Wilden TURBO-FLO T8 Engineering, Operation & Maintenance

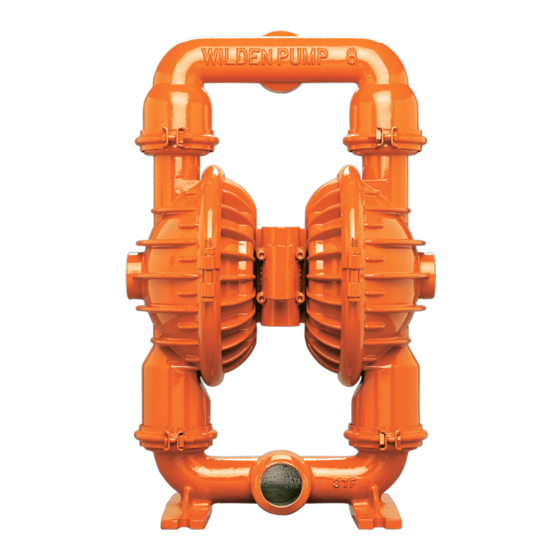

Clamped metal pump

Hide thumbs

Also See for TURBO-FLO T8:

- Engineering, operation & maintenance (31 pages) ,

- Operation & maintenance manual (28 pages) ,

- Engineering, operation & maintenance (31 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Wilden TURBO-FLO T8

- Page 1 ENGINEERING OPERATION & MAINTENANCE T8 Clamped Metal Pump Where Innovation Flows WIL-10272-E-01...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works Section 4: Dimensional Drawings Section 5: Performance T 8 Me ta l Rub ber - F itt ed T 8 Me ta l T P E- Fi tt ed... - Page 3 Warranty Each and every product manufactured by Wilden is built to meet the highest standards of quality. Every pump is functionally tested to insure integrity of operation. Wilden warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

-

Page 4: Section 1: Precautions - Read First

–20°F to 300°F NOTE: Tighten clamp bands and retainers prior to NOTE: Not all materials are available for all models. See "Wilden Pump installation. Fittings may loosen during transportation. Designation System " on page 5 for material options for your pump. -

Page 5: Section 2: Wilden Pump Designation System

NOTE: Not all models are available with all material options. ® is a registered trademarks of DuPont Dow Elastomers. ® Santoprene is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P. ® Hytrel is a registered trademark of DuPont Dow Elastomers. ® Wilden WIL-10272-E-01... -

Page 6: Section 3: How It Works

Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 7: Section 4: Dimensional Drawings

Section 4 DIMENSIONAL DRAWING T8 Metal DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 15.9 24.8 26.3 14.2 10.7 13.5 10.0 10.1 12.3 11.1 11.1 15.2 Ø15 Ø0.6 15.9 BSP threads available. ® Wilden WIL-10272-E-01... - Page 8 DIMENSIONAL DRAWING ® T8 Metal Stallion DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 16.1 24.6 26.2 24.0 14.8 10.4 13.6 11.1 11.0 Ø15 Ø0.6 BSP threads available. ® Wilden WIL-10272-E-01...

-

Page 9: Section 5: Performance

2.1 bar (30 psig) requires 4.1 bar (60 psig) and 85 Nm /h (50 scfm) air consumption. (See dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. ® Wilden WIL-10272-E-01... -

Page 10: T 8 Ptf E- Fi Tte D

2.1 bar (30 psig) requires 4.1 bar (60 psig) operation parameters will fall in the center of the pump performance curve. and 110.5 Nm /h (65 scfm) air consumption. (See dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. ® Wilden WIL-10272-E-01... -

Page 11: T8 Metal Stallion Tpe -Fitted

2.1 bar (30 psig) requires 4.1 bar (60 psig) operation parameters will fall in the center of the pump performance curve. and 94 Nm /h (55 scfm) air consumption. (See dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. ® Wilden WIL-10272-E-01... -

Page 12: Su Ct Ion - Li Ft Ca Pab Il It Y

The number of intake and discharge elbows, viscosity of pumping fluid, elevation (atmospheric pressure) and pipe friction loss all affect the amount of suction lift your pump will attain. ® Wilden WIL-10272-E-01... -

Page 13: Section 6: Suggested Installation, Operation

AND USDA PUMPS SHOULD BE CLEANED AND/OR SANITIZED BEFORE USE ON EDIBLE PRODUCTS. time to make sure that inadvertent restrictions are not created for any remaining sites. CAUTION: DO NOT HANG T8 STALLION PUMPS BY THEIR HANDLES. ® Wilden WIL-10272-E-01... - Page 14 Frequency of use, line pressure, viscosity and air supply to the pump, therefore stopping output. This shut- off valve abrasiveness of process fluid all affect the parts life of a Wilden pump. should be located far enough away from the pumping equipment such...

- Page 15 Air bubbles in pump discharge. and out air exhaust. Use only Wilden Glyd™ rings as 1. Check for ruptured diaphragm. they are of special construction and ISO 15-5 wt oil with 2.

-

Page 16: Section 7: Disassembly / Reassembly

• 14 mm (9/16") Box Wrench The Wilden T8 has a 51 mm (2") inlet and 51 mm (2") outlet and is designed • for flows up to 617 lpm (163 gpm). The model T8 is available in aluminum, cast 17 mm (11/16") Socket... - Page 17 Replace worn parts with genuine Wilden parts for reliable performance. PTFE o-rings should be replaced when reassembled. Step 7 Step 6 With 14 mm (9/16") socket and 17 mm (11/16") box wrench,...

- Page 18 Inspect diaphragm assembly and shaft for signs of wear wrench, remove diaphragm assembly from shaft. Inspect all parts for or chemical attack. Replace all worn parts with genuine Wilden wear and replace with genuine Wilden parts if necessary. parts for reliable performance.

-

Page 19: Ai R Va Lve D Is As Sem Bl Y

The bushing in the center block, along with the diaphragm shaft, provides the “trigger” to tell the air valve to shift. The following procedure will ensure that the air valve on your Wilden pump will provide long trouble-free service. - Page 20 The bushing in the center block, along with the diaphragm shaft, provides the “trigger” to tell the air valve to shift. The following procedure will ensure that the air valve on your Wilden pump will provide long trouble-free service.

- Page 21 Stainless bolts should be lubed to reduce the possibility of be taken to keep the coating intact. seizing during tightening. • When installing Glyd™ rings, the use of the Wilden • Be sure to tighten outer pistons simultaneously on PTFE- Ringer tool simplifies seal installation fitted pumps to ensure proper torque values.

-

Page 22: Gasket Kit / Installation

Gasket Kit / Installation The Wilden T8 cast iron pumps require PTFE gasket tape on the liquid Carefully prepare sealing surfaces by removing all debris and foreign chambers (P/N 04-9502-99). Other pump types may use PTFE gasket matter from diaphragm bead and all mating surfaces If necessary, kits for additional sealing characteristics. -

Page 23: Section 8: Exploded View And Parts List

Section 9 EXPLODED VIEW AND PARTS LISTING T8 METAL EXPLODED VIEW Rubber/TPE-Fitted ® Wilden WIL-10272-E-01... - Page 24 T8 Stallion pumps utilize only four (4) of P/N’s 08-6100-03 and 08-6408-08 on the bottom manifold and water chambers. *Refer to elastomer options in Section 9. NOTE: BSP threads available. All boldface items are primary wear parts. 0030 Specialty Code = Screen Base 0050 Specialty Code = Stallion ® Wilden WIL-10272-E-01...

- Page 25 T8 METAL EXPLODED VIEW Rubber/TPE-Fitted ® Wilden WIL-10272-E-01...

- Page 26 **Refer to elastomer options in Section 9. **Refer to Stallion elastomer options in Section 9. NOTE: BSP threads available. All boldface items are primary wear parts. 0030 Specialty Code = Screen Base 0050 Specialty Code = Stallion ® Wilden WIL-10272-E-01...

-

Page 27: T 8 Me Ta L Pt F E - F Itt Ed

T8 METAL EXPLODED VIEW PTFE - Fitted ® Wilden WIL-10272-E-01... - Page 28 08-6050-03 request. See elastomer chart options in Section 9. Small Hex Nut 5/16”-18 08-6400-03 08-6400-03 NOTE: BSP threads available. PTFE Valve Seat O-Ring 08-1200-55 08-1200-55 All boldface items are primary wear parts Muffler (not shown) 08-3510-99 08-3510-99 ® Wilden WIL-10272-E-01...

-

Page 29: Section 9: Elastomer Options

T8 Metal STALLION Pumps Diaphragms (2) Valve Balls (4) Valve Seats (4) Material Polyurethane 08-1010-50 08-1080-62-50 08-1120-62-50 Wil-Flex™ 08-1010-58 08-1080-58-50 08-1120-58-50 Saniflex™ 08-1010-56 08-1080-56-50 08-1120-56-50 Neoprene 08-1010-51 08-1080-51-50 08-1120-51-50 Buna-N 08-1010-52 08-1080-52-50 08-1120-52-50 08-1020-53 08-1080-53-50 08-1120-53-50 EPDM 08-1020-54 08-1080-54-50 08-1120-54-50 ® Wilden WIL-10272-E-01... - Page 30 Notes WIL-10272-E-01 ® Wilden...

- Page 31 Notes WIL-10272-E-01 ® Wilden...

- Page 32 Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-10272-E-01 ® Wilden...

Need help?

Do you have a question about the TURBO-FLO T8 and is the answer not in the manual?

Questions and answers