Summary of Contents for Caravaggi Bio 90

- Page 1 USE AND MAINTENANCE INSTRUCTION MANUAL Bio 90 BEFORE USING MACHINE , READ INSTRUCTION MANUAL...

-

Page 2: How To Use Manual

1. HOW KEEP INSTRUCTION MANUAL This instruction manual is aimed at the user of the machine , the owner , the maintenance cleaning operator and the repair technician and must always be avaiable for consultation . The instruction manual shows the user for which the machine was designed and the machine’s technical characteristics . -

Page 3: Identification Of Main Parts

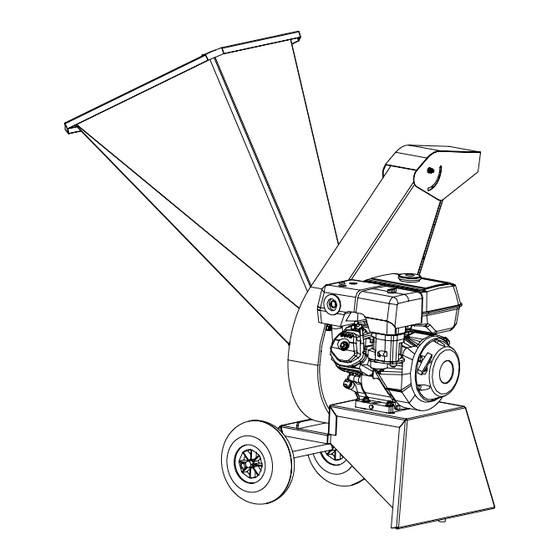

2. IDENTIFICATION OF MAIN PARTS 1. Hopper with guards 2. Outlet 3. Petrol engine 4. Wheels 5. Frame 6. Inspecting the screen Fig. 2... -

Page 4: Correct Use Of The Machine

The operator must be aware of all the instructions given in the instruction manual . 4. UNPACKING AND PREPARATION The Bio 90 bio-shredder is delivered partially dismantled. It ca be arranged on pallets to facilitate handling and transport before installation, depending on the versions. - Page 5 Fig. 3 Kg. 150 Fig. 4 Fig. 5...

-

Page 6: Technical Characteristics

5. TECHNICAL CHARACTERISTICS The EC identification plate is clearly visible on the Bio 90 bio- chopper ( fig. 6 ) . In all communications with the manufacturer state the serial number on the identification plate . MACCHINE INDUSTRIALI 25037 PONTOGLIO (BS) - VIA M. ADAMELLO, 20 TELEF. -

Page 7: Safety Norms

6. SAFETY NORMS Training • The machine must not be used by under 16’s and persons who have not learnt the user instructions . • The operator is responsible for third parties present in the work area . Keep children and domestic animals at distance when the bio-chopper is in operation . - Page 8 Caution ! The fuel is highly flammable : • Keep fuel only in the containers made avaiable for this purpose ; • Refuel only in the open air . Do not smoke or in any way cause naked flames during refuelling . •...

- Page 9 7. START - UP Caution ! Before starting up the engine / motor check that the bio- chopper is on a stable surface and that there are no animals or unauthorised persons in the work zone . Read the engine / motor manufacturer’s instruction book carefully . Check that there is oil and fuel in the tank .

- Page 10 Ø 7 cm Fig. 10 Caution ! Take the material to the hopper mouth and let it fall in . Never put hands and arms in to push material into the hopper ! The material that can be worked and chopped in this hopper must not exceed 7 cm diameter .

-

Page 11: Maintenance

8. MAINTENANCE Caution ! Before proceeding with any maintenance operations with off the engine / motor and in any case ensure that there is no possibility of the machine functioning . Suitable gloves are obligatory for all maintenance operations . 8.1 Replacing the chipping blade •... - Page 12 8.2 Replacing the cutting elements • Unscrew the screws . • Replacing the knives , keeping to the original position for proper balancing . • Fit and tighten the screws . Blade TR 3 Screw Fig. 12...

- Page 13 8.3 Replacing the counter blade • Remove the side hopper by unscrewing the 7 nuts . • Unscrew the security nuts of the counter blade to remove the counter blade. Fig. 13 Screw Counter blade Fig. 14...

- Page 14 8.4 Routine maintenance Beginning Before End of of season each job season ♦ Check engine oil level ♦ ♦ Check screws , tightness , casing, hopper , etc . ♦ ♦ Check wear on cutters ♦ ♦ Check wear on blade ♦...

-

Page 15: Troubleshooting - Remedies

9. TROUBLESHOOTING - REMEDIES Troubleshooting Remedies The bio-chopper does Check cutters , blade , counter-blade not start presence of material in the milling chamber . Check state of engine / motor ( consult the instruction manual supplied ) . Difficult start-up or Check state of engine / motor ( consult the loss of power instruction manual supplied ) . - Page 16 Seller authorised CARAVAGGI importer . 2. You are required to present the guarantee duly filled in or the bill , if this is not avaiable. 3. The claim will be completed by the Dealer , who will forward it to the Manufacturer .

-

Page 17: Declaration Of Conformity

11. DECLARATION OF CONFORMITY The company Caravaggi , hereby declares under its own responsability , that the machine BIO - SHREDDER Type Bio 90 petrol versions , complies with the Basic Safety and Health Requirements prescribed in EC Directive 98/37 , 89/336 e 89/392 , 94/626 and subsequent modifications thereto 89/686, 91/368, 93/44 , 93/68 and 2000/14. - Page 18 SPARES BIO 90 - TAV. 1 MACHINE ASSEMBLY...

- Page 19 SPARES BIO 90 - TAV. 1 MACHINE ASSEMBLY Pos. Description Q.ty Code Frame 000018 Rotor group 000019 Hopper Group 000020 Bearing support PF 000021 Spacer L=38 000022 Bearing 208 900023 Screw TE 5/16”x 2”½ UNF 900024 Washer 000023 Screw TE 7/16” x 3” UNF...

- Page 20 SPARES BIO 90 - TAV. 2 ROTOR ASSEMBLY...

- Page 21 SPARES BIO 90 - TAV. 2 ROTOR ASSEMBLY Pos. Description Q.ty Code Rotor disc 000036 000037 Washer ø16x3 900003 Blade TR 3 000038 Spacer H=21 000039 Spacer H=11.5 000041 Screw TSPEI M10x20 900042 Screw TSPEI M8x20 900043 Washer ø10 900028...

- Page 22 SPARES BIO 90 - TAV. 3 HOPPER ASSEMBLY...

- Page 23 SPARES BIO 90 - TAV. 3 HOPPER ASSEMBLY Pos. Description Q.ty Code Hopper 000044 Counterblade 000045 Screw TSPEI M8x25 900045 Washer ø8 900038 Self-lock nut M8 900027 Rubber fixing plate 000046 Hopper protection rubber 000047 Washer ø6x18 900046 Screw TE M6x25...

- Page 24 CARAVAGGI MACCHINE INDUSTRIALI Via Monte Adamello , 20 25037 Pontoglio ( BS ) - ITALY Tel. +39 030 7470464 - Fax +39 030 7470004 Internet http://www.caravaggi.com Email info@caravaggi.com Rev.1-2008...

Need help?

Do you have a question about the Bio 90 and is the answer not in the manual?

Questions and answers