Garmin GI 275 Maintenance Manual

Hide thumbs

Also See for GI 275:

- Installation manual (531 pages) ,

- Pilot's manual (332 pages) ,

- Maintenance manual (155 pages)

Table of Contents

Advertisement

GI 275 Part 27 AML STC

Maintenance Manual

Contains Instructions for Continued Airworthiness

for STC SR01980WI

Rotorcraft make, model, registration number, and serial

number, along with the applicable STC configuration

information, must be completed in Appendix A and

saved with rotorcraft permanent records.

190-02246-C2

December 2022

Revision 3

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Garmin GI 275

- Page 1 GI 275 Part 27 AML STC Maintenance Manual Contains Instructions for Continued Airworthiness for STC SR01980WI Rotorcraft make, model, registration number, and serial number, along with the applicable STC configuration information, must be completed in Appendix A and saved with rotorcraft permanent records.

- Page 2 Garmin. Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and to print one copy of this manual or of any revision...

- Page 3 The AES file encryption software is provided “as is” with no explicit or implied warranties in respect of its properties, including, but not limited to, correctness and/or fitness for purpose. 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page ii...

- Page 4 Software License Agreement (hereinafter the “Agreement”) and is subject to the following terms and conditions which are agreed to by End User (“Licensee”, “you” or “your”), on the one hand, and Garmin and its licensors and affiliated companies of Garmin and its licensors, on the other hand. The Licensed Software is licensed, not sold, to you. Garmin and Licensee may be referred to individually as a “Party”...

- Page 5 No Devices or Services. Licensee acknowledges and agrees that nothing in this Agreement shall be construed as requiring Garmin to: (a) provide or supply the Devices or any other devices or hardware to Licensee; (b) grant any licenses to any software other than the Licensed Software; or (c) provide any services, such as support, maintenance, installation or professional services for the Licensed Software.

- Page 6 Assignment. Licensee may not assign this Agreement or any of its rights, interests or obligations hereunder without the prior written consent of Garmin. Any purported assignment in violation of this Section 6.3 shall be null and void. Subject to the foregoing, this Agreement shall be binding upon and shall inure to the benefit of the Parties and their respective successors and permitted assigns and transferees.

- Page 7 Added a check of pitot-static drains to Table 3-1 Periodic Maintenance. 5.5.1 Clarified wording of Caution. 5.6.2 Updated Backup GPS Re-Installation Procedure. A.4.5 Added wiring diagram for Airbus AS350. 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page vi...

- Page 8 Battery replacement and removal must be performed by a licensed A&P technician. CAUTION To avoid damage to the GI 275, take precautions to prevent electrostatic discharge (ESD) when handling the unit, connectors, and associated wiring. ESD damage can be prevented by touching an object of the same electrical potential as the unit before handling the unit itself.

-

Page 9: Table Of Contents

A.1 General Information .........................A-1 A.2 LRU Information ........................A-2 A.3 Equipment Location .........................A-3 A.4 Wire Routing ..........................A-4 A.5 Saved Configuration File ......................A-9 A.6 Print Configuration Log ......................A-9 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page viii... - Page 10 LIST OF FIGURES Figure 2-1 GI 275 Normal Mode ......................2-4 Figure 2-2 Entering Configuration Mode on the GI 275 ...............2-5 Figure 2-3 GI 275 Display ........................2-12 Figure 2-4 Backup GPS Antenna ......................2-12 Figure 2-5 GMU 44B Magnetometer ....................2-13 Figure 2-6 GTP 59 Outside Air Temperature Probe ................2-13...

- Page 11 Table 5-4 Airspeed Test Points ......................5-29 Table 5-5 Advanced Airframe Specific Configuration Data – Arc Ranges ........5-30 Table 5-6 Advanced Airframe Specific Configuration Data – Markings ..........5-30 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page x...

- Page 12 1 INTRODUCTION Purpose..............................1-2 Scope..............................1-2 Organization............................1-2 Applicability .............................1-2 Publications............................1-3 Revision and Distribution .........................1-3 Terminology and Acronyms ......................1-3 1.7.1 Terminology ..........................1-3 1.7.2 Acronyms ...........................1-4 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 1-1...

-

Page 13: Purpose

Provides a template to record rotorcraft-specific installation and configuration data for the GI 275 system. 1.4 Applicability This document applies to all rotorcraft with the GI 275 system installed in accordance with AML STC SR01980WI. Modification of a rotorcraft by this STC obligates the rotorcraft operator to include the maintenance information provided by this document in the operator’s Rotorcraft Maintenance Manual and... -

Page 14: Publications

In addition to this manual, the following documents are recommended for performing maintenance on the GI 275 system. It is the responsibility of the owner/operator to ensure the latest applicable versions of these documents are used during operation, servicing, or maintenance of the GI 275 system. - Page 15 Coordinated Universal Time Indicated Air Speed Very High Frequency Instructions for Continued Airworthiness VHF Omni-Directional Range Localizer WAAS Wide Area Augmentation System Line Replaceable Unit Weather Radar 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 1-4...

-

Page 16: System Description

GI 275 Display .........................2-12 2.4.2 Backup GPS Antenna.......................2-12 2.4.3 Integrated ADAHRS ........................2-12 2.4.4 GMU 44B Magnetometer......................2-13 2.4.5 GTP 59 OAT Probe........................2-13 2.4.6 Backup Battery .........................2-14 2.4.7 GSB 15 .............................2-14 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 2-1... -

Page 17: Overview

2.1 Overview The GI 275 installation can provide Primary ADI, HSI, Standby ADI, and MFD. Two unit variants are available: the GI 275 Base and the GI 275 ADAHRS, which contains an integrated ADAHRS. System limitations are contained in Section 2 of the GI 275 installation manual (refer to Table 1-1). -

Page 18: Table 2-1 Gi 275 Lru Electrical Load

2.1.5 GI 275 Current Draw Electrical load information for the GI 275 system LRUs is provided in Table 2-1. Appendix A contains details specific to the load changes for the specific rotorcraft installation. Table 2-1 GI 275 LRU Electrical Load... -

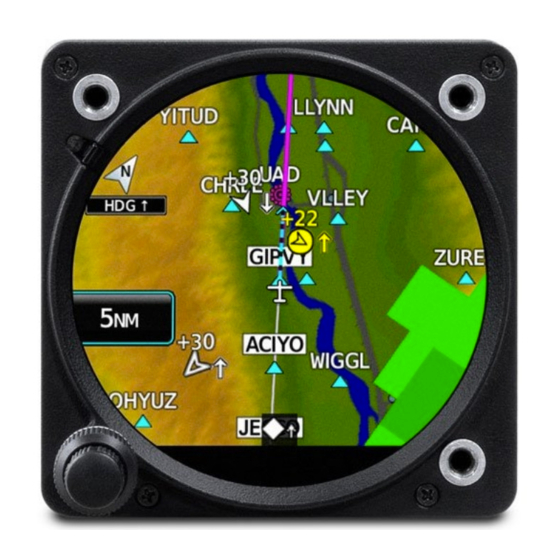

Page 19: Normal Mode Operation

The Normal mode home page differs depending on the configuration and purpose of the GI 275 unit. The menu can be accessed on any page by swiping up from the bottom of the screen or by pressing and holding the inner knob for 2 seconds. -

Page 20: Configuration Mode Operation

2.3.1 Entering Configuration Mode The Configuration mode of the GI 275 can be accessed by holding down the inner knob located at the bottom-left of the unit upon initial power-up. The knob must be pressed until the Garmin splash screen with “Configuration Mode”... -

Page 21: Database Loading

3. Touch the Bluetooth Name button and select the device. 4. Touch the Pair button. The GI 275 can store up to 13 paired devices. Once a device is paired, it can be connected to automatically in Normal mode to initiate database uploads. - Page 22 8. Touch the Update button. 9. Insert the USB drive into the USB dongle or optional GSB 15 and wait for the GI 275 to recognize the drive (USB status will change from “Not Connected” to “Connected” at the top of the screen).

-

Page 23: Table 2-2 Database Summary

4. Touch the Update button. The GI 275 internal Wi-Fi will now be available to be connected with a PED. 5. Connect the PED to the GI 275’s Wi-Fi network. The SSID and password can be set or viewed on the Wireless page. -

Page 24: Import Configuration

Configuration settings can be imported via USB using the following procedure: 1. Power on the GI 275 and all LRUs in the system in Configuration mode. 2. Insert the USB drive containing the configuration files into the USB dongle or GSB 15 (if installed). -

Page 25: Maintenance Menu

1. Power on all GI 275s in the system in Configuration mode. 2. Insert a USB drive into the USB dongle or optional GSB 15 and wait for the GI 275 to recognize the drive (a USB icon will appear in the bottom-left of the screen). - Page 26 Event ID (optionally select All), and a date range to be included. Touch View events to view a list of events. Select each event to view additional information. 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 2-11...

-

Page 27: Lru Description, Control, And Operation

Backup GPS Antenna The GI 275 has an internal VFR GPS receiver that may be used as a primary GPS source for VFR navigation only or as a backup GPS. If the backup GPS antenna is installed, the internal VFR GPS is automatically used when the primary GPS source is unavailable. -

Page 28: Figure 2-5 Gmu 44B Magnetometer

The GTP 59 is a remotely mounted temperature probe that interfaces to the internal ADC for OAT display and computations. The GTP 59 is mounted externally on the rotorcraft and is powered from the GI 275. Figure 2-6 GTP 59 Outside Air Temperature Probe... -

Page 29: Figure 2-7 Backup Battery

Backup Battery The backup battery is a lithium-ion battery that is required when installing the GI 275 as a standby or when the GI 275 is installed as the Primary Flight Indicator, replacing airspeed, altitude, and attitude if there is no alternate source of altitude (mechanical or electronic with an independent power supply). -

Page 30: Instructions For Continued Airworthiness

Reconditioned Electrical Bonding .....................3-6 3.5.3 Aluminum Surface Preparation....................3-7 Overhaul Period ..........................3-8 Special Inspection Requirements......................3-8 Application of Protective Treatments ....................3-8 Data Relative to Structural Fasteners....................3-8 3.10 Additional Instructions ........................3-8 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 3-1... -

Page 32: Servicing Information

3.2 Servicing Information There are no servicing requirements for the GI 275 system. In the event of a system or LRU failure, troubleshoot the GI 275 system in accordance with Section 4. 3.2.1 Periodic Maintenance Instructions The GI 275 system is designed to detect internal failures. A thorough self-test is executed automatically upon application of power to the unit, and built-in tests are continuously executed while the LRUs are operating. -

Page 33: Maintenance Intervals

Dealer Resource Center or by contacting Garmin. Every 2000 flight Electrical Bonding Perform an electrical bonding check of the GI 275 system hours or 10 years, Check LRUs in accordance with Section 3.5. whichever comes first Interval must be in Test according to 14 CFR §43 Appendix E. -

Page 34: Visual Inspection

3.4 Visual Inspection Operation of the GI 275 system is not permitted unless an inspection, as described in this section, has been completed within the preceding 12 calendar months. Conduct the following visual inspection of the GI 275 system LRUs and associated wiring harnesses to ensure installation integrity: 1. -

Page 35: Electrical Bonding

3.5.1 Electrical Bonding Maintenance Check GI 275 LRU electrical bonding must be checked every 2,000 flight hours or 10 years, whichever occurs first. During the check, any cables normally attached to the LRU must be disconnected from the LRU. Resistance must be measured from a bare metal portion of the LRU to an airframe grounding location. The airframe grounding location should be as close to the LRU as possible, unless otherwise noted in Table 3-2. -

Page 36: Table 3-3 Bonding Requirements

5. Install bonding aluminum tape or equipment at grounding location. 6. After the bond is complete, if any films or coatings were removed from the surface, re-apply a suitable film or coating to the surrounding area. 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 3-7... -

Page 37: Overhaul Period

The system does not require overhaul at a specific time period. Power on self-test and continuous BIT will monitor the health of the GI 275 system. If any LRU indicates an internal failure, the unit may be removed and replaced. Refer to Section 4 of this document for fault corrective actions. -

Page 38: Troubleshooting

GSB 15 ............................4-7 Troubleshooting Flow Charts ......................4-8 This section provides information to assist troubleshooting if fault codes are displayed on the GI 275 or problems occur after completing system maintenance. Refer to Appendix A of this document retained in the rotorcraft permanent records for a list of the interfaced equipment and system configuration data. When troubleshooting the GI 275 system, refer to wire routing drawings and interconnect diagrams retained in Appendix A of this document or with the rotorcraft’s permanent records. -

Page 39: General System Troubleshooting

Section 4.3. 4.1.1 System Maintenance Log The GI 275 system has a maintenance and error log that can be accessed or printed to assist with system maintenance and troubleshooting. The maintenance and error log can be printed using the following procedure: 1. -

Page 40: Connector Information

The J2752/P2752 connector is only included with GI 275 ADAHRS models. GI 275 displays have up to three connectors: • J2751/P2751 - 78-pin female contact HD D-sub • J2752/P2752 - 78-pin female contact HD D-sub (GI 275 ADAHRS units only) • BNC, Male Figure 4-1 GI 275 Connectors 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. -

Page 41: Figure 4-2 Gi 275 J2751 Connector (Looking At Connector)

Figure 4-2 GI 275 J2751 Connector (Looking at Connector) Table 4-2 GI 275 J2751/P2751 Connector Function Function CONFIG MODULE GROUND CONFIG MODULE DATA AIRCRAFT POWER 1 AIRCRAFT GROUND AIRCRAFT POWER 2 LIGHTING BUS LO DISCRETE OUT 1 LO DISCRETE OUT 2*... -

Page 42: Figure 4-3 Gi 275 J2752 Connector (Looking At Connector)

Figure 4-3 GI 275 J2752 Connector (Looking at Connector) Table 4-3 GI 275 J2752/P2752 Connector Function Function DISCRETE OUT 7 LO DISCRETE OUT 8 LO SPARE RESERVED RESERVED RESERVED DISCRETE IN 5 LO DISCRETE IN 6 LO RESERVED RESERVED RESERVED... -

Page 43: Figure 4-4 J442/P442 Connector

MAG POWER INPUT 4.2.3 GTP 59 The GTP 59 Temperature Probe does not have a connector. Rather, a 3-conductor shielded cable extends from the sensor for interface with a GI 275. Table 4-5 GTP 59 3-Conductor Shielded Cable Conductor Color Name... -

Page 44: Figure 4-5 Gsb 15 Connectors

P/N 011-04937-01, -30, -50 Figure 4-5 GSB 15 Connectors Table 4-6 GSB 15 J201/P201 & J202/P202 Function AIRCRAFT POWER USB DN USB DP USB GND BACKLIGHT ENABLE POWER GROUND 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-7... -

Page 45: Troubleshooting Flow Charts

If a specific alert or fault condition is not listed, or the fault still exists after completing the given corrective action, contact Garmin Aviation Technical Support at the number listed for your specific region on the “Support” tab of the flyGarmin.com... -

Page 46: Figure 4-6 Gi 275 Alert Message Troubleshooting

Free display knob from the configuration mode pushed position If fault persists, contact Garmin. Figure 4-6 GI 275 Alert Message Troubleshooting Sheet 1 of 2 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-9... - Page 47 Shut down GI 275 reconfigure Garmin for service for at least 30 min Replace configuration module If fault persists, contact Garmin. Figure 4-6 GI 275 Alert Message Troubleshooting Sheet 2 of 2 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-10...

-

Page 48: Figure 4-7 Battery Alert Message Troubleshooting

Run battery Ensure battery is Replace battery with capacity test properly installed authentic Garmin battery If fault persists, contact Garmin. Figure 4-7 Battery Alert Message Troubleshooting Sheet 1 of 4 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-11... - Page 49 Return GI 275 to Return GI 275 to Garmin for service Garmin for service Garmin for service If fault persists, contact Garmin. Figure 4-7 Battery Alert Message Troubleshooting Sheet 2 of 4 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-12...

- Page 50 Return GI 275 to Garmin for service Replace battery Replace battery Replace battery Replace battery If fault persists, contact Garmin. Figure 4-7 Battery Alert Message Troubleshooting Sheet 3 of 4 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-13...

- Page 51 Return GI 275 to Garmin for test; recharge fully service Replace battery Return GI 275 to Garmin for service If fault persists, contact Garmin. Figure 4-7 Battery Alert Message Troubleshooting Sheet 4 of 4 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-14...

-

Page 52: Figure 4-8 Ahrs Alert Message Troubleshooting

Verify wiring is Verify connections and wiring heading sources configured sources and wiring correct If fault persists, contact Garmin. Figure 4-8 AHRS Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-15... -

Page 53: Figure 4-9 Adc Alert Message Troubleshooting

ADCs ADC configuration is correct Ensure there are no Verify wiring is leaks in the pitot correct static system If fault persists, contact Garmin. Figure 4-9 ADC Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-16... -

Page 54: Figure 4-10 Terrain/Taws Alert Message Troubleshooting

TAWS and enablement GI 275 have the same aircraft type Inspect GPS antenna configured and wiring If fault persists, contact Garmin Figure 4-10 Terrain/TAWS Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-17... -

Page 55: Figure 4-11 Traffic Alert Message Troubleshooting

ADS-B LRU UAT LRU ADS-B LRU ADS-B LRU maintenance maintenance maintenance maintenance manual manual manual manual If fault persists, contact Garmin Figure 4-11 Traffic Alert Message Troubleshooting Sheet 1 of 2 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-18... - Page 56 TAS/TCAS LRU TIS-A LRU LRU maintenance maintenance maintenance manual manual manual If fault persists, contact Garmin Figure 4-11 Traffic Alert Message Troubleshooting Sheet 2 of 2 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-19...

-

Page 57: Figure 4-12 Audio And Weather Alert Message Troubleshooting

Inspect GDL 69/69A accordance with accordance with wiring and audio device audio device connectors maintenance maintenance manual manual If fault persists, contact Garmin Figure 4-12 Audio and Weather Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-20... -

Page 58: Figure 4-13 Nav Alert Message Troubleshooting

Inspect GPS antenna, wiring Verify configuration settings and connections settings Inspect NAV wiring Inspect NAV wiring and connections and connections If fault persists, contact Garmin. Figure 4-13 NAV Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-21... -

Page 59: Figure 4-14 Miscellaneous Gi 275 Alert Messages

Corrective Corrective Action Action Update database to Activate databases: the current version follow system prompts If fault persists, contact Garmin. Figure 4-14 Miscellaneous GI 275 Alert Messages 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-22... -

Page 60: Figure 4-15 External Lru Alert Message Troubleshooting

GTX 3X5 the same maintenance Verify configuration settings manual Replace configuration module Verify proper software version Verify wiring If fault persists, contact Garmin. Figure 4-15 External LRU Alert Message Troubleshooting 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 4-23... -

Page 61: Equipment Maintenance And Checkout Procedures

Refer to Section 4.2 for the connectors and pin functions for GI 275 system LRUs. Before performing any maintenance on the GI 275 system, all information in Appendix A must be filled out. It is highly recommended to save the system configuration to a USB drive and print the configuration log before replacing any system LRUs. -

Page 62: Figure 5-1 Gi 275 Installation Example

5.1 GI 275 Figure 5-1 GI 275 Installation Example 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-2... -

Page 63: Gi 275 Removal

3. If removed, seal the 1/8-27-NPT male thread fittings with MIL-S-15204 Sealing Compound (Type A or B) and connect the pitot-static lines to the unit. 4. Connect the backshell wiring connector(s) to the back of the GI 275 and tighten the retaining screws. -

Page 64: Figure 5-2 Configuration Module Installation

System ID will change and must be updated on the associated flyGarmin.com account to re- enable purchased feature enablements on the system. Replace the GI 275 configuration module using the following procedure: 1. Save the current configuration in accordance with the instructions in Section 2.3.7. -

Page 65: Backup Battery

5.2 Backup Battery Figure 5-3 Backup Battery Replacement 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-5... -

Page 66: Backup Battery Periodic Maintenance

For maximum battery longevity, store within a temperature range of -4°F to 68°F (-20°C to 20°C). The GI 275 battery should be kept partially charged when unused for longer periods of time and should not be stored when completely discharged. Charge the battery to 30% within 1 year of receipt and recharge to 30% every 2 years thereafter if the GI 275 is not in use. -

Page 67: Gmu 44B

5.3 GMU 44B Figure 5-4 GMU 44B Installation 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-7... -

Page 68: Gmu 44B Removal

NOTE If reusing the original mounting screws, the anti-rotation properties of the mounting screws must be restored. This may be done by replacing the screws with new Garmin P/N 211-60037-08. If original screws are reused, coat screw threads with MIL-S-46163 Type II Grade N thread locking compound. -

Page 69: Gtp 59

5.4 GTP 59 Figure 5-5 GTP 59 Installation 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-9... -

Page 70: Gtp 59 Removal

GTP 59 Removal Remove the GTP 59 using the following procedure: 1. Remove power from the GI 275 that is directly interfaced to the GTP 59. 2. Remove the mounting nut shown in Figure 5-5. 3. Remove the GTP 59 from the hole. -

Page 71: Gsb 15

5.5 GSB 15 Figure 5-6 GSB 15 Installation 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-11... -

Page 72: Figure 5-7 Gsb 15 Installation With Adapter Plate

Figure 5-7 GSB 15 Installation with Adapter Plate 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-12... -

Page 73: Figure 5-8 Gsb 15 Decorative Cover Installation

Figure 5-8 GSB 15 Decorative Cover Installation 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-13... -

Page 74: Gsb 15 Removal

Remove the GSB 15 using the following procedure: CAUTION The GSB 15 Decorative Cover is only intended for a single installation. The cover may be damaged during removal. A damaged cover should not be re-installed. Contact Garmin to order a replacement. 1. Disconnect the GSB 15 connector. -

Page 75: Backup Gps Antenna

5.6 Backup GPS Antenna Figure 5-9 Backup GPS Antenna Installation (Screw Mount Example) 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-15... -

Page 76: Figure 5-10 Backup Gps Antenna Installation (Hook And Loop Example)

Backup GPS Antenna Removal Use the following procedure to remove the Backup GPS antenna: 1. Remove power from the GI 275 connected to the Backup GPS antenna. 2. Disengage the BNC connector from the GI 275. 3. Remove the two screws securing the antenna (if installed per Figure 5-9 only). -

Page 77: Calibration

Magnetometer Calibration Procedure. A rotorcraft equipped with a GI 275 can be used to evaluate a candidate site for magnetic disturbances and determine whether it is a suitable location to perform the Magnetometer Calibration Procedure. The Magnetometer Calibration Procedure itself contains the logic to simultaneously survey the location for magnetic cleanliness while it is computing the magnetometer calibration parameters. - Page 78 5.7.1.3 Calibrate Pitch/Roll Offset This procedure must be completed on each GI 275 with an integrated ADAHRS. This procedure can be conducted for each AHRS simultaneously on each display. The rotorcraft must be leveled to within 0.25° of zero pitch and zero roll using the procedures in the rotorcraft maintenance manual or RFM/POH. The following procedures must be completed with the engine off: 1.

- Page 79 7. Touch Done when the test sequence is completed. The GI 275 will display a test Pass or Fail, the worst-case percentage of magnetic interference, and the time stamp at which it occurred.

-

Page 80: Table 5-1 Example Magnetic Interference Test Sequence List

3:40 AP engaged in a pitch and roll made (to engage servos) 3:50 AP disengaged 4:00 Pitot heat on 4:10 Pitot heat off 4:20 End of test 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-20... - Page 81 360° (Magnetic North), or select a level and magnetically clean location and use a calibrated sight compass. 3. Power on the GI 275(s) in Configuration mode. 4. Navigate to the test page (Calibration/Test → Attitude/Heading → Calibrate Magnetometer).

- Page 82 360° (Magnetic North) or select a level and magnetically clean location and use a calibrated sight compass. 2. With the GI 275 in Normal mode, hold the knob in to open the menu. 3. Navigate to the Units page (System → Units).

-

Page 83: Table 5-2 Heading Verification Ahrs

Displayed AHRS Standby Compass Heading (A) Heading Error (A-B) Heading or AHRS #2 Heading (B) 360° (North) 30° 60° 90°(East) 120° 150° 180°(South) 210° 240° 270°(West) 300° 330° 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-23... -

Page 84: Analog Nav Calibration

5.7.2 Analog NAV Calibration If a Composite NAV connection is interfaced to a GI 275, the displays must be calibrated to each individual NAV radio using the following procedure: 1. Power on the GI 275 in Configuration mode and then power on NAV1. -

Page 85: Backup Battery Check

8. The GI 275 will power off automatically when the test is completed. 9. Power on the GI 275(s) in Configuration mode and navigate to the Backup Battery Test page. 10. Touch the Test Results button and then Rundown Test Results button. -

Page 86: Uploading Software

5.8 Uploading Software The SW/Config page is used to update the software for the GI 275 and any LRUs directly interfaced to the GI 275. The approved software version and part numbers can be found in the most recent revision of GI 275 Part 27 AML STC Equipment List (P/N 005-01208-C3). -

Page 87: System Checks

5.9 System Checks Periodic system checks that do not require a Garmin dealer to perform are contained in this section. 5.9.1 Configuration Ground Check The configuration ground check procedures are intended to verify that each LRU and interface in the GI 275 system has been properly configured. -

Page 88: Pitot-Static And Airspeed Tape Settings Checks

30 minutes may be required if the environmental temperature is below 0º C. The GI 275 airspeed tape display and settings must be verified using the procedures in Section 5.9.2.1 or Section 5.9.2.2 depending on the airspeed tape configuration (Basic or Advanced, respectively). The airspeeds referenced in the following steps must match those shown in the printed configuration log. -

Page 89: Table 5-4 Airspeed Test Points

1. Power on the GI 275 system in Normal mode. 2. Using a pitot-static test set, increase the airspeed until the ADI airspeed tape pointer is at the bottom of the white band. -

Page 90: Table 5-5 Advanced Airframe Specific Configuration Data - Arc Ranges

Vne (Power Off) 2 - Limitations pole) is shown in the POH/RFM, set (Power off) to given value. Otherwise, set to OFF. White Triangle A small white triangle Disable. 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page 5-30... - Page 91 5.9.2.3 Altimeter Check The GI 275 standby altitude displays must be verified per Title 14 of the CFR 91.411 and Part 43 Appendix E, with the following exception to 14 CFR Part 43 Appendix E, paragraph (b)(1): • The tests of sub-paragraphs (iv) (Friction) and (vi) (Barometric Scale Error) are not applicable to the GI 275 due to the internal ADAHRS interface and instrument display being digital 5.9.2.4...

-

Page 92: Oat Checks

This check is required for units configured as a Primary ADI, Standby ADI, HSI, and MFD (with the CDI page) only if the VFR GPS is enabled and the antenna installed. 1. Power on the GI 275 system in Normal mode and verify that the rotorcraft has an unobstructed view of the sky (or GPS repeater coverage). -

Page 93: Appendix A Installation-Specific Information

MFD/Standby ADI HSI/Standby ADI Backup Battery Base ADI HSI GI 6 ADAHRS MFD Backup Battery MFD/Standby ADI HSI/Standby ADI 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-1... -

Page 94: Lru Information

GI 6 Backup Battery 011-04528- GMU 44B #1 011-04201- GMU 44B #2 011-04201- GTP 59 #1 011-00978- GTP 59 #2 011-00978- VFR GPS Antenna 011-04036- GSB 15 011-04937- 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-2... -

Page 95: Equipment Location

GI 275 #4 Battery Installed GI 275 #5 Battery Installed GI 275 #6 Battery GMU 44B #1 GMU 44B #2 GTP 59 #1 GTP 59 #2 GSB 15 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-3... -

Page 96: Wire Routing

A.4 Wire Routing The following diagrams depict the wire routing for the GI 275 LRUs throughout the aircraft structure for each rotorcraft on the AML. A.4.1 Bell 206B Series 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3... - Page 97 A.4.2 Bell 206L Series 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-5...

- Page 98 A.4.3 Robinson R22 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-6...

- Page 99 A.4.4 Robinson R44 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-7...

- Page 100 A.4.5 Airbus AS350 190-02246-C2 GI 275 Part 27 AML STC Maintenance Manual Rev. 3 Page A-8...

-

Page 101: Saved Configuration File

A.5 Saved Configuration File The GI 275 system configuration must be saved to a USB drive and placed with the permanent rotorcraft maintenance records. For instructions on saving the aircraft configuration file to a USB drive, refer to Section 2.3.7. It is recommended that the USB drive be taped or otherwise secured to this page in the location marked below.

Need help?

Do you have a question about the GI 275 and is the answer not in the manual?

Questions and answers