Summary of Contents for WAGNER PROSPRAY 20

- Page 1 PROSPRAY 20 OWNER‘S MANUAL • INSTRUCCIONES DE USO • MANUAL DEL PROPRIETÁRIO wagner-group.com 0419 • Form No. 0532487B / Doc. # 11291027...

- Page 2 Before any work is done on the unit or for every break in work the following rules must be observed: Release the pressure from spray gun and hose. Secure the Wagner spray gun using the trigger lock on the trigger. Switch off unit. Be safety conscious!

-

Page 3: Table Of Contents

Airless process ________________________________8 11.6 Replacing the gears ___________________________21 Functioning of the unit _________________________8 11.7 Replacing the transducer ______________________21 Legend for explanatory diagram ProSpray 20 _______9 11.8 ProSpray 20 connection diagram ________________22 Explanatory diagram ProSpray 20 _________________9 Technical data _______________________________10 APPENDIX _____________________________ 23 Transportation in vehicle _______________________10 12.1 Selection of tip _______________________________23... -

Page 4: Safety Regulations For Airless Spraying

ProSpray 20 SAFETY PRECAUTIONS SAFETY REGULATIONS FOR AIRLESS SPRAYING HAZARD: INJECTION INJURY EXPLANATION OF SYMBOLS USED Attention: Danger of injury by injection! A high This manual contains information that must be read and pressure stream produced by this equipment can understood before using the equipment. - Page 5 • For reasons of function, safety and durability use only working light switches. original Wagner high-pressure hoses. • Do not smoke in spray area. • Before each use, check all hoses for cuts, leaks, abrasion •...

-

Page 6: Electric Safety

ProSpray 20 SAFETY PRECAUTIONS ELECTRIC SAFETY HAZARD: HAZARDOUS VAPORS Electric models must be earthed. In the event of an electrical Paints, solvents, and other materials can be short circuit, earthing reduces the risk of electric shock by harmful if inhaled or come in contact with body. -

Page 7: General View Of Application

ProSpray 20 GENERAL VIEW OF APPLICATION GENERAL VIEW OF APPLICATION APPLICATION COATING MATERIALS The unit performance is conceived so that its use is possible on PROCESSIBLE COATING MATERIALS building sites for small- to middle-area dispersion work. Pay attention to the Airless quality of the coating materials to be processed. -

Page 8: Description Of Unit

Wagner ProSpray 20 units are electrically driven high-pressure A piston pump takes in the coating material by suction and spraying units. conveys it to the tip. Pressed through the tip at a pressure of A gear unit transfers the driving force to a crankshaft. -

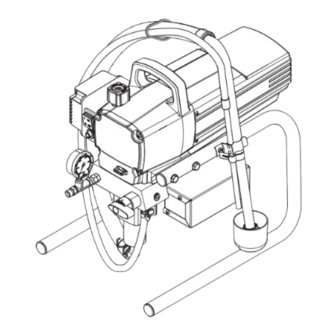

Page 9: Legend For Explanatory Diagram Prospray 20

3. Return hose 8. Pressure control knob 4. Suction hose 9. ON/OFF switch 5. Frame 10. Circuit breaker 6. Drip cup 11. Pressure gauge 12. Oil cup for EasyGlide (EasyGlide prevents increased wear of the packings) EXPLANATORY DIAGRAM PROSPRAY 20 PRIME SPRAY... -

Page 10: Technical Data

ProSpray 20 DESCRIPTION OF UNIT / STARTING OPERATION STARTING OPERATION TECHNICAL DATA HIGH-PRESSURE HOSE, SPRAY GUN AND SEPARATING OIL Voltage 1. If equipped, screw the pressure gauge (1) to the coating 100-110 VAC~, 50/60 Hz or material outlet (Fig. 2, Item 2). -

Page 11: Connection To The Mains Network

The connection must be equipped with a residual current protective device with INF ≤ 30 mA. Wagner‘s accessories program also includes a mobile operator protection device for the electronic supply, which can also be used with other electronic equipment. -

Page 12: Spraying Technique

ProSpray 20 SPRAYING SPRAYING Injection hazard. Do not spray without the tip guard in place. NEVER trigger the gun unless the tip is completely turned to either the spray or the unclog position. ALWAYS engage the 25 - 30 cm... -

Page 13: Handling The High-Pressure Hose

Never pull on the high-pressure hose to move the device. cleaning agent. Make sure that the high-pressure hose cannot twist. This can be avoided by using a Wagner spray gun with a swivel joint and a If fast-drying or two-component coating material hose system. -

Page 14: Cleaning The Unit (Shutting Down)

ProSpray 20 CLEANING THE UNIT (SHUTTING DOWN) CLEANING THE UNIT (SHUTTING DOWN) CLEANING UNIT FROM OUTSIDE A clean state is the best method of ensuring operation without problems. After you have finished spraying, clean the unit. Under no First of all pull out mains plug from socket. -

Page 15: Cleaning The High-Pressure Filter

ProSpray 20 CLEANING THE UNIT (SHUTTING DOWN) CLEANING THE HIGH-PRESSURE FILTER CLEANING AIRLESS SPRAY GUN Clean the filter cartridge regularly. A soiled or Clean the spray gun after each use. clogged high-pressure filter can cause a poor spray pattern or a clogged tip. -

Page 16: Remedy In Case Of Faults

Unit loses power Pressure setting too low. Turn pressure control knob clockwise to increase. Pump over-pressurizes and will not Pressure switch defective. Take unit to a Wagner authorized service center. shut off. Transducer defective. Take unit to a Wagner authorized service center. -

Page 17: Servicing

11.1 RELIEF VALVE The risk of damage rises with the age of the high- pressure hose. Wagner recommends replacing The valve housing (4) should not be repaired. If high-pressure hoses after 6 years. worn, it should always be replaced with a new one. -

Page 18: Inlet And Outlet Valve

ProSpray 20 REPAIRS AT THE UNIT 11.2 12. Clean all the parts with the corresponding cleaning agent. INLET AND OUTLET VALVE Check outlet valve housing (7), outlet valve seat (12), 1. Remove the four screws in the front cover and then remove outlet valve ball (11) and upper ball guide (10) for wear the front cover. -

Page 19: Packings

ProSpray 20 REPAIRS AT THE UNIT 11.3 PACKINGS 1. Remove inlet valve housing in accordance with the steps in Chapter 11.2. 2. It is not necessary to remove the outlet valve. 11. Insert lower packing (Fig. 14) with the beveled edge (1) 3. -

Page 20: Replacing The Motor

ProSpray 20 REPAIRS AT THE UNIT 11.4 REPLACING THE MOTOR 1. Open the relief valve, valve position PRIME (k circulation), switch the unit OFF, and unplug the power cord. 2. Remove the four motor cover screws (Fig. 15, Item 1). -

Page 21: Replacing The Gears

ProSpray 20 REPAIRS AT THE UNIT 11.6 11.7 REPLACING THE GEARS REPLACING THE TRANSDUCER 1. Open the relief valve, valve position PRIME (k circulation), 1. Open the relief valve, valve position PRIME (k circulation), switch the unit OFF, and unplug the power cord. -

Page 22: Prospray 20 Connection Diagram

ProSpray 20 REPAIRS AT THE UNIT 11.8 PROSPRAY 20 CONNECTION DIAGRAM... -

Page 23: Appendix

ProSpray 20 APPENDIX APPENDIX 12.1 12.2 SELECTION OF TIP SERVICING AND CLEANING OF AIRLESS HARD-METAL TIPS To achieve faultless and rational working, the selection of the tip is of the greatest importance. STANDARD TIPS In many cases the correct tip can only be determined by means of a spraying test. -

Page 24: Airless Tip Table

TradeTip 3 tip F thread (11/16 - 16 UN) G thread (7/8 - 14 UN) up to 270 bar for Wagner spray guns for Graco/Wagner spray guns (27 MPa) Order no. 0289391 Order no. 0289390 All of the tips in the table below are supplied together with the appropriate gun filter. - Page 25 ProSpray 20 APPENDIX Application Tip marking Spray Bore Spraying Gun filter Order no. angle inch / mm width mm 1) Flame retardant 20° 0.021 / 0.53 white 0553221 30° 0.021 / 0.53 white 0553321 40° 0.021 / 0.53 white 0553421 50°...

-

Page 26: 2Speed Tip Table

ProSpray 20 APPENDIX 12.5 2SPEED TIP TABLE The innovative changeover nozzle from WAGNER combines two nozzle cores into one nozzle. 2 Speed Tip holder Order no. 0271065 Tip table Object size Painting material Lacquer (L) Emulsion (D) Filler (S) Nozzles: 111 / 415 Nozzles: 225 / 629 Order no. -

Page 27: Nozzle Cases

ProSpray 20 APPENDIX 12.6 NOZZLE CASES Nozzle cases are a perfect addition to your paint spraying equipment, with everything safely stowed away and with project-specific equipment. Ideally matched to meet your particular application, there are four different versions available. Part No. -

Page 28: Tempspray

ProSpray 20 APPENDIX 12.7 TEMPSPRAY The paint material is heated to the required temperature uniformly by an electric heating element, which is located inside the hose (regulated from 20°C to 60°C). Advantages: • Constant paint temperature even at low outside temperatures •... -

Page 29: Hea Nozzles For Low-Mist Spraying At Low Pressure

TradeTip 3 nozzle holders and WAGNER devices. Some paints may need to be diluted to achieve the best result possible. The experts at Wagner application technology have therefore tested a wide range of materials for you. Their recommendations can be found in the Wagner Spray Guide at sprayguide.wagner- group.com. - Page 30 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES ACCESSORIES DIAGRAM CUADRO DE ACCESORIOS DIAGRAMA DAS ACESSÓRIOS...

- Page 31 ProSpray 20 PS 20 Description Denominación Descrição 0538 041 Spray gun, Vector Pro 2-finger Pistola de pulverización Vector Pro 2 dedos Pistola de pulverização Vector Pro 2 dedos 0538 040 Spray gun, Vector Pro 4-finger Pistola de pulverización Vector Pro 4 dedos Pistola de pulverização Vector Pro 4 dedos...

- Page 32 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES MAIN ASSEMBLY CONJUNTO PRINCIPAL CONJUNTO PRINCIPAL BS4343 0532 253 ~110V CEE 7/7 0558 465 220V-240V~...

- Page 33 ProSpray 20 PS 20 Description Denominación Descrição 0552 300 Motor shroud Cubremotor Cobertura do motor 9805 287 Screw (4) Tornillo (4) Parafuso (4) 0558 555 Power cord jumper Cable de conexión Cabo de alimentação 0551 714 Cord grip (2) Pinza de contacto (2)

- Page 34 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES FLUID SECTION ZONA DE PINTURA SECÇÃO DE FLUIDO...

- Page 35 ProSpray 20 PS 20 Description Denominación Descrição 0509 594 Retainer Tuerca guía Porca de fixação 0509 584 Piston guide Guía de pistón Guia do pistão ------- Upper packing Empaquetadura superior Empanque superior 0551 112 Transducer assembly Impulsor manométrico Conjunto do transdutor...

- Page 36 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES DRIVE ASSEMBLY CONJUNTO DEL MECANISMO IMPULSOR UNIDADE DE COMANDO PS 20 Description Denominación Descrição 806-100A Housing assembly (includes item 9) Conjunto de carcasa (incluye le Conjunto do alojamento (inclui os...

- Page 37 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES MOTOR ASSEMBLY CONJUNTO DEL MOTOR UNIDADE DE MOTOR PS 20 Description Denominación Descrição 0551 967 Capacitor assembly, 220-240V~ Condensadores, 220-240V~ Condensador, 220-240V~ 0522 100 Capacitor assembly, 100-110V~...

- Page 38 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES STAND ASSEMBLY BASTIDOR-SOPORTE ESTRUTURA PS 20 Description Denominación Descrição 0508 377 Cord holder Soporte de cable de red Suporte do cabo 806-071 Leg, left Arco a la izquierda...

- Page 39 SPARE PARTS DIAGRAM CUADRO DE PIEZAS DE RECAMBIO ProSpray 20 DIAGRAMA DAS PEÇAS SOBRESSELENTES SUCTION SYSTEM SISTEMA DE ASPIRACIÓN SISTEMA DE SUCÇÃO PS 20 Description Denominación Descrição 0558672A Siphon tube assembly (includes items Sistema de aspiración (Pos. 1-8) Sistema de sucção (Pos. 1-8)

-

Page 40: Important Notes On Product Liability

- for products to which attempts at repairs have been carried out by to the products listed for that customer on the Internet under www.wagner- unauthorised persons. group.com/profi-guarantee. - Page 41 Festnetz, Mobilfunk max. 42 Cent/Min) Servicestützpunkt Siemensstraße 16-18 Olbernhauer Straße 11 91126 Rednitzhembach 09526 Heidersdorf T 09122 - 79473 T 037361 - 15707 F 09122 - 794750 F 037361 - 15708 email: info@grimmer-sc.de www.grimmer-sc.de WAGNER KONTAKTNETZ DEUTSCHLAND, IM INTERNET ZU FINDEN UNTER: GO.WAGNER-GROUP.COM/PROFI...

- Page 42 J. Wagner Ges.m.b.H. Wagner Spraytech Wagner Spraytech (UK) Limited Ottogasse 2/20 Scandinavia A/S Innovation Centre 2333 Leopoldsdorf Helgeshøj Allé 28 Silverstone Park Österreich Silverstone 2630 Taastrup Tel. +43/ 2235 / 44 158 Northants NN12 8GX Denmark Telefax +43/ 2235 / 44 163 Great Britain Tel.

Need help?

Do you have a question about the PROSPRAY 20 and is the answer not in the manual?

Questions and answers