Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bosch rexroth PSK

- Page 1 Precision Modules PSK R320103170/2022-10 Instruction...

- Page 2 Please note that our products are subject to a natural process of wear and aging. © This document, as well as the data, specifications, and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without our consent.

-

Page 3: Table Of Contents

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 3/42 Contents About these instructions ..........................4 Scope and purpose of the documentation .....................4 Required documentation ........................4 Presentation of information ........................4 Safety instructions ............................6 Scope of delivery ............................6 Delivery condition ..........................6 Accessories ............................6... -

Page 4: About These Instructions

4/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 About these instructions Scope and purpose of the documentation This documentation applies to the following products: • Precision Modules PSK as described in the “Precision Modules PSK” catalog. This documentation is intended for assembly/installation personnel, line operators and machinery/plant users. - Page 5 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 5/42 Safety instructions are structured as follows: SIGNAL WORD Type of hazard. Consequences if ignored. Precautions to avoid hazard. • Warning sign: draws attention to the hazard • Signal word: indicates the degree of hazard •...

-

Page 6: Safety Instructions

• Final inspection certificate Upon receipt of the delivery, immediately check for completeness against the receipt and notify the carrier or Bosch Rexroth Corporation if any parts are missing. Delivery condition • Depending on the order, fully assembled with drive. -

Page 7: Product Description

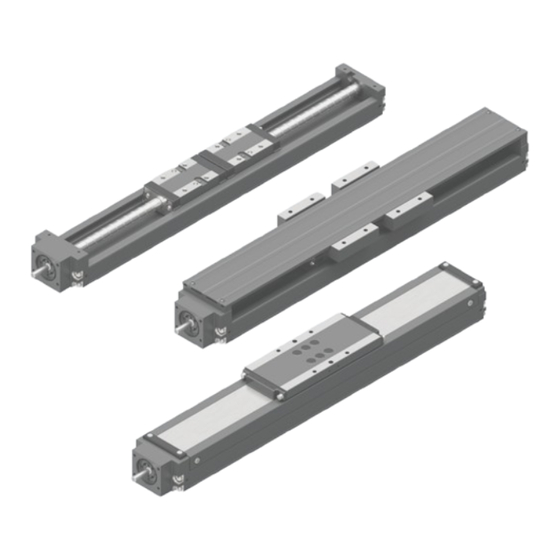

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 7/42 Product description Features Precision Modules are precise, ready-to-install Linear Motion Systems that feature high performance in a compact size and can be delivered quickly at an affordable price. Product description Fig. 1: Parts of the Precision Module (with drive) -

Page 8: Precision Modules Overview

8/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Precision Modules overview Precision Modules are available in three sizes ! catalog. The name plate of the product contains the following information: Table 5: Information on name plate Name plate information... -

Page 9: Transport And Storage

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 9/42 Transport and storage Transporting the product Precision Modules come ready to install. WARNING Risk of product falling due to inadequate load handling equipment. Death or serious injury. Use only inspected and suitable load handling equipment. -

Page 10: Assembly

10/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Assembly For dimensions and part numbers of the individual components ! catalog. WARNING Risk of product falling due to inadequate load handling equipment. Death or serious injury. Use only inspected and suitable load handling equipment. -

Page 11: Installation Conditions

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 11/42 Installation conditions Note operating conditions ! 15 and catalog. For special operating conditions, please contact us. NOTICE Risk of damage due to improper loads. Damage to the product. Do not attach any projecting loads. -

Page 12: Attaching Precision Module To Adjoining Structures

12/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Attaching Precision Module to adjoining structures NOTICE Risk of product loosening or warping due to improper mounting. Damage to the product. Be sure to use enough supports for the system dynamics at work. -

Page 13: Installing The Drive

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 13/42 Installing the drive NOTICE Risk of excessive torque and rotary speed if limits are not observed. Damage to the product. Observe the specified limits. For technical data and limits ! see catalog. - Page 14 14/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.6.1 Installing the motor with mount and coupling WARNING Risk of electric shock due to contact with live parts. Death or serious injury. Before working on the electrical equipment, switch off the power supply and secure it against reactivation.

- Page 15 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 15/42 Dimension table Motor ±0.1 (mm) -050 MSM 019B 11.0 MSM 031B MS2N 03-B -060 MSM 019B 10.0 MSM 031B MS2N 03-B MSM 031C -090 MSM 041B 13.0 MS2N 03 MS2N 04 10.5...

-

Page 16: Installing The Motor With Timing Belt Side Drive

16/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Installing the motor with timing belt side drive The timing belt side drive can be attached on any side in four directions. S000 S090 S180 S270 Fig. 8: Options for installing the timing belt side drive CAUTION Risk of excessive torque and rotary speed if limits are not observed. - Page 17 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 17/42 Belt pulley clearance (A) Motor ±0.1 (mm) -050 MSM019B -060 MSM019B MSM031B MS2N03-B -090 MSM031C MSM041B MS2N03 MS2N04 Tensioning unit tightening torques M2.5 (Nm) Fig. 9: Installing the first belt pulley...

- Page 18 18/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.7.2 Installing the support bearing Push the first retaining ring (16) onto the journal of the tensioning unit to act as a stop. Push the bearing (15) manually onto the journal of the tensioning unit and secure it with the second retaining ring (17).

- Page 19 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 19/42 Tensioning the toothed belt: We recommend a low pretension for the toothed belt. NOTICE Excessive belt pulley pretensioning can cause the toothed belt to break at the product or the motor.

- Page 20 20/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.7.4 Installing second belt pulley and motor for i = 1.5 Installing the belt pulley: Lightly lubricate the tensioning unit (12). Insert belt pulley (11) and tensioning unit (12) or just the belt pulley onto the journal of the motor (2), then thread the belt on.

- Page 21 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 21/42 6.7.5 Installing the belt pulley on the motor Observe specified tightening torque. Installing the standard Belt pulley clearance (C) belt pulley Motor ±0.1 (mm) -050 MSM019B -060 MSM019B MSM031B 12.0 MS2N03-B 12.0...

- Page 22 22/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.7.6 Completing assembly Install all covers to the housing of the timing belt side drive. Fig. 13: Installing covers on the timing belt side drive...

-

Page 23: Switch Mounting

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 23/42 Switch mounting Switching system overview Fig. 14: Switching system The switching system contains the following parts: 23 Mounting channel 24 Switching tab 25 Clamp for mounting channel 30 Switch... - Page 24 24/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.8.1 Installing the switching system NOTICE Potential collision due to incorrect installation of the switching system. Damage to product, adjoining structure and workpieces. Install the entire switching system on one side of the product.

- Page 25 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 25/42 Fig. 16: Installing the switching system 6.8.2 Completing assembly Install the carriage plate (27). ! 6.9 Lay the adapter plates (33) on the end blocks (6). Install cover plate (26). ! 6.10.

- Page 26 26/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.8.3 Moving or removing the switch WARNING Switch off the power supply. Death or serious injury. Before working on the electrical equipment, switch off the power supply and secure it against reactivation.

-

Page 27: Installing Carriage Plates On Precision Modules With Cover Plate

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 27/42 Installing carriage plates on Precision Modules with cover plate Place the carriage plate (27) on the carriage (8), then pre-install with screws (34). Tighten the screws (34) to the specified tightening torque. -

Page 28: Installing The Cover Plate

28/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 6.10 Installing the cover plate Lay the adapter plates (33) on the end blocks (6). Place the cover plate (26), then tighten the screws to the specified tightening torque. Fig. 20: Installing the cover plate 6.11... -

Page 29: Installing The Sealing Strip

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 29/42 6.12 Installing the sealing strip WARNING Do not grip the steel strip with bare hands. Risk of injury! Soak any dry felt pads in oil for at least 5 minutes. Slide the steel strip (28) through the carriage plate (27) and deflectors (37). -

Page 30: Connecting The Precision Module To Power

30/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Connecting the Precision Module to power 8. 8 ra ma Fig. 24: Connecting the product to power WARNING Risk of electric shock due to contact with live parts. Death or serious injury. -

Page 31: Start-Up

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 31/42 Start-up Do not start up the product until it has been verified that the end product (for example a machine or system) into which the Rexroth product has been installed complies with the country-specific requirements, safety regulations and standards for the application. -

Page 32: Checking Operating Conditions

32/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 Checking operating conditions Observe the technical data ! catalog. For operating conditions ! 15. Test run, running in WARNING Dangerous movements. Risk of death or serious injury, or property damage. Do not stand in the product's range of movement. -

Page 33: Operation

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 33/42 Operation NOTICE Lubricant may leak if installed vertically. Environmental contamination. Take suitable precautions to collect any leaking lubricant and dispose of it properly. Risk of motor overheating when overloaded. Fire risk. -

Page 34: Lubrication

Only use recommended lubricants and observe lubrication intervals. Special operating conditions. Possible damage to the product. Consult Bosch Rexroth before starting up the product under special operating conditions, specifically in the presence of fiber glass or wood dust and solvents, or in short-stroke operations and extreme temperatures. -

Page 35: Overview Of Lubrication Types

R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 35/42 NOTICE Lubrication of the preserved carriage with H1 lubricant. Loss of H1 approval H1 lubricants or release agents (anti-corrosion agents) only have H1 approval if they are separated and unmixed (including at the lubrication point). A blend of two H1 approval lubricants or separating agents does not have H1 approval. -

Page 36: Lubricants

36/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 11.4 Lubricants The Precision Module is designed to be lubricated with grease from a grease gun. Before using lubricants, read and observe the appropriate safety data sheets. For Precision Modules with two carriages, always lubricate both carriages. - Page 37 R320103170/2022-10 | Precision Modules PSK Bosch Rexroth AG 37/42 Dynalub 520 Castrol Tribol GR 100-2 PD Castrol Tribol GR 100-00 PD PSK-050, -060, -090 PSK-050: 8x2.5; 8x5 PSK-050: 8x1; 8x2 PSK-060: 12x5; 12x10 PSK-060: 12x2 PSK-090 NLGI 00 (DIN 51818)

-

Page 38: Lpg-Type Lubrication

38/42 Bosch Rexroth AG Precision Modules PSK | R320103170/2022-10 11.6 LPG-type lubrication NOTICE Lack of lubrication. Failure to perform basic lubrication will damage the product. Never start up product without basic lubrication. Pay attention to the notes on lubrication ! 11 Lube fittings ! 11.3... -

Page 39: Relubrication Intervals (For Lss, Lpg, Lcf, Lsc)

P = 5 P = 2.5 P = 2 P = 1 0.00 0.05 0.10 0.15 0.20 0.25 0.30 Fig. 29: Relubrication – Lubricant NLGI 00 (Dynalub 520) 11.9 Repairs Repairs to the linear axis should only be performed by Bosch Rexroth. -

Page 40: Removal And Replacement

Precision Modules PSK | R320103170/2022-10 12 Removal and replacement To ensure the accuracy of the product after replacement of assemblies (e.g. Ball Rail Systems, carriage, frame, etc.), such assemblies should only be removed and replaced by Bosch Rexroth. 12.1 Removing the drive Removal is the reverse of the 6.6 section. -

Page 41: Operating Conditions

Table 12: Tightening torques M2.5 (Nm) A max m = 0.125 16 Service and support The Bosch Rexroth Customer Service help desk and hot-line staff will be happy to assist you in any way they can. Phone: (800) REXROTH (739-7684) E-mail: info@boschrexroth-us.com... - Page 42 Bosch Rexroth AG Ernst-Sachs-Straße 100 97424 Schweinfurt, Germany Tel. +49 9721 937-0 +49 9721 937-275 www.boschrexroth.com Find your local contact person here: www.boschrexroth.com/contact Subject to modifications © Bosch Rexroth AG 2022 Printed in Germany R320103170/2022-10...

Need help?

Do you have a question about the rexroth PSK and is the answer not in the manual?

Questions and answers