Trane TH 150-300 Series Installation, Operation And Maintenance Manual

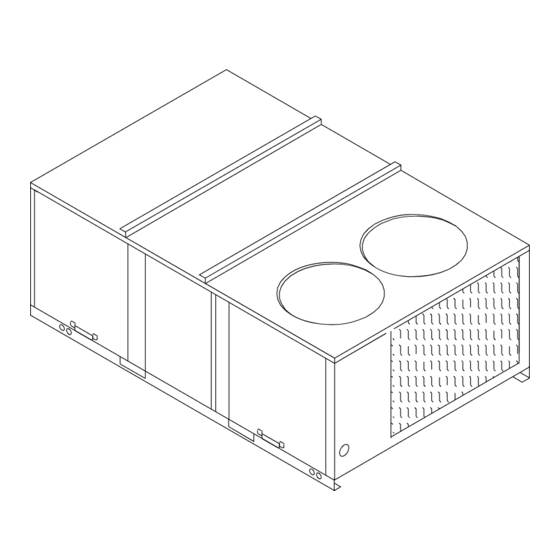

Packaged rooftop air conditioners voyager–electric/electric

Hide thumbs

Also See for TH 150-300 Series:

Table of Contents

Advertisement

Quick Links

Installation, Operation,

and Maintenance

Packaged Rooftop Air Conditioners

Voyager™

Electric/Electric

–

12½ – 25 Tons, 60/50Hz

Model Number:

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-

conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

January 2015

TS*150–300

TH*150-300

SAFETY WARNING

RT-SVX25J-EN

Advertisement

Table of Contents

Summary of Contents for Trane TH 150-300 Series

- Page 1 Installation, Operation, and Maintenance Packaged Rooftop Air Conditioners Voyager™ Electric/Electric – 12½ – 25 Tons, 60/50Hz Model Number: TS*150–300 TH*150-300 SAFETY WARNING Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air- conditioning equipment can be hazardous and requires specific knowledge and training.

- Page 2 Hydrogen, Chlorine, Fluorine and serious injury. Carbon (HCFCs). Not all refrigerants containing these compounds have the same potential impact to the environment. Trane advocates the responsible handling of WARNING all refrigerants-including industry replacements for CFCs Proper Field Wiring and Grounding such as HCFCs and HFCs.

- Page 3 Introduction NOTICE: Water Damage! Non-factory penetrations through the base of this unit are not allowed. Any penetration in the base of the unit may affect the water tight integrity of the unit and lead to water leaks into the conditioned space. Failure to follow instructions could result in equipment and property damage.

-

Page 4: Table Of Contents

Table of Contents Model Number Description System Status Checkout Procedure ..42 ....5 Resetting Cooling and Heating Lockouts . .43 General Information . -

Page 5: Model Number Description

High Efficiency Motor Cooling Capacity (MBh) Single Zone Variable Air Volume Without Communications Options 150 = 12½ Tons, 60Hz Standard Motor Trane Communications Interface 155 = 15 Tons, 50Hz Multi-Speed Standard Motor Lontalk Communications 180 = 15 Tons, 60Hz Single Zone Variable Air Volume... - Page 6 Model Number Description Note: Most Factory Installed Options mounted disconnect or circuit Digit 25 — System Monitoring available for Downflow Air Controls breaker. Discharge units only. Please verify No Monitoring Controls 13. This option consists of the Novar with ordering system for Clogged Filter Switch availability.

-

Page 7: General Information

Functions powered by 24 Vac. The RTRM must have a zone sensor or thermostat input in RTCI—ReliaTel™ Trane Communication order to operate the unit. The flexibility of having several Interface (Optional) mode capabilities depends upon the type of zone sensor or thermostat selected to interface with the RTRM. - Page 8 General Information proven by the differential pressure switch connected to the If four consecutive open conditions occur during the first RTOM (factory set point 0.07“ w.c.) within 40 seconds three minutes of operation, the compressor for that circuit nominally, the RTRM will shut off all mechanical will be locked out, a diagnostic communicated to the operations, lock the system out, send a diagnostic to ICS, remote panel (if installed), and a manual reset will be...

-

Page 9: Sensors

If this circuit is closed before the compressor is started, the and timed override with override cancellation. It is used compressor will not be allowed to operate. Anytime this with a Trane Integrated Comfort™ building management circuit is closed for 1 continuous second during system. - Page 10 General Information Thermostat (BAYSTAT151) Failure to follow these instructions will prevent the smoke detector from performing its design function. This thermostat is a single-stage 1 heat/1 cool, auto- changeover digital display thermostat. It is a non- Unit Model Minimum Allowable Airflow with programmable, wall-mounted thermostat.

-

Page 11: Unit Inspection

General Information Unit Inspection First Aid Measures • Eye Contact - Flush eyes with water to remove dust. If As soon as the unit arrives at the job site: symptoms persist, seek medical attention. • Verify that the nameplate data matches the data on the •... -

Page 12: Unit Dimensions

Unit Dimensions Figure 1. Typical installation clearance for single and multiple unit applications 5' 8" 5' 0" RT-SVX25J-EN... - Page 13 Unit Dimensions Figure 2. Unit dimensional data for 12½ tons standard efficiency units Note: 51 mm(2“) Electrical Connection: Single Point Power When Heat Installed Figure 3. Unit dimensional data for 12½ tons standard efficiency units RT-SVX25J-EN...

- Page 14 Unit Dimensions Figure 4. Horizontal duct dimensional data 12½ tons standard efficiency units Figure 5. Unit dimensional data 15–25 tons standard efficiency units 1372 mm (54”) 25 mm (1”) 173 mm (6 13/16”) DOWNFLOW CONDENSATE DRAIN CONN 25 mm (1”) NPT 679 mm (26 3/4”) 151 mm...

- Page 15 Unit Dimensions Figure 6. Unit dimensional data 12½ ton high efficiency units 1372 mm (54”) 25 mm (1”) DOWNFLOW CONDENSATE DRAIN CONN 25 mm (1”) NPT 679 mm (26 3/4”) 152 mm (6”) 1643 mm (64 11/16”) GAS CONNECTION (SEE NOTE 1) 843 mm (33 3/16”) 3091 mm...

- Page 16 Unit Dimensions Figure 8. Unit dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units Figure 9. Horizontal duct dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units RT-SVX25J-EN...

-

Page 17: Unit Weights

Unit Weights Table 1. Typical unit weights and point loading data (lb) Table 2. Typical unit weights and point loading data (kg) Corner Weights (lb) Corner Weights (kg) Weights Weights Unit (25mm/ Unit (25mm/ Models 18mm) Models 18mm) TS*150F 1413/1409 475/473 368/368 263/261 308/308 TS*150F 641/639 215/215 167/167 119/118 140/140... -

Page 18: Rigging

Unit Weights Rigging Figure 11. Rigging and center of gravity data WARNING Heavy Objects! Ensure that all the lifting equipment used is properly rated for the weight of the unit being lifted. Each of the cables (chains or slings), hooks, and shackles used to lift the unit must be capable of supporting the entire weight of the unit. -

Page 19: Installation

Installation Foundation All outdoor ductwork between the unit and the structure should be weather proofed after installation is completed. Note: For sound consideration, cut only the holes in the WARNING roof deck for the ductwork penetrations. Do not cut out the entire roof deck within the curb perimeter. Risk of Roof Collapsing! If a Curb Accessory Kit is not used: Confirm with a structural engineer that the roof... - Page 20 Installation Factory Installed Economizer trap condition which could result in condensate backup due to “air lock” . • Ensure the standard economizer has been pulled out Figure 12. Condensate trap installation into the operating position. Refer to the economizer Installation Instructions for proper setup. Note: Low Leak Economizers do not pull out.

-

Page 21: Main Unit Power

Installation Main Unit Power Figure 13. Through the base electrical option WARNING Proper Field Wiring and Grounding Required! All field wiring MUST be performed by qualified personnel. Improperly installed and grounded field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field wiring installation and grounding as described in NEC and your local/state electrical codes. - Page 22 Installation Controls using 24 Vac Table 4. Zone sensor module wiring Distance from Unit to Before installing any connecting wiring, refer to “Unit Control Recommended Wire Size Dimensions, ” p. 12 for the electrical access locations 0–150 feet (0–45.7 m) 22 gauge (0.33 mm provided on the unit and Table 3, p.

- Page 23 Installation Figure 16. ReliaTel relative humidity sensor (dehumidification option) Figure 17. ReliaTel humidistat (dehumidification option) RT-SVX25J-EN...

- Page 24 Installation Figure 18. Typical field wiring diagrams for optional controls (ReliaTel only) BAYSENS075* BAYSENS075* BAYSENS108* BAYSENS106* BAYSENS110* BAYSENS119* BAYSENS073* BAYSENS074* BAYSENS075* ASYSTAT669A OPTIONAL REMOTE SENSOR RT-SVX25J-EN...

-

Page 25: Space Temperature Averaging

Installation Space Temperature Averaging Space temperature averaging is accomplished by wiring a number of remote sensors in a series/parallel circuit. Using the BAYSENS016* or BAYSENS077*, at least four sensors are required to accomplish space temperature averaging. Example #1 illustrates two series circuits with two sensors in each circuit wired in parallel. - Page 26 Installation Table 6. Space temperature averaging examples RT-SVX25J-EN...

- Page 27 Installation Use the following checklist in conjunction with the general • VD = Line Voltage reading that deviates the farthest checklist (“General Unit Requirements, ” p. 19) to ensure from the average voltage. that the unit is properly installed and ready for operation. Example: If the voltage readings of the supply power measured 221, 230, and 227, the average volts would be: WARNING...

- Page 28 Installation ReliaTel Controls WARNING Upon power initialization, the RTRM performs self- Live Electrical Components! diagnostic checks to insure that all internal controls are functional. It also checks the configuration parameters During installation, testing, servicing and against the components connected to the system. troubleshooting of this product, it may be necessary to work with live electrical components.

-

Page 29: Factory-Mounted Unit Options

Factory-Mounted Unit Options Circuit Breaker (FIYUCB) & Unit disconnect switch or circuit breaker. Connect the power conductors to the lugs provided. Connect the Disconnect (FIYUDC) ground wire to the unit ground lug. Note: Wire size for the length of run should be determined using the circuit ampacity found on WARNING the unit nameplate and the N.E.C. -

Page 30: Powered And Unpowered Convenience

Factory-Mounted Unit Options Powered and Unpowered WARNING Convenience Proper Field Wiring and Grounding Required! WARNING All field wiring MUST be performed by qualified personnel. Improperly installed and grounded field Hazardous Voltage w/Capacitors! wiring poses FIRE and ELECTROCUTION hazards. To Disconnect all electric power, including remote avoid these hazards, you MUST follow requirements for disconnects and discharge all motor start/run field wiring installation and grounding as described in... -

Page 31: Return Air Smoke Detector

Factory-Mounted Unit Options Unpowered Convenience Outlet WARNING Unpowered Option (FIYCOUP) Hazardous Voltage w/Capacitors! 1. When the unpowered convenience outlet option is installed, remove the receptacle. Disconnect all electric power, including remote disconnects and discharge all motor start/run 2. The field wiring should be routed through the hole in capacitors before servicing. - Page 32 Factory-Mounted Unit Options Figure 23. Return air smoke detector for downflow units TWO PIECE HOOD PLASTIC ELBOW METAL INTAKE TUBE SMOKE DETECTOR COPPER TUBE (FACTORY INSTALLED) VINYL TUBES (7-3/4 INCHES LONG) VINYL TUBES (2 INCHES LONG) METAL EXHAUST TUBE (16.34 INCHES LONG) TUBES INSTALL FROM BOTTOM, TOP DOES NOT NEED TO BE REMOVED FROM SMOKE DETECTOR...

- Page 33 Factory-Mounted Unit Options In order for the return air smoke detector to properly sense Figure 24. Smoke detector wiring scheme smoke in the return air stream, the air velocity entering the unit must be between 500 and 4000 feet per minute. Most models of equipment covered by this instruction will develop an airflow velocity that falls within these limits over the entire airflow range specified in the evaporator...

-

Page 34: Pre Start

Pre Start Test Modes Verifying Proper Air Flow (Units with Belt Drive Indoor Fan) There are three methods in which the “Test” mode can be cycled at LTB-Test 1 and LTB-Test 2. Much of the systems performance and reliability is closely 1. -

Page 35: Start Up

Note: The Copeland, SSA and SPA scroll compressors for disconnect switch to the “Off” position or proceed to R-410A units use Trane OIL00094. The correct oil for the next component start-up procedure. Remove Trane CSHD is Trane OIL00079 or OIL00080. -

Page 36: Dehumidification Option

Start Up 2. ReliaTel Control Using the Service Test Guide in Table 10. POE Oil recharge amount (fl. oz.) Table 8, p. 34, continue the SERVICE TEST start-up procedure for each compressor circuit. Model 25mm/18mm 25mm/18mm Momentarily jump across the Test 1 and Test 2 TS*150 56/105.6 62/99.2... - Page 37 Start Up Supply Duct Static Pressure Control Table 11. Variable air volume mode operation The supply duct static pressure is measured by a System Mode Fan “Auto” Fan “On” transducer with a 0.25 to 2.125 Vdc proportional output DWU Active which corresponds to an adjustable supply duct static Heat DWU Off...

-

Page 38: Final System Set Up

Start Up Figure 28. RTAM module IGV - OFF OFF VFD - ON OFF OFF ON VAV w/o IGV ON ON Static Static pressure pressure No Reset OFF OFF setpoint deadband For remote deadband cut Return Air OFF ON this jumper Zone Temp ON OFF Outdoor Air ON ON Supply Air Heating... -

Page 39: Maintenance

Maintenance Make sure all personnel are standing clear of the unit 6. Compare the “force” scale reading (Step 5) with the before proceeding. The system components will start appropriate “force” value listed in Table 13, p. 39. If the when the power is applied. “force”... -

Page 40: Monthly Maintenance

Maintenance Monthly Maintenance • Check supply fan motor bearings; repair or replace the motor as necessary. Before completing the following checks, turn the unit OFF • Check the fan shaft bearings for wear. Replace the and lock the main power disconnect switch open. bearings as necessary. -

Page 41: Final Process

Maintenance Microchannel (MCHE) Coils Final Process For future reference, you may find it helpful to record the NOTICE: unit data requested below in the blanks provided. Coil Damage! (1) Complete Unit Model Number: DO NOT use any detergents with microchannel _____________________________________________________ condenser coils. -

Page 42: Troubleshooting

Troubleshooting unit. This procedure will allow you to check all of the RTRM outputs, and all of the external controls (relays, WARNING contactors, etc.) that the RTRM outputs energize, for Hazardous Service Procedures! each respective mode. Proceed to Step The maintenance and troubleshooting procedures 6. -

Page 43: Resetting Cooling And Heating Lockouts

Troubleshooting – “Flashing” indicates an evaporator fan failure or a • Heating Failure = voltage alternates between 32 Vdc Condenser Overflow Switch (COF) failure. and 0.75 Vdc The following is the complete listing of indication causes: Cool Failure System Failure Measure the voltage between terminals J6-8 and J6-6. -

Page 44: Zone Temperature Sensor (Zts) Service Indicator

Troubleshooting Method 2 Test 1 Zone Temperature Thermistor (ZTEMP) To reset the system at the unit, cycle the unit power by turning the disconnect switch “Off” and then “On” . This component is tested by measuring the resistance Lockouts can be cleared through the building between terminals 1 and 2 on the Zone Temperature management system. -

Page 45: Programmable & Digital Zone Sensor Test

Troubleshooting Method 2 Programmable & Digital Zone Testing the LED with an analog Ohmmeter. Connect Sensor Test Ohmmeter across LED in one direction, then reverse the leads for the opposite direction. The LED should have at Testing Serial Communication Voltage least 100 times more resistance in reverse direction, as compared with the forward direction. - Page 46 Troubleshooting 4. Locate the RTRM (J6). Connect two (2) wires to terminals J6-1 and 2. 5. Connect the sensor (OAS) using two wire nuts to the two (2) field supplied wires that were connected to terminals 1 and 2 on J6. Unit Economizer Control (ECA) Troubleshooting ReliaTel Control Verify Economizer Status by Economizer Actuator (ECA)

-

Page 47: Wiring Diagrams

Wiring Diagrams Note: Wiring diagrams can be accessed via e-Library by entering the diagram number in the literature order number search field or by contacting technical support. Table 18. Wiring diagrams Type of Schematic Diagram Airflow Type Voltage Number Description 2313-1478 TS*150-300 50/60HZ, Cooling Only with or without Electric Heat Power 200-575... - Page 48 Wiring Diagrams Table 19. Wiring diagrams for units with High Short Circuit Rating (SCCR) Type of Schematic Diagram Airflow Type Voltage Number Description 2313-1578 TS*150-300 Cooling Only with or without Electric Heat Power 208-575 1213-1004 TH*150-300 Cooling Only with or without Electric Heat 2313-1582 TS*150-300 Cooling Only with or without Electric Heat 1213-1012 TH*150-300 Cooling Only with or without Electric Heat Control...

-

Page 49: Warranty

The Company warrants for a period of 12 months from Use* initial start-up or 18 months from date of shipment, This warranty is extended by Trane, to the original whichever is less, that the Company products covered by purchaser and to any succeeding owner of the real... - Page 52 The manufacturer has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice. © 2015 Trane All rights reserved We are committed to using environmentally RT-SVX25J-EN 21 Jan 2015 conscious print practices that reduce waste.

Need help?

Do you have a question about the TH 150-300 Series and is the answer not in the manual?

Questions and answers