Summary of Contents for El-Björn TF 100HW

- Page 1 Manual TF 15HW, TF 30HW, TF 50HW, TF 100HW This product is only suitable for well-insulated areas or occasional use.

-

Page 2: Personal Protective Equipment

ain hot water. SAFETY • Take care not to damage the electrical cable. Do not jerk the electrical cable out of the Read the instruction manual carefully electrical inlet/outlet. Do not expose it to high and ensure you understand the content temperatures, oil, or sharp edges. -

Page 3: Risk Assessment

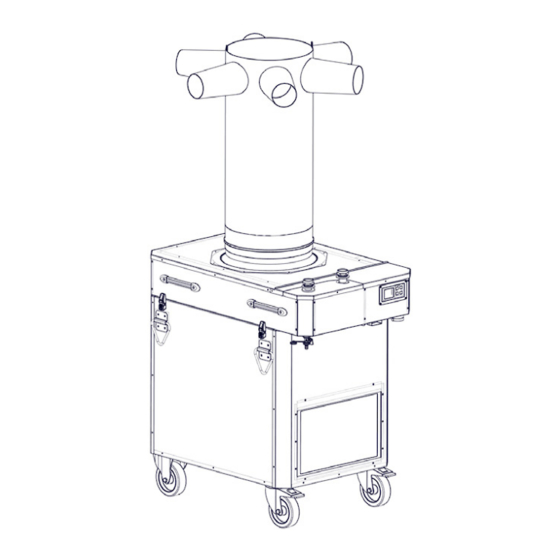

RISK ASSESSMENT Using spare parts or accessories that have not been recommended by El-Björn increases the risk of injury or damage to the machine. The machine is only intended for temporary drying and heating of rooms. When using electrical machinery, basic safety regulations shall always be followed, in order to reduce the risk of fire, electric shocks, burns or other personal injury. - Page 4 - 4 x lifting eyes for moving machine or suspending it from ceiling. - 2 x filters with additional pre-filter for extended life TF 30HW, TF 50HW, TF 100HW). 1 x filters with additional pre-filter for extended life (TF 15HW).

-

Page 5: Menu Description

DESCRIPTION OF DISPLAY DESCRIPTION OF BUTTONS Scroll up/down Choose/Cancel 1. On/Off 2. Back 3. Press for 3 sec- onds to - Log out - Pause for 30 min - Switch off MENU DESCRIPTION Signal strength Current temperature Log-in authority level A = Administrator S = Service Relative humidity... - Page 6 STARTING/STOPPING THE DRYING FAN IN DRYING MODE To turn on the display, press the RED ON BUTTON on the control panel for 1 second. The above menu will appear in the display. The drying fan is pre-set by default to drying mode. To start the drying fan, press and hold the GREEN BUTTON for 2 seconds (the fan will start).

- Page 7 CHANGING DEFAULT SETTINGS DESIRED TEMPERATURE, FAN SPEED, POWER (ELECTRIC DRYING FAN) To log in, press and hold any button for 1 second, the window below will appear. Use the arrows to enter your password, and press the GREEN button to confirm. There are two levels of authorisation: Administrator and Service.

-

Page 8: List Of Alarms

LIST OF ALARMS Time to replace filter: • To cancel the alarm, press the green button • The alarm symbol will shrink, but will stay on until the filter is replaced The product has overheated for some reason The product has not been switched off correctly: •... -

Page 9: Technical Data

TECHNICAL DATA TF 15HW TF 30HW TF 50HW TF 100HW 230 VAC 230 VAC 400 VAC 400 VAC H incl. air distributor 945mm 1950mm 2150 mm 2170 mm H excl. air distributor 745mm 1000mm 1222 mm 1250 mm 435mm 550mm... -

Page 10: Application Area

NOTE! APPLICATION AREA The section concerning safety must be read and The TF model is intended for drying and heating understood by everyone who uses or services this buildings where there is a need for temporary machine. The instructions describe operation and heating, drying or air circulation. -

Page 11: Assembly And Disassembly

OPERATION HANDLING DURING NORMAL OPERA- HANDLING DURING ABNORMAL OPER- TION ATION The machine does not start If you want to use antifreeze in a hot water system, Check that the fuses in the nearest electrical cabinet use polypropylene glycol with the right freezing have not blown and that the residual current device point. -

Page 12: Service & Maintenance

SERVICE MAINTENANCE Day-to-day maintenance should be performed on site by an appointed operator. Warning! To eliminate the risk of injury, always disconnect from the electrical supply before starting any service work. The following points must be checked by the operator. •... -

Page 13: Warranty

TRANSPORTATION/STORAGE Transportation The machine must always be transported upright. During transportation, the machine must be anchored to the transport vehicle. The machine should only be lifted using the 4 lifting eyes on Module 1 of the machine. If the heat exchangers have not been completely emptied and you want to protect the machines from damage, the heat exchangers should be filled with ethylene glycol before transport. - Page 14 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

- Page 15 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

- Page 16 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

- Page 17 El-Björn UK LTD Unit 2 Oyester Park, 109 Chertsey Road, West Byfleet, GB-Surrey, KT14 7AX Phone: (+44) 01483 729 348, E-mail: info@elbjorn.com El-Björn AB Box 29, SE-334 21 Anderstorp, Sweden, +46 (0)371-588 100 info@elbjorn.se, www.elbjorn.com...

Need help?

Do you have a question about the TF 100HW and is the answer not in the manual?

Questions and answers