Table of Contents

Advertisement

Quick Links

VISIT VIKINGPUMP.COM FOR PDF OF CURRENT TSM ISSUE & TO VIEW REPAIR VIDEOS

TECHNICAL SERVICE MANUAL: INSTALLATION, OPERATION & MAINTENANCE

TABLE OF CONTENTS

Model Number Chart ..................................................................1

Introduction ................................................................................1

Safety Information & Instructions ...............................................2

Component & Unit Lifting Features ...........................................3

Foundation .............................................................................3

Special Information ....................................................................3

Installation ..................................................................................4

General ...................................................................................4

Pressure Protection ................................................................4

Mounting .................................................................................4

Alignment................................................................................4

Piping/Hose ............................................................................4

Start Up ..................................................................................5

Maintenance ...............................................................................5

Cleaning Pump .......................................................................5

Storage ...................................................................................5

Suggested Seal Replacement & Pump Rebuild Tools ..........5

Type 2 Mechanical Seal .............................................................7

Seal Removal .........................................................................7

Seal Installation ......................................................................8

Type 8B5 Mechanical Seal ........................................................9

Seal Removal .........................................................................9

Seal Installation ......................................................................9

Type 5611Q Cartridge Seal......................................................10

Seal Removal .......................................................................10

Seal Installation ....................................................................10

Repair Parts .............................................................................10

Pump Repair ............................................................................10

Repair Tools .........................................................................10

Disassembly ............................................................................. 11

Reassembly .............................................................................12

Troubleshooting .......................................................................14

Vacuum Gauge - Suction Port .............................................14

Pressure Gauge - Discharge Port ........................................14

Miscellaneous .......................................................................14

Do's & Don'ts ...........................................................................15

Installation ............................................................................15

Operation ..............................................................................15

Maintenance .........................................................................15

SPUR GEAR PRODUCT LINE: DUCTILE IRON

GB-414 SERIES™

HIGH PRESSURE EXTERNAL GEAR PUMPS

FOR PIPELINE INJECTION

© 2020 Viking Pump, Inc. • Cedar Falls, IA

MODEL NUMBER CHART

Clockwise

GB-41415-*0O

GB-41420-*0O

GB-41430-*0O

GB-41440-*0O

GB-41445-*0O

GB-41455-*0O

GB-41460-*0O

* R = Type 2 Mechanical Seal

K = Type 8B5 Mechanical Seal

N = Cartridge Mechanical Seal

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and cannot be used for ordering parts.

Obtain a parts list from your Viking Pump

Always give a complete name of part, part number and

material with the model number and serial number of pump

when ordering repair parts. The unmounted pump or pump

unit model number and serial number are on the nameplate.

This manual only applies to the pump models specified in the

"Model Number Chart" on page 1. Pump specifications and

recommendations are listed in the Catalog Sections, which

are available at vikingpump.com.

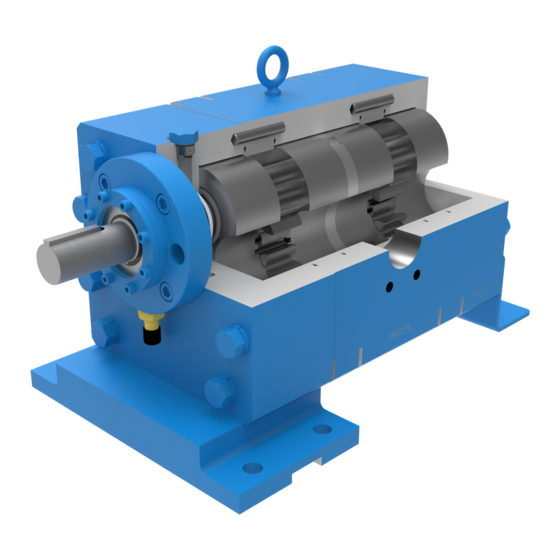

FIGURE 1:

GB-41415 SERIES™

FIGURE 3:

GB-41445 SERIES™

TSM

1655

Page

1 of 15

Issue

A

Counter-Clockwise

GB-41415-*1O

GB-41420-*1O

GB-41430-*1O

GB-41440-*1O

GB-41445-*1O

GB-41455-*1O

GB-41460-*1O

representative.

®

FIGURE 2:

GB-41430 SERIES™

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Viking pump GB-41415 Series

-

Page 1: Table Of Contents

Reassembly ................12 Troubleshooting ...............14 Vacuum Gauge - Suction Port ..........14 Pressure Gauge - Discharge Port ........14 Miscellaneous ...............14 Do’s & Don’ts ................15 FIGURE 3: Installation ................15 GB-41445 SERIES™ Operation ................15 Maintenance .................15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 2: Safety Information & Instructions

BEFORE operating the pump, be sure that: information, refer to Appendix, General Installation Notes, • It is clean and free from debris. item 5 on Pressure Protection or contact your Viking Pump ® representative for Engineering Service Bulletin ESB-31. • All valves in the suction and discharge pipelines are fully opened. -

Page 3: Component & Unit Lifting Features

Improper lifts can then fastened down. result in personal injury and/or damage to the unit. Following are general guidelines for lifting Viking Pump Units. SPECIAL INFORMATION FIGURE 4: EXAMPLE OF PROPER LIFTING METHOD ⚠... -

Page 4: Installation

2. Make final check on alignment after all piping connections Failure to properly mount guards may result in serious have been made. injury or death. TSM 1655 | Issue A | Page 4 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 5: Start Up

& PUMP REBUILD TOOLS 10. The above checklist is a general guideline to be used prior to starting the pump. Since Viking Pump cannot foresee The following tools must be available to properly replace every application for our product and possible system the seals in these external gear pumps. - Page 6 Seal Washer Alignment Pins Washers Bearing Match Ground Casing & Gears Assembly Separation Plate Bearing End Cap Pump Assembly Capscrews Plug TSM 1655 | Issue A | Page 6 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA...

-

Page 7: Type 2 Mechanical Seal

(Item 6) slowly from the pump Failure to follow above listed precautionary measures bracket (Item 1). may result in serious injury or death. TSM 1655 | Issue A | Page 7 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 8: Seal Installation

Be careful not to scratch the shaft in the sealing area. P-80 is a registered trademark of International Products Corporation ® TSM 1655 | Issue A | Page 8 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 9: Type 8B5 Mechanical Seal

4. Remove end cap (Item 9A), then remove thrust bearing Be careful not to scratch the shaft in the sealing area. (Item 9) from seal holder (Item 6) TSM 1655 | Issue A | Page 9 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 10: Type 5611Q Cartridge Seal

6. Remove or turn seal centering clips so as to clear the seal drive collar prior to operation P-80 is a registered trademark of International Products Corporation ® TSM 1655 | Issue A | Page 10 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 11: Disassembly

13. Remove the driver gear from the driver shaft. Remove the 9. Remove the spacer (Item 24) from the separation plate driven shaft and gear assembly. (Item 29). TSM 1655 | Issue A | Page 11 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... -

Page 12: Reassembly

(Item 10) into driver shaft (Item 12). Then slide the driver shaft (Item 12) into bracket (Item 1) until the retaining ring contacts the bottom of the seal bore. TSM 1655 | Issue A | Page 12 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA... - Page 13 The gasket will be installation instructions for the seal type of the pump compressed when the fasteners are tightened. (pages 7-10). TSM 1655 | Issue A | Page 13 of 15 © 2020 Viking Pump, Inc. • Cedar Falls, IA...

-

Page 14: Troubleshooting

TROUBLESHOOTING MISCELLANEOUS Pump does not pump: A Viking pump that is properly installed and maintained will 1. The pump has lost its prime from air leak or low level in give long satisfactory performance. tank. If trouble does develop, one of the first steps toward finding 2. -

Page 15: Do's & Don'ts

OPERATION Viking through regular mail at Viking Pump, Inc., 406 State Street, Cedar Falls, Iowa 50613, USA. 1. DON’T run the pump at speeds faster than those shown in the catalog at that size.

Need help?

Do you have a question about the GB-41415 Series and is the answer not in the manual?

Questions and answers