Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tatu Marchesan GNL

- Page 1 OPERATOR’S MANUAL...

- Page 2 IDENTIFICATION Dealer: Owner: Firm / Farm: City: State: No. of the Certificate of Guarantee: Serial / No.: Date: Invoice No.: Product: Notes:...

- Page 3 MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. Marchesan Av., 1979 - Zip Code 15994-900 - Matão - SP - Brazil Telephone 55.16.3382.8282 www.marchesan.com.br GNL - Rev. 07 - Mar/22...

-

Page 4: Table Of Contents

Hydraulic cylinder maintenance / assembly 49 & 50 Hydraulic safety Troubleshooting guide 52 & 53 Disk harrow maintenance 9. Important data 55 to 57 Hourly income calculation Average income table Torque table 10. Important GNL - Rev. 07 - Mar/22... -

Page 5: To The Owner

- The warranty shall not be applied to any equipment or any part that has been altered elsewhere than at the place of manufacture, or which the original purchaser thereof at retail has used or allowed to be used parts, not made or supplied by Marchesan. GNL - Rev. 07 - Mar/22... -

Page 6: To The Operator

Follow every recommendation, warning and safety practice that can be found inside this manual, as any accident may lead to injuries or death. REMEMBER, ACCIDENTS MUST BE AVOIDED! REMEMBER, ACCIDENTS MUST BE AVOIDED! GNL - Rev. 07 - Mar/22... - Page 7 Never transport the equipment on highways or paved roads. Avoid that the tractor wheels touch the drawbar in sharp turns. Always use the safety locks to carry out any maintenance or to transport the equipment. GNL - Rev. 07 - Mar/22...

- Page 8 Always use protective gloves. Every professional should be oriented when lifting and carrying heavy loads to avoid any serious accident that a bad execution of this process may cause. . GNL - Rev. 07 - Mar/22...

- Page 9 Personal clothing must be used. Avoid tight or hanging clothes that may become entangled to the moving parts of the equipment may become entangled to the moving parts of the equipment. NOTE - Only certified PPE must be used. GNL - Rev. 07 - Mar/22...

- Page 10 14. In case of a fire outbreak or any possible hazard, the operator must leave the area as fast as possible and look for a safe place. Always have emergency numbers in hands. 15. In case of emergency, know how to stop the tractor and equipment quickly. GNL - Rev. 07 - Mar/22...

- Page 11 22. If there is any doubt after reading it, ask your dealer. For more complicated operations, there will be the right person to help you there. 23. Please check the general safety instructions on the back cover of this manual. GNL - Rev. 07 - Mar/22...

- Page 12 10. Check all laws and regulations regarding the height limits and load width while transporting the equipment on truck or trailer. If necessary use banners, lights and other devices to give adequate warning to the other drivers. GNL - Rev. 07 - Mar/22...

- Page 13 • This Regulatory Standard has the purpose to establish the precept to be applied on the organization and on the working environment, in order to make compatible the planning and development of agriculture, livestock, forestry, forest exploration and aquaculture with safety on the working environment. GNL - Rev. 07 - Mar/22...

- Page 14 The equipment has adequate lifting points located on the frame. When carrying out the maintenance or lifting the equipment with a hoist, it is essential to hitch the cables to all of these points. GNL - Rev. 07 - Mar/22...

- Page 15 Marchesan provides decals, upon request and indication of the respective serial number. Decal set Quantity Model Serial number GNL decal 05.03.03.4057 Tatu logotype decal 05.03.03.5341 05.03.03.4438 Warning decal Lifting points decal 05.03.03.4078 Read the manual decal 05.03.03.1428 05.03.03.1827 Lubricate and tighten daily decal GNL - Rev. 07 - Mar/22...

-

Page 16: Data Sheet

The GNL disk harrow break clods and level the soil, incorporating herbicides and destroying weeds on the pre-cultivation for several types of crop. - Page 17 85 - 90 3487 95 - 100 IMPORTANT - The weights above were obtained using Ø 20" x 3.5 mm. - Optional hydraulic cylinder for the models with 32, 36 and 42 disc blades. GNL - Rev. 07 - Mar/22...

- Page 18 3. Data sheet Dimensions for transportation and storage GNL - Rev. 07 - Mar/22...

- Page 19 Number of Model disc blades 1710 1585 2160 1925 1710 1585 2160 2290 1710 1585 2660 2625 1710 1585 2426 2910 1710 1585 2960 3325 1710 1585 2960 3850 NOTE - Measures in millimeters. GNL - Rev. 07 - Mar/22...

-

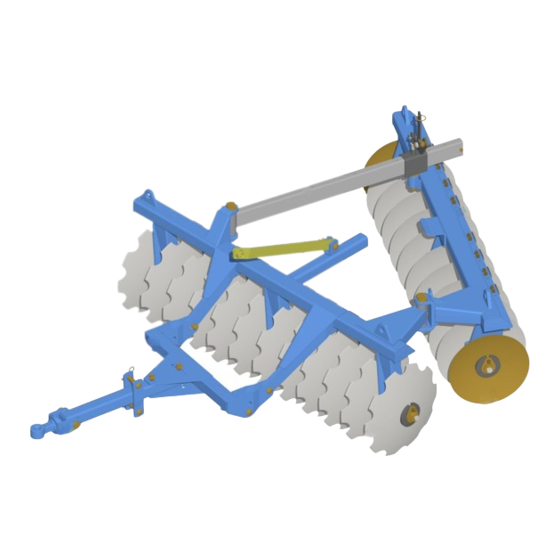

Page 20: Components

4. Components GNL - 20 to 42 disc blades 01 - Front frame 05 - Opening adjustment set 02 - Rear frame 08 - Traction set 03 - Front disc gang 09 - Tractor hitch 04 - Rear disc gang 10 - Transport bar GNL - Rev. - Page 21 01 - Front frame 05 - Opening adjustment set 02 - Rear frame 08 - Traction set 03 - Front disc gang 09 - Tractor hitch 04 - Rear disc gang 10 - Transport bar GNL - Rev. 07 - Mar/22...

- Page 22 4. Components GNL - 36 to 42 disc blades (with hydraulic cylinder) 01 - Front frame 07 - Tractor hitch 02 - Rear frame 08 - Transport bar 03 - Front disc gang 09 - Course limiter 04 - Rear disc gang...

- Page 23 4. Components GNL - 32 disc blades (with hydraulic cylinder) 01 - Front frame 06 - Traction set 02 - Rear frame 07 - Tractor hitch 03 - Front disc gang 08 - Transport bar 04 - Rear disc gang...

-

Page 24: Assembly

• Use the box end wrench (B) to tighten the nuts on the drawbar. • Use the L shaped wrench (C) to tighten the nuts on the bearing bolts. ATTENTION - We recommend wearing gloves, especially while assembling the disc gangs. GNL - Rev. 07 - Mar/22... -

Page 25: Assembly Of Bearings And Spacer Spools

04 bearings 14 spacer spools 14 spacer spools 24 disc blades 24 disc blades 06 bearings 06 bearings 16 spacer spools 16 spacer spools Spacer spool Spacer spool Furrow filler Furrow filler Bearing Bearing GNL - Rev. 07 - Mar/22... - Page 26 06 bearings 20 spacer spools 20 spacer spools 32 disc blades 32 disc blades 06 bearings 06 bearings 24 spacer spools 24 spacer spools Spacer spool Spacer spool Furrow filler Furrow filler Bearing Bearing GNL - Rev. 07 - Mar/22...

- Page 27 08 bearings 24 spacer spools 24 spacer spools 42 disc blades 42 disc blades 10 bearings 10 bearings 28 spacer spools 28 spacer spools Spacer spool Spacer spool Furrow filler Furrow filler Bearing Bearing GNL - Rev. 07 - Mar/22...

-

Page 28: Disc Gangs Assembly Sequence

IMPORTANT - Check the correct side of the bearings and spacer spools according to the concavity of the disc blades. Friction Friction Grease fitting Grease fitting bearing bearing or plug or plug GNL - Rev. 07 - Mar/22... - Page 29 2890 1.3/4" 3020 2" 3150 2.1/8" 3300 2.1/2" 3500 3" 4000 NOTE - The axle threads (B) must be cleaned and greased before their assembly. Check the torque table on the 'important data' section. GNL - Rev. 07 - Mar/22...

-

Page 30: Disc Gangs Assembly Sequence With Friction Bearing

2. Being the disc gangs assembled, use the wrenches from the 'set of wrenches' page to tighten the nut (J), flat and spring washer (K) that will join the bearing (E) to the bearing hanger through the clamp (L). GNL - Rev. 07 - Mar/22... -

Page 31: Assembly Of The Disc Gangs On The Frame

1. Put the bolt (A) and a square washer (B), passing through the bearing housing and the bearing hanger holes. On the upper part, put a flat washer (C), nut and counternut (D). 2. Repeat this operation for the other bearings. GNL - Rev. 07 - Mar/22... - Page 32 On the upper part, place a spring washer and nuts (C). NOTE - The scrapers feature an adjustment to approach or distance them from the disc blades, on a range from 5 to 10 mm. GNL - Rev. 07 - Mar/22...

-

Page 33: Opening Adjustment Set Assembly

(D) and couple it to the front frame (E) using a junction axle and cotter pin (F). 3. Put the bolt (G) in the adjustment bar (transversal hole) using a spring washer and nut. GNL - Rev. 07 - Mar/22... -

Page 34: Hydraulic Cylinder Assembly

2. Fasten the cylinder rod to the rear stabilizer bar (C) using a junction axle (G) and cotter pin. For the GNL model with 36 - 42 disc blades and hydraulic cylinder: 1. Fasten the cylinder barrel (D) to the front frame (E) using a junction axle (G) and cotter pin. -

Page 35: Traction Set Assembly

3. Assemble the hose support (E) to the drawbar (C) using a flat washer and nut. NOTE - When assembling the traction set, note the correct position of the upper and lower plates as shown below. GNL - Rev. 07 - Mar/22... -

Page 36: Transport Bar Assembly

(C) to the transport bar (A) along with the pin and cotter pin (D). NOTE - To transport the harrow, the drawbar should be always locked in the central hole. Transport Transport position position GNL - Rev. 07 - Mar/22... -

Page 37: Hydraulic Circuit

Pressure Pressure 3/8 X 3600 TC-TM hose 3/8 X 3600 TC-TM hose Return Return Male quick coupler 1/2 NPT with cap GNL with 36 - 42 disc blades Item Quantity Description Hydraulic cylinder Pressure Pressure 3/8 X 4800 TC-TM hose... -

Page 38: Set-Up Instructions

4. Use a clean cloth or a paper towel to clean the couplers in the end of the hoses. Also, clean the area around the tractor couplers; 5. Lubricate all grease fittings appropriately (see the 'lubrication' page in the 'maintenance' section). GNL - Rev. 07 - Mar/22... - Page 39 - During transportation, the hydraulic lower arms must remain adjusted. - Position the tractor control valve until the disk harrow is leveled. - Maintain the third-point arms always opened, locked and lifted to the maximum. GNL - Rev. 07 - Mar/22...

- Page 40 6. Set-up instructions Procedures to transport the equipment Every GNL model can be transported using the tractor three-point hitch. In order to do so, follow the instructions below: 1. Retreat the disk harrow totally. 2. Place the drawbar in the central hole of the upper and lower plates (A).

-

Page 41: Adjustments And Operations

- To open or close the equipment, the operator must activate the hydraulic cylinder control valve. - Note that the disk harrow opening just change the cutting angle of the rear gang. Increasing "A": bigger disc blades penetration. Decreasing "A": smaller disc blades penetration. GNL - Rev. 07 - Mar/22... -

Page 42: Scrapers Adjustment

- The adjustments previously described determine the cutting depth, so it is necessary to keep an agreement between them for a greater performance. Scrapers adjustment The scrapers must be adjusted as instructed on the 'scrapers assembly' page. GNL - Rev. 07 - Mar/22... -

Page 43: Ways To Start The Harrowing

Entrance Entrance Entrance Entrance Harrowing in level Harrowing in level Entrance Entrance Exit Exit IMPORTANT - Note that the harrowed ground is always on the left hand side of the operator. GNL - Rev. 07 - Mar/22... -

Page 44: Direction Of The Maneuvers

- It is necessary to perform the maneuvers in the left hand side to avoid overloading the equipment and allow it to operate normally. - Following these instructions also avoids the undesirable formation of large furrows in the local maneuvers. GNL - Rev. 07 - Mar/22... -

Page 45: Operations - Important Points

12. Only pull the equipment using a tractor with enough power. 13. During work or transportation, do not allow passengers on the tractor or in the equipment. 14. Always keep the equipment centered related to the tractor and leveled related to the soil. GNL - Rev. 07 - Mar/22... - Page 46 21. Do not check eventual leaks using your bare hands, as the high pressure may cause body injury. Use a cardboard or any other suitable object instead. 22. As previously mentioned, this disk harrow has several settings. However, only the local conditions can determine its best adjustment. GNL - Rev. 07 - Mar/22...

-

Page 47: Maintenance

2. Then, start to check weekly. 3. Change all the oil every 1,000 operating hours. 4. Use SAE 90 mineral oil only. d) DMO bearings do not need maintenance. GNL - Rev. 07 - Mar/22... - Page 48 - Duromark steel-plated bearing. - Assembled with a high-performance lubricant, the Duromark steel-plated bearing do not have a plug since there is no need to refill it, avoiding the risk of mixing incompatible lubricants. GNL - Rev. 07 - Mar/22...

-

Page 49: Lubrication / Lubrication Points

8. Maintenance Lubrication points Lubricate every 24 hours of service. NOTE - Lubricate the points shown above and all grease fittings as well. GNL - Rev. 07 - Mar/22... - Page 50 8. Maintenance Lubrication points Lubricate every 24 hours of service. NOTE - Lubricate the points shown above and all grease fittings as well. GNL - Rev. 07 - Mar/22...

-

Page 51: Hydraulic Cylinder Maintenance / Assembly

7. Inspect the inside of the cylinder barrel, piston, rod and other polished parts for burrs and scratches. Smooth areas as needed with an emery cloth. NOTE - Do not clamp rod by chrome surface. GNL - Rev. 07 - Mar/22... - Page 52 IMPORTANT - Insert the gland (E) on the cylinder head and align it with the tube so it will fit correctly on the cylinder barrel. NOTE - Do not clamp rod by chrome surface. GNL - Rev. 07 - Mar/22...

-

Page 53: Hydraulic Safety

Carry out the operations on a carefully and controlled manner. Avoid to let the hydraulic system working when it is not being used. Failure to follow these procedures may lead to fatal accidents or even death. GNL - Rev. 07 - Mar/22... -

Page 54: Troubleshooting Guide

L i f t t h e d i s c b l a d e t o r e d u c e t h e soil. penetration. Worn out / incorrectly Adjust or change the scrapers when adjusted scrapers. necessary. GNL - Rev. 07 - Mar/22... - Page 55 Q u i c k c o u p l e r s thread. carefully. leaking. Damaged repairings. Replace the repairings. IMPORTANT - Only CAPABLE, QUALIFIED and AUTHORIZED personnel must carry out the maintenance of the equipment. GNL - Rev. 07 - Mar/22...

-

Page 56: Disk Harrow Maintenance

The operator also have to know the need to follow the instructions, as the lack of safety may increase the risk of accidents. NOTE - Use TATU original parts only. GNL - Rev. 07 - Mar/22... -

Page 57: Important Data

L = Harrow working width (meters); V = Average speed of the tractor (meters per hour); E = Efficiency: 0.90; X = Hectare value = 10,000 m Example with a GNL (32 disc blades): R = ? L = 2.64 m V = 9,000 m/h E = 0.90... -

Page 58: Average Income Table

To know how many hours will be spent to work a certain previously known area, it is necessary to divide the value of the area by the hourly income. Example: An area of 50 hectares to be worked with a GNL that has 32 disc blades (Hourly income = 2.13 hectares). -

Page 59: Torque Table

5008,386 c) Newton-meters M 39 x 1.5 1073 1454,988 2860,5 3878,84 4201,5 5697,234 d) Nominal thread diameter in millimeters x thread pitch Values are for reference and are based on average steel-to-steel friction conditions. GNL - Rev. 07 - Mar/22... -

Page 60: Important

Serial number.: 05.01.09.1146 Revision: 07 MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. Marchesan Av., 1979 - Zip Code 15994-900 - Matão - SP - Brazil Telephone 55.16.3382.8282 www.marchesan.com.br GNL - Rev. 07 - Mar/22... - Page 62 www.marchesan.com.br...

Need help?

Do you have a question about the GNL and is the answer not in the manual?

Questions and answers