Summary of Contents for SOLIDSVAC SV150-CVCD

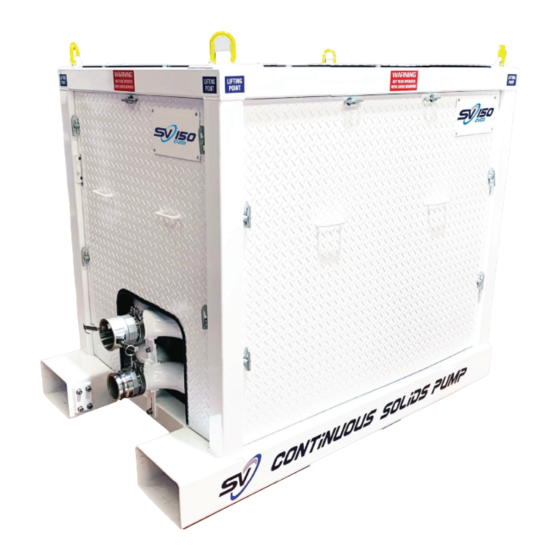

- Page 1 SOLIDS PUMPING SYSTEMS SV150-CVCD Operations Manual 201 First Avenue - Bribie Island - QLD 4507 - Australia +61 456 000 665 / info@solidsvac.com / www.solidsvac.com ISSUED DATE - 140421 V 1.3 LAST REVISED - 140421...

-

Page 2: Table Of Contents

CONTENTS Description Page Safety First 1. Operation Overview 2. Design Registration 3. Technical Data 4. Schematic 5. Pump Set-Up 6. Operation, Timer Cycling & Adjustments 7. Maintenance 8. Accessories 9. Operation Risk Assessment 10. Job Safety Analysis Scan this QR Code for an electronic version of this Operations Manual... -

Page 3: Safety First

This manual contains important information concerning the installation, operation and maintenance of the Solidsvac Pump, Model SV150-CVCD. To prevent injury to personnel or equipment damage, this manual MUST be read and understood by those responsible for the installation, operation and maintenance of the equipment. -

Page 4: Technical Data

Displacement cycle 130 ltr 34 gal Operating pressure 7 bar (Required) @ 690 kPa 100 psi (Required) Vacuum options 73 to 86.5 kPa 21.5” to 25.5” Hg Maximum solids 55 mm 2.5” Water throughput 800 lpm 211 gpm telephone +61 456 000 665 email info@solidsvac.com page 4... -

Page 5: Schematic

4. SV70-SPDK SCHEMATIC www.solidsvac.com page 5... -

Page 6: Pump Set-Up

QR code on each pump. Note: No formal training is required to operate the SV150-CVCD however, it is essential for the safe operation of this equipment that the Operator has read and understands the SV150-CVCD Operation Manual. -

Page 7: Operation, Timer Cycling & Adjustments

The second pressure gauge is mounted on the exterior of the control box and displays the working pressure of the pump. This gauge will only show the operational air pressure at the pump, this is not to be assumed as the pressure output of the compressor. Solidsvac recommend checking the compress's gauge to obtain a reading. -

Page 8: Maintenance

7. MAINTENANCE The Solidsvac SV150-CVCD generally require a minimum of maintenance although Solidsvac recommend the following be adhered to as a minimum: DAILY: - Check that all fittings and connection are serviceable. WEEKLY: - The unit’s auto drain filter be inspected and cleaned as required. The exhaust box be inspected and cleared of any carry over material. - Page 9 MAINTENANCE CONTINUED... In use, the Solidsvac SV150-CVCD requires little to no maintenance, however Solidsvac recommends that the following strict measures are taken to ensure the pump remains in good working order. Maintenance, repairs and the disassembling of the unit be carried out by any qualified Fitter with a basic knowledge of pneumatics. SERVICE TIPS Set up a maintenance schedule and follow it diligently.

- Page 10 STEP 6: REACH A CONCLUSION - Use a troubleshooting chart to check the list of possible causes; then decide which is the most likely. Note: 99% of all issues are air supply related. telephone +61 456 000 665 email info@solidsvac.com page 10...

- Page 11 When servicing a pneumatic system, always do the following to ensure cleanliness: Keep the compressor and machine's lubricating oil clean Keep the system clean Keep your work area clean - Be careful when you change seal or components (take photos) Use caution with compressed air Ensure all pneumatic components supply lines are secure www.solidsvac.com page 11...

-

Page 12: Accessories

Dropbox - Delivery of material to a skip, conveyor or specific point. Service Kit - Contains all you need for basic maintenance on your pump. telephone +61 456 000 665 email info@solidsvac.com page 12... -

Page 13: Operation Risk Assessment

OPERATIONAL RISK ASSESSMENT www.solidsvac.com page 13... - Page 14 MUST read and understand the manual. - Procedures (change management, traffic rules, risk assessed, developed, effectively implemented, etc.) - Equipment fit for purpose (rated, designed compatible, maintained, inspected, monitored, etc.) - Leadership (communication, directions, monitoring, etc.) - Environmental conditions are compatible to the operational capabilities of the equipment (natural vs. man-made, etc.) INCLUSIONS: Only the aspects directly related to Solidsvac SV150 Mobile Solids Pump. EXCLUSIONS: Transporting and storing the Solidsvac SV150 Mobile Solids Pump (Users operational risk assessment, training, competence); Assessment of the environmental conditions in the operational area (Users planning and local risk control) REFERENCE MATERIAL: QLD Coal Mining Safety & Health Act 1999 QLD Coal Mining Safety &...

- Page 15 RISK MATRIX www.solidsvac.com page 15...

- Page 16 RISK MATRIX telephone +61 456 000 665 email info@solidsvac.com page 16...

- Page 17 17...

- Page 18 COMP DATE REVIEW/AUDIT DATE Operation Storage Communicate to end user to Solidsvac Delivery develop work procedures for storage of Solidsvac SV20 Mobile Fluids Pump Travel position Communicate to end user to Solidsvac Delivery develop work procedures for travelling Use of Solidsvac...

- Page 19 PUMP PREVENTATIVE MAINTENANCE PROGRAM The following is the work to be performed to a SV150-CVCD Pump during Preventative Maintenance Check. All items, except annual checks (Tradesman), are to be carried out by a Competent Operator. Lock and tag out equipment...

- Page 20 PRV operation of the PRV. Pressure Vessel Inspect the vessel for wear, cracks and/or damage. Inspection Conduct a full service on the pump and replace the Full Service and PRV PRV. telephone +61 456 000 665 email info@solidsvac.com page 20...

- Page 21 21...

- Page 22 +61 456 000 665 email info@solidsvac.com page 22...

- Page 23 23...

- Page 24 +61 456 000 665 email info@solidsvac.com page 24...

- Page 25 25...

-

Page 26: Job Safety Analysis

JOB SAFETY ANALYSIS Note: It is recommended that a site-specific JSA is conducted prior to operation of the unit. telephone +61 456 000 665 email info@solidsvac.com page 26... - Page 27 SOLIDSVAC SV150-CVCD SLURRY PUMP Date Of Audit – June 2020. Equipment/Task: Set-up and operate Solidsvac Solids/Slurry Pump. Note: Site Safety requirements MUST be adhered to at all times. Personal Protective Equipment including approved safety eyewear and hearing protection are to be worn at all times whilst operating this equipment.

- Page 28 SOLIDSVAC SV150-CVCD SLURRY PUMP Date Of Audit – June 2020. Equipment/Task: Set-up and operate Solidsvac Solids/Slurry Pump. Note: Site Safety requirements MUST be adhered to at all times. Personal Protective Equipment including approved safety eyewear and hearing protection are to be worn at all times whilst operating this equipment.

- Page 29 Model Number Serial Number Date of Manufacture Inspected by 201 First Avenue - Bribie Island - QLD 4507 - Australia +61 456 000 665 / info@solidsvac.com www.solidsvac.com...

Need help?

Do you have a question about the SV150-CVCD and is the answer not in the manual?

Questions and answers