Table of Contents

Advertisement

Quick Links

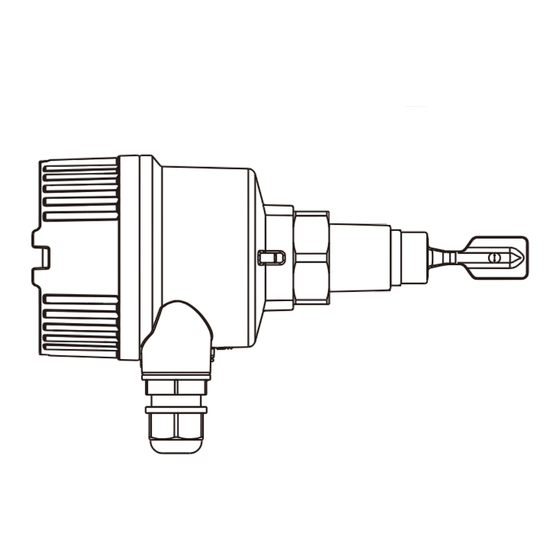

SC38 Multi-functional Tuning Fork Level Switch

(NPN/PNP Three-wire Type) Operation Manual

WORKING PRINCIPLE

The piezoelectric component is used to drive the tuning fork and feedback

signal, which produces the resonation on the fork. When the fork comes into

contact with a material, it relies on the damping effect by covering the testing

material on the tuning fork which changes the frequency of the tuning fork. The

frequency is judged by the micro-processor in the circuit. The signal display

and output status are determined based on the conditions set by the user.

SPECIFICATION

Power supply

10~55 Vdc

Power consumption

15mA

Input protection

Reverse protection function

OVP

Overvoltage category III

Max. measurement error

Max. ±1 mm

Repeatability

0.5mm

Hysteresis band

Approx. 2 mm

Storage temp.

-40~85°C

Environment temp.

-40~85°C

Operating temp.

-40~150°C

Material viscosity

2

Max. 10000 mm /s (10000 cst)

Particle size in liquid

Max. 5 mm

f

General cable

f6~10 mm

Operating pressure

Max. 40 Bar

Protection grade

IP 66/67

Contact capacity

350mA, 55Vdc

PANEL AND ELECTRICAL

F.S.

D.T.

S.G.

S. I.

Calibration Button

MAX

S

H

F .S.

MIN

L

L

O.S.

Test

SC38

U 10...55VDC

-

PWR

SIG

L-

O/P

PNP: L+

GND

NPN: L-

L+

O/P

Fuse

R

50mA

10~55 Vdc

R=External Load

U

max. 55Vdc@I

max. 350mA

L

FEATURES

All-in-one design, 3/4" thread is suitable to the installation of a small tube

(SC38 series).

A maximum length of 3m for the ultra-extension type.

Sensitivity adjustment is available for different density of media.

(ρ >0 . 5 g/cm or ρ >0 . 7 g/cm )

3

3

High/low failure safe mode, safe and reliable.

Self-diagnosis can detect the fork abrasion

Switch delay function

Alarm indicators based on failure status or output status selected according

to the customer's habits

Test button can be tested after the installation is completed

Calibration of the operation points for different density of media by the

customer if required

DIMENSIONS

(Unit:mm)

f84

107

1/2"PF

Hex38

3/4"PT

L

40

17

SC380

Common Type

120

75

SC380

SC381

SC382

High-Temperature Type

120

120

17.4

17.4

120

75

SC380

SC381

SC382

DESCRIPTION OF FEATURES

Abbr.

Function

Options description

Reverse the signal output

Test

Test Bottom

MAX: High

F.S.

Fail Safe

MIN: Low

S: Default setting

Delay Time

D.T.

L: Delay for 5 second

H: ³0.7 g/

Specific Gravity

S.G.

L:

³

0.5 g/

F.S.: Fail-Safe mode

S.I.

Signal Indicator

O.S.: Output mode

OUTPUT STATUS

SC38 provides Max./Min. operation modes, and has the corresponding

indicators and output status according to the functional settings and whether it

is covered by the material. The working status is detailed in the figure below.

Failure Mode

Material Level Output Signal

MAX

MIN

Instrument failure

Over Load(IL>350mA)

I : Load current

L

FORK TRIGGER POINT

The position of the SC38 fork trigger point depends on the mounting position

as shown in the figure below: (When the testing medium is water, S.G.=1

g/cm , temperature 23°C, and working pressure 0 Bar ). If the testing medium

3

120~3000

3

has an S.G lower than 1g/cm , the trigger point would rise. Similarly, the trigger

point will move downward while the S.G is larger than that of water. The

moving range is depended on the S.G

※Operating point position:

120

17.4

120~3000

Top Mounting

Notes

It is for the test after the installation is completed.

It is for the high and low Fail-Safe mode.

Covered by material: Approx. 0.5s

Not covered by material: Approx. 1.s

Switch to L to set it as 5 seconds for being covered or not covered by the material.

3

cm

The switch to set the material density.

3

cm

Turn ON/OFF the red indicator based on the output status or the fail-safe status.

DESCRIPTION OF TEST BUTTON

This button is mainly provided for the user to check whether the output

operation works normally after the installation is completed. When the button is

pressed, the output and indicator (ON<->OFF) will be reversed. Once the

button is released, it will recover the original status.

LED Indicator

FUNCTION OF SELF-SET OPERATING POINT POSITION

O.S.

I

L

F.S.

SC38 provides the function of customizing the operating point position in

accordance with what is required by the user.

O.S.

<100mA

F.S.

Calibration

Normal model

O.S.

I

L

F.S.

Settings

O.S.

1. Keep pressing the "Calibration Button" for 3 seconds. When the red and

<100 A

m

green LED indicators flash in turn every 0.5 second, it enters the calibration

F.S.

mode. Press the calibration button again to enter the Empty Bin Calibration

mode.

m

[Empty Bin Calibration]

<100 A

2. Calibration status: The red LED indicator flashes every 0.5 second, and the

output current switches to operate every 0.5 second.

3. This mode is to calibrate the vibration frequency of the tuning fork in the air.

<100 A

m

Thus, it shall press "Calibration Button" when the tuning fork doesn't sense

any material. In this case, it will write the vibration frequency in the air, and

enter the operating point calibration mode.

: Flash

: ON

: OFF

[Operating Point Calibration]

1. Calibration status: The red LED indicator flashes every 0.25 second, and the

output current switches to operate every 0.25 second.

2. Cover the material to the desired operating point position under this mode,

and then press "Calibration Button". It will be adjusted to the corresponding

operating point position according to the H/L setting of the S.G.

ENVIRONMENT/MEDIUM TEMPERATURE LIMITATION

T

a

T

p

13mm

: Temp. range for the common type

: Temp. range for the high-temp. type installed with the external

radiating pipe.

Empty

Operation point

model

calibration

bin calibration

T

a

85LC

(175LF)

50LC

T

p

-40LC

0LC

90LC

150LC

(-40LF)

(32LF)

(194LF)

(300LF)

-40LC

(

-40

LF)

Advertisement

Table of Contents

Summary of Contents for FineTek SC38

- Page 1 F.S. D.T. S.G. S. I. The position of the SC38 fork trigger point depends on the mounting position and then press “Calibration Button”. It will be adjusted to the corresponding Calibration Button F .S. as shown in the figure below: (When the testing medium is water, S.G.=1 operating point position according to the H/L setting of the S.G.

- Page 2 PRODUCT APPLICATION 3. When installing the standard tuning fork, please make sure it is in flush 4. The protective tube should be installed when the liquid fluctuates The product can detect the high/low level of the medium in the tank or the tube, which is applicable to various liquids, such as in the food or pharmaceuticals with the sidewall.

Need help?

Do you have a question about the SC38 and is the answer not in the manual?

Questions and answers