Summary of Contents for Caravaggi CIPPO 25

- Page 1 USER & SAFETY MANUAL CHIPPER CIPPO 25 READ CAREFULLY THIS BOOKLET BEFORE OPERATING WITH THE MACHINE .

- Page 2 . CARAVAGGI CHIPPERS are designed to last a long time and run very safely provided that the instructions herein are carried out to the letter .

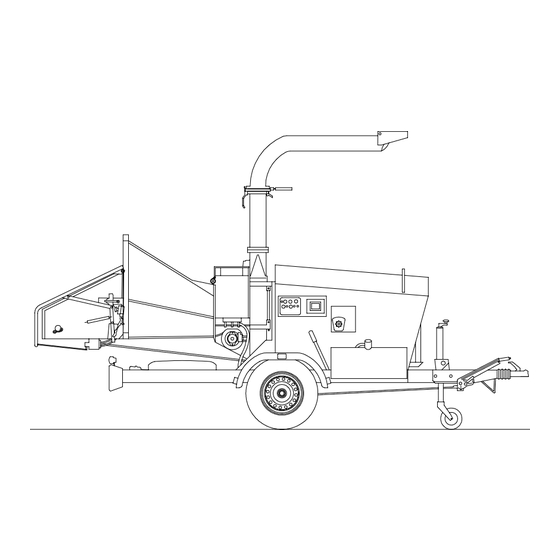

- Page 3 2. DIMENSIONS , WEIGHT & TRANSFERS POINTS Diesel model Tractor model LENGTH mm 4000 LENGTH mm 3900 WIDTH mm 1590 WIDTH mm 1250 HEIGHT mm 2400 HEIGHT mm 2400 WEIGHT Kg. 1345 WEIGHT Kg. 107 dB WA MAX WA MAX HOPPER ROAD FRAME EXHAUST FAN...

- Page 4 3. TRANSFERS AND SYMBOLS...

-

Page 5: Safety Regulations

GENERAL REGULATIONS 1. Read this booklet carefully before using the chipper . If you mislay it apply for another copy from : CARAVAGGI , Via M. Adamello , 20 - I - 25037 Pontoglio - BS . 2. DO NOT ALLOW children or anyone else who is not authorized or acquainted with the instructions to use the machine . - Page 6 17. This chipper has been built to comply with all the latest safety standards . To keep it in safe running order , always use original parts and spares . 18. Only perform the routine maintenance work specified herein . Contact Caravaggi dealer major repairs other maintenance .

-

Page 7: Setting To Work

5 . SETTING TO WORK 5.1 DIESEL VERSION 5.1.1 Place the chipping machine on a flat firm surface. With the road trailer version, apply the parking brake. 5.1.2 Check that the engine is filled with oil and fuel. 5.1.3 Check that the emergency button on the hopper is not pressed (released). - Page 8 5.2 TRACTOR VERSION 5.2.1 Place the chipping machine on a flat firm surface 5.2.2 Connect the chipping machine to the hoist and the 3 point of the tractor. 5.2.3 Connect the cardan shaft to the tractor power takeoff with the engine switched off and with the power takeoff disengaged (use the type of cardan shaft recommended by the manufacturer).

- Page 9 6. OPERATING INSTRUCTIONS Position A Position B 6.1.1 Move the lever to position A to operate the feed roller. 6.1.2 Feed prunings and branches up to 25 cm in diameter into the feed hopper. Accompany them in and let them drop. 6.1.3 Set the delivery mouthpiece in the safest position to prevent injury.

- Page 10 Standard factory-set values: Model Rotor disc rpm Set limit Interval Cippo 25 T 1234 1200 Cippo 25 D 1400 1200 6.2.2 Operation When the motor or engine is running at the maximum revs, display A shows the current number of revs.

- Page 11 6.3 Programming the HENGSTLER TICO 732 tico 732 HENGSTLER Setting the minimum threshold • Press buttons ”E” and ”1” together • Enter the required value. For example to enter 1650, press button 4 for ”1”, button 3 for ”6”, button 2 for ”5” and button 1 for ”0”.

- Page 12 Function Display A key F Number of chipping disc revs. Gefran Display B Restart limit tico 732 HENGSTLER Electronic I / O switch No-stress Function Modification Display key E keys number of chipping disc revs.

-

Page 13: Maintenance

7. MAINTENANCE Always service the machine with the motor off and follow the safety rules. In the tractor version, remove the cardan shaft. In the diesel engine version, remove the sparkplug. 7.1 REPLACING THE CHIPPING BLADE Fixing screw Safety catch •... - Page 14 Adjusting screw Blade assembly fixing screws • Remove the three screws in the blade assembly and remove it. • Replace the blade. • Insert and tighten the three screws. Adjusting the blade: • Tighten the two blade adjusting screws equally to ensure uniform wear and longer life.

- Page 15 7.2 REPLACING THE COUNTER-BLADE Counter-blade Counter-blade fixing screws • Unscrew and remove the five screws. • Replace the counter-blade. • Insert ant tighten the screws. It is also advisable to replace the self-locking nuts.

-

Page 16: Troubleshooting

8. TROUBLE - SHOOTING PROBLEM CHECK CHIPPER DOES NOT TO START B + C TROUBLE STARTING UP OR POWER LOSS C + D CHIPPER MOTOR RUNS UNEVELY A + B + C + D SLOWS DOWN EXCESSIVE VIBRATION REDUCED OUTPUT MATERIAL REJECTED BY HOPPER A + B + E REASONS AND WHAT TO DO... -

Page 17: Maintenance Schedule

9. MAINTENANCE SCHEDULE START OF START OF END OF EACH EACH EACH SEASON OPERATION SEASON 1 - CHECK MOTOR booklet booklet booklet • • 2 - CHECK MACHINE P.T.O. • 3 - CHECK SCREWS, GUARDS, HOPPERS, ETC. • • 4 - CHECK BLADE WEAR •... -

Page 18: Declaration Of Conformity

10 . DECLARATION OF CONFORMITY The company Caravaggi, hereby declares under its own responsability, that the machine CARAVAGGI type CIPPO 25 Diesel and P.T.O. model, complies with the Basic Safety and Health Requirements prescribed in EC Directive 89/336 and 89/392, 94/626 and subsequent modifications thereto 89/686, 91/368, 93/44 and 93/68. - Page 19 Seller authorised CARAVAGGI importer . 2. You are required to present the guarantee duly filled in or the bill , if this is not avaiable . 3. The claim will be completed by the Dealer , who will forward it to the Manufacturer .

- Page 20 Cippo 25 - TABLE 1 – Basic Machine Pos. Description Part No. Control spring CP25010001 Roller control lever CP25010002 Galvanised plate CP25010003 M 10x40 knob CP25010004 Chain CP25010005 M 10x60 knob CP25010006 Spacer φ 18x30 CP25010007 Adjusting plate CP25010008 M 10 Fork...

- Page 21 Cippo 25 - TABLE 1 – Basic Machine...

- Page 22 Cippo 25 - TABLE 1 – Basic Machine Pos. Description Part No. Cast iron block CP25010034 Floating roller guard CP25010035 Cast iron block guard CP25010037 Hex. screw M 14x70 CP25010038 Chipping disk CP25010039 Blade CP25010040 Hex. screw M 12x35 CP25010041...

- Page 23 Cippo 25 - TABLE 1 – Basic Machine...

- Page 24 Cippo 25 - TABLE 2 – Diesel Transmission Pos. Description Part No. Engine bonnet CP25020001 Bonnet angle CP25020002 Drive shaft end screw CP25020003 Stop washer CP25020004 Pulley 4B 160 CP25020005 Tensioning device end screw CP25020006 Stop washer CP25020007 Pulley 4B 100...

- Page 25 Cippo 25 - TABLE 2 – Diesel Transmission...

- Page 26 Cippo 25 - TABLE 3 – PTO TRANSMISSION Pos. Description Q.ty Part No. Towing eye CP25030001 V Shaft CP25030002 PTO cover CP25030003 Belt guard CP25030004 Handle CP25030005 CP25030006 R plug CP25030007 Reduction gear CP25030008 Locking pin CP25030009 CP25030010 point gudgeon pin...

- Page 27 Cippo 25 - TABLE 3 – PTO TRANSMISSION...

- Page 28 Cippo 25 - TABLE 4 – D Hydraulic System Pos. Description Part No. Distributor CP25040001 Hydraulic pipe CP25040002 Hydraulic pipe CP25040003 Hydraulic pipe CP25040004 Hydraulic pipe CP25040005 Oil tank CP25040006 Hydraulic pipe CP25040007 Hydraulic pump CP25040008 Orbital hydraulic motor (fixed)

- Page 29 Cippo 25 - TABLE 4 – D Hydraulic System...

- Page 30 Cippo 25 - TABLE 5 – PTO Hydraulic System Pos. Description Part No. Floating roller hydraulic motor CP25050001 Limiting valve CP25050002 Hydraulic pipe CP25050003 12 V solenoid valve connector CP25050004 Limiting valve CP25050005 Fixed roller hydraulic motor CP25050006 Hydraulic pipe...

- Page 31 Cippo 25 - TABLE 5 – PTO Hydraulic System...

- Page 32 Cippo 25 - TABLE 6 –80 Km / h trailer Pos. Description Part No. Supporting caster CP25060001 Q 251 S Distance pin CP25060002 Front clearance light CP25060003 Pneumatic CP25060004 Axle with sheathing CP25060005 Plastic mud guard CP25060006 Side clearance reflector...

- Page 33 Cippo 25 - TABLE 6 –80 Km / h trailer...

- Page 34 CARAVAGGI MACCHINE INDUSTRIALI Via Monte Adamello , 20 25037 Pontoglio ( BS ) - ITALY Tel. +39 030 7470464 - Fax +39 030 7470004 Internet http://www.caravaggi.com Email info@caravaggi.com 0105...

Need help?

Do you have a question about the CIPPO 25 and is the answer not in the manual?

Questions and answers