GEA HGX2/70-4 CO2 T Assembly Instructions Manual

Bock compressor

Hide thumbs

Also See for HGX2/70-4 CO2 T:

- Assembly instructions manual (28 pages) ,

- Assembly instructions manual (34 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GEA HGX2/70-4 CO2 T

- Page 1 Gm bH , Ge rm Bo ck hau sen GE A Fric ken 726 36 GEA Bock Compressor HGX2 CO Assembly instructions HGX2/70-4 CO HGX2/90-4 CO HGX2/110-4 CO HGX2/130-4 CO engineering for a better world GEA Refrigeration Technologies...

- Page 2 Observe the safety instructions contained in these instructions. These instructions must be passed onto the end customer along with the unit in which the compres- sor is installed. Manufacturer GEA Bock GmbH 72636 Frickenhausen Contact GEA Bock GmbH Benzstraße 7...

-

Page 3: Table Of Contents

Contents Page Safety 1.1 Identification of safety instructions 1.2 Qualifications required of personnel 1.3 Safety instructions 1.4 Intended use Product description 2.1 Short description 2.2 Name plate 2.3 Type key Areas of application 3.1 Refrigerants 3.2 Oil charge 3.3 Limits of application Compressor assembly 4.1 Storage and transportation 4.2 Setting up 4.3 Connecting the pipelines - solder system 4.4 Connecting the pipelines - cutting ring system... -

Page 4: Safety

1| Safety 1.1 Identification of safety instructions: DANGER Indicates a dangerous situation which, if not avoided, will cause immediate fatal or serious injury WARNING Indicates a dangerous situation which, if not avoided, may cause fatal or serious injury CAUTION Indicates a dangerous situation which, if not avoided, may immediately cause fairly severe or minor injury. ATTENTION Indicates a situation which, if not avoided, may cause property damage INFO Important information or tips on simplifying work 1.2 Qualifications required of personnel WARNING Inadequately qualified personnel poses the risk of accidents, the consequence being serious or fatal injury. Work on compressors must therefore only be performed by personnel with the qualifications listed below: •... -

Page 5: Safety Instructions

These assembly instructions describe the standard version of the compressors named in the title manufactured by GEA Bock. GEA Bock refrigerating compressors are intended for installing in a machine (within the EU according to the EU Directives 2006/42/EC Machinery Directive, 97/23/EC Pressure Equipment Directive and 2006/95/EC – Low Voltage Directive). -

Page 6: Product Description

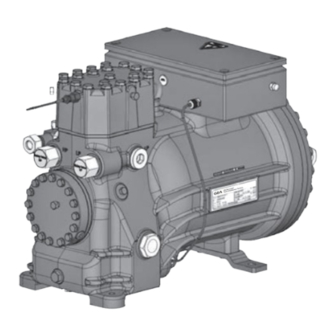

2 | Product description 2.1 Short description • Semi-hermetic two-cylinder reciprocating compressor with suction gas-cooled drive motor. • T he refrigerant coming from the evaporator is entering the compressor and flowing over the motor. This ensures an especially intensive cooling of the motor. Therefore the motor temperature remains on a relatively low level - especially at high load. -

Page 7: Type Key

2 | Product description 2.2 Name plate (example) GEA Bock GmbH 72636 Frickenhausen, Germany HGX2/110-4 CO 380-420V Y/YY AS30046A002 9,66 32,3 A 440-480V Y/YY Y Y : 110 A Y: 141 A 11,66 1740 100/150 bar CO2,C 85 E Fig. 3... -

Page 8: Areas Of Application

3 | Areas of application 3.1 Refrigerants • CO : R744 (Recommendation CO quality 4.5 (< 5 ppm H 3.2 Oil charge The compressors are filled at the factory with the following oil type: GEA Bock C 85 E (only this oil may be used). ATTENTION Property damage possible. max. The oil level must be in the visible part of the sight glass; oil level 2,0 Ltr. damage to the compressor min. - Page 9 3 | Areas of application Unlimited application range HGX2/130-4 CO Applications limit Fig. 5 Evaporation temperature (°C) Max. permissible operating ∆t Suction gas superheat (K) pressure (LP/HP) : 100/150 bar Suction pressure (bar) LP = Low pressure Discharge end pressure (bar) HP = High pressure...

-

Page 10: Compressor Assembly

4 | Compressor assembly INFO New compressors are factory-filled with inert gas (3 bar nitrogen). Leave this service charge in the compressor for as long as possible and prevent the ingress of air. Immediately after coolingtechnical connection of the compressor of shutoff devices in suction-, discharge-, oil return line etc. close and compressors evacuate. Check the compressor for transport damage before starting any work. -

Page 11: Connecting The Pipelines - Solder System

4| Compressor assembly 4.3 Connecting the pipelines - solder system ATTENTION Damage possible. Superheating can damage the valve. Remove the pipe supports therefore from the valve for soldering and accordingly cool the valve body during and after soldering. Only solder using inert gas to inhibit oxidation products (scale). Material soldering / welding connection: S235 (JRG2C) The pipe connections have graduated inside diameters so that pipes with standart millimetre and inch dimensions can be used. -

Page 12: Pipes

4| Compressor assembly 4.5 Pipes Pipes and system components must be clean and dry inside and free of scale, swarf and layers of rust and phosphate. Only use hermetically sealed parts. Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being cracked and broken by severe vibrations. -

Page 13: Laying Suction And Pressure Lines

4 | Compressor assembly 4.8 Laying suction and pressure lines ATTENTION Property damage possible. Improperly installed pipes can cause cracks and tears which can result in a loss of refrigerant. INFO Proper layout of the suction and pressure lines directly after the compressor is integral to the smooth running and vibration behaviour of the system. -

Page 14: Operating Mode Of The Lockable Service Connections

4 | Compressor assembly 4.10 Operating mode of the lockable service connections Connection cannot Connection be shut off blocked Spindle Service connec- Fig. 13 tion closed Pipe connection Opening the shut-off valve: Spindle: turn to the left (counter-clockwise) as far as it will go. —> Shut-off valve completely opened / service connection closed. The connection which cannot be shut off is intended for safety devices. -

Page 15: Electrical Connection 15 Dgb

5| Electrical connection Electrical connection DANGER Risk of electric shock! High voltage! Only carry out work when the electrical system is disconnected from the power supply! INFO Connect the compressor motor in accordance with the circuit diagram (see inside of terminal box). Use suitable cable entry point of the correct protection type (see name plate) for routing cables into the terminal box. Insert the strain reliefs and prevent chafe marks on the cables. -

Page 16: Standard Motor, Designed For Direct Or Part Winding Start

5 | Electrical connection 5.2 Standard motor, designed for direct or part winding start Designation on the name plate Sticker on the terminal box Y/YY Compressors marked in this way are suitable for direct or part winding start. The motor winding is divided into two parts: part winding 1 = 70% and part winding 2 = 30%. This winding devision redu- ces the start-up current during a part winding start to approx. - Page 17 5| Electrical connection In the factory, the motor is switched for direct starting (YY). For part winding start (Y/YY), remove the bridges and connect the motor feed cable according to the circuit diagram: 400 V Direct start YY Part winding start Y/YY ATTENTION Property damage possible.

-

Page 18: Basic Circuit Diagram For Part Winding Start E

5.3 Basic circuit diagram for part winding start 0 1 2 3 4 F1.2 F1.1 I=33% I=66% F1.1 F1.2 XSS X1 L1 L1 N N 43 43 11 Y/YY X2 1 MP10 Compressor terminal box AnschluákastenVerdichter Fig. 22 Cold conductor (PTC sensor) motor winding Thermal protection thermostat (PTC sensor) F1.1 /1.2 2 motor protection switches (70% / 30% of I total) - Page 19 5 6 7 8 9 L1.1 L2.1 L3.1 L1.2 P> P< P™l Main switch Compressor motor Mains contactor (part winding 1) Mains contactor (part winding 2) Delay relay max. 1s Control voltage switch Oil sump heater Terminal strip in the external switch cabinet PWMP10 BOCKCOMPRESSORS...

-

Page 20: Electronic Trigger Unit Mp10

5 | Electrical connection 5.6 Electronic trigger unit MP10 The compressor motor is fitted with cold conductor temperature sensors (PTC) connected to the elec- tronic trigger unit MP10 in the terminal box. Readiness to operate is signalled by the H3 LED (green) after the power supply is applied. In the case of excess temperature in the motor winding, the unit switches off the compressor and the H1 LED lights red. -

Page 21: Oil Sump Heater

5 | Electrical connection 5.8 Function test of the trigger unit MP10 Before start-up, troubleshooting or making changes to the control power circuit, check the functionality of the trigger unit: LED H1 LED H2 LED H3 Procedure green • Interrupt power supply (L1 or S1) • Release the motor temperature sensor connection (1 or 2) •... -

Page 22: Commissioning

6| Commissioning 6.1 Preparations for start-up INFO In order to protect the compressor against inadmissible opera- ting conditions, high-pressure and low-pressure pressostats controls are mandatory on the installation side. The compressor has undergone trials in the factory and all functions have been tested. There are therefore no special running-in instructions. -

Page 23: Evacuation

6| Commissioning 6.4 Evacuation ATTENTION Do not start the compressor if it is under vacuum. Do not apply any voltage - even for test purposes (must only be operated with r efrigerant). Under vacuum, the spark-over and creepage current distances of the terminal board connection bolts shorten; this can result in winding and terminal board damage. -

Page 24: Start-Up

6 | Commissioning 6.6 Start-up WARNING Ensure that both shut-off valves are open before starting the compressor! Check that the safety and protection devices (pressure switch, motor protection, electrical contact protection measures, etc.) are functioning properly. Switch on the compressor and let it run for at least 10 minutes. The machine should reach a state of equilibrium. -

Page 25: Decompression Valves

6 | Commissioning 6.8 Decompression valves ATTENTION The compressor is fitted with two decompression valves. One valve each on the suction and discharge side. If excessive pressures are reached, the valves open and prevent further pressure increase. Thereby CO is blown off to the ambient! In the event that a pressure relief valve activates repeatedly, check valve and replace if necessary as during blow-off extreme condi- tions can occure, which may result in a permanent leak. Always check system for refrigerant loss after activation of pressure relief valve! The decompression valves do not replace any pressure switches... -

Page 26: Filter Dryer

7 | Maintenance 6.9 Avoid slugging ATTENTION Slugging can result in damage to the compressor and cause refrigerant to leak. To prevent slugging: The complete refrigeration plant must be properly designed. All components must be compatibly rated with each other with regard to output (particularly the evaporator and expansion valves). -

Page 27: Work To Be Carried Out

80528 80529 Set of connecting rod 80520 Only use genuine GEA Bock spare parts! 7.4 Accessories Available accessories can be found on the Internet at www.gea.com. 7.5 Lubricants For operation with CO the GEA Bock oil C 85 E is necessary! 7.6 Decommissioning Close the shut-off valves on the compressor. CO does not need to be recycled and can therefore be blown off into the environment. -

Page 28: Technical Data

8 | Technical data Oil charge Weight 380-420 V Y/YY - 3 - 50 Hz PW 440-480 V Y/YY - 3 - 60 Hz PW PW=Part Winding Winding ratio: 70%/30% No. of cylinders... -

Page 29: Dimensions And Connections

9 | Dimensions and connections Centre of gravity Vibrations damper Dimensions in mm Fig. 25 Suction line see technical data, Chapter 8 Discharge line Connection suction side, not lockable 16 “ UNF Connection suction side, lockable 16 “ UNF Connection suction side, not lockable 8 “... -

Page 30: Declaration Of Conformity And Installation

DECLARATION OF INSTALLATION for using the compressors within the European Union (in accordance with Machinery Directive 2006/42/EC) The manufacturer: GEA Bock GmbH, Benzstraße 7 72636 Frickenhausen, Tel.: 07022/9454-0 hereby declares that the refrigerating compressor HGX2 CO T complies with the basic require- ments of Appendix II 1B of the Machinery Directive 2006/42/EC. -

Page 31: Service

11| Service Dear customer, GEA Bock compressors are top-quality, reliable and service-friendly quality products. If you have any questions about installation, operation and accessories, please contact our techni- cal service or specialist wholesaler and/or our representative. The GEA Bock service team can be contacted by phone with a toll-free hotline 00 800 / 800 000 88 or via e-mail: refrigeration@gea.com Yours faithfully GEA Bock GmbH Benzstraße 7... - Page 32 • • GEA Group is a global engineering company with multi-billion euro sales and operations in more than 50 countries. Founded in 1881, the company is one of the largest providers of innovative equipment and process technology. GEA Group is listed in the STOXX Europe 600 index.

Need help?

Do you have a question about the HGX2/70-4 CO2 T and is the answer not in the manual?

Questions and answers