Subscribe to Our Youtube Channel

Summary of Contents for Kärcher BGA-252737

- Page 1 High Pressure Cleaner Cold Water OPERATOR’S MANUAL MODEL # ORDER # BGA-252737 1.106-057.0 BGA-373537 1.106-058.0 BGA-373537 1.107-251.0 8.919-400.0...

-

Page 3: Table Of Contents

CONTENTS Important Safety Information ..............4-6 Component Identification ................. 7 Assembly Instructions ................8 Operating Instructions.................9-10 Detergent and General Operating Techniques ........11 Shut Down and Clean-Up ..............12 Storage ....................13 Troubleshooting ................14-15 Preventive Maintenance ................ 16 Hose and Spray Gun Assembly and Parts list ........17 Oil Change Record ................ -

Page 4: Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION Thank you for purchasing this Pressure Washer. WARNING: Risk of asphyxiation. WARNING Use this product only in a well We reserve the right to make changes at any time ventilated area. without incurring any obligation. 5. - Page 5 IMPORTANT SAFETY INFORMATION WARNING: Keep wand, hose, and 12. To reduce the risk of injury, close supervision WARNING water spray away from electric is necessary when a machine is used near wiring or fatal electric shock may children. Do not allow children to operate the pres- sure washer.

- Page 6 IMPORTANT SAFETY INFORMATION 18. Do not operate this machine when fatigued or under the influence of alcohol, prescription medications, or drugs. 19. Inlet water must be clean fresh water and no hotter then 90°F. 20. Manufacturer will not be liable for any changes made to our standard machines or any components not purchased from us.

-

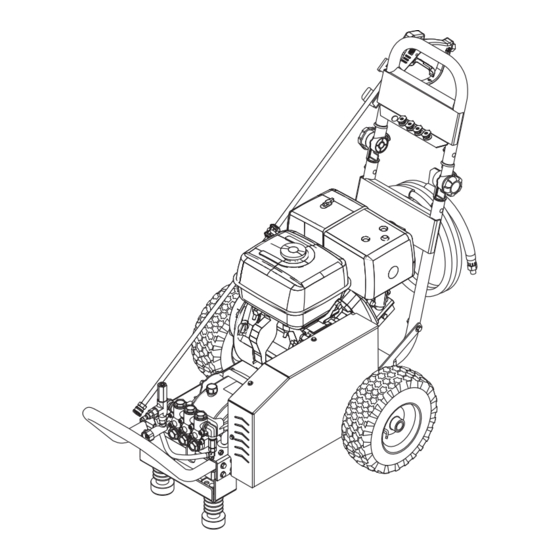

Page 7: Component Identification

COMPONENT IDENTIFICATION Pressure Straight Nozzle Through Wand Spray Gun Detergent Bucket (not included) Trigger Pump Unloader High Pressure ENGINE Hose Pump Protector PUMP Inlet Hose Screen Detergent Detergent Injector (Not Included) Garden Hose (not included) Starter Grip Pump — Develops high pressure. High Pressure Hose —... -

Page 8: Assembly Instructions

ASSEMBLY INSTRUCTIONS Spray Spray Gun/Wand Safety Latch Wand High Pressure Hose STEP 2: Attach the high pressure STEP 3: Attach wand to spray gun STEP 1: Adjust handle at the de- hose to the spray gun using teflon using teflon tape on wand threads. sired position. -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS Dipstick Oil Dipstick Oil Window STEP 1: Check engine oil level. Oil level should be level with the bottom STEP 2: Remove shipping cap of the oil filler neck. Be sure the machine is level when checking the oil and install oil dipstick. - Page 10 OPERATING INSTRUCTIONS On-Off Switch STEP 8: Turn the engine switch to "On" position. STEP 9: Pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pres- On Vanguard engines, move the throttle lever to sure and repeat step.

-

Page 11: Detergent And General Operating Techniques

DETERGENT AND GENERAL CLEANING TECHNIQUES THERMAL PUMP PROTECTION WARNING: Some detergents WARNING may be harmful if inhaled or in- If you run the engine on your pressure washer for 1-2 gested, causing severe nausea, minutes without pressing the trigger on the spray gun, fainting or poisoning. -

Page 12: Shut Down And Clean-Up

SHUTTING DOWN AND CLEAN-UP On-Off Switch STEP 1: Remove detergent suc- STEP 2: Turn off the engine. STEP 3: Turn off water tion tube from container and insert supply. into one gallon of fresh water. Slide nozzle forward for low pressure or to connect black detergent nozzle. -

Page 13: Storage

STORAGE CAUTION: Always store your pressure washer in a and replace the plug. Then pull the starter grip location where the temperature will not fall below slowly until you feel increased pressure which in- dicates the piston is on its compression stroke and 32°F (0°C). -

Page 14: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Faulty pressure gauge Install new gauge. PRESSURE Use larger supply hose; clean filter at water Insufficient water supply inlet. Match nozzle number to machine and/or Old, worn or incorrect spray nozzle replace with new nozzle. Belt slippage Tighten or replace;... - Page 15 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION WATER OR OIL A small amount of leaking is If excessive leaking occurs, call local LEAKING FROM normal distributor. BOTTOM OF PUMP PRESENCE OF Water sprayed at machine Change oil. Direct spray away from ma- WATER IN PUMP chine.

-

Page 16: Preventive Maintenance

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION SPRAY WAND Spray wand not properly attached Slide the spray wand into the gun. Turn the LEAKS wand collar clockwise onto the spray gun threads until tight. Broken o-ring Call local distributor and order an o-ring. PUMP IS NOISY Pump is sucking air Check that hoses and fittings are air tight. -

Page 17: Hose And Spray Gun Assembly And Parts List

HOSE & SPRAY GUN ASSEMBLY HOSE & SPRAY GUN ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.916-740.0 Hose, 3/8" x 50', Quick Connect 1 Wire Tuff-Skin (BGA Models) 1 Nozzle Kit (3500 PSI Models) 1 8.739-011.0 Hose, 3/8"... -

Page 18: Oil Change Record

OIL CHANGE RECORD Check pump oil and engine oil level before first use of your new pressure washer. Check pump oil and engine oil level before first use of your new pressure washer. Pump oil: Check level daily before first use of your new Power Washer. Change pump oil after first 50 hours every year or 500 hours thereafter. - Page 19 Form #8.919-400.0 • BGA • Revised 04/19 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the BGA-252737 and is the answer not in the manual?

Questions and answers