Wilden Original Series Operation & Maintenance Manual

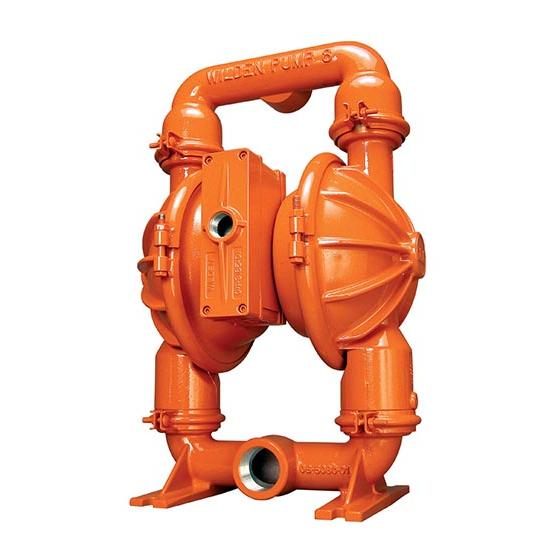

Metal pumps

Hide thumbs

Also See for Original Series:

- Engineering, operation & maintenance (43 pages) ,

- Operation & maintenance manual (39 pages) ,

- Engineering, operation & maintenance (8 pages)

Summary of Contents for Wilden Original Series

- Page 1 Engineering Operation & Maintenance TZ15 Original™ Series METAL PUMPS W h e r e I n n o v a t i o n F l o w s . WIL-16080-E-01...

-

Page 2: Table Of Contents

T A B L E O F C O N T E N T S SEC TION 1 CAUTIONS—READ FIRST! SEC TION 2 WILDEN® PUMP DESIGNATION SYSTEM SEC TION 3 HOW IT WORKS—PUMP DISTRIBUTION SYSTEM SEC TION 4 DIMENSIONAL DRAWING(S) SEC TION 5 A. -

Page 3: Cautions-Read First

Pump, valves, and containers must be properly grounded TZ-Series pumps do not need lubrication NOTE: when handling flammable fluids and whenever dis- charge of static electricity is a hazard WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC... -

Page 4: Sec Tion 2 Wilden® Pump Designation System

0014 BSPT Inlet & Discharge NOTE: Most elastomeric materials use colored dots for identification. NOTE: Not all models are available with all material options. Hytrel® and Viton® are registered trademarks of DuPont Dow Elastomers. WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... -

Page 5: How It Works-Pump Distribution System

H O W I T W O R K S — P U M P D I S T R I B U T I O N S Y S T E M The Wilden® diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. -

Page 6: Dimensional Drawing(S)

STANDARD (inch) ALUMINUM 19.9 19 mm 25 mm (1") FNPT (3/4") FNPT 30.0 AIR INLET EXHAUST 32.4 16.5 FNPT 12.3 16.8 14.2 12.0 10.2 11.1 76 mm (3") FNPT - ALUM. BSPT threads available. WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... -

Page 7: Performance

(See dot on chart.) For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump performance curve. CAUTION: Do not exceed 8.6 bar (125 psig) air supply pressure. WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC... -

Page 8: Ptfe-Fitted

CAUTION: Do not exceed 8.6 bar (125 psig) For optimum life and performance, pumps should be specified so that daily operation air supply pressure. parameters will fall in the center of the pump performance curve. WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... -

Page 9: Suction Lift

The number of intake and discharge elbows, viscosity of pumping fluid, elevation (atmospheric pres- sure) and pipe friction loss all affect the amount of suction lift your pump will attain WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC... -

Page 10: Suggested Installation

Should major repairs become necessary, ease of access can play a key role in speeding the repair process and reducing downtime Wilden® TZ series pumps cannot be used in submersible appli- cations For submersible applications requiring a single point AIR SUPPLY: Every pump location should have an air line large... -

Page 11: Operation/Maintenance

Frequency of use, line pressure, viscosity and abrasiveness of the method) An air regulator is used to regulate air pressure A needle process fluid all affect the parts life of a Wilden® pump Periodic valve is used to regulate volume The pump discharge rate can... -

Page 12: Troubleshooting

3 Check center block Glyd™ rings If worn excessively, 2 Check tightness of clamp bands, especially at intake manifold they will not seal and air will simply flow through the pump and out of the air exhaust port Use only Wilden ® PRODUCT COMES OUT OF Glyd™... -

Page 13: Pump Disassembly

If applicable, remove the clamp bands that fasten the intake Remove discharge manifold and inspect valve balls, seats and manifold to the liquid chambers Lift the intake manifold away to O-rings (if equipped) expose the valve balls and seats WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC... - Page 14 If applicable, using a socket and box wrench, remove one set of Check valve balls, seats and O-rings for nicks, gouges, chemical clamp bands that attach the liquid chamber to the center section attack or abrasive wear Replace worn parts with genuine Wilden ® assembly...

- Page 15 Repeat disassembly instructions for oppo- site liquid chamber Inspect diaphragm assembly and shaft for signs of wear or chemical attack Replace all worn parts with genu- ine Wilden® parts for reliable performance Step 10A. Step 10B. (if applicable)

-

Page 16: Air Valve/Center Block Disassembly

The following procedure will ensure that the air valve on the Wilden® pump will provide long, trouble-free service NOTE: Do not force the piston to move by inserting a metal object... - Page 17 An enhanced (01-3800-03-07) shaft should be utilized to maxi- mize performance The center section O-rings (01-3200-52) must be installed in the appropriate grooves as shown (1, 3, 6, 8) See Figure C Figure C WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 18: Reassembly Hints & Tips

Small Clamp Band (Rubber-fitted)) 5.6 N•m (50 in-lbs) Large Clamp Band (All) 47.4 N•m (35 ft-lbs) Air Chambers 27.1 N•m (20 ft-lbs) Center Block Assembly 27.1 N•m (20 ft-lbs) 2C-Ring Inner Piston 18.9 N•m (14 ft-lbs) WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... - Page 19 N O T E S WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 20: Exploded View And Parts Listing

R U B B E R / T P E / P T F E / U L T R A - F L E X - F I T T E D E X P L O D E D V I E W PTFE ULTRA-FLEX 14 31 WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... - Page 21 Air Valve Assembly Shaft 15-3800-09-07 15-3800-09-07 includes items 5, 8, 9, Piston, Inner 15-3750-01 15-3750-01 10 and 11. Diaphragm, Primary, PTFE 15-1010-55 15-1010-55 Piston, Outer 15-4600-03 15-4600-03 items are boldface Back-up, Diaphragm, PTFE primary wear parts. WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC...

-

Page 22: Elastomer Options

PTFE 15-1010-55 15-1080-55 15-1200-55 Saniflex™ 15-1010-56 15-1060-56 15-1080-56 15-1120-56 Wil-Flex™ 15-1010-58 15-1080-58 15-1120-58 Aluminum 15-1121-01 Stainless Steel 15-1121-03 Mild Steel 15-1121-08 Rubber valve seats do not require O-ring. Utilize in conjunction with metallic seat. WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01... - Page 23 N O T E S WIL-16080-E-01 WILDEN PUMP & ENGINEERING, LLC...

- Page 24 N O T E S WILDEN PUMP & ENGINEERING, LLC WIL-16080-E-01...

- Page 25 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

- Page 26 FLUID DYNAMICS™ POLYMER BLENDING SYSTEMS SYSTEM ONE® neptune1 com CENTRIFUGAL PUMPS blackmer com GRISWOLD™ CENTRIFUGAL PUMPS WILDEN® griswoldpump com AIR-OPERATED DIAPHRAGM PUMPS wildenpump com MAAG® GROUP GEAR PUMPS, PELLETIZING, & FILTRATION SYSTEMS maag com PSG reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 04-2012...

Need help?

Do you have a question about the Original Series and is the answer not in the manual?

Questions and answers