Summary of Contents for Woodward SECM70

- Page 1 Product Manual 26784 (Revision D, 07/2022) Original Instructions SECM70 Digital Control Installation Manual EC-US-L1...

- Page 2 Revisions— A bold, black line alongside the text identifies changes in this publication since the last revision. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

-

Page 3: Table Of Contents

Engineering Services ..........................15 Contacting Woodward’s Support Organization ................... 15 Technical Assistance ..........................16 ........................17 EVISION ISTORY The following are trademarks of Woodward, Inc.: • SECM70 The following are trademarks of their respective companies: TE (TE Connectivity Corporation) •... - Page 4 Figure 2-1. Location of Accelerometer to Measure Mounting Vibration ............7 Figure 2-2. Random Vibration Spectrum ...................... 7 Figure 3-1: SECM70 Isolators ........................9 Figure 3-2: SECM70 Outline Drawing ......................10 Figure 3-3. Preferred Mounting Orientation ....................11 Figure 3-4. Acceptable Mounting Orientation ..................... 11 Figure 3-5.

-

Page 5: Warnings And Notices

Manual 26784 SECM70 Digital Control Warnings and Notices Important Definitions This is the safety alert symbol used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. •... - Page 6 Manual 26784 SECM70 Digital Control On- and Off-Highway Mobile Applications: Unless Woodward's control functions as the supervisory control, customer should install a system totally independent of the prime mover control system that monitors for supervisory control of engine (and takes appropriate...

-

Page 7: Electrostatic Discharge Awareness

• board with your hands or with conductive devices. To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715 , Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 8: Chapter 1. Introduction

Chapter 1. Introduction The SECM70 is a full authority engine control module capable of withstanding the environment within the engine compartment and either on or off engine mounting. The 4 mounting feet on the controller are designed to accept specific rubber grommets and aluminum bushings to provide both vibration isolation as well as electrical isolation of the module case from chassis ground. -

Page 9: Chapter 2. Environmental Requirements

The SECM70 is designed for engine mount operation with the vibration isolators. If the SECM70 is mounted on a bracket not provided by Woodward, the bracket needs to be evaluated in the application. It is possible for a bracket resonance to be incompatible with the SECM70 product, causing premature failure of the module. -

Page 10: Temperature

Customers can verify the temperature in the desired mounting location by placing a thermocouple in the air near the operating SECM70. If the external ambient conditions are not worse case, this needs to be taken into consideration when measuring the SECM70 package temperature. If the measured air temperature when operating at worse case (fastest) engine speed and worse case (hottest) ambient conditions is less than 105 °C, the mounting location thermal stress is acceptable for the SECM70. -

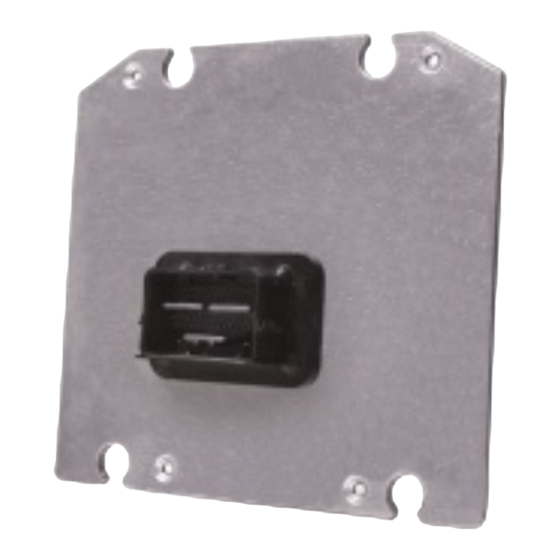

Page 11: Chapter 3. Packaging

Manual 26784 SECM70 Digital Control Chapter 3. Packaging Isolators The SECM70 has 4 mounting feet. Figure 3-1 illustrates the isolator components and shows the isolator pre-assembled on the module. Washer Grommet Bushing Figure 3-1: SECM70 Isolators The isolators must be inspected for wear at least once per year. For on-engine mounting, Woodward recommends replacing the vibration isolators once a year or sooner if wear is observed. -

Page 12: Outline Drawings

Manual 26784 SECM70 Digital Control Outline Drawings Figures 3-2 illustrates the package outline. Measurements shown are in millimeters. Figure 3-2: SECM70 Outline Drawing Woodward EC-US-L1... -

Page 13: Orientation

SECM70 Digital Control Orientation The SECM70 has been validated for high pressure spray and steam cleaning, however it is not recommended to mount with the connector facing up or with the harness routed upward directly from the module (Figure 3-5). This orientation can allow moisture to run down the harness to the wire seals in the connectors. -

Page 14: Connector Information

SECM70 Digital Control Connector Information The SECM70 mating connectors, terminals, wire caps (back shells) and wire plug part numbers are listed in Table 3-2 below. All unused pins must be plugged with the proper wire plugs to maintain environmental integrity. -

Page 15: Chapter 4 Product Support And Service Options

An Authorized Independent Service Facility (AISF) provides authorized service that includes repairs, • repair parts, and warranty service on Woodward's behalf. Service (not new unit sales) is an AISF's primary mission. A Recognized Engine Retrofitter (RER) is an independent company that does retrofits and •... -

Page 16: Returning Equipment For Repair

• To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715, Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 17: Engineering Services

Field Service engineering on-site support is available, depending on the product and location, from one of our Full-Service Distributors. The field engineers are experienced both on Woodward products as well as on much of the non-Woodward equipment with which our products interface. -

Page 18: Technical Assistance

SECM70 Digital Control Technical Assistance If you need to contact technical assistance, you will need to provide the following information. Please write it down here before contacting the Engine OEM, the Packager, a Woodward Business Partner, or the Woodward factory: General... -

Page 19: Revision History

Manual 26784 SECM70 Digital Control Revision History Changes in Revision D— Added Lockout/Tagout and IOLock warnings (pages 3 and 4) • • Revised Electrostatic Discharge Awareness section (page 5) Corrected mounting hardware (Chapter 3): • Changed screw size from M8 to M6 and washer size from 8 mm to 6 mm Added recommended torque for M6 hex screw: 57-67 in-lbs (6.5-7.6Nm) - Page 20 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

Need help?

Do you have a question about the SECM70 and is the answer not in the manual?

Questions and answers