Table of Contents

Advertisement

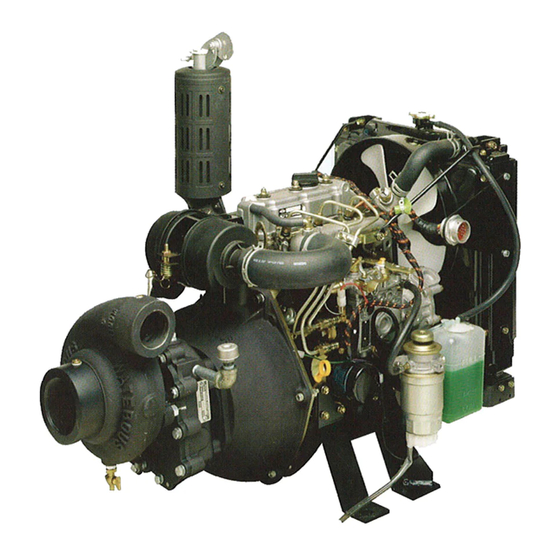

E500 Series Motor Pump

W

Safety Instructions ------------------------------------1, 2

Introduction ------------------------------------------------- 3

Installation ------------------------------------------------ 3

Fire Hose Testing---------------------------------------- 4

Maintenance and Repair------------------------------- 5

Preparation----------------------------------------------- 5

Operation-----------------------------------------------

Starting the Engine-------------------------------------- 5

Priming the Pump--------------------------------------- 5

Setting the Throttle---------------------------------------5

Engine Maintenance------------------------------------ 6

Pump Maintenance------------------------------------- 6

Engine Repair------------------------------------------- 6

Pump Repair--------------------------------------------- 6

Overhaul----------------------------------------------------- 7

E501 Volute Body Removal------------------------ 7

E511 Volute Body Removal------------------------ 7

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

Table of Contents

5

Inspection----------------------------------------------------------------------13

Reassembling and Testing-----------------------------------------------13

Instructions subject to change without notice.

Operation, Maintenance

and Overhaul Instructions

Form No.

F-2390

E511 Impeller and Mechanical Seal Removal -------------------- 8

E501 Gear Case Cover and Impeller Shaft Removal---------- 8

E511 Gear Case Cover and Impeller Shaft Removal-------------9

E501 Impeller Shaft Assembly------------------------------------------9

E511 Impeller Shaft Assembly----------------------------------------10

E501, E511 Gear Case Removal-------------------------------------10

E501, E511 Engine Adapter Removal-------------------------------11

E501, Mechanical Seal Assembly------------------------------------11

E511 Mechanical Seal Assembly-------------------------------------12

Impeller Wear--------------------------------------------------------------13

Mechanical Seal-----------------------------------------------------------13

Oil Seals---------------------------------------------------------------------13

Reassembling the Pump------------------------------------------------13

Testing-----------------------------------------------------------------------14

Read through the safety information and

operating instructions carefully before

using your Waterous Fire Pump.

Visit us at www.waterousco.com

Issue Date

Rev. Date

09/04

3/27/17

Advertisement

Table of Contents

Summary of Contents for Waterous E501-A

-

Page 1: Table Of Contents

E501 Impeller and Mechanical Seal Removal Read through the safety information and operating instructions carefully before using your Waterous Fire Pump. Visit us at www.waterousco.com Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000 Instructions subject to change without notice. -

Page 2: Safety Instructions

SAFETY INSTRUCTIONS Page 1 of 14 DANGER Exhaust gas and fire hazard. Can cause illness, personal injury or death. DO NOT run the engine in an enclosed area. Exhaust gases contain carbon monoxide, an odorless, deadly poison. Refuel outdoors or only in well ventilated areas. DO NOT operate the engine when an odor of fuel is present or other explosive conditions exist. - Page 3 SAFETY INSTRUCTIONS Page 2 of 14 ! WARNING High temperature components. May cause severe burns. Do not touch hot mufflers, cylinders or fins as contact may cause burns. ! WARNING Accidental starting hazard. May cause personal injury to the hand, arm or feet. When servicing the engine or equipment, always disconnect the negative wire from the battery terminal to prevent accidental starting.

-

Page 4: Introduction

INTRODUCTION Page 3 of 14 Waterous E500 Motor Pumps are gear driven centrifu‐ 2. Fuel line - Route the fuel line from the fuel tank (not supplied by Waterous) such that low pockets gal pumps powered by a three-cylinder, 952 cc diesel or gasoline Briggs &... -

Page 5: Fire Hose Testing

Page 4 of 14 Fire Hose Testing WARNING Hose Testing Hazard. May result in serious personal injury. Due to a potential for catastrophic hose failure during service testing of fire hose, it is vital that safety precautions be taken to prevent exposure of anyone to this danger. Fire pumps on fire department apparatus are not designed for and should not be used for service testing of fire hoses. -

Page 6: Maintenance And Repair

Starting the Engine 2. The E500 is shipped without the battery. Install a E501-A and E511-A w/Deluxe Engine Panel 12 VDC battery with a minimum capacity of 380 Amps (63 Amp-hours). Pump the fuel filter primer until hard to push. Turn the ignition switch to the RUN position and wait for the glow lamp to shut off. -

Page 7: Engine Maintenance

“Preparation” section of this manual. reference numbers for ordering. Be sure to give the pump model, serial number and parts list number when ordering parts. Contact your Waterous dealer, or call a Waterous ser‐ vice specialist at 651-450-5200 with any questions. -

Page 8: Overhaul

OVERHAUL Page 7 of 14 Figure 1. E501 Volute Body Removal Figure 2. E511 Volute Body Removal Remove (4) hex head screws from the pump volute body. Remove the (4) hex nuts and lock washers Slide the volute body off the gear case cover. Wear ring attaching the volute body to the gear case cover. -

Page 9: E511 Impeller And Mechanical Seal Removal

OVERHAUL Page 8 of 14 Figure 3. E511 Impeller and Mechanical Seal Removal 1. Remove the impeller nut and washer from the impeller shaft. If the impeller does not pull off the impeller shaft easily, use a gear puller or two pry bars between the im‐ peller and adapter. -

Page 10: E511 Gear Case Cover And Impeller Shaft Removal

OVERHAUL Page 9 of 14 Figure 6. E511 Gear Case Cover and Impeller Shaft Removal Remove the 10 hex head screws and lock washers from the gear case cover. Remove the gear case cover from the gear case. Press out the impeller shaft and bear‐ ing assembly from the gear case cover. -

Page 11: E511 Impeller Shaft Assembly

Note: The impeller shaft/ball bearing as‐ sembly is available from Waterous. If the ball bearing is not pressed on by Waterous, see the Reassembling section of this manual for helpful hints. -

Page 12: E501, E511 Engine Adapter Removal

OVERHAUL Page 11 of 14 Figure 10. E501, E511 Engine Adapter Removal Note: The engine adapter and the drive plate assembly should not require disassembly unless inspection reveals wear of the drive plate. 1. Remove the M10 and 5/16 bolts from the engine adapter (Note: The starter is supported by two of the M10 bolts) to separate the engine adapter from the engine. -

Page 13: E511 Mechanical Seal Assembly

Installing in Head with Mechanical Seal Lubricant Before Installing Stationary Ring Primary Ring Sealing Surface Must Face Primary Ring Note: If Waterous Mechanical Seal Lubricant Pat No. 52608 is not Available, P80 Rubber Lubricant, Straight Dish Soap or Glycerin May be Substituted. -

Page 14: Inspection

3. Before installing an oil seal in a housing, apply a thin The following are suggested methods of installing coat of sealant to housing oil seal seat. (Waterous the ball bearing onto the impeller shaft: recommends Loctite Ultra Blue RTV Silicon Sealant to 1. -

Page 15: Testing

10. Insert the impeller shaft assembly in the gear case E511 Pumps Only (Steps 17-20): (See Figure 12) cover. Be sure the inner race is on the shaft end, ta‐ Note: If Waterous Mechanical Seal Lubricant part pered end facing out. no. 52608 is not available, P80 rubber lubricant, 11. - Page 16 WATEROUS COMPANY 125 HARDMAN AVENUE SOUTH SOUTH ST. PAUL, MINNESOTA 55075-2456 U.S.A. Phone: (651) 450-5000 FAX: (651) 450-5090 Web Site: www.waterousco.com...

Need help?

Do you have a question about the E501-A and is the answer not in the manual?

Questions and answers