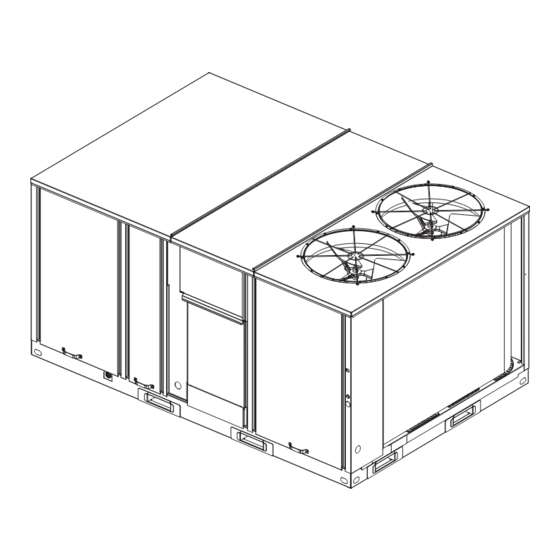

Trane Voyager TS 150-300 Series Installation, Operation And Maintenance Manual

Packaged rooftop air conditioners

Hide thumbs

Also See for Voyager TS 150-300 Series:

Table of Contents

Advertisement

Installation, Operation, and Maintenance

Packaged Rooftop Air Conditioners

Voyager™ – Electric/Electric

12.5 to 25 Tons, 60/50Hz

Model Number:

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of

heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury.

When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are

attached to the equipment.

December 2021

TS*150–300

TH*150-300

SAFETY WARNING

RT-SVX25Q-EN

Advertisement

Table of Contents

Summary of Contents for Trane Voyager TS 150-300 Series

- Page 1 Installation, Operation, and Maintenance Packaged Rooftop Air Conditioners Voyager™ – Electric/Electric 12.5 to 25 Tons, 60/50Hz Model Number: TS*150–300 TH*150-300 SAFETY WARNING Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury.

- Page 2 (Global Harmonized System of Classification and compounds have the same potential impact to the Labeling of Chemicals) guidelines for information on environment. Trane advocates the responsible handling of allowable personal exposure levels, proper all refrigerants-including industry replacements for CFCs respiratory protection and handling instructions.

- Page 3 Copyright This document and the information in it are the property of Trane, and may not be used or reproduced in whole or in part without written permission. Trane reserves the right to revise this publication at any time, and to make changes to its content without obligation to notify any person of such revision or change.

-

Page 4: Table Of Contents

Table of Contents Model Number Description Single Zone Variable Air Volume (Single Zone ....5 VAV) Control ......45 Model Number Notes . -

Page 5: Model Number Description

Digit 3 — Airflow Configuration Options Standard Motor Downflow Oversized Motor Without Communications Options Horizontal High Efficiency Motor Trane Communications Interface Digit 4, 5, 6 — Nominal Gross Single Zone Variable Air Volume Lontalk Communications Standard Motor Interface Cooling Capacity (MBh) Multi-Speed Standard Motor Building Automation Control... -

Page 6: Model Number Notes

Model Number Description Clogged Filter Switch, Fan 3. Requires Economizer. 16. For use with multi-speed and Failure SZVAV units only. 4. All 22 digit model numbers for Switch and Discharge Air reheat coil (B) require additional 17. Demand Control Ventilation Sensing Condensate Drain Pan Overflow factory installed options: Frostat,... -

Page 7: General Information

The RTRM is mounted in the control panel and is factory wireless communication between system controls, unit wired to the respective internal components. The RTRM controls, and wireless sensors for Trane control products receives and interprets information from other unit that use BACnet protocol. The WCI replaces the need for modules, sensors, remote panels, and customer binary communications wire in all system applications. -

Page 8: System Input Devices And Functions

General Information System Input Devices and Please note that on units equipped with factory installed MERV 13 filters, a clogged filter switch with different Functions pressure settings will be installed. This switch will close when the differential pressure is approximately 0.8” w.c. The RTRM must have a zone sensor or thermostat input in and open when the differential falls to 0.7”... -

Page 9: Sensors

This electronic sensor features single setpoint capability parallel with the FOS. and timed override with override cancellation. It is used with a Trane Integrated Comfort™ building management If this circuit is closed before the compressor is started, the system. compressor will not be allowed to operate. Anytime this... - Page 10 General Information The sensor is used to detect high temperatures due to fire Maintenance Instructions provided with the literature in the air conditioning or ventilation ducts. The sensor is package for this unit. designed to mount directly to the sheet metal duct. Each kit In order for the supply air smoke detector or return air contains two sensors.

-

Page 11: Unit Inspection

General Information Precautionary Measures • USB port that enables the downloading of component runtime information as well as trended historical sensor data WARNING • Customized reports Fiberglass Wool! Unit Inspection Exposure to glass wool fibers without all necessary PPE equipment could result in cancer, respiratory, skin or As soon as the unit arrives at the job site: eye irritation, which could result in death or serious injury. -

Page 12: Unit Clearances

General Information Unit Clearances Figure 1, p. 13 illustrates the minimum operating and service clearances for either a single or multiple unit installation. These clearances are the minimum distances necessary to assure adequate serviceability, cataloged unit capacity, and peak operating efficiency. Providing less than the recommended clearances may result in condenser coil starvation, “short-circuiting”... -

Page 13: Unit Dimensions

Unit Dimensions Figure 1. Typical installation clearance for single and multiple unit applications 5' 8" 5' 0" RT-SVX25Q-EN... - Page 14 Unit Dimensions Figure 2. Unit dimensional data for 12½ tons standard efficiency units 2”(51MM) ELECTRICAL CONNECTION SINGLE POINT POWER ENTRY DOWNFLOW CONDENSATE DRAIN CONN 1”(25MM) NPT 7/8”(22MM) DIA. HOLE (UNIT CONTROL WIRE) 2”(51MM) DIA. HOLE (UNIT POWER WIRE) SERVICE GAUGE PORT ACCESS Note: 51 mm(2“) electrical connection: single point power when heat installed.

- Page 15 Unit Dimensions Figure 4. Horizontal duct dimensional data 12½ tons standard efficiency units CLEARANCE 48” CLEARANCE 60” 1219 MM 1524 MM FILTER ACCESS DOOR HORIZONTAL UNITS CLEARANCE 72” ONLY 1829 MM SUPPLY RETURN HORIZONTAL CONDENSATE DRAIN CONNECTION 1.0 IN. NPT CLEARANCE 38”...

- Page 16 Unit Dimensions Figure 6. Unit dimensional data 15–25 tons high efficiency units Note: 51 mm(2“) Electrical Connection: Single Point Power When Heat Installed Figure 7. Unit dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units RT-SVX25Q-EN...

- Page 17 Unit Dimensions Figure 8. Horizontal duct dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units RT-SVX25Q-EN...

-

Page 18: Unit Weights

Unit Weights Table 1. Typical unit weights and point loading data (lb) Table 2. Typical unit weights and point loading data (kg) Corner Weights (lb) Corner Weights (kg) Unit Models Weights Unit Models Weights TS*150G 1373 TS*150G TH*150G 1868 TH*150G THD150G THD150G 1959... -

Page 19: Rigging

Unit Weights Rigging 7. Downflow units; align the base rail of the unit with the curb rail while lowering the unit onto the curb. Make sure that the gasket on the curb is not damaged while positioning the unit. WARNING Figure 10. -

Page 20: Installation

Installation Foundation When attaching the ductwork to the unit, provide a water- tight flexible connector at the unit to prevent operating sounds from transmitting through the ductwork. WARNING All outdoor ductwork between the unit and the structure should be weather proofed after installation is completed. Risk of Roof Collapsing! Note: For sound consideration, cut only the holes in the Failure to ensure proper structural roof support could... - Page 21 Installation • Ensure unit-to-curb seal is tight and without buckles or A condensate drain line must be connected to the P-Trap. cracks. Pitch the drain lines at least ½-inch for every 10 feet of horizontal run to assure proper condensate flow. Do not •...

-

Page 22: Main Unit Power

Installation breaker, a field supplied disconnect switch must be Figure 12. Through the base electrical option installed at or near the unit in accordance with the National Electrical Code (NEC latest edition). Main Unit Power WARNING Proper Field Wiring and Grounding Required! Failure to follow code could result in death or serious injury. - Page 23 Installation Controls using 24 Vac Table 4. Zone sensor module wiring Distance from Unit to Before installing any connecting wiring, refer to “Unit Control Recommended Wire Size Dimensions,” p. 13 for the electrical access locations 0–150 feet (0–45.7 m) 22 gauge (0.33 mm provided on the unit and Table 3, p.

- Page 24 Installation Figure 15. ReliaTel relative humidity sensor (dehumidification option) Figure 16. ReliaTel humidistat (dehumidification option) RT-SVX25Q-EN...

- Page 25 Installation Figure 17. Typical field wiring diagrams for optional controls (ReliaTel only) BAYSENS075* BAYSENS075* BAYSENS108* BAYSENS106* BAYSENS110* BAYSENS119* BAYSENS073* BAYSENS074* BAYSENS075* ASYSTAT669A OPTIONAL REMOTE SENSOR CONTROL BOX RTRM TEST 1 TEST 2 RT-SVX25Q-EN...

-

Page 26: Space Temperature Averaging

Installation Space Temperature Averaging Space temperature averaging is accomplished by wiring a number of remote sensors in a series/parallel circuit. Using the BAYSENS016* or BAYSENS077*, at least four sensors are required to accomplish space temperature averaging. Example #1 illustrates two series circuits with two sensors in each circuit wired in parallel. - Page 27 Installation Table 6. Space temperature averaging examples RT-SVX25Q-EN...

- Page 28 Installation Use the following checklist in conjunction with the general • VD = Line Voltage reading that deviates the farthest checklist (“General Unit Requirements,” p. 20) to ensure from the average voltage. that the unit is properly installed and ready for operation. Example: If the voltage readings of the supply power measured 221, 230, and 227, the average volts would be: WARNING...

- Page 29 Installation ReliaTel Controls WARNING Upon power initialization, the RTRM performs self- Live Electrical Components! diagnostic checks to insure that all internal controls are functional. It also checks the configuration parameters Failure to follow all electrical safety precautions when against the components connected to the system. exposed to live electrical components could result in death or serious injury.

-

Page 30: Factory-Mounted Unit Options

Factory-Mounted Unit Options Circuit Breaker (FIYUCB) and Unit disconnect switch or circuit breaker. Connect the power conductors to the lugs provided. Connect the Disconnect (FIYUDC) ground wire to the unit ground lug. Note: Wire size for the length of run should be determined using the circuit ampacity found on WARNING the unit nameplate and the N.E.C. -

Page 31: Powered And Unpowered Convenience

Factory-Mounted Unit Options Powered and Unpowered WARNING Convenience Proper Field Wiring and Grounding Required! WARNING Failure to follow code could result in death or serious injury. Hazardous Voltage w/Capacitors! All field wiring MUST be performed by qualified Failure to disconnect power and discharge capacitors personnel. -

Page 32: Return Air Smoke Detector

Factory-Mounted Unit Options Unpowered Convenience Outlet WARNING Unpowered Option (FIYCOUP) Hazardous Voltage w/Capacitors! 1. When the unpowered convenience outlet option is installed, remove the receptacle. Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury. 2. - Page 33 Factory-Mounted Unit Options Figure 21. Brackets Figure 22. Return air smoke detector for downflow units THREE PIECE HOOD PLASTIC ELBOW METAL INTAKE TUBE SMOKE DETECTOR COPPER TUBE (FACTORY INSTALLED) VINYL TUBES (7-3/4 INCHES LONG) VINYL TUBES (2 INCHES LONG) METAL EXHAUST TUBE (16.34 INCHES LONG) TUBES INSTALL FROM BOTTOM, TOP DOES NOT NEED TO BE...

- Page 34 Factory-Mounted Unit Options Note: In order to perform the last part of this operation, it procedures, including recommended intervals will be necessary to remove the barometric relief between filter changes and coil cleaning, is required. filter, open the barometric relief damper, and reach •...

-

Page 35: Air-Fi™ Wireless Communication Interface (Wci)

Air-Fi™ Wireless Communication Figure 26. WCI mounting location - T*D180-300 Interface (WCI) When installed, the Trane Air-Fi Wireless Communication Interface is located in the evaporator section, near the return air ductwork. The exact mounting location is dependent on the airflow configuration, cabinet size, and fresh air selection. -

Page 36: Pre Start

Pre Start Test Modes Verifying Proper Air Flow (Units with Belt Drive Indoor Fan) There are three methods in which the “Test” mode can be cycled at LTB-Test 1 and LTB-Test 2. Much of the systems performance and reliability is closely 1. - Page 37 Pre Start 7. To stop the SERVICE TEST, turn the main power disconnect switch to the “Off” position or proceed to the next component start-up procedure. Remove electro mechanical test mode connections (if applicable). RT-SVX25Q-EN...

-

Page 38: Start Up

Note: The Copeland, SSA and SPA scroll compressors for 5. To stop the SERVICE TEST, turn the main power R-410A units use Trane OIL00094. The correct oil for disconnect switch to the “Off” position or proceed to Trane CSHD is Trane OIL00079 or OIL00080. -

Page 39: Dehumidification Option

Start Up Heating Start-Up Table 10. POE Oil recharge amount (fl. oz.) 1. Clamp an amp meter around one of 1 stage heater Model 25mm/18mm 25mm/18mm power wires at the heater contactor. TS*150 2. ReliaTel Control Using the Service Test Guide in TH*150 Table 8, p. - Page 40 Start Up supply air temperature is within the setpoint deadband, Table 11. Variable air volume mode operation the system is considered to be satisfied and no staging up or down will occur. System Mode Fan “Auto” Fan “On” DWU Active Supply Duct Static Pressure Control Heat DWU Off...

-

Page 41: Final System Set Up

Start Up Figure 32. RTAM module IGV - OFF OFF VFD - ON OFF OFF ON VAV w/o IGV ON ON Static Static pressure pressure No Reset OFF OFF setpoint deadband For remote deadband cut Return Air OFF ON this jumper Zone Temp ON OFF Outdoor Air ON ON Supply Air Heating... -

Page 42: Sequence Of Operation

Sequence of Operation The ReliaTel Controls is a microelectronic control feature, maintain the zone temperature to within ±2°F of the sensor which provides operating function that is significantly setpoint at the sensed location. different than conventional electro-mechanical units. The ReliaTel Control Evaporator Fan master module is the ReliaTel Refrigeration Module Operation (RTRM). - Page 43 Sequence of Operation actuator (ECA) to open the economizer damper. The RTRM Table 13. Potentiometer settings tries to cool the zone utilizing the economizer to slightly 23 Btu/lb (53 kJ/kg) 67°F (19.4°C) below the zone temperature setpoint. If the mixed air 22 Btu/lb (51 kJ/kg) 63°F (17.2°C) sensor (MAS) senses that the mixed air temperature is...

-

Page 44: Two-Speed Indoor Fan (Title 24) Control

Sequence of Operation the normal 2-compressor dehumidification mode energize the first compressor and will switch the supply cycle will be used. fan to high speed until the Y2 request is cleared. 5. The purge cycle will ignore the Low Ambient Economizer Minimum Position Handling Dehumidification lockout feature. -

Page 45: Single Zone Variable Air Volume (Single Zone Vav) Control

Sequence of Operation Low Ambient Operation on Units with 2- zone requirements. Note that the supply fan speed will remain at the compressor stage's associated minimum Speed Indoor Fan value until the control requires additional capacity to meet The indoor fan motor (IDM) will continue to operate at the zone demand. - Page 46 Sequence of Operation Economizer Damper Position Set-Up with Economizer Damper Position Set-Up without This new scheme will require the setting of 5 OA Damper For units not configured with DCV (no CO sensor value position setpoints; 3 more than on non-SZ VAV. These new available), additional minimum position setpoints to setpoints are located on the RTVM module: increase outdoor airflow accuracy will be supported.

- Page 47 Sequence of Operation Heating on units configured with Staged Heat types will be will also be disabled if any of the functional disables that identical to traditional Constant Volume units; heating apply to CV or traditional VAV have gone active. stages will be energized/de-energized to meet the Zone Purge Mode (Comfort and Dehumidification) Heating demand.

-

Page 48: Variable Air Volume Applications (Traditional Vav)

Sequence of Operation Zone Temperature Control without Variable Air Volume Applications a Night Setback Panel or ICS - Unoccupied (Traditional VAV) Cooling Supply Air Temperature Control - When a field supplied occupied/unoccupied switching Occupied Cooling and Heating device is connected between RTRM J6-11 and RTRM J6-12, both the economizer and the mechanical cooling will be The RTRM is designed to maintain a selectable supply air disabled. - Page 49 Sequence of Operation MWU and DWU setpoints come from the higher Table 16 lists the selectable dry bulb values by priority LCI-R DAC. potentiometer setting. 2. Reference Enthalpy - controlling the economizer cycle Table 14. Variable air volume mode operation by sensing the outdoor air humidity.

-

Page 50: Constant Volume Or Variable Air Volume Applications (Szvav Or Traditional)

Sequence of Operation types, the Supply Fan will be controlled at maximum fan and cooling is turned off. For the case where the unit is speed during active heating operation as during Occupied required to turn off, the Emergency Stop input is used. The periods. - Page 51 Sequence of Operation If four consecutive open conditions occur during the first three minutes of operation, the compressor(s) in that circuit will be locked out, a diagnostic communicated to Tracer, and a manual reset will be required to restart the compressor(s).

-

Page 52: Maintenance

Maintenance Make sure all personnel are standing clear of the unit 6. Compare the “force” scale reading (Step 5) with the before proceeding. The system components will start appropriate “force” value listed in Table 18, p. 52. If the when the power is applied. “force”... -

Page 53: Monthly Maintenance

Maintenance Monthly Maintenance • Verify that all damper linkages move freely; lubricate with white grease, if necessary. Before completing the following checks, turn the unit OFF • Check supply fan motor bearings; repair or replace the and lock the main power disconnect switch open. motor as necessary. -

Page 54: Final Process

Maintenance instructions as closely as possible to avoid damaging the perpendicular to the face of the coil during cleaning. coils. Optimum clearance between the sprayer nozzle and the microchannel coil is 1”–3”. Microchannel (MCHE) Coils Final Process NOTICE For future reference, you may find it helpful to record the Coil Damage! unit data requested below in the blanks provided. -

Page 55: Troubleshooting

Troubleshooting 5. If no failures are indicated, use one of the TEST mode procedures described in “Start Up,” p. 38 to start the WARNING unit. This procedure will allow you to check all of the Hazardous Service Procedures! RTRM outputs, and all of the external controls (relays, contactors, etc.) that the RTRM outputs energize, for Failure to follow all precautions in this manual and on the tags, stickers, and labels could result in death or... -

Page 56: Resetting Cooling And Heating Lockouts

Troubleshooting • LED 4 (Service) • Heat Operating = approximately 32 Vdc – “On” indicates a clogged filter. • Heat Off = less than 1 Vdc, approximately 0.75 Vdc – “Off” during normal operation. • Heating Failure = voltage alternates between 32 Vdc and 0.75 Vdc –... -

Page 57: Zone Temperature Sensor (Zts) Service Indicator

Troubleshooting Method 2 Test 1 Zone Temperature Thermistor (ZTEMP) To reset the system at the unit, cycle the unit power by turning the disconnect switch “Off” and then “On”. This component is tested by measuring the resistance Lockouts can be cleared through the building between terminals 1 and 2 on the Zone Temperature management system. -

Page 58: Programmable And Digital Zone Sensor Test

Troubleshooting Method 2 Programmable and Digital Zone Testing the LED with an analog Ohmmeter. Connect Sensor Test Ohmmeter across LED in one direction, then reverse the leads for the opposite direction. The LED should have at Testing Serial Communication Voltage least 100 times more resistance in reverse direction, as compared with the forward direction. - Page 59 Troubleshooting 3. Use two (2) wire nuts, to individually cap the wires. 4. Locate the RTRM (J6). Connect two (2) wires to terminals J6-1 and 2. 5. Connect the sensor (OAS) using two wire nuts to the two (2) field supplied wires that were connected to terminals 1 and 2 on J6.

-

Page 60: Wiring Diagrams

Wiring Diagrams Note: Wiring diagrams can be accessed via e-Library by number search field or by contacting technical entering the diagram number in the literature order support. Table 23. Wiring diagrams Schematic Diagram Type Voltage Number Description Power 1213-2098 TS/H*150-300 50/60HZ, Cooling Only with or without Electric Heat Controls 1213-2117 TS/H*150-300 Cooling with or without Dehumidification 200-575... -

Page 61: Warranty

In addition, if the sealed motor-compressor fails because of a manufacturing defect within the second through fifth This warranty is extended by Trane, to the original year from the date of original purchase, Warrantor will purchaser and to any succeeding owner of the real... - Page 62 Notes RT-SVX25Q-EN...

- Page 63 Notes RT-SVX25Q-EN...

- Page 64 For more information, please visit trane.com or americanstandardair.com. Trane and American Standard have a policy of continuous product and product data improvement and reserve the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Need help?

Do you have a question about the Voyager TS 150-300 Series and is the answer not in the manual?

Questions and answers