Table of Contents

Advertisement

Quick Links

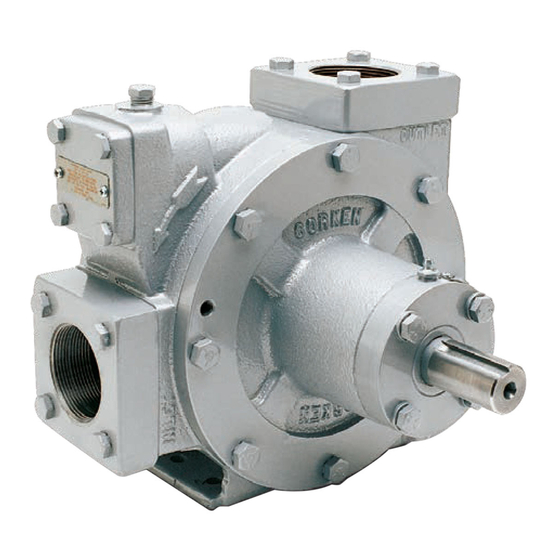

ID105E

Installation, Operation

& Maintenance Manual

Z-Series Truck Pumps

Z2000

Z3200

Z4200

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and

ANSI K61.1-1972 for Anhydrous Ammonia). (4) Transfer of toxic, dangerous, flammable or explosive substances using Corken products

is at user's risk and equipment should be operated only by qualified personnel according to applicable laws and safety standards.

Advertisement

Table of Contents

Summary of Contents for Idex Corken Z-Series

- Page 1 ID105E Installation, Operation & Maintenance Manual Z-Series Truck Pumps Z2000 Z3200 Z4200 Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products must comply with Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia).

- Page 2 Warning Install, use and maintain this equipment according to Corken’s instructions and all applicable federal, state, local laws and codes. Periodic inspection and maintenance is essential. Corken One Year Limited Warranty Corken, Inc. warrants that its products will be free from defects in material and workmanship for a period of 12 months following date of purchase from Corken.

-

Page 3: Table Of Contents

Table of Contents Principles of the Z-Series Coro-Vane ® Truck Pump ....................... 4 Exclusive Features of Your Z-Series Coro-Vane ® Truck Pump..................4 ® Installation of the Z-Series Coro-Vane Truck Pumps ....................4 Outlet Piping Should Include the Following ......................... 5 By-Pass System ................................ -

Page 4: Principles Of The Z-Series Coro-Vane

Principles of the Z-Series Coro-Vane AN EXTERNAL BY-PASS VALVE MUST BE INSTALLED. Truck Pumps Installation of Your Corken Z-Series The Corken Z-Series truck pump is a special type of rotary ® Coro-Vane Pump positive displacement pump, known as a sliding vane pump. -

Page 5: Outlet Piping Should Include The Following

Figure 1: Shaft Alignment frame. A fixed driveshaft transfers the forces directly into the pump and PTO and will shorten the life of both considerably. The yokes of the driveshaft universal joints must be positioned as shown. Improper positioning will soon wear them out and potentially destroy the bearings in the pump and PTO. -

Page 6: Hydraulic Drive Systems

Improper installation of the U-joints will soon destroy Information on the Char-Lynn hydraulic motor is found in them along with the bearings in the pump and PTO. Appendix H. Properly mounted, the second universal gives uniform motion ® Operation of Your Z-Series Coro-Vane to the drive shaft by compensating for the rotational error introduced by the first U-joint. -

Page 7: Maintenance Of Your Z-Series Coro-Vane Truck Pump System

ARE NOT PERMITTED REMEMBER THAT A QUIET on page 9. Use only genuine Corken replacement parts PUMP IS AN EFFICIENT PUMP. A NOISY PUMP IS NOT when repairing your Corken Z-Series pump. Follow the EFFICIENT AND THE CONDITIONS THAT CAUSE THE instructions provided with the parts. -

Page 8: Preventive Maintenance Program

Preventative Maintenance Program for Z-Series LPG Pumps 5. Lubricate Motor Bearing: Purpose By following an effective preventive maintenance program, Follow the recommendations of the electric motor unscheduled downtime can be eliminated. This program manufacturer for the type of grease to use and the should be used by the Operation Manager to get a lubrication frequency. -

Page 9: Z-Series Coro Vane ® Seal Replacement Instructions

® Z-Series Coro-Vane Seal Replacement Instructions Please Note: The photos listed below contain a Z2000; while installing the seal. Never touch the smooth lapped however, all Z-Series pumps use the same procedures for faces of the carbon rotor or seal seat. For LP-Gas, seal replacement. - Page 10 ® Z-Series Coro-Vane Seal Replacement Instructions Step 5 Step 7 Seal retainer and carbon installation Completing installation Clean the pump and apply a generous amount of light oil. Torque the head bolts in a crossing pattern. There is no need to disassemble or re-shim the bearing caps. Repeat Install the new seal assembly by aligning the seal retainer all of the above steps when replacing the seal assembly on slot with the seal drive pin on the shaft.

-

Page 11: Repair/Re-Build Kits

Repair/Re-build Kits Z2000 Repair Kit 3193-X1 Z2000 Re-Build Kit 3194-X1 Includes all items in the Repair Kit plus the following: 2-224A O-ring, Buna-N 2-231A O-ring, Buna-N 4414 2754-X Roller bearing 4427 Sideplate 4262-X Vane driver 4428 Vane 4431-XA2 Seal assembly 4432 Thrust bearing 4435... -

Page 12: Assembly Instructions For Z-Series Truck Pumps

Pump Assembly Instructions For Z-Series Truck Pumps 1. Place the pump head on a clean work surface with the deforming the cam inlet port. This is done by bolting bolting flange down. those bolts over the solid portion of the cam port. 2. -

Page 13: Parts Details

Parts Details for Model Z2000 O-ring Code A Buna-N See Page 11 for repair/re-build kits. B Neoprene ®1 ®1 D Viton CAUTION: Always relieve pressure in the unit before attempting any repairs. E Teflon ®1 Ref. Ref. no. Part no. Description Qty. - Page 14 Parts Details for Model Z3200 O-ring Code A Buna-N ®1 B Neoprene D Viton ®1 See Page 11 for repair/re-build kits. E Teflon ®1 CAUTION: Always relieve pressure in the unit before attempting any repairs. Ref. Ref. No. Part No. Description No.

- Page 15 Parts Details for Model Z4200 O-ring Code A Buna-N B Neoprene ®1 See Page 11 for repair/re-build kits ®1 D Viton CAUTION: Always relieve pressure in the unit before E Teflon ®1 attempting any repairs. Ref. Ref. No. Part No. Description No.

-

Page 16: Model Number And Identification Code

Appendix A—Model Number and Identification Code Example Models Involved Description Code Feature Z2000 Foot mounted (NPT connections) General Z3200 300# inlet flange for direct mounting construction Z4200 to truck outlet 180° from inlet Sliding vane pump with floating rotor and two shaft extensions Flow rate 41–85 gpm 2000... -

Page 17: Operating, Material And Flange Specifications

Appendix B—Specifications Operating Specifications Maximum Minimum Maximum Maximum Maximum Internal temperature temperature working pressure differential pressure relief valve -25°F (-32°C) 225°F (107°C) 400 psig (28.6 bar) 125 psid (8.6 bar) Material Specifications Part Material Case, head, rotor, relief valve cap, bearing cap Ductile iron ASTM A536 Gray iron ASTM A48, Class 50 Sideplate... -

Page 18: Performance Curves And Charts

Appendix C—Z2000 Performance Curves 750 RPM 650 RPM 600 RPM 500 RPM Differential Pressure (psi) The chart shows approximate delivery rates as seen in vapor equalized propane systems at 70°F (21°C) with no pressure loss in pump suction piping. The following will cause increased vaporization of the liquid in the pump suction, adversely affecting the delivery: 1. - Page 19 Appendix C—Z3200 Performance Curves 750 RPM 650 RPM 600 RPM 500 RPM Differential Pressure (psi) The chart shows approximate delivery rates as seen in vapor equalized propane systems at 70°F (21°C) with no pressure loss in pump suction piping. The following will cause increased vaporization of the liquid in the pump suction, adversely affecting the delivery: 1.

- Page 20 Appendix C—Z4200 Performance Curves 750 RPM 650 RPM 600 RPM 500 RPM Differential Pressure (psi) The chart shows approximate delivery rates as seen in vapor equalized propane systems at 70°F (21°C) with no pressure loss in pump suction piping. The following will cause increased vaporization of the liquid in the pump suction, adversely affecting the delivery: 1.

- Page 21 Appendix C—Performance Charts ® Z2000 Coro-Vane Truck Pump Pump Differential Approximate Delivery Brake hp Pump Torque Speed Pressure of Propane Required Required (kPa) gpm (L/min) bhp (kW) • • (345) (303) (2.2) 20.4 (27.7) 100 (689) (269) (4.3) 40.8 (55.3) (345) (261) (1.9)

-

Page 22: Appendix D Outline Dimensions

1/4 x 1-9/16 square key INTERNAL RELIEF VALVE SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE CORKEN, INC. 2-1/8 2-1/8 A Unit Of IDEX Corp. (5.40) (5.40) 1-1/8 (2.85) 3-1/4 (8.25) Internal relief valve Outlet: 2" NPT... - Page 23 Appendix D—Outline Dimensions for Model Z3200 17-1/2 10-15/16 1-1/8 (44.43) (27.78) (2.86) 4-15/16 8-3/4 (12.47) (22.23) 3-7/16 2" NPT auxiliary inlet 1/4" (8.73) 6-3/4 (17.14) 14-15/16 (37.94) INTERNAL RELIEF VALVE (12.70) 1/4" NPT Internal 1-5/8 (4.13) relief 2" NPT valve discharge 5-11/32 3-7/8...

- Page 24 Appendix D—Outline Dimensions for Model Z4200 1-3/16 (3.01) Internal relief valve INLET 1/4 NPT 2" NPT auxiliary (20.32) inlet 2-5/8 (6.67) 13-13/16 (35.08) OUTLET 3-1/4 (8.26) 1/4" NPT 7-3/4 (17.78) (19.69) 16-31/32 (43.08) 19-1/2 (49.53) 7-7/8 BC (20.00) 10-1/8 D (25.72) 2-1/8 Inlet:...

- Page 25 Appendix D—Outline Dimensions for Model ZH2000 1/4" square keyway Hydraulic drive adapter assembly 2-1/8 (5.40) 4248 1-1/8 D (2.85) Hydraulic motor 3-1/4 (8.25) 13/16 (2.06) 10-1/2 (26.63) (20.30) 17-11/16 (44.90) 5-15/16 4-9/16 (15.08) (11.59) 2-3/8 Outlet - 2" NPT (6.03) 1/4"...

- Page 26 SET AT 150 P.S.I. NOT FOR RECIRCULATING INSTALLER TO PROVIDE SEPARATE BY-PASS VALVE SET AT 125 P.S.I. MAXIMUM CORKEN, INC. A Unit Of IDEX Corp. 3" 300 lb ANSI flange inlet Hydraulic drive adapter Assembly 6-5/8 D B.C. 3-7/8 (16.83) (9.84)

- Page 27 Appendix D—Outline Dimensions for Model ZH4200 19-9/16 9-3/4 (49.69) (24.77) 12-3/8 (31.43) MODEL SERIAL LISTED 656L PAT. NOS. 3,072,066 AND 3,392,677 Hydraulic motor Hydraulic drive adapter assembly (10.16) (10.16) 7-7/8 B.C. 10-1/8 D (20.00) (25.72) Intlet: 4" 300 lb ANSI flange 2-1/8 (5.40) 5/16"...

-

Page 28: Appendix E Troubleshooting Guide

Appendix F—Troubleshooting Guide In diagnosing pump and system troubles, record the 4. Pressure in tank being filled. following data during product transfers: 5. Pipe size and length of suction and discharge lines. 1. Pressure at pump suction. 6. Size and length of vapor equalizing line. 2. -

Page 29: Storage Of The Z-Series Coro-Vane

® Z-Series Coro-Vane Truck Pumps If your Corken Z-Series pump is to be removed from service for some time, the pump must be protected as propane, butane and anhydrous ammonia all leave the metal "bare" and open to corrosion. Piping and tanks not in service should also be protected, as the rust particles can destroy the pump's seals almost immediately after startup. -

Page 30: Hydraulic Motor Specifications

Appendix H—Hydraulic Motor Specifications Operating Specifications for Char-Lynn Hydraulic Motor Mounting flange 2 bolt SAE A Input shaft 1” diameter straight keyed Port ‘A’ 7/8-14 O-ring Port ‘B’ 7/8-14 O-ring Pilot diameter 3.250/3.245 in (57.15/57.02 mm) Motor displacement 6.2 cubic inches per revolution Maximum speed continuous duty 742 RPM Flow continuous duty... - Page 32 Corken, Inc. • A Unit of IDEX Corporation P.O. Box 12338, Oklahoma City, OK 73157 U.S.A. 3805 N.W. 36th St., Oklahoma City, OK 73112 Phone (405) 946-5576 • Fax (405) 948-7343 Visit our website at http://www.corken.com or e-mail us at info.corken@idexcorp.com Printed in the U.S.A.

Need help?

Do you have a question about the Corken Z-Series and is the answer not in the manual?

Questions and answers