Subscribe to Our Youtube Channel

Summary of Contents for ESAB 0700300989

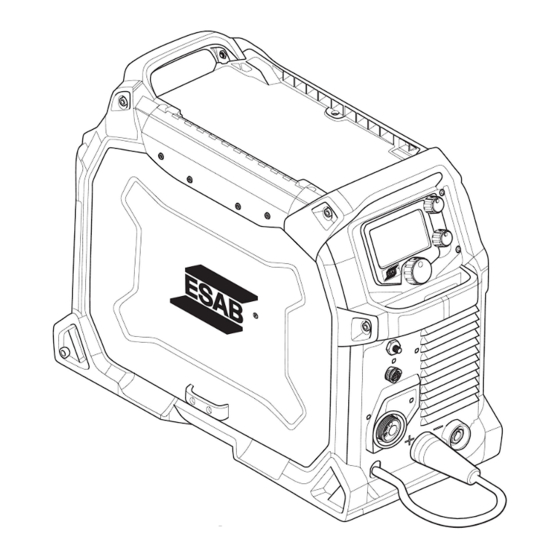

- Page 1 EMP 235ic Instruction manual Valid for: serial no. EMP 235ic 709-, 740-xxx-xxxx 0463 486 001 GB 20210628...

-

Page 3: Table Of Contents

6.1.9 Icon reference guide................MAINTENANCE ................... Routine maintenance ................Power source and wire feeder maintenance ........Torch and liner maintenance ..............TROUBLESHOOTING ................. ORDERING SPARE PARTS ................ DIAGRAM ......................ORDERING NUMBERS ..................34 0463 486 001 © ESAB AB 2021... - Page 4 TABLE OF CONTENTS WEAR PARTS ...................... ACCESSORIES ....................37 REPLACEMENTS PARTS ................... 38 Rights reserved to alter specifications without notice. 0463 486 001 © ESAB AB 2021...

-

Page 5: Safety

Safety Data Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 6 Protect your eyes and body. Use the correct welding screen and filter lens and wear protective clothing. • Protect bystanders with suitable screens or curtains. NOISE - Excessive noise can damage hearing Protect your ears. Use earmuffs or other hearing protection. 0463 486 001 - 6 - © ESAB AB 2021...

- Page 7 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0463 486 001 - 7 - ©...

-

Page 8: Introduction

2 INTRODUCTION INTRODUCTION The ESAB EMP product family is a new generation of MIG and Multi-Process (MIG/MMA/TIG) welding power sources. The EMP 235ic power source is designed to match the needs of the light-medium fabrication user. It is tough, durable and portable, providing excellent arc performance across a variety of welding applications. -

Page 9: Technical Data

16 A / 20.6 V – 210 A / 28.4 V 16 A / 20.6 V – 130 A / 25.2 V Open circuit voltage (OCV) VRD deactivated, nominal 68 V / (90 V) 68 V / (90 V) OCV (Boost OCV) Efficiency Power factor 0.98 0.99 0463 486 001 - 9 - © ESAB AB 2021... - Page 10 Equipment marked IP 23S is intended for indoor and outdoor use; however, should not be operated in precipitation. Application class The symbol indicates that the power source is designed for use in areas with increased electrical hazard. 0463 486 001 - 10 - © ESAB AB 2021...

-

Page 11: Installation

Position the power source so that its cooling air inlets and outlets are not obstructed. A. 100 mm (4 in.) B. 100 mm (4 in.) Lifting instructions The power source can be lifted using any of the handles. 0463 486 001 - 11 - © ESAB AB 2021... -

Page 12: Mains Supply

Ensure input power line disconnect switch is locked (lock-out/Tagging) in the ‘Open’ position BEFORE removing input power fuses. Connection/Disconnect should be carried out by competent persons. Rating plate with supply connection data 0463 486 001 - 12 - © ESAB AB 2021... -

Page 13: Recommended Fuse Sizes And Minimum Cable Area

Generators with Automatic Voltage Regulation (AVR) or with equivalent or better type of regulation, with rated power 8 kW, are recommended. 0463 486 001 - 13 - © ESAB AB 2021... -

Page 14: Operation

Assure that the side panels are closed during operation. WARNING! Tighten the bobbin locking nut in order to prevent it from sliding off the hub. 100 mm (4 in.) 200 mm (8 in.), 300 mm (12 in.) 0463 486 001 - 14 - © ESAB AB 2021... -

Page 15: Connections

Mains cable Gas outlet, optional: TIG torch or Mains supply switch ON/OFF Spool-gun Torch/Remote control connection Gas inlet, optional: TIG torch or Spool-gun Negative output [-] Gas inlet for MIG/MAG 0463 486 001 - 15 - © ESAB AB 2021... -

Page 16: Connection Of Welding And Return Cables

Check the recommended polarity for the welding wire you want to use. The polarity can be changed by moving the polarity changeover cable to suit the applicable welding process. 0463 486 001 - 16 - © ESAB AB 2021... -

Page 17: Inserting And Replacing Wire

Re-secure the pressure roller arm and wire drive tension screw and adjust the pressure if necessary. With the MIG torch lead reasonably straight feed the wire through the MIG torch by depressing the trigger switch. Close the spool side door. 0463 486 001 - 17 - © ESAB AB 2021... -

Page 18: Setting The Wire Feed Pressure

(illustration A), the feed rollers should slip. If you hold the welding torch approximately 50 mm (2 in.) from the piece of wood, the wire should be fed out and bend (Illustration B). 0463 486 001 - 18 - © ESAB AB 2021... -

Page 19: Changing The Feed/Pressure Rollers

). Aluminium and silicon bronze use pure argon gas (Ar). In the sMIG mode (see section "sMIG mode" in the USER INTERFACE chapter), the optimal welding arc with the gas used will be automatically set. 0463 486 001 - 19 - © ESAB AB 2021... -

Page 20: Duty Cycle

A different combination of duty cycle and welding current can be selected. Use the graphs below to determine the correct duty cycle for a given welding current. Duty cycle on 120 V AC 0463 486 001 - 20 - © ESAB AB 2021... -

Page 21: Overheating Protection

When this occurs, the welding current is interrupted and an overheating symbol appears on the display. The overheating protection resets automatically when the temperature has returned to normal working temperature. 0463 486 001 - 21 - © ESAB AB 2021... -

Page 22: User Interface

Flux cored wire mode MMA mode Lift-TIG mode Settings User manual information Dialogue box 6.1.2 sMIG mode Basic Home screen Information Memory Material selection Wire feed speed Material thickness Dialogue box 0463 486 001 - 22 - © ESAB AB 2021... -

Page 23: Manual Mig Mode

Advanced Home screen Information Memory Material selection Parameter Wire feed speed Voltage Dialogue box 6.1.4 Flux cored wire mode Basic Home screen Information Memory Wire feed speed Voltage Dialogue box 0463 486 001 - 23 - © ESAB AB 2021... -

Page 24: Mma Mode

Voltage (OCV or Arc) Dialogue box Advanced Home screen Information Memory Parameter Amperage Voltage (OCV or Arc) Arc ON/OFF Dialogue box 6.1.6 LIFT-TIG mode Basic Home screen Information Memory Amperage Dialogue box 0463 486 001 - 24 - © ESAB AB 2021... -

Page 25: Settings

User manual information Maintenance information Wear & Spare parts Operation information Home screen Dialogue box 6.1.9 Icon reference guide Home Spot time on/off selection Information MIG Torch Spot time on adjustment 0463 486 001 - 25 - © ESAB AB 2021... - Page 26 4T, Trigger Hold/Lock User manual on main menu Plate thickness at sMIG Amps mode 0463 486 001 - 26 - © ESAB AB 2021...

- Page 27 Unit of Measure Upslope, Sloping the current up over a period of Bead profile, concave time at the beginning of the weld cycle Volts Bead profile, convex Wire feed speed Wire diameter 0463 486 001 - 27 - © ESAB AB 2021...

-

Page 28: Maintenance

Every 6 month Clean inside equipment. Power source and wire feeder maintenance General good practice is to perform a power source clean each time a wire bobbin is replaced. 0463 486 001 - 28 - © ESAB AB 2021... -

Page 29: Torch And Liner Maintenance

Remove the liner from the torch and inspect it for damage or kinks. Clean the liner by blowing compressed air (max. 5 bar) through the end of the liner that was mounted closest to the power source. Re-install the liner. 0463 486 001 - 29 - © ESAB AB 2021... -

Page 30: Troubleshooting

Make sure you are using the correct polarity. The welding problems electrode holder is usually connected to the positive polarity and the work lead to the negative polarity. If in doubt, consult the electrode data sheet. 0463 486 001 - 30 - © ESAB AB 2021... - Page 31 See section "Duty cycle" in the OPERATION chapter. • Make sure the air inlets or outlets are not clogged. 0463 486 001 - 31 - © ESAB AB 2021...

-

Page 32: Ordering Spare Parts

9 ORDERING SPARE PARTS ORDERING SPARE PARTS CAUTION! Repair and electrical work should be performed by an authorised ESAB service technician. Use only ESAB original spare and wear parts. The EMP 235ic is designed and tested in accordance with international standards IEC-/EN 60974-1, IEC-/EN 60974-5 and IEC-/EN 60974-10. -

Page 33: Diagram

DIAGRAM DIAGRAM EMP 235ic 0463 486 001 - 33 - © ESAB AB 2021... -

Page 34: Ordering Numbers

EMP 235ic Bobbin Ø100–300 mm (4–12 in.) Euro Connector 0700 300 994 EMP 235ic Bobbin Ø100–300 mm (4–12 in.) Euro Connector 0463 485 001 Spare parts list 0459 560 101 Instruction manual for MXL™ 270 0463 486 001 - 34 - © ESAB AB 2021... - Page 35 0558 102 518 Locking knob 0558 102 331 Pressure arm complete assembly 0558 102 550 Shoulder screw 0558 102 459 Euro adapter locating screw 0464 636 880 Euro adapter assembly 0463 486 001 - 35 - © ESAB AB 2021...

- Page 36 WEAR PARTS 0463 486 001 - 36 - © ESAB AB 2021...

- Page 37 0700 300 857 TIG Torch TXH™ 201 4 m (13 ft) TIG torch c/w 8 pin plug W4014450 Foot control Contactor on/off and current control with 4.6 m (15 ft) cable and 8-pin male plug 0463 486 001 - 37 - © ESAB AB 2021...

- Page 38 MIG Torch MXL™ 270, 3 m (10 ft) 0349 312 105 Gas hose, 4.5 m (14.8 ft) 0700 006 900 MMA welding cable kit, 3 m (10 ft) 0700 006 901 Return welding cable kit, 3 m (10 ft) 0463 486 001 - 38 - © ESAB AB 2021...

- Page 39 REPLACEMENTS PARTS 0463 486 001 - 39 - © ESAB AB 2021...

- Page 40 For contact information visit esab.com ESAB AB, Lindholmsallén 9, Box 8004, 402 77 Gothenburg, Sweden, Phone +46 (0) 31 50 90 00 http://manuals.esab.com...

Need help?

Do you have a question about the 0700300989 and is the answer not in the manual?

Questions and answers