Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

7

ISO 9001 Certified

ISO 14001 Certified

1935/2004/EC

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

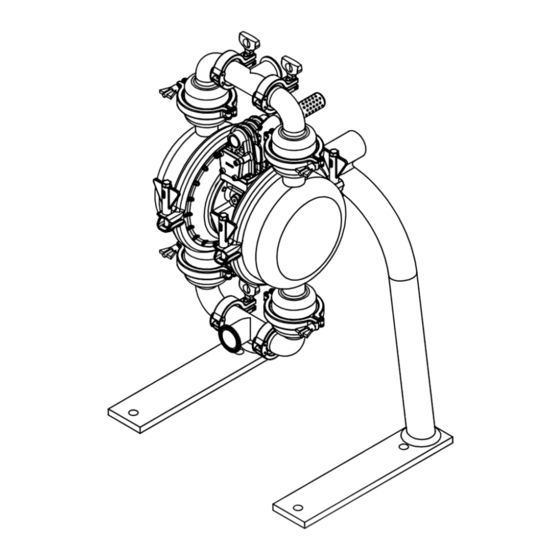

Model F15C

Metallic Sanitary Processing Pump

Constructed with FDA Compliant Materials

Design Level 1

s a n d p i p e r p u m p. c o m

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Idex SANDPIPER F15C

- Page 1 Constructed with FDA Compliant Materials Design Level 1 ISO 9001 Certified ISO 14001 Certified 1935/2004/EC Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM © Copyright 2017 Warren Rupp, Inc.

- Page 2 Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

- Page 3 Temperature Tables Table 1. Category 2 ATEX Rated Pumps Ambient Temperature Process Temperature Temperature Maximum Surface Range [°C] Range [°C] Class Temperature [°C] -20°C to +80°C T100°C -20°C to +108°C T135°C -20°C to +60°C -20°C to + 160°C T200°C -20°C to +177°C (225°C) T2 Table 2. Category M2 ATEX Rated Pumps for Mining Ambient Temperature Process Temperature Range [°C] Range [°C]...

-

Page 4: Table Of Contents

Table of Contents SECTION 1: PUMP SPECIFICATIONS ....5 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ...9 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......12 •... -

Page 5: Explanation Of Nomenclature

Explanation of Pump Nomenclature Your Model #: F __ ____ ____ (fill in from pump nameplate) Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Muffler Pump Brand Size Valve Level Material Check Valve Seat Material Options Style Options Options Model #:... -

Page 6: Performance

Performance 1 1/2" Sanitary Pump ELASTOMERIC AND TPE FITTED Flow Rate Displacement Per Stroke, 0.32 Gal. (1.21 L) Adjustable to . . . . . . . 0-86 gpm (325 .5 lpm) 5 10 20 AIR CONSUMPTION IN SCFM Port Size AIR PRESSURE IN PSI... -

Page 7: Materials

Materials Material Profile: Operating Temperatures: Max. Min. CAUTION! Operating temperature limitations are as follows: EPDM: Shows very good water and chemical resistance . Has 280°F -40°F poor resistance to oils and solvents, but is fair in ketones and 138°C -40°C alcohols . -

Page 8: Dimensional Drawings

Dimensional Drawings Sanitary Processing Metallic Dimensions in inches (mm dimensions in brackets) . The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.95 1-1/2” 15.72 DISCHARGE SANITARY CLAMP FLANGE 2.50 2.00 1/2"... -

Page 9: Principle Of Pump Operation

Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen . The main directional (air) control valve distributes ① compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm . -

Page 10: Recommended Installation Guide

Recommended Installation Guide Available Accessories: 1. Surge Suppressor Unregulated Air 2. Filter/Regulator Supply to Surge Surge Suppressor Suppressor 3. Air Dryer Pressure Gauge Shut-Off Valve Pipe Connection Note: Surge Suppressor and (Style Optional) Piping must be supported after Flexible Connector Discharge the flexible connection Check Valve Shut-Off... -

Page 11: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure) . (Does not apply to high pressure 2:1 units) . Air valve or intermediate gaskets installed incorrectly . - Page 12 Pump Inspection and Cleaning The Elima-Matic sanitary pump can be cleaned using several techniques. However, it is important to follow guidelines set by the IAMFES, the USPHS, and the DIC and/or internal rules for inspection, cleaning and sanitization. Remove the valve balls and ball cages from the pump and clean components separate from the pump. If the pump is to be steam cleaned, disconnect the suction line from the pump. Connect the steam line to the pump inlet. Maintain the flow of steam through the pump for at least five minutes after the temperature at the outlet has reached 200°F (94°C). Hot water may also be used. Pump water that is maintained at minimum of 170°F (77°C) through the pump for at least five minutes. Please note that the maximum cleaning temperature of the pump is 220° (104°C). Chemical cleaning may also be used in sanitizing the pump. Be sure to consult your distributor or the manufacturer to verify that the elastomer(s) used in the pump are compatible with the chemicals being used in the cleaning process. sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219...

- Page 13 Composite Repair Parts Drawing FUSION DIAPHRAGM E PILOT Y DETAIL FUSION TWO PIECE DIAPHRAGM DIAPHRAGM FUSION DIAPHRAGM PILOT ASY DETAIL Torque Setting: Torque Setting: 60 in-lbs. (6 N-m) 350 in-lbs. (39 N-m) Torque Setting: 200 in-lbs. (22 N-m) Torque Setting: 350 in-lbs.

- Page 14 Composite Repair Parts List Air Valve Assembly Item # Qty. Description Part Number Valve Body Assembly (includes items 2-8) P31-200-NP Valve Body P31-201NP End Cap P50-300NP End Cap Gasket P50-110 Valve Body Gasket P31-202 Valve Spool P50-104 Glyde Ring Assembly P50-104C Mounting Screws (8 included on item 1) S1001...

- Page 15 Liquids - Common Safety Requirements, to verify conformance. October 20, 2005 Date of issue Signature of authorized person Director of Engineering Authorised Representative: Title IDEX Pump Technologies R79 Shannon Industrial Estate February 27, 2017 Shannon, Co. Clare, Ireland Date of revision Attn: Barry McMahon Revision Level: F...

- Page 16 Declaration of Conformity Manufacturer: Warren Rupp, Inc., 800 N. Main Street, Mansfield, Ohio, 44902 USA certifies that SANDPIPER Air-Operated Double Diaphragm Food Processing Pump Models ® and Tranquilizer Surge Suppressor Models comply with the European Community Regulations: ® (EC) No 1935/2004 for Food Contact Materials (EC) No 2023/2006 Good Manufacturing Practice (EU) No 10/2011 on plastic materials and articles intended to come in contact with food Food Processing Pump Models:...

- Page 17 ATEX EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfield, OH 44902 USA Warren Rupp, Inc. declares that Air Operated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of Directive 2014/34/EU and all applicable standards.

Need help?

Do you have a question about the SANDPIPER F15C and is the answer not in the manual?

Questions and answers