Table of Contents

Advertisement

Quick Links

Operator's Manual

EAGLE

For use with machines having Code Numbers:

11618,11735, 11791, 11798,

12094, 12200

Register your machine:

https://lered.info/locator

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

IM10028-D

| Issue D ate May-22

© Lincoln Global, Inc. All Rights Reserved.

™

10,000 PLUS

PRODUCT

REGISTRATION

Registering your product only takes a few minutes, ensures

your qualification for available warranties and allows you to

receive updates and information on your product.

Follow the QR code below to register.

https://lered.info/product_registration-5

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric 11618

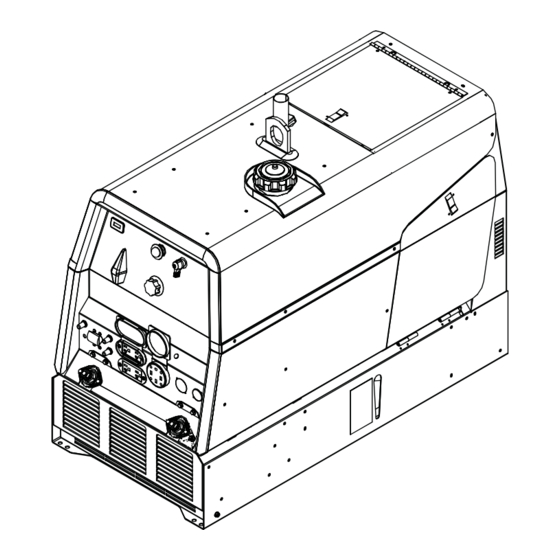

- Page 1 ™ EAGLE 10,000 PLUS PRODUCT For use with machines having Code Numbers: 11618,11735, 11791, 11798, 12094, 12200 REGISTRATION Registering your product only takes a few minutes, ensures your qualification for available warranties and allows you to receive updates and information on your product.

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 P.O. Box 351040, Miami, Florida 33135 or CSA Standard W117.2. A Free copy of “Arc Welding Safety” booklet E205 2.a. Electric current owing through any conductor is available from the Lincoln Electric Company, 22801 causes localized Electric and Magnetic Fields (EMF). St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS Page Installation........................Section A Technical Specifications .......................A-1 Safety Precautions ......................A-2 Machine Grounding .......................A-2 Spark Arrester .......................A-2 Towing...........................A-2 Vehicle Mounting......................A-3 Pre-Operation Engine Service....................A-3 Fuel, Oil, Battery Connections ..................A-3 Welding Cable Connections ..................A-4 Angle of Operation ......................A-4 Lifting, Additional Safety Precautions................A-4 High Altitude Operation ....................A-4 Muffler Outlet Pipe ......................A-4 Location and Ventilation ....................A-5... -

Page 7: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - EAGLE™ 10,000 Plus ( K2343-3) INPUT - GASOLINE ENGINE Description Operating Displacement Capacities Make/Model Starting Horsepower Speed (RPM) cu. in. System (cu.cm.) 2 cylinder High Idle 3700 12VDC 4 Cycle Kohler Battery Fuel: Air-Cooled 41.1(674) CH23S, Electric Start 12 Gal (45.4 L) Gasoline... -

Page 8: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS When this welder is mounted on a truck or trailer, itʼs frame must be electrically bonded to the metal frame of the vehicle. Use a #8 or larger copper wire connect- WARNING ed between the machine grounding stud and the Do not attempt to use this equipment until you frame of the vehicle. -

Page 9: Vehicle Mounting

INSTALLATION 3. Proper placement of the equipment on the trailer to FUEL insure stability side to side and front to back when being moved and when standing by itself while Fill the fuel tank with clean, fresh, lead-free gasoline. being operated or serviced. Observe fuel gauge while filling to prevent overfilling. -

Page 10: Angle Of Operation

INSTALLATION WELDING OUTPUT CABLES ADDITIONAL SAFETY PRECAUTION With the engine off, connect the electrode and work WARNING cables to the studs provided. These connections should be checked periodically and tightened if neces- • Lift only with equipment of sary. Loose connections will result in overheating of adequate lifting capacity. -

Page 11: Location And Ventilation

INSTALLATION LOCATION / VENTILATION The welder should be located to provide an unrestrict- ed flow of clean, cool air to the cooling air inlets and to avoid heated air coming out of the welder recirculating back to the cooling air inlet. Also, locate the welder so that engine exhaust fumes are properly vented to an outside area. - Page 12 INSTALLATION WELDER OPERATION 120/240 VOLT DUAL VOLTAGE RECEPTACLE WELDER OUTPUT • Maximum Open Circuit Voltage at 3700 RPM is 80 The 120/240 volt receptacle can supply up to 38 Volts RMS. amps of 240 volt power to a two wire circuit, up to 38 •...

-

Page 13: Electrical Device Used With The Eagle™ 10,000 Plus

DO NOT USE THESE DEVICES WITH A EAGLE™ 10,000 Plus The Lincoln Electric Company is not responsible for any damage to electrical components improperly connected to the EAGLE™ 10,000 Plus. EAGLE™ 10,000 PLUS... - Page 14 INSTALLATION 1. Install a double pole, double throw switch between AUXILIARY POWER WHILE WELDING the power company meter and the premises dis- connect. Simultaneous welding and power loads are permitted by following Table I. The permissible currents shown Switch rating must be the same or greater than the assume that current is being drawn from either the customerʼs premises disconnect and service over- 120V or 240V supply (not both at the same time).

-

Page 15: Premises Wiring

INSTALLATION Figure 1 CONNECTION OF EAGLE™ 10,000 Plus TO PREMISES WIRING WARNING Connection of EAGLE™ 10,000 Plus to premises wiring must be done by a licensed electrician and must comply with the National Electrical Code and all other applicable electrical codes. EAGLE™... -

Page 16: Operation

OPERATION SAFETY PRECAUTIONS WELDER CONTROLS - FUNCTION AND OPERATION Do not attempt to use this equipment until you have thoroughly read the engine manufacturerʼs manual supplied with your welder. It includes ENGINE SWITCH important safety precautions, detailed engine The engine switch is used to Start the Engine, Select starting, operating and maintenance instructions, High Idle or Auto Idle while the engine is running, and and parts lists. - Page 17 OPERATION “ RANGE” SWITCH The “Range” switch is used to select one of four amperage ranges with generous overlap for Stick/TIG welding. Process Range Setting Current Range STICK/TIG 90 Max. 40 to 90 Amps (Constant current) 145 Max. 70 to 145 Amps (3 range settings) 225 MAX.

-

Page 18: Start In/Shutdown Instructions

OPERATION STARTING/SHUTDOWN INSTRUCTIONS STOPPING THE ENGINE STARTING THE ENGINE Remove all welding and auxiliary power loads and WARNING allow engine to run at low idle speed for a few minutes to cool the engine. • Do not touch electrically live parts Stop the engine by placing the Engine switch in the of electrode with skin or wet cloth- ing. -

Page 19: Welding Process

OPERATION WELDING PROCESS The EAGLE™ 10,000 Plus can be used with a broad For any electrodes the procedures should be kept range of DC stick electrodes. See “Welding Tips 1” within the rating of the machine. For electrode infor- included with the EAGLE™ 10,000 Plus for electrodes within the rating of this unit and recommended weld- mation see the appropriate Lincoln publication. -

Page 20: Arc Gouging

OPERATION ARC GOUGING The EAGLE™ 10,000 Plus can be used for limited arc gouging. Set the Range switch to adjust output current to the desired level for the gouging electrode being used according to the ratings in the following table: ELECTRODE SETTING CURRENT RANGE (DC, electrode positive) 30 - 60 Amps... -

Page 21: Accessories

ACCESSORIES K704 Accessory Kit - Includes 35 ft (Im) 2/0 AWG elec- OPTIONAL EQUIPMENT (Field Installed) trode cable, 30 ft. (Im) 2/0 AWG work cable, headshield with No. 12 filter, GC300 work clamp and cooltong® 300 elec- K2635-1 SMALL TWO-WHEEL ROAD TRAILER trode holder. -

Page 22: Recommended Equipment

ACCESSORIES RECOMMENDED EQUIPMENT STICK K704 Accessory Kit- (400 AMP Capacity) which includes: • Electrode Holder & Cable • Work Clamp & Cable • Headshield K875 Accessory Kit- (150 AMP Capacity) Magnum™ TIG Torch K1783-4 - TIG Torch KP509-Magnum Parts Kit and Argon Gas K930-2 TIG Module - Provides high frequency and shield- ing gas control. -

Page 23: Maintenance

MAINTENANCE SAFETY PRECAUTIONS CAUTION WARNING Make certain that the oil filler cap is securely tight- ened after checking or adding oil. If the cap is not Have qualified personnel do the maintenance tight, oil consumption can increase significantly work. Turn the engine off before working inside which may be evidenced by white smoke coming the machine. - Page 24 MAINTENANCE Use 4-stroke motor oil that meets or exceeds the AIR CLEANER AND OTHER MAINTENANCE requirements for APIO service classification SG or SH. Always check the APIO SERVICE label on the oil con- • Air Cleaner - With normal operating conditions, the tainer to be sure it includes the letters SG or SH.

-

Page 25: Engine Adjustments

MAINTENANCE ENGINE ADJUSTMENTS WARNING GASES FROM BATTERY can explode. OVERSPEED IS HAZARDOUS • Keep sparks, flame and cigarettes away from battery. To prevent EXPLOSION when: WARNING • INSTALLING A NEW BATTERY - disconnect negative cable from old battery first and connect to new bat- tery last. -

Page 26: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 27 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION No welder output power or Auxiliary 1. Open in miscellaneous leads. Power. 2. Open lead in flashing or field circuit. 3. Faulty rotor. 4.

- Page 28 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Engine will not go to high idle when No voltage signal from the using auxiliary power. current sensor. Auxiliary power load less than 100 to 150 watts.

- Page 29 DIAGRAMS Enhanced Diagram EAGLE™ 10,000 PLUS...

- Page 30 DIMENSION PRINT EAGLE™ 10,000 PLUS...

- Page 31 DIMENSION PRINT EAGLE™ 10,000 PLUS...

- Page 32 NOTES EAGLE™ 10,000 PLUS...

- Page 33 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 34 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 35 Lincoln Electric is a responsive manufacturer, but the de nition of speci cations, and the selection and use of speci c products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Need help?

Do you have a question about the 11618 and is the answer not in the manual?

Questions and answers