Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for IFM Electronic LR8300

- Page 1 Operating instructions Electronic level sensor LR8300...

-

Page 2: Table Of Contents

Contents 1 Preliminary note ���������������������������������������������������������������������������������������������������4 1�1 Symbols used ������������������������������������������������������������������������������������������������4 2 Safety instructions �����������������������������������������������������������������������������������������������4 3 Items supplied������������������������������������������������������������������������������������������������������5 4 Functions and features ����������������������������������������������������������������������������������������6 4�1 Applications ���������������������������������������������������������������������������������������������������6 4�1�1 Restriction of the application area ��������������������������������������������������������6 5 Function ���������������������������������������������������������������������������������������������������������������7 5�1 Measuring principle ���������������������������������������������������������������������������������������7 5�2 Features of the unit ����������������������������������������������������������������������������������������8 5�2�1 Easy set-up �������������������������������������������������������������������������������������������8 5�2�2 Display functions ����������������������������������������������������������������������������������8 5�2�3 Switching functions �������������������������������������������������������������������������������8... - Page 3 10 Parameter setting ��������������������������������������������������������������������������������������������24 10�1 Parameter setting in general ���������������������������������������������������������������������24 10�2 Probe length (unit on delivery) �������������������������������������������������������������������26 10�3 Configuration of the display �����������������������������������������������������������������������26 10�4 Selecting the evaluation mode ������������������������������������������������������������������26 10�5 Offset setting ����������������������������������������������������������������������������������������������27 10�6 Setting of output signals ����������������������������������������������������������������������������27 10�6�1 Setting of the output function ������������������������������������������������������������27 10�6�2 Set the switching limits (hysteresis function) ������������������������������������27 10�6�3 Set the switching limits (window function) ����������������������������������������27 10�6�4 Setting of the switch-off delay �����������������������������������������������������������28...

-

Page 4: Preliminary Note

1 Preliminary note 1.1 Symbols used ► Instructions > Reaction, result […] Designation of keys, buttons or indications → Cross-reference Important note Non-compliance may result in malfunction or interference� Information Supplementary note� 2 Safety instructions • The device described is a subcomponent for integration into a system� - The manufacturer of the system is responsible for the safety of the system�... -

Page 5: Items Supplied

140 / 55�1 E43209 160 / 63�0 E43210 Flange plate Size / process connection Order number 73 - 90 / ¾” NPT E43206 Only use rods from ifm electronic gmbh� The optimum function is not ensured when using components from other manufacturers�... -

Page 6: Functions And Features

4 Functions and features The unit continuously detects the level in tanks and generates output signals according to the parameter settings� 4 switching outputs are available� They can be set separately� For correct function the unit needs a large enough metal launching plate� It is necessary for transferring the microwave pulse to the tank with optimum transmission power�... -

Page 7: Function

• The unit is not suitable for media with a dielectric constant < 20 (e�g� oils, fats, plastic granulates, bulk material)� • If the unit is to be used in acids or alkalis, in hygienic areas or in electroplating applications: first check the compatibility of the product materials (→ 12 Technical data and scale drawing) with the media to be monitored�... -

Page 8: 5�2 Features Of The Unit

pulse directly relates to the travelled distance (D) and the current level� The reference for distance measurement is the lower edge of the process connection� 5.2 Features of the unit 5.2.1 Easy set-up • When operating voltage is applied to the unit for the first time, the probe length must be entered�... -

Page 9: 5�2�4 Offset For Indicating The Real Level In The Tank

The width of the window can be set by means of the difference between FHx and FLx� FHx = upper value, FLx = lower value� Fig. 5-3 Fig. 5-4 L = level; HY = hysteresis; FE = window • For each switching output a switch-off delay of max� 60 s can be set (e�g� for especially long pump cycles)�... -

Page 10: 5�2�7 Binary Mode

If, however, it is not received again in sufficient strength within the delay time, the outputs pass into the safe state� In case of heavy foam formation and turbulence, note the examples of how to create a steady area (→ 6.1)� 5.2.7 Binary mode In the binary mode the outputs OUT1���OUT4 indicate the level as a 8-4-2-1 binary code�... -

Page 11: 5�3 Io-Link

5.3 IO-Link General information This unit has an IO-Link communication interface which requires an IO-Link- capable module (IO-Link master) for operation� The IO-Link interface enables direct access to the process and diagnostic data and provides the possibility to set the parameters of the unit during operation� In addition communication is possible via a point-to-point connection with a USB adapter cable�... - Page 12 • For tank walls which are not straight, steps, supports or other structures in the tank a distance of 50 mm to the tank wall must be adhered to� • When operating the unit in small tanks (probe lengths shorter than 200 mm and less than 300 mm distance to the tank wall), mount the unit off-centre (eccentrically) to prevent possible interference from tank resonances�...

- Page 13 Fig. 6-1 Fig. 6-2 • Do not install the unit in the immediate vicinity of a fill opening (fig� 6-3)� If possible, install a fill pipe (A) in the tank (fig� 6-4)� Minimum distance between the fill pipe and the rod = 50 mm; higher for probe lengths > 70 cm and in case of heavy soiling�...

-

Page 14: 6�2 Installation Of The Probe

Min� diameter of the bypass and still pipe: d = 100 mm� The upper access to the steady area (fig� 6-5: A / B) has to be above the max� level� The lower access (fig� 6-5: C / D) or the area with perforated sheet has to be below the min�... -

Page 15: 6�3 Shortening Of The Probe

In case of high mechanical stress (strong vibration, moving viscous media) it may be necessary to secure the screw connection, e�g� by a screw retaining compound� Substances such as screw retaining compounds may migrate into the medium� Make sure that they are harmless� When using mechanical means of securing (e�g�... -

Page 16: 6�4�1 Installation In Closed Metal Tanks (Without Flange Plate)

• Installation in the tank lid using a flange plate, e�g� for tanks with thin walls (→ 6.4.2)� Furthermore, installation in open tanks (→ 6.4.3) and plastic tanks is possible (→ 6.4.4)� 6.4.1 Installation in closed metal tanks (without flange plate) Fig. -

Page 17: 6�4�3 Installation In Open Tanks

► Arrange for a bore hole in the tank lid� It must have a minimum diameter (d) to enable sufficient transfer of the measured signal to the probe (fig� 6-8)� The diameter depends on the wall thickness of the tank lid: Wall thickness [mm] 1���5 5���8... -

Page 18: 6�4�4 Installation In Plastic Tanks

► Avoid non-flush installation (see fig� 6-7)� ► The height can be slightly corrected by means of appropriate sealing material (e�g� Teflon tape)� 6.4.4 Installation in plastic tanks 150 mm To enable sufficient transfer of the measured signal, note in case of installation in plastic tanks or metal tanks with plastic lid: ►... -

Page 19: Electrical Connection

7 Electrical connection The unit must be connected by a qualified electrician� The national and international regulations for the installation of electrical equipment must be adhered to� Voltage supply according to SELV, PELV� ► Disconnect power� ► Connect the unit as follows: Out 2 Out 1 / IO-Link Out 3... -

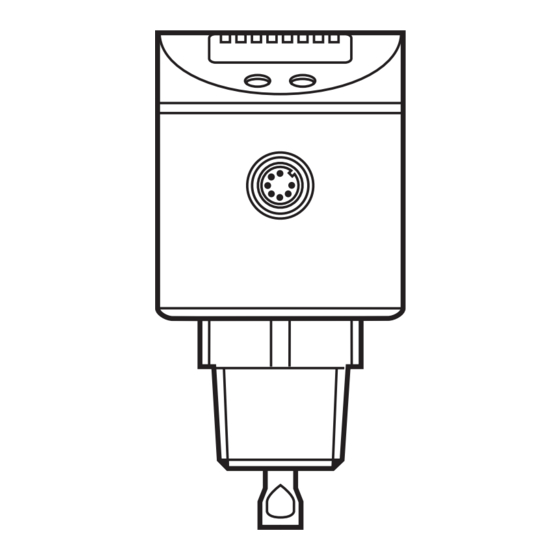

Page 20: Operating And Display Elements

8 Operating and display elements 3 4 5 6 Mode/Enter 1 to 8: Indicator LEDs - LED 1: green = indication of the level in cm� - LED 2: green = indication of the level in inch� - LED 3: green = indication of the level in % of the final value of the measuring range� - LED 4: not used�... -

Page 21: Menu

9 Menu 9.1 Menu structure / switching mode (bin = OFF) cm inch S... -

Page 22: 9�2 Menu Structure / Binary Mode (Bin

9.2 Menu structure / binary mode (bin = on) cm inch S... -

Page 23: 9�3 Explanation Of The Menu

9.3 Explanation of the menu SP1/rP1 Upper / lower limit value for the level at which OUT1 switches� FH1/FL1 Upper / lower limit for the acceptable range (monitored by OUT1)� SP2/rP2 Upper / lower limit value for the level at which OUT2 switches� FH2/FL2 Upper / lower limit for the acceptable range (monitored by OUT2)�... -

Page 24: Parameter Setting

10 Parameter setting During parameter setting the unit remains in the operating mode internally� It continues to monitor with the existing parameters until the parameter setting has been completed� 10.1 Parameter setting in general 3 steps must be taken for each parameter setting: Select parameter ►... - Page 25 • Change from menu level 1 to menu level 2: ► Press [Mode/Enter] until [EF] is displayed. Mode/Enter Set ► Briefly press [Set]� > The first parameter of the submenu is Mode/Enter Set displayed (here: [res])� • Locking / unlocking The unit can be locked electronically to prevent unintentional settings�...

-

Page 26: 10�2 Probe Length (Unit On Delivery)

10.2 Probe length (unit on delivery) On delivery of the unit, you must first enter the probe length� The complete parameter setting menu cannot be accessed before this� Malfunctions may occur if the wrong probe length is set� ► Apply operating voltage� >... -

Page 27: 10�5 Offset Setting

10.5 Offset setting ► Select [OFS] and enter the distance between bottom of the tank and lower edge of the probe� Afterwards, display and switch points refer to the real level� Factory setting: [OFS] = 0� Note: Set [OFS] before setting the switching limits (SPx/FHx, rPx/FLx)� Otherwise, the switching limits shift by the value of the set offset�... -

Page 28: 10�6�4 Setting Of The Switch-Off Delay

► Select [FL1] ��� [FL4] and set the lower limit of the acceptable range� FLx is always lower than FHx� The unit only accepts values which are lower ��� than the value for FHx� 10.6.4 Setting of the switch-off delay ►... -

Page 29: 10�8 Changing The Probe Length

10.8 Changing the probe length Required after changes to the probe or to the application area� ► Select [LEnG] and set probe length L� Note the set unit of measurement (cm or inch)� Step increment: 0�5 cm / 0�2 inch� Remarks on the determination of the probe length: ►... -

Page 30: 11�3 Changing The Display Unit In The Run Mode

11.3 Changing the display unit in the Run mode (= switching between length indication (cm / inch) and percentage)� ► Briefly press [Set] in the Run mode� > The selected unit is displayed for 30 s, the corresponding LED is lit� With each push of the button the display type is changed�... -

Page 31: 11�5 Output Response In Different Operating States

11.5 Output response in different operating states OUT1��� OUT4 Initialisation according to the level and the setting of the output function Normal operation (bin, OU1���OU4) OFF for FOUx = OFF; Fault (E�0xx) ON for FOUx = on 12 Technical data and scale drawing Technical data and scale drawing at www�ifm�com�... -

Page 32: Servicing

13 Servicing ► Keep the process connection free of deposits and foreign bodies� ► In case of heavy soiling: clean the process connection and the probe at regular intervals� In case of longer operation separation layers can form in the medium (e�g� oil on water)�... -

Page 33: Applications

14 Applications 14.1 Storage tanks / level monitoring Level monitoring with evaluation in the binary mode • Menu setting: bin = on� • The settings for SPx, rPx, drx and OUx are not effective� OUT4 OUT3 OUT2 OUT1 XX�X = display value A = binary value P1: position 1, e�g�... -

Page 34: 14�2 Storage Tank

14.2 Storage tank Level control and min / max monitoring with 4 switching outputs� Replaces 4 float switches� Configuration of the switching outputs 1 ��� 4 (bin = OFF) Maximum value exceeded → alarm. Hysteresis function, normally closed (Hnc)� Upper preset value reached → finish refilling. Hysteresis function, normally open (Hno)�... -

Page 35: 14�3 Pumping Station

• If the level is below SP1, the output is switched� If the level is above SP1 or if there is a wire break, output 1 switches OFF (alarm message "overflow / wire break")� • If the level reaches SP2, output 2 switches (upper preset value reached; finish refilling)�... -

Page 36: Factory Setting

OUT1 OUT2 OUT3 XX�X = display value; A = empty the tank; B = overflow protection • If the level is below SP1, the output is switched� If the level is above SP1 or if there is a wire break, output 1 switches OFF (alarm message "overflow / wire break")�... - Page 37 Factory setting User setting rP3 / FL3 75% rP/FLmax SP4 / FH4 100% SP/FHmax rP4 / FL4 100% rP/FLmax FOU1 FOU2 FOU3 FOU4 inch SELd LEnG nonE SP/FHmax = LEnG value in inch minus 1�2� rP/FLmax = LEnG value in inch minus 1�4� When the LEnG value is entered, the program calculates the basic setting�...

Need help?

Do you have a question about the LR8300 and is the answer not in the manual?

Questions and answers