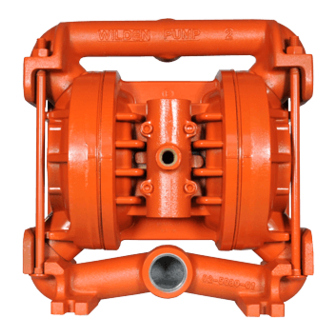

Summary of Contents for Wilden T2 Original Metal

- Page 1 E n g i n e e r i n g O p e r a t i o n & Original Series METAL Pumps ™ M a i n t e n a n c e S i m p l i f y y o u r p r o c e s s WIL-10200-E-03 REPLACES EOM-T2M 10/03...

-

Page 2: Table Of Contents

TABLE OF CONTENTS PAGE # SECTION 1 — CAUTIONS .................... SECTION 2 — PUMP DESIGNATION SYSTEM......... SECTION 3 — HOW IT WORKS (PUMP & AIR SYSTEMS) .... SECTION 4 — DIMENSIONAL DRAWINGS T2 METAL & T2 UL METAL ....................T2 METAL SANIFLO ...................... -

Page 3: Section 1 - Cautions

Consult engineering guide for chemical compat- ibility and temperature limits. NOTE: All non lube-free air-operated pumps must be lubricated. Wilden suggests an arctic 5 weight oil CAUTION: Always wear safety glasses when operat- (ISO grade 15). Do not over-lubricate pump. Over-lubri- ing pump. -

Page 4: Section 2 - Pump Designation System

0251 Discharge facing forward, BSPT, 0104 Wil-Gard II™ 110V, spark free special instructions *O-RINGS NOT REQUIRED. NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION. Viton is a registered trademark of DuPont Dow Elastomers. WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... -

Page 5: Section 3 - How It Works (Pump & Air Systems)

THE WILDEN PUMP — HOW IT WORKS The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 6: Section 4 - Dimensional Drawings A. T2 Metal & T2 Ul Metal

19 mm (3/4") DIMENSIONS BSPT (FNPT) LIQUID DISCHARGE ITEM METRIC (mm) STANDARD (inch) 10.5 13 mm (1/2") 10.0 FNPT AIR EXHAUST 11.0 6 mm (1/4") FNPT AIR INLET 25 mm (1") BSPT (FNPT) LIQUID INLET WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... -

Page 7: T2 Metal Saniflo

SECTION 4B DIMENSIONAL DRAWING T2 METAL SANIFLO DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.4 10.1 10.5 11.6 WIL-10200-E-03 WILDEN PUMP & ENGINEERING, LLC... -

Page 8: Section 5 - Performance Curves

Caution: Do not exceed 8.6 bar (125 psig) air For optimum life and performance, pumps should be specified so that daily operation parameters supply pressure. will fall in the center of the pump performance curve. WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... -

Page 9: T2 Metal Ptfe-Fitted

(atmospheric pressure) and pipe friction loss all affect the a guide only. There are many variables which can affect amount of suction lift your pump will attain. your pump’s operating characteristics. The number of intake WIL-10200-E-03 WILDEN PUMP & ENGINEERING, LLC... -

Page 10: Installation

The impact of current and future installations should be considered ahead of time to make sure that inadvertent restrictions are not created for any remaining sites. WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... -

Page 11: Operation & Maintenance

The Wilden T2 pump runs solely on Personnel familiar with the pump’s construction and service compressed air and does not generate heat, therefore your should be informed of any abnormalities that are detected process fluid temperature will not be affected. -

Page 12: Troubleshooting Pumps

Check for excessive moisture in compressed air. Either and out air exhaust. Use only Wilden Glyd™ rings as they install dryer or hot air generator for compressed air. are of special construction. -

Page 13: Section 8 - Directions For Disassembly/Reassembly

Be aware of any hazardous effects of contact with your process fluid. The Wilden model T2 has a 25 mm (1”) inlet and 19 mm (3/4”) outlet and is designed for flows up to 132 lpm (35 gpm). The single-piece center section, consisting of center block and air chambers, is molded of polypropylene or aluminum. - Page 14 Check for nicks, gouges, chemical attack diaphragm assembly. attack or abrasive wear. Replace worn or abrasive wear. Replace worn parts with parts with genuine Wilden parts for reli- genuine Wilden parts for reliable perfor- able performance. PTFE o-rings should mance. PTFE o-rings should be replaced be replaced when reassembled.

-

Page 15: Turbo-Flo™ Pump Air Valve/Center Section - Disassembly, Cleaning, Inspection

The following procedure will ensure that the the air valve should be disassembled as follows: Remove air valve on your Wilden pump will provide long trouble-free the snap ring from the top end of the air valve and apply an service. -

Page 16: Reassembly Hints & Tips

• Install #4 jumper wire to the front-left vertical bolt. Install jam nut onto vertical bolt. • Route the #4 wire to front of pump (left liquid chamber) and attach to liquid chamber with 1/4-20 fastener. WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... - Page 17 WIL-10200-E-03 WILDEN PUMP & ENGINEERING, LLC...

-

Page 18: Section 9 - Exploded View/Parts Listing

SECTION 9A EXPLODED VIEW/PARTS LISTING METAL AIR-OPERATED RUBBER/TPE- FITTED WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... -

Page 19: T2 Metal Rubber/Tpe-Fitted

**Part to be used with item 10 to secure air valve and muffler plate. NOTE: Models T2/SSPPN/0070 have 1-1/2” cast tri-clamp inlet and outlet ports and use wing nut type fasteners on manifold bolts. All boldface items are primary wear parts. WIL-10200-E-03 WILDEN PUMP & ENGINEERING, LLC... - Page 20 SECTION 9B EXPLODED VIEW/PARTS LISTING METAL AIR-OPERATED PTFE- FITTED WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03...

-

Page 21: T2 Metal Ptfe-Fitted

**Part to be used with item 10 to secure air valve and muffler plate. NOTE: Model T2/SSPPN/0070 has 1-1/2” cast tri-clamp inlet and outlet ports and uses wing nut type fasteners on manifold bolts. All boldface items are primary wear parts. WIL-10200-E-03 WILDEN PUMP & ENGINEERING, LLC... -

Page 22: Section 10 - Elastomer Options

02-1200-50 Buna-N 02-1010-52 02-1080-52 02-1200-52 Neoprene 02-1010-51 02-1080-51 EPDM 02-1010-54 02-1080-54 02-1200-54 Viton 02-1010-53 02-1080-53 ® Wil-Flex™ 02-1010-58 02-1080-58 02-1200-58 Sanifl ex™ 02-1010-56 02-1080-56 02-1200-56 PTFE 02-1010-55 02-1080-55 02-1200-55 Stainless Steel 02-1120-03 Aluminum 02-1120-01 WILDEN PUMP & ENGINEERING, LLC WIL-10200-E-03... - Page 23 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

Need help?

Do you have a question about the T2 Original Metal and is the answer not in the manual?

Questions and answers