Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Xylem FLYGT APP 412

- Page 1 Installation, Operation, and Maintenance manual 90001701_4.0 APP 412...

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 Introduction and Safety.................... 3 1.1 Introduction......................3 1.2 Safety terminology and symbols..............3 1.3 User safety......................4 1.3.1 Power lock-out................... 5 1.3.2 Qualification of personnel................ 5 1.4 End-of-life product disposal................5 1.5 Spare parts......................6 1.6 Warranty......................6 1.7 Support....................... - Page 4 Table of Contents 7 Maintenance......................24 7.1 Preventive maintenance................. 24 7.2 Change the battery..................24 8 Troubleshooting......................26 8.1 The unit does not work................... 26 9 Technical Reference....................27 9.1 Dimensions.......................27 9.2 Environmental requirements................. 27 9.3 IP rating......................27 9.4 Electrical data....................28 9.5 RTC battery.......................28 9.6 Terminals......................

-

Page 5: Introduction And Safety

This includes any modification to the equipment or use of parts not provided by Xylem. If there is a question regarding the intended use of the equipment, please contact a Xylem representative before proceeding. -

Page 6: User Safety

1 Introduction and Safety Hazard level Indication A hazardous situation which, if not avoided, could WARNING: result in death or serious injury A hazardous situation which, if not avoided, could CAUTION: result in minor or moderate injury Notices are used when there is a risk of equipment NOTICE: damage or decreased performance, but not personal injury. -

Page 7: Power Lock-Out

Risk of electrical shock or burn. A certified electrician must supervise all electrical work. Comply with all local codes and regulations. All work on the product must be carried out by certified electricians or Xylem authorized mechanics. Xylem disclaims all responsibility for work done by untrained, unauthorized personnel. -

Page 8: Spare Parts

1.6 Warranty For information about warranty, see the sales contract. 1.7 Support Xylem only supports products that have been tested and approved. Xylem does not support unapproved equipment. APP 412 Installation, Operation, and Maintenance manual... -

Page 9: System Description

2 System Description 2 System Description 2.1 Adaptive mixers ADC The system consists of one to eight mixers, with one APP 412 controller and one FPG 415 gateway for each additional mixer. Parts Number Part Product name Description Mixer • SR 4220 A mixer with an integrated intelligent technology •... -

Page 10: Adaptive Ultra-Low Head Propeller Pumps Adc

2 System Description Number Part Product name Description Controller APP 412 • Based on process conditions, the controller regulates the mixer. • The operator changes the mixer settings through the local HMI or through a SCADA system over Modbus. • Data is logged by and stored in the controller. - Page 11 2 System Description Parts Number Part Product name Description Pump • PP 4220 A pump with an integrated intelligent technology • PP 4230 Controller APP 412 • The controller starts and stops the pump based on input signals. • The operator changes the pump settings through the local HMI or through a SCADA system over Modbus.

- Page 12 2 System Description Number Part Product name Description FOP 402 HMI - Alternative 1 • A touchscreen HMI that is used for navigation and selection in the menus. • The touchscreen HMI is connected to a web server that is embedded in the controller.

-

Page 13: Product Description

3 Product Description 3 Product Description 3.1 Product design APP 412 is a controller that is connected to Flygt adaptive mixers or to Flygt adaptive ultra low head pumps. Product name Part number Description APP 412 8355100 Controller for Flygt adaptive mixers or Flygt adaptive ultra low head pumps 3.2 Approvals •... -

Page 14: The Data Plate

3 Product Description 3.4 The data plate 8xxxxxx 1. Brand 2. MAC address 3. Country of origin. Manufacturer. 4. Product 5. Rated supply 6. Approvals 7. Waste disposal symbol 8. Serial number 9. Part number APP 412 Installation, Operation, and Maintenance manual... -

Page 15: Mechanical Installation

4 Mechanical Installation 4 Mechanical Installation 4.1 Do not install in an explosive zone NOTICE: Do not use this unit in environments that may contain flammable/explosive or chemically aggressive gases or powders. 4.2 Install the controller 4.2.1 Install the unit Snap the unit onto the DIN rail. - Page 16 4 Mechanical Installation 2. Install the backplane connectors on the DIN rail. 3. Snap the unit or units onto the DIN rail. APP 412 Installation, Operation, and Maintenance manual...

-

Page 17: Electrical Installation

5 Electrical Installation 5 Electrical Installation 5.1 Precautions Before starting work, make sure that the safety instructions have been read and understood. DANGER: Electrical Hazard Before starting work on the unit, make sure that the unit and the control panel are isolated from the power supply and cannot be energized. -

Page 18: Connect The Controller

5 Electrical Installation Requirements These requirements apply for electrical installation: • All fuses and circuit breakers must have the proper rating, and comply with local regulations. • The cables must be in accordance with the local rules and regulations. 5.2 Connect the controller Some of the connection terminals are configurable. - Page 19 5 Electrical Installation FOP 315 HMI 3. Connect the FOP 315 cable to the HMI terminal. The maximum cable length is 100 m (328 ft). Description HMI cable Cable color HMI terminal on the controller Ground Black CAN low Blue Shield —...

-

Page 20: Set The Switches

5 Electrical Installation The digital outputs are potential free relay outputs. Connect a power supply unit maximum 250 VAC, or 30 VDC, 5 A. The digital outputs are configurable to be normally open or normally closed. NO/NC Analog output 8. Connect the analog output cables to the analog output terminal. The analog output is active. -

Page 21: Connect The Controller And The Gateways

5 Electrical Installation NODE ADDRESS 24VDC RS485 ALARM A ALARM B RUN/CLEAN COMMS RS485 NODE ADDRESS MASTER SLAVE ETHERNET NO COM NO COM 5.3 Connect the controller and the gateways Some of the connection terminals are configurable. For more information, see the System Installation and Operation Manual. -

Page 22: Set The Switches

5 Electrical Installation 5.3.2 Set the switches Set the switches. Switch Correct setting NODE ADDRESS, 0–9 All the node addresses in the system must be unique and not 0. MASTER/SLAVE – APP 412: MASTER – FPG 415: SLAVE TERM, ON/OFF –... -

Page 23: Operation

6 Operation 6 Operation 6.1 Startup and operation For instructions about the system operation, see the System Installation and Operation manual. 6.2 LED indicators ALARM A ALARM B COMMS RS485 NODE ADDRESS Table 1: Normal operation Description Color Indication Power Green The power is on. - Page 24 6 Operation Description Color Indication Constant red The alarm condition is present. The alarm is acknowledged, or no acknowledgement is required. – There is no alarm. ALARM B Alarm, Class B Flashing red The alarm is not acknowledged. The alarm condition is either present or has ceased.

- Page 25 6 Operation ALARM A ALARM B COMMS RS-485 Indication Flashing red Flashing red – – – communication between the controller and the gateways in the system is lost. The gateways are operating in redundancy mode. APP 412 Installation, Operation, and Maintenance manual...

-

Page 26: Maintenance

7 Maintenance 7 Maintenance 7.1 Preventive maintenance DANGER: Crush Hazard Moving parts can entangle or crush. Always disconnect and lock out power before servicing to prevent unexpected startup. Failure to do so could result in death or serious injury. Make sure that the unit is clean from dust and dirt. Use a wet cloth and soapy water for cleaning. - Page 27 7 Maintenance 7. Turn on the power to the system. 8. Make sure that the real-time clock (RTC) shows the correct time. APP 412 Installation, Operation, and Maintenance manual...

-

Page 28: Troubleshooting

8 Troubleshooting 8 Troubleshooting 8.1 The unit does not work Make sure that all wires are correctly connected according to the cable chart. Cause Remedy The PWR LED is not lit. • Make sure that the unit receives voltage. • Restart the unit. The unit does not communicate with the mixer/ •... -

Page 29: Technical Reference

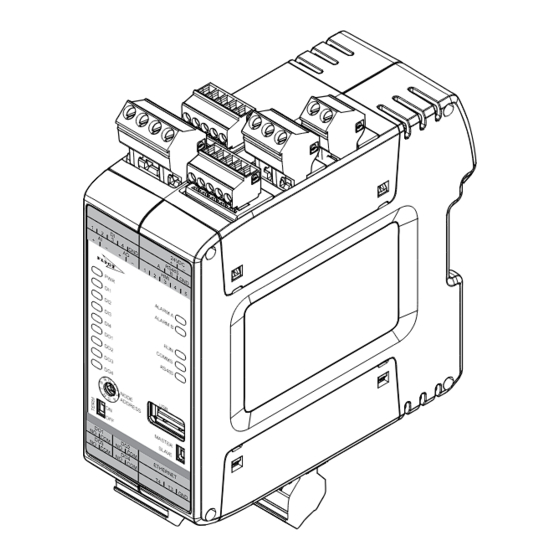

9 Technical Reference 9 Technical Reference 9.1 Dimensions 24VDC RS485 ALARM A ALARM B COMMS RS485 NODE ADDRESS MASTER SLAVE ETHERNET NO COM NO COM 1. 112 mm (4.4 in) 2. 45 mm (1.8 in) 3. 106 mm (4.2 in) 9.2 Environmental requirements Parameter Value... -

Page 30: Electrical Data

9 Technical Reference Degree of protection, IP20 Code Description The enclosure is protected against: • Fingers or objects that are less than 80 mm (3.15 in) in length • Objects that are larger than 12.5 mm (0.49 in) in diameter The enclosure is not protected against water. - Page 31 9 Technical Reference Section Terminal Description TERM Backplane termination switch Standard type A USB socket MASTER, SLAVE MASTER/SLAVE switch Isolated analog input, 4–20 mA Maximum 24 VDC – Scaling: 0–100% Offset: 0–16 mA with 0.1 mA resolution Analog output, 4–20 mA Maximum 24 VDC –...

- Page 32 9 Technical Reference Section Terminal Description Ethernet • Modbus TCP • Web server Backplane The Flygt controller communicates with the Flygt gateways through the backplane. APP 412 Installation, Operation, and Maintenance manual...

- Page 36 For more information on how Xylem can help you, go to www.xylem.com Xylem Water Solutions Global Visit our Web site for the latest...

Need help?

Do you have a question about the FLYGT APP 412 and is the answer not in the manual?

Questions and answers