s) OP TS1503 EL C OP TS1503 EL C OP TS1503 EL C OP TS1503 EL C (Surface Mounted) 33.5 148 - 158 Need help? Need help? Give us a call on 0844 701 6273 Need help? Need help? 0844 701 6273 0844 701 6273 and speak to one of our trained advisors. - Page 8 Dimensions (mm’s) OP TS1503 CL C OP TS1503 CL C (Concealed Model) OP TS1503 CL C OP TS1503 CL C 63.5 – 72.5 63.5 – 72.5 Suitable for wall cavity depths of between 63.5-72.5mm. Need help? Need help? Need help?

- Page 9 Dimensions (mm’s) OP TS1503 ISOL C OP TS1503 ISOL C OP TS1503 ISOL C OP TS1503 ISOL C 33.5 Need help? Need help? Give us a call on 0844 701 6273 Need help? Need help? 0844 701 6273 0844 701 6273 and speak to one of our trained advisors. 0844 701 6273...

- Page 10 Dimensions (mm’s) OP TS1503 SCL C OP TS1503 SCL C OP TS1503 SCL C OP TS1503 SCL C 125-132 centres Need help? Need help? Need help? Need help? Give us a call on 0844 701 6273 0844 701 6273 0844 701 6273 and speak to one of our trained advisors. 0844 701 6273...

-

Page 11: Installation Requirements

Installation Requirements These fittings need to be installed in These fittings need to be installed in These fittings need to be installed in These fittings need to be installed in Size of tap or Size of tap or Size of tap or Size of tap or Vertical distance Vertical distance... - Page 12 Installation Requirements Conditions of use for Type 3 (Thermostatic mixer) valves Conditions of use for Type 3 (Thermostatic mixer) valves Conditions of use for Type 3 (Thermostatic mixer) valves Conditions of use for Type 3 (Thermostatic mixer) valves In order to give compliance with N.H.S. specification DO8 the table below lists the conditions for normal use.

-

Page 13: Flow Regulators

Flow Regulators Fit to Elbows Fit to Elbows Fit to Elbows Fit to Elbows Cold Cold Supply Cold Cold Supply Supply Supply Hot Supply Hot Supply Hot Supply Hot Supply Comments Comments Comments Comments Cold Cold Cold Cold 0.1 to 1.0bar 0.1-1.0 bar Max ratio of Hot (1 to 10 MTR... - Page 14 Flow Regulators The table on page 13 shows the flow regulator requirements and valve adjustments for various hot / cold supplies. # Flow limiters are fitted and will be required to be removed when installed in low pressure (gravity fed) applications below 1.0 bar. To remove: unscrew the retaining ring and remove limiter and washer.

-

Page 15: Installation

Installation OP TS1503 EH C, OP TS1503 ISOL C OP TS1503 EH C, OP TS1503 ISOL C OP TS1503 EH C, OP TS1503 ISOL C OP TS1503 EH C, OP TS1503 ISOL C Before Installation Before Installation Before Installation Before Installation Important: Important: Water supplies to the mixer Important:... - Page 16 Installation cont. OP TS1503 EH C, OP TS1503 ISOL C OP TS1503 EH C, OP TS1503 ISOL C continued OP TS1503 EH C, OP TS1503 ISOL C OP TS1503 EH C, OP TS1503 ISOL C 3. Attach shower valve 3. Attach shower valve 3.

- Page 17 Installation cont. OP TS1503 CL C (Concealed) OP TS1503 CL C OP TS1503 CL C OP TS1503 CL C Before Installation Before Installation Before Installation Before Installation Important: Important: Water supplies to the mixer Important: Important: Flush through the pipework to ensure must be with hot on the left and cold on removal of debris.

- Page 18 OP TS1503 CL C OP TS1503 CL C OP TS1503 CL C OP TS1503 CL C (Concealed) continued. 3. Attach isolation elbows to mixer valve 3. Attach isolation elbows to mixer valve 3. Attach isolation elbows to mixer valve 3.

- Page 19 Installation cont. OP TS1503 SCL C OP TS1503 SCL C OP TS1503 SCL C OP TS1503 SCL C Before Installation Before Installation Before Installation Before Installation Important: Important: Water supplies to the mixer Important: Important: Flush through the pipework to ensure must be with hot on the left and cold on removal of debris.

- Page 20 Installation cont. OP TS1503 SCL C OP TS1503 SCL C continued OP TS1503 SCL C OP TS1503 SCL C 3. Attach shower valve to backplate cover 3. Attach shower valve to backplate cover 3. Attach shower valve to backplate cover 3.

-

Page 21: Operation & Temperature Setting

Operation & Temperature Setting On/Off and Temperature Control On/Off and Temperature Control On/Off and Temperature Control On/Off and Temperature Control Turn the control (1) anti-clockwise to OP TS1503 ISOL C shown below OP TS1503 ISOL C OP TS1503 ISOL C OP TS1503 ISOL C turn on and increase the temperature. -

Page 22: Commissioning

Commissioning wait for five seconds, if the water is still Commissioning notes for Commissioning notes for Commissioning notes for Commissioning notes for flowing check that the temperature is Thermostatic Mixing Valves Thermostatic Mixing Valves Thermostatic Mixing Valves Thermostatic Mixing Valves below 46ºC. -

Page 23: In Service Testing

In Service Testing Purpose Purpose Purpose Purpose c) Any isolating valves are fully open. The purpose of in service tests is to regularly monitor and record the With an acceptable mixed water performance of the thermostatic mixing temperature, complete the following valve. - Page 24 In Service Testing cont. Annex F of D 08 (informative) Annex F of D 08 (informative) Annex F of D 08 (informative) Annex F of D 08 (informative) Frequency of in-service tests c) If small changes (e.g. 1 to 2 K) in mixed water temperatures are recorded in General both of these periods, necessitating...

-

Page 25: Maintenance

• Unscrew the half cartridge (bottom leave behind. Order through your section of the cartridge) by inserting a flat Bristan stockist (order code: ECLOTH). tool into the slots and a suitable spanner onto the hexagonal part of the cartridge Servicing... - Page 26 Please visit: facing out into the centre of the www.bristan.com/sparesfinder in cartridge assembly. order to find spare parts for this product. • Screw the complete assembly into the valve body and tighten.

-

Page 27: Map Of Hard Water Regions In The Uk

Hard Water Regions in the UK Soft to Soft to Soft to Soft to Hard to very hard Hard to very hard Hard to very hard Hard to very hard moderately soft moderately soft moderately soft moderately soft Above 200mg/l as 0 - 100mg/l as calcium carbonate calcium carbonate... -

Page 28: Troubleshooting

Troubleshooting Symptom Symptom Symptom Symptom Cause Cause Cause Cause Remedy Remedy Remedy Remedy Maximum water Maximum water temperature Reset maximum water temperature too set incorrectly. temperature. Refer to ‘Maximum hot or cold Temperature Setting’ in Commissioning section (page 22) and ‘Adjusting the Temperature’ in Operation &... - Page 29 Troubleshooting Symptom Symptom Symptom Symptom Cause Cause Cause Cause Remedy Remedy Remedy Remedy No flow when Inlet filter is partially blocked. Check insert filters for any shower is turned blockages and clean as necessary. Blocked or damaged check Remove check valve and clean / valve.

-

Page 30: Guarantee

Guarantee Bristan offers solid guarantees to provide *Labour provided by an approved Bristan engineer. Guarantee only applies to products you with complete peace of mind. with a manufacturing fault. A deferred payment will be necessary in order to secure Taps and Mixers... -

Page 31: Service Policy

Our service staff are fully qualified to advise on correct installation procedures and will be able to diagnose whether the fault will require a replacement part or a visit from a Bristan engineer. If required, a service call will be booked and either yourself or an appointed representative (who should be a person of 18 years or over) must be present during the visit. - Page 32 Part Number: 800446 Issue: FI Opac Lever Range D1 Bristan Group Ltd. Birch Coppice Business Park Dordon Tamworth Staffordshire B78 1SG Web: www.bristan.com Email: enquire@bristan.com A Masco Company www.qssupplies.co.uk...

Need help?

Do you have a question about the OP TS1503 CL C and is the answer not in the manual?

Questions and answers