Table of Contents

Advertisement

Quick Links

POWERFUL SOLUTIONS. GLOBAL FORCE.

L4026

Rev. A

Repair Parts Sheets for this product are available from the

Enerpac web site at www.enerpac.com, or from your nearest

Authorized Enerpac Service Center or Enerpac Sales offi ce.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

2.0 SAFETY ISSUES

Read all instructions, warnings and precautions

carefully.

Follow

precautions to avoid personal injury or damage to

the jack. Enerpac cannot be responsible for any damage or injury

from unsafe use, lack of maintenance or incorrect operation. Do

not remove warning labels, tags, or decals. In the event any

questions or concerns arise, contact ENERPAC or a local

Enerpac distributor for clarifi cation.

The maximum working pressure of the jack hydraulic system is

4,250 psi [293 bar] on the advance side. Catastrophic failure of

jack and/or related hydraulic components may occur if this limit

is exceeded. Serious personal injury, property damage and/or

damage to jack may result.

If you have never been trained on high-pressure hydraulic safety,

consult your distributor or service center for a free Enerpac

Hydraulic Safety Course.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction

of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

2.1 Hydraulic Jack Safety Precautions

Failure to comply with the following safety precautions could

result in equipment damage and/or personal injury:

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: The jack is to be used for lifting only!

Support the load after completing the lift using

approved accessories or by other appropriate means.

Never get under a load being supported only by the jack.

WARNING: Never exceed the rated capacity of the

jack. Allow for a margin of safety that accounts for

possible shifting loads or side loading conditions.

DANGER: To avoid serious personal injury, keep

hands and feet away from hydraulic cylinder and

related components during jack operation.

DANGER: Do not handle pressurized lines. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

12/12

any

recommended

Instruction Sheet

Hydraulic Wheel Truck Jack

safety

WARNING: The jack's hydraulic components must not be

repaired or adjusted except by an authorized service center.

Never tamper with overload protection devices. Higher

settings may result in equipment damage and/or personal injury.

CAUTION: When jack is not in use, fully retract the

cylinder and protect the entire unit from external damage.

Keep the jack clean, avoid weld splatter, and store in a

clean dry area. INSPECT ALL JACK COMPONENTS BEFORE USE.

CAUTION: Keep the jack away from fl ames and

heat. For optimum performance, do not expose the

jack to temperatures above 65 °C [150 °F].

WARNING: BE SURE LIFTING ARRANGEMENT IS

STABLE BEFORE LIFTING LOAD. Use jack on solid

surface capable of supporting the load and the base of

the jack. Always center the load on the lifting saddle of the jack.

If the jack is not perpendicular to the load, slipping or loss of

load is possible. Damage to jack may also occur.

WARNING: Distribute the load evenly when performing

lifts with multiple jacks. Failure to heed this warning may

cause loss of load and/or failure of the jack, resulting in

property damage and/or personal injury.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged

parts with genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property

damage. ENERPAC parts are designed to fi t properly and

withstand high loads.

CAUTION: To avoid damage to jack internal

components, do not continue pressurizing the jack

cylinder after it reaches maximum extension or

retraction.

CAUTION: Refer to the Jacking Safely section of this

manual (Section 5.2) before lifting any loads with the

jack. Be certain to observe and follow all rules and

precautions contained in this section.

Model WJ60

Advertisement

Table of Contents

Summary of Contents for Enerpac WJ60

- Page 1 Failure to comply with the following safety precautions could service, contact the Authorized ENERPAC Service result in equipment damage and/or personal injury: Center in your area. To protect your warranty, use only ENERPAC oil. WARNING: Wear proper personal protective gear when WARNING: Immediately replace worn or damaged operating hydraulic equipment.

-

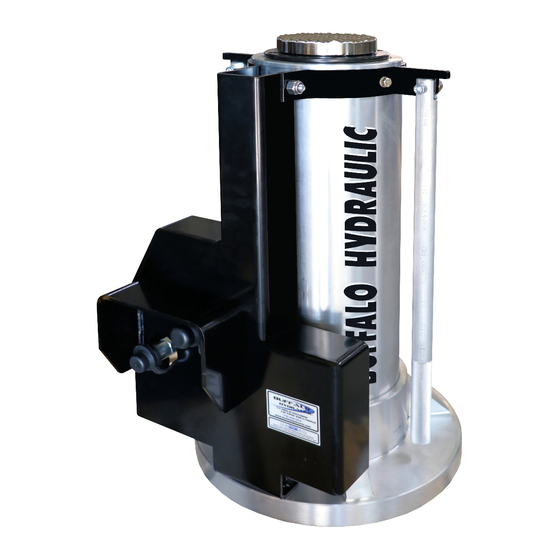

Page 2: Product Data

3.0 PRODUCT DATA Table 1 - General Specifi cations, Model WJ60 Wheel Truck Jack Load Rating 60 US tons [54 metric tons, 533 kN] Maximum Working Pressure (cylinder advance) 4250 psi [293 bar] Required Working Pressure (cylinder retract) 1650 psi [114 bar]... - Page 3 Firmly push the male coupler half into the female coupler Figure 2, Features and Components, Model WJ60 half until a “click” is heard and engagement is felt. If needed, rotate sleeve on female coupler half so that notch 4.0 INITIAL SETUP...

-

Page 4: Operation

Refer to Section 5.6 for additional information. supports) of appropriate load rating. 5.0 OPERATION WARNING: Use of U-Rings with the model WJ60 wheel truck jack will result in a potentially unstable lifting 5.1 Control Valve arrangement. The load cap may become disengaged Hydraulic fl... -

Page 5: After Completing The Job

5.5 Stacking Instructions - Extensions and Spacers Extensions and spacers are available as optional accessories Important: Refer to from your Enerpac authorized distributor. They may be ordered Table 4 for maximum individually or in sets. See Figure 6. additional stack height information. -

Page 6: Oil Specifications

WARNING: Failure to observe the following instructions could allow load to shift or drop. Serious personal injury Use Enerpac HF hydraulic oil or an equivalent hydraulic oil and/or property damage may result. meeting the specifi cations shown in the following table:... - Page 7 [6,3 mm]. Pilot-operated check valve leaking Have pilot-operated check valve and related components internally. inspected by an Enerpac Authorized Service Center. Repair or replace components as required. External hydraulic leakage. If oil leakage is visible, have jack hydraulic components inspected by an Enerpac Authorized Service Center.

- Page 8 Rep. office Enerpac For the location of your nearest authorized Russian Federation Une division d’ACTUANT France S.A. Enerpac Integrated Solutions B.V. Enerpac Service Center, visit us at ZA de Courtaboeuf Admirala Makarova Street 8 Opaalstraat 44 www.enerpac.com 32, avenue de la Baltique...

Need help?

Do you have a question about the WJ60 and is the answer not in the manual?

Questions and answers